Conservation of Energy Approach to System Analysis

Overview

Source: Ricardo Mejia-Alvarez and Hussam Hikmat Jabbar, Department of Mechanical Engineering, Michigan State University, East Lansing, MI

The purpose of this experiment is to demonstrate the application of the energy conservation equation to determine the performance of a flow system. To this end, the energy equation for steady, incompressible flow is applied to a short pipe with a gate valve. The gate valve is then gradually closed and its influence on flow conditions is characterized. In addition, the interplay between this flow system and the fan that drives the flow is studied by comparing the system curve with the characteristic curve of the fan.

This experiment helps understanding how energy dissipation is used by valves to restrict the flow. Also, under the same principle, this experiment offers a simple method to measure flow rate using the pressure change across a sharp entrance.

Procedure

1. Setting the facility

- Make sure that the fan is not running, so there is no flow in the facility.

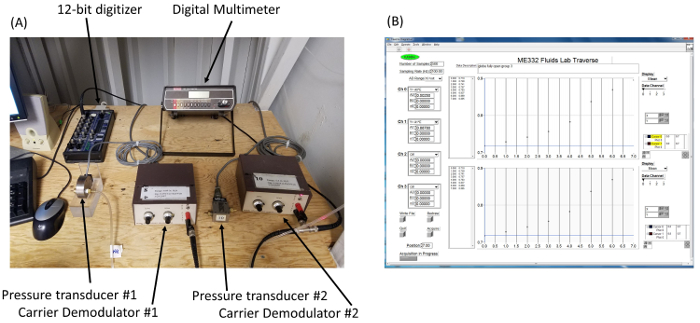

- Verify that the data acquisition system (Figure 4(A)) follows the schematic in figure 2B.

- Connect the positive port of pressure transducer #1 (see figure 2B for reference) to the pressure tap upstream of the valve (

).

). - Leave the negative port of the pressure transducer #1 open to the room conditions

- Connect the positive port of pressure transducer #1 (see figure 2B for reference) to the pressure tap upstream of the valve (

Results

Figure 5 shows the results for the current measurements. Here, the black solid line was generated with equation (2), and each red line with equation (3) for different values of the valve's loss coefficient. From the figure, it is evident that the system curve increases its slope as the valve closes. In other words, this experiment demonstrates that the principle behind the operation of a valve is to increase energy dissipation to restrict the flow. On the other hand,

Application and Summary

This experiment explored the application of the energy equation to characterize the action of a valve on pipe flow. It was observed that the valve induces flow resistance by increasing energy dissipation. Considering that the pressure drop along the flow system is directly proportional to the square of the flow rate, the effect of energy dissipation is captured by the magnitude of the proportionality coefficient. This coefficient is the addition of the loss coefficients of all the elements in the flow system, including t

References

- White, F. M. Fluid Mechanics, 7th ed., McGraw-Hill, 2009.

- Munson, B.R., D.F. Young, T.H. Okiishi. Fundamentals of Fluid Mechanics. 5th ed., Wiley, 2006.

Tags

Skip to...

Videos from this collection:

Now Playing

Conservation of Energy Approach to System Analysis

Mechanical Engineering

7.4K Views

Buoyancy and Drag on Immersed Bodies

Mechanical Engineering

30.0K Views

Stability of Floating Vessels

Mechanical Engineering

22.6K Views

Propulsion and Thrust

Mechanical Engineering

21.7K Views

Piping Networks and Pressure Losses

Mechanical Engineering

58.2K Views

Quenching and Boiling

Mechanical Engineering

7.7K Views

Hydraulic Jumps

Mechanical Engineering

41.0K Views

Heat Exchanger Analysis

Mechanical Engineering

28.0K Views

Introduction to Refrigeration

Mechanical Engineering

24.7K Views

Hot Wire Anemometry

Mechanical Engineering

15.6K Views

Measuring Turbulent Flows

Mechanical Engineering

13.5K Views

Visualization of Flow Past a Bluff Body

Mechanical Engineering

11.9K Views

Jet Impinging on an Inclined Plate

Mechanical Engineering

10.8K Views

Mass Conservation and Flow Rate Measurements

Mechanical Engineering

22.7K Views

Determination of Impingement Forces on a Flat Plate with the Control Volume Method

Mechanical Engineering

26.0K Views

Copyright © 2025 MyJoVE Corporation. All rights reserved

). Hence, the reading of this transducer will be directly

). Hence, the reading of this transducer will be directly  .

. ).

). , as required by equation (10).

, as required by equation (10).

).

).

. Consider the total loss coefficient as

. Consider the total loss coefficient as  .

.