Pressure Transducer: Calibration Using a Pitot-static Tube

Source: Shreyas Narsipur, Mechanical and Aerospace Engineering, North Carolina State University, Raleigh, NC

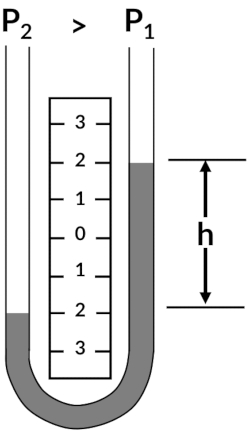

Fluid pressure is an important flow characteristic that is required to determine the aerodynamics of a system. One of the oldest and still existing pressure measurement systems is the manometer due to its accuracy and simplicity of operation. The manometer is generally a U-shaped glass tube that is partially filled with liquid, as shown in Figure 1. The U-tube manometer requires no calibration because it does not have any moving parts, and its measurements are functions of gravity and the liquid's density. Therefore, the manometer is a simple and accurate measurement system.

Figure 1. Schematic of a U-tube manometer.

Real-time pressure measurements are obtained in aircraft by connecting the stagnation and static pressure ports of a pitot-static probe, a device that is commonly used to measure fluid flow pressure, to the ports of a pressure measurement device. This allows pilots to obtain existing flight conditions and to warn them if any changes to the flight conditions occur. While manometers provide very accurate pressure readings, they are inherently bulky. A more realistic solution is needed to measure aircraft pressures, as one of the primary design objectives is to keep the overall aircraft weight as low as possible. Today, electromechanical pressure transducers, which convert the applied pressure to an electric signal, are widely used for pressure sensing applications on aircraft because they are small, lightweight, and can be placed almost anywhere in the airframe. The above characteristics not only help reduce weight but also reduce the amount of tubing required to connect the pitot-static probe to the transducer, thereby decreasing the data response time. Additionally, in experimental aircraft flight testing, miniature pressure transducers come in handy as they allow researchers to maximize pressure data collection without significantly adding to the weight of the aircraft. While different types of pressure transducers with varying measurement techniques exist, one of the more common types of transducer is the capacitive pressure transducer. As transducers are capable of only sending signals in terms of voltage and current, calibration of the transducer is required to relate the strength of a particular signal to the pressure that causes the transducer to generate the signal. The final curve fit that relates the transducer current or voltage to a physical measurement, in our case pressure, is commonly referred to as the transducer calibration curve.

In this experiment, a pitot-static probe is placed in a subsonic wind tunnel with the stagnation and static pressure ports connected to the total and static ports of both the U-tube manometer and the pressure transducer. The wind tunnel is then run at different dynamic pressure settings, and the corresponding pressure reading from the U-tube manometer, and current readings produced by the transducer are recorded. This data is then used to generate calibration curves for the pressure transducer.

1. Pressure Transducer Calibration

In this demonstration, a subsonic wind tunnel with a 2.6 ft x 3.7 ft test section and maximum dynamic pressure setting of 25 psf was used. A pre-calibrated pressure transducer was used to set the dynamic pressure in the wind tunnel test section, and a differential U-tube manometer with colored water and scale was used to measure fluid height (Figure 3). A differential pressure transducer (Figure 4), st

The following constants were used in the analysis: water density, ρwater: 61.04 lb/ft3; acceleration due to gravity, g: 32.15 ft/s2; and manometer off-set, hoff = 0.8 in. The variation in manometer data for increasing and decreasing dynamic pressures (with and without correcting for the instrument off-set) is shown in Figure 7. Figure 8 shows a plot of the transducer current readings against the manometer pressur

Electromechanical transducers are popular replacements for some of the bulkier measurement systems. However, transducers need to be calibrated regularly using standardized measuring devices in order to be effective experimental tools. In this experiment, an off-the-shelf capacitive type electromechanical pressure transducer was calibrated by comparing the current signals generated by the transducer for a range of dynamic pressure conditions in a subsonic wind tunnel to the pressure measurements from a U-tube manometer. R

Passer à...