Aby wyświetlić tę treść, wymagana jest subskrypcja JoVE. Zaloguj się lub rozpocznij bezpłatny okres próbny.

Method Article

Precision Milling of Carbon Nanotube Forests Using Low Pressure Scanning Electron Microscopy

W tym Artykule

Podsumowanie

Low pressure scanning electron microscopy in a water vapor ambient is used to machine nanoscale to microscale features in carbon nanotube forests.

Streszczenie

A nanoscale fabrication technique appropriate for milling carbon nanotube (CNT) forests is described. The technique utilizes an environmental scanning electron microscope (ESEM) operating with a low pressure water vapor ambient. In this technique, a portion of the electron beam interacts with the water vapor in the vicinity of the CNT sample, dissociating the water molecules into hydroxyl radicals and other species by radiolysis. The remainder of the electron beam interacts with the CNT forest sample, making it susceptible to oxidation from the chemical products of radiolysis. This technique may be used to trim a selected region of an individual CNT, or it may be used to remove hundreds of cubic microns of material by adjusting ESEM parameters. The machining resolution is similar to the imaging resolution of the ESEM itself. The technique produces only small quantities of carbon residue along the boundaries of the cutting zone, with minimal effect on the native structural morphology of the CNT forest.

Wprowadzenie

Carbon nanotubes (CNTs) and graphene are carbon-based nanomaterials that have attracted significant attention because of their superior strength, durability, thermal, and electrical properties. Precision machining of carbon nanomaterials has become an emerging topic of research and offers the potential to engineer and manipulate these materials towards a variety of engineering applications. Machining CNTs and graphene requires nanoscale spatial precision to first locate a nanoscale area of interest and then to selectively remove only the material within the area of interest. As an example, consider the machining of vertically oriented CNT forests (also known as CNT arrays). The cross section of CNT forests may be precisely defined by lithographic patterning of catalyst films. The top surface of the vertically oriented forests, however, are frequently poorly ordered with non-uniform height. For surface-sensitive applications such as thermal interface materials, the irregular surface may impede optimal surface contact and reduce device performance. Precision trimming of the irregular surface to create a uniform flat surface could potentially offer better, more repeatable performance by maximizing the available contact area.

Precision machining techniques for nanomaterials frequently do not resemble conventional macroscale mechanical machining technologies such as drilling, milling, and polishing by means of hardened tooling. To date, techniques using energetic beams have been most successful at site-selective milling of carbon nanomaterials. These techniques include laser, electron beam, and focused ion beam (FIB) irradiation. Of these, laser machining techniques provide the most rapid material removal rate1,2; however, the spot size of laser systems is on the order of many microns and is too large to isolate nanometer-scale entities such as a single carbon nanotube segment within a densely populated forest. By contrast, electron and ion beam systems produce a beam that may be focused to a spot that is several nanometers or less in diameter.

FIB systems are specifically designed for nanoscale milling and deposition of materials. These systems utilize an energetic beam of gaseous metal ions (typically gallium) to sputter material from a selected area. FIB milling of CNTs is achievable, but often with unintended byproducts including gallium and carbon redeposition in surrounding regions of the forest3,4. When the technique is used for CNT forests, the redeposited material masks and/or alters the morphology of selected milling region, altering the native appearance and behavior of the CNT forest. The gallium may also implant within the CNT, providing electronic doping. Such consequences often make FIB-based milling prohibitive for CNT forests.

Transmission electron microscopes (TEMs) utilize a finely focused beam of electrons to probe the internal structure of materials. Acceleration voltages for TEM operation typically range from 80-300 kV. Because the knock-on energy of CNTs is 86.4 keV5, the electron energy produced by TEM is sufficient to directly remove atoms from the CNT lattice and induce highly localized milling. The technique mills CNTs with potentially sub-nanometer precision5,6,7; however, the process is very slow – often requiring minutes to mill a single CNT. Importantly, TEM-based milling approaches require CNTs to first be removed from a growth substrate and dispersed onto a TEM grid for processing. As a result, TEM-based methods are generally not compatible with CNT forest milling in which the CNTs must remain on a rigid substrate.

Milling of CNT forests by scanning electron microscopes (SEMs) has also received attention. In contrast to TEM-based techniques, SEM instruments are typically unable to accelerate electrons with sufficient energy to impart the knock-on energy required to directly remove carbon atoms. Rather, SEM-based techniques utilize an electron beam in the presence of a low-pressure gaseous oxidizer. The electron beam selectively damages the CNT lattice and may dissociate the gaseous ambient into more reactive species such as H2O2 and the hydroxyl radical. Water vapor and oxygen are the most commonly reported gases to achieve selective area etching. Because the SEM-based techniques rely on a multiple-step chemical process, numerous processing variables may influence the milling rate and precision of the process. It has been previously observed that increasing acceleration voltage and beam current directly increase the milling rate because of an increased energy flux, as expected11. The effect of chamber pressure is less obvious. A pressure that is too low suffers from a deficiency of the oxidizing agent, decreasing the milling rate. Further, an over-abundance of gaseous species scatters the electron beam and decreases the electron flux in the milling region, also decreasing the material removal rate.

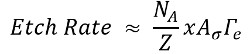

To estimate the carbon removal rate, an approach similar to that used by Lassiter and Rack12 was employed, whereby electrons interact with precursor molecules near the surface to generate reactive species that etch the substrate surface. From this model, the etch rate is estimated as

where NA is the surface concentration of the etchant species, Z is the surface concentration of available reaction sites, x is a stoichiometry factor relating the volatile etching products generated relative to the reactants, Aσ represents the probability of generating the desired etching species from an electron-water vapor collision, and Γe is the electron flux at the surface. The factors of x and Aσ are assumed to be unity, while Z is assumed to be nearly constant and significantly larger than NA. Further details may be found in our previous work.11

In this article, a procedure is explored that uses low-pressure water vapor within a SEM to mill regions ranging from individual CNTs to large volume (tens of cubic micrometers) material removal. Here we demonstrate the technique used to mill CNT forests using an ESEM by the use of reduced area rectangles, horizontal line scans, and software-controlled rastering of the electron beam. Additional software and hardware are required for pattern generation, as outlined in the Materials List. Emphasis is placed on removing relatively large (100's of cubic microns) material volume from a CNT forest, so the following processing conditions are relatively aggressive.

When handling the sample and the sample stub, it is important to wear disposable nitrile gloves. This will prevent oils from being transferred to the stub or sample and consequently deteriorating the effectiveness of the pumps.

Protokół

1. Preparation of CNT Forest Sample for Milling

- CNT Synthesis

- Deposit 10 nm of aluminum oxide (alumina) on a thermally oxidized silicon wafer using atomic layer deposition13 or other physical vapor deposition methods.

- Deposit 1 nm of iron on the alumina support layer by sputtering14 or other physical vapor deposition method.

- Synthesize CNTs using an established process, such as thermal chemical vapor deposition15.

- Heat a 20 mm diameter tube furnace to 750 °C in 400 standard cubic centimeters (sccm) of flowing helium and 100 sccm hydrogen. Introduce 100 sccm ethylene as a hydrocarbon feedstock gas for a growth rate of approximately 50 μm/min.

- SEM Preparation

- Apply carbon tape to a standard 1/2" diameter SEM stub. If tilting the stage is required, overlap the region of the CNT forest sample to be milled over the edge of the stub. If software-controlled electron beam rastering will be used in the milling procedure, secure the CNT sample to an electron beam lithography mount in a similar manner.

- If milling the CNT cross section, secure the stub to a 45° stub holder with a set screw.

- Vent the ESEM by selecting the "Vent" icon from the ESEM control software.

- Open the ESEM stage door, and secure the stub to the SEM stage with a set screw.

- Close the SEM chamber and select "High Vacuum" in the ESEM control software.

- While the ESEM chamber is pumping, select the electron beam parameters of 5 kV and spot size of 3.0 using the Beam Control tab within the control software.

- Select the secondary electron detector by selecting Detectors | ETD(SE) in the ESEM control software.

- Select the "Beam On" icon in the control software. The beam can be activated only once the chamber vacuum is less than 10-4 Torr. Use manual SEM focus control knobs to focus the sample.

- Tilt the sample to 45° using manual tilt stage control knob or by inputting 45° in the "Tilt" field in the "Coordinates" tab of the ESEM software. Focus on the highest sample. Link the focal distance to the working distance by selecting Stage | Link Z to FWD in the ESEM software menu. Input 7 mm into the "Z" field in the "Coordinates" tab within the control software.

- Adjust focus, stigmation, brightness and contrast using the manual control knobs to resolve a well-focused image.

- Beam Adjustment in High Vacuum Mode

- Locate a region for milling using navigation controls. Double click within the SEM image view or by manually turning the x and y control knobs of the SEM stage control to navigate.

- Navigate to an adjacent location approximately 100 μm away from the milling region.

- Consult Figure 1 to estimate the material removal rate of the CNT forest as a function of pressure, acceleration voltage, dwell time per pixel, and beam current.

- Adjust the acceleration voltage to 30 kV and spot size to 5.0 using the ESEM control software. Adjust image focus, brightness, and contrast using the ESEM control knobs. For nanometer-scale milling of individual or few CNTs, select 5 kV and spot size of 3.0.

- Select a 1 mm aperture by manual aperture adjustment. Adjust focus, stigmation, brightness, and contrast to obtain a well-resolved image, as previously detailed.

- Decrease magnification to <1,000X.

- SEM Setup in Low Pressure Water Vapor

- Select a pressure of 11 Pa in the control software dropdown box.

- Select "Low Pressure" mode in the "Vacuum" settings in the ESEM software to introduce water vapor.

- Select "Beam On" in the control software upon pressure stabilization. Select a dwell time of <10 μs and a resolution of 1,024 x 884 in the drop-down boxes of the control software.

- Adjust the image brightness, contrast, focus, and stigmation as previously detailed.

- Navigate to the desired milling region. Rotate the image orientation by selecting Scan | Scan Rotation in the control software, if required. Select a suitable rotation angle that aligns with the native vertical and horizontal scan orientation of the SEM.

- For milling feature sizes on the order of 1 μm, select a magnification of 40,000X. Select a magnification of 20,000X to mill features with dimensions up to 5 μm.

- Pause the electron beam by selecting the ' " ' icon . An image of the CNT forest will be displayed and may be used for selecting reduced area milling regions while the beam is paused.

2. CNT Forest Milling

- Instructions for CNT forest milling using a rectangular selected area

- Choose the 'Reduced Area' tool in the control software, or select Scan-Reduced Area in the software menu. Extend a reduced area rectangle over the area to be milled.

- Adjust the image resolution to 2,048 x 1,768. Increase the dwell time to 2 ms. If 2 ms is not available, navigate to the Scan |Preferences and select the "Scanning" tab. Select an existing scan time and type "2.0 ms" into the "Dwell Time" field. Click "OK" to close the menu.

- Select the ' " ' icon in the control software to activate the electron beam.

- Select the ' " ' icon so that the beam rasters over the selected area one time. Select the icon immediately after step 2.1.3. The scan duration depends on the size of the selected area, resolution and dwell time and may be approximated by multiplying the number of pixels within the scan area and the dwell time per pixel.

- Decrease magnification to <1,000X once the beam has completed rastering the selected area. Revert to the parameters used in step 1.3, including High Vacuum. Select "Beam On" to engage the beam.

- Instructions for CNT forest milling along a horizontal line

- Select the line scan feature by navigating to Scan | Line in the control software. The line width is determined by the size of the electron beam itself. Adjust the image resolution to 2,048 x 1,768 from the control software dropdown box. Increase the dwell time to 2 ms as detailed in step 2.1.2.

- Using the still image acquired before pausing the electron beam, place the line over the area to be milled.

- Select the videoscope icon or navigate to the Scan menu and select "Videoscope." Using the videoscope tool provides feedback relative to when a line scan has fully completed.

- Select the ' " ' icon to scan electron beam across the width of the line.

- Select the ' " ' icon to blank the electron beam.

- Instructions for CNT Forest milling using software-controlled electron beam rastering

- Pattern Generation

- Design a milling pattern of interest using a CAD software package such as AutoCAD.

- Using "Nanometer Pattern Generation System" (NPGS) software, import the CAD pattern file.

- Convert the shapes to solid features by selected "Filled Polygons" in the NPGS software.

- Save the drawing as a '.dc2' file in a designated project folder of NPGS.

- Using NPGS, navigate to the project folder containing the ".dc2" file. Right select the ".dc2" file and select "Run File Editor" to convert the drawing to NPGS code. Typical parameters used to pattern CNT forests at given conditions are as listed below:

Center-to-center distance = 5 nm

Line Spacing = 5 nm

Magnification = 10,000X

Desired Beam Current = 26

Line Dose = 100 nC/cm

- Electron Beam Milling using NPGS Lithography Software

- Select the "NPGS Mode" in NPGS software button to give control of the SEM to NPGS.

- Highlight the pattern file and select "Process Run File" in NPGS to initiate milling.

- Select "SEM Mode" in the NPGS software when patterning is finished. Select "High Vacuum" in the ESEM control software.

- Select "Beam On" to inspect the milled region. Use conditions detailed in step 1.3.

- Pattern Generation

3. Sample Removal

- Vent the chamber by selecting "Vent" in the ESEM control software.

- Open the ESEM door. Remove the stub by loosening the set screw.

- Close the chamber door. Select "High Vacuum" in the control software.

Wyniki

The ESEM technique was used to mill a CNT forest synthesized using thermal CVD15,16. Selected area removal of a few CNTs from within a forest is shown in Figure 211. For this demonstration, parameters include 5 kV, spot size of 3, 11 Pa, 170,000X magnification, 2 ms dwell time, and an aperture of 30 µm.

To demonstrate a large...

Dyskusje

The protocol details best practices for milling relatively large (micron-scale) features in CNT forests. In general, the material removal rate may be reduced by reducing the acceleration voltage, spot size, and aperture diameter. To trim a specific CNT within a forest, recommended conditions include 5 kV, a spot size of 3, and an aperture that is 50 μm or less in diameter. Note that the milling technique using reduced area rectangles is detailed such that the electron beam rasters the enclosed region only one time. ...

Ujawnienia

The authors declare that they have no competing financial interests.

Podziękowania

This work was supported by the Air Force Office of Scientific Research grant FA9550-16-1-0011 and University of Missouri startup funds. The authors would like to thank the University of Missouri Electron Microscopy Core facility for assistance with SEM imaging and use of patterning equipment and software.

Materiały

| Name | Company | Catalog Number | Comments |

| 100 mm diameter silicon wafer with 1 micron thermal oxide | University Wafer | Beginning substrate | |

| Iron sputter target | Kurt J. Lesker | EJTFEXX351A2 | Sputter target |

| Savannah 200 | Cambridge | For atomic layer deposition of alumina | |

| Quanta 600F Environmental SEM | FEI | Environmental scanning electron microscope used to support a low-pressure water vapor ambient environment for CNT forest milling | |

| xT Microscope Control software | FEI | 4.1.7 | Control software used on Quanta 600F ESEM |

| Nanometer Pattern Generation System - Software | JC Nabity Lithography Systems | Version 9 | Software used for electron-beam lithography |

| Dedicated computer with PCI516 Lithography board | Equipment used for electron-beam lithography | ||

| DesignCAD software | V 21.2 | Optional equipment used to generate patterns for electron-beam lithography | |

| E-beam lithography mount | Ted Pella | 16405 | Electron beam lithography mount with a Faraday cup and gold nanoparticles on carbon tape |

| Picoammeter | Keithley | 6485 | Used with the Faraday cup to quantify beam current |

| 12.7 mm diameter SEM stub | Ted Pella | 16111 | SEM stub |

| 45 degree pin stub holder | Ted Pella | 15329 | Optional equipment used to mill the cross section of a CNT forest |

Odniesienia

- Labunov, V., et al. Femtosecond laser modification of an array of vertically aligned carbon nanotubes intercalated with Fe phase nanoparticles. Nanoscale Res Lett. 8 (1), 375-375 (2013).

- Lim, K. Y., et al. Laser Pruning of Carbon Nanotubes as a Route to Static and Movable Structures. Adv Mater. 15 (4), 300-303 (2003).

- Raghuveer, M. S., et al. Nanomachining carbon nanotubes with ion beams. Appl Phys Lett. 84 (22), 4484-4486 (2004).

- Sears, K., Skourtis, C., Atkinson, K., Finn, N., Humphries, W. Focused ion beam milling of carbon nanotube yarns to study the relationship between structure and strength. Carbon. 48 (15), 4450-4456 (2010).

- Smith, B. W., Luzzi, D. E. Electron irradiation effects in single wall carbon nanotubes. J Appl Phys. 90 (7), 3509-3515 (2001).

- Banhart, F., Li, J., Terrones, M. Cutting Single-Walled Carbon Nanotubes with an Electron Beam: Evidence for Atom Migration Inside Nanotubes. Small. 1 (10), 953-956 (2005).

- Krasheninnikov, A. V., Banhart, F., Li, J. X., Foster, A. S., Nieminen, R. M. Stability of carbon nanotubes under electron irradiation: Role of tube diameter and chirality. Phys Rev B. 72 (12), 125428 (2005).

- Royall, C. P., Thiel, B. L., Donald, A. M. Radiation damage of water in environmental scanning electron microscopy. J Microsc. 204 (3), 185-195 (2001).

- Yuzvinsky, T. D., Fennimore, A. M., Mickelson, W., Esquivias, C., Zettl, A. Precision cutting of nanotubes with a low-energy electron beam. Appl Phys Lett. 86 (5), 053109 (2005).

- Liu, P., Arai, F., Fukuda, T. Cutting of carbon nanotubes assisted with oxygen gas inside a scanning electron microscope. Appl Phys Lett. 89 (11), (2006).

- Rajabifar, B., et al. Three-dimensional machining of carbon nanotube forests using water-assisted scanning electron microscope processing. Appl Phys Lett. 107 (14), 143102 (2015).

- Lassiter, M. G., Rack, P. D. Nanoscale electron beam induced etching: a continuum model that correlates the etch profile to the experimental parameters. Nanotechnology. 19 (45), 455306 (2008).

- Amama, P. B., et al. Influence of Alumina Type on the Evolution and Activity of Alumina-Supported Fe Catalysts in Single-Walled Carbon Nanotube Carpet Growth. ACS Nano. 4 (2), 895-904 (2010).

- Almkhelfe, H., Carpena-Nunez, J., Back, T. C., Amama, P. B. Gaseous product mixture from Fischer-Tropsch synthesis as an efficient carbon feedstock for low temperature CVD growth of carbon nanotube carpets. Nanoscale. , (2016).

- Maschmann, M. R., Ehlert, G. J., Tawfick, S., Hart, A. J., Baur, J. W. Continuum analysis of carbon nanotube array buckling enabled by anisotropic elastic measurements and modeling. Carbon. 66, 377-386 (2014).

- Maschmann, M. R., et al. Visualizing Strain Evolution and Coordinated Buckling within CNT Arrays by In Situ Digital Image Correlation. Adv Funct Mater. 22 (22), 4686-4695 (2012).

- Abadi, P. P. S. S., Maschmann, M. R., Baur, J. W., Graham, S., Cola, B. A. Deformation response of conformally coated carbon nanotube forests. Nanotechnology. 24 (47), 475707 (2013).

- Brieland-Shoultz, A., et al. Scaling the Stiffness, Strength, and Toughness of Ceramic-Coated Nanotube Foams into the Structural Regime. Adv Funct Mater. 24 (36), 5728-5735 (2014).

- Maschmann, M. R., Dickinson, B., Ehlert, G. J., Baur, J. W. Force sensitive carbon nanotube arrays for biologically inspired airflow sensing. Smart Mater Struct. 21 (9), 094024 (2012).

- Maschmann, M. R., et al. In situ SEM Observation of Column-like and Foam-like CNT Array Nanoindentation. ACS Appl Mater Inter. 3 (3), 648-653 (2011).

- Pathak, S., Raney, J. R., Daraio, C. Effect of morphology on the strain recovery of vertically aligned carbon nanotube arrays: An in situ study. Carbon. 63, 303-316 (2013).

- Pour Shahid Saeed Abadi, P., Hutchens, S. B., Greer, J. R., Cola, B. A., Graham, S. Effects of morphology on the micro-compression response of carbon nanotube forests. Nanoscale. 4 (11), 3373-3380 (2012).

- Maschmann, M. R. Integrated simulation of active carbon nanotube forest growth and mechanical compression. Carbon. 86, 26-37 (2015).

Przedruki i uprawnienia

Zapytaj o uprawnienia na użycie tekstu lub obrazów z tego artykułu JoVE

Zapytaj o uprawnieniaThis article has been published

Video Coming Soon

Copyright © 2025 MyJoVE Corporation. Wszelkie prawa zastrzeżone