Aby wyświetlić tę treść, wymagana jest subskrypcja JoVE. Zaloguj się lub rozpocznij bezpłatny okres próbny.

Method Article

Viscoelastic Characterization of Soft Tissue-Mimicking Gelatin Phantoms using Indentation and Magnetic Resonance Elastography

W tym Artykule

Podsumowanie

This article presents a demonstration and summary of protocols of making gelatin phantoms that mimic soft tissues, and the corresponding viscoelastic characterization using indentation and magnetic resonance elastography.

Streszczenie

Characterization of biomechanical properties of soft biological tissues is important to understand the tissue mechanics and explore the biomechanics-related mechanisms of disease, injury, and development. The mechanical testing method is the most straightforward way for tissue characterization and is considered as verification for in vivo measurement. Among the many ex vivo mechanical testing techniques, the indentation test provides a reliable way, especially for samples that are small, hard to fix, and viscoelastic such as brain tissue. Magnetic resonance elastography (MRE) is a clinically used method to measure the biomechanical properties of soft tissues. Based on shear wave propagation in soft tissues recorded using MRE, viscoelastic properties of soft tissues can be estimated in vivo based on wave equation. Here, the viscoelastic properties of gelatin phantoms with two different concentrations were measured by MRE and indentation. The protocols of phantom fabrication, testing, and modulus estimation have been presented.

Wprowadzenie

Most of the soft biological tissues appear to have viscoelastic properties that are important to understand their injury and development1,2. In addition, viscoelastic properties are important biomarkers in the diagnosis of a variety of diseases such as fibrosis and cancer3,4,5,6. Therefore, the characterization of viscoelastic properties of soft tissues is crucial. Among the many characterization techniques used, ex vivo mechanical testing of tissue samples and in vivo elastography using biomedical imaging are the two widely used methods.

Although various mechanical testing techniques have been used for soft tissue characterization, the requirements for sample size and testing conditions are not easy to be satisfied. For example, shear testing needs to have samples fixed firmly between the shear plates7. Biaxial testing is more suitable for membrane tissue and has specific clamping requirements8,9. A compression test is commonly used for tissue testing, but cannot characterize specific positions within one sample10. The indentation test does not have additional requirements to fix the tissue sample and can be used to measure many biological tissue samples such as the brain and liver. In addition, with a small indenter head, regional properties within a sample could be tested. Therefore, indentation tests have been adopted to test a variety of soft tissues1,3,11.

Characterizing the biomechanical properties of soft tissues in vivo is important for translational studies and clinical applications of biomechanics. Biomedical imaging modalities such as ultrasound (US) and magnetic resonance (MR) imaging are the most used techniques. Although US imaging is relatively cheap and easy to carry out, it suffers from low contrast and is hard to measure organs such as the brain. Capable of imaging deep structures, MR Elastography (MRE) could measure a variety of soft tissues6,12, especially the brain13,14. With applied external vibration, MRE could measure the viscoelastic properties of soft tissues at a specific frequency.

Studies have shown that at 50-60 Hz, the shear modulus of the normal brain is ~1.5-2.5kPa5,6,13,14,15 and ~2-2.5 kPa for normal liver16. Therefore, gelatin phantoms that have similar biomechanical properties have been widely used for mimicking soft tissues for testing and validation17,18,19. In this protocol, gelatin phantoms with two different concentrations were prepared and tested. Viscoelastic properties of the gelatin phantoms were characterized using a custom-built electromagnetic MRE device14 and an indentation device1,3. The testing protocols could be used for testing many soft tissues such as the brain or liver.

Protokół

1. Gelatin phantom preparation

- Weigh gelatin, glycerol, and water according to Table 1. Mix the gelatin powder with water to obtain the gelatin solution.

NOTE: The concentrations of the individual components for preparing the two phantoms are shown in Table 1. The higher the concentration of gelatin, the stiffer the phantom. - Heat the gelatin solution to 60 °C in a water bath. Add glycerol to the gelatin solution while maintaining the temperature.

NOTE: Glycerol stabilizes gelatin mixtures by increasing their melting temperature and shear modulus17. - Stir the solution and heat it to 60 °C again. Pour the mixed solution into a container that will be used for MRE and indentation tests. Cool the solution to room temperature and wait till the solution is solidified.

2. MRE test

- Put the vibration plate on top of the gelatin phantom. Ensure that the contact between the phantom and the vibration plate is firm (Figure 1A).

NOTE: The vibration plate is made of Polyamide with a dimension of 50 x 50 x 5 mm3. - Place the gelatin phantom into the head coil. Put sponges and sandbags around the gelatin phantom to make sure the phantom is firmly placed. Use a custom-built electromagnetic actuator with a transmission bar14,18. Mount an electromagnetic actuator on the head coil. Connect the transmission bar to the vibration plate (Figure 1B).

- Connect the power lines of the actuator with the amplifier. Connect the control lines with the controller (Figure 1C).

- Actuator and MRI scan parameter settings

- Set the waveform, vibration frequency, and amplitude in the function generator. Set the desired vibration amplitude by adjusting the power amplifier.

NOTE: Here, the waveform is set to sinusoidal in the function generator; the vibration frequency is set to 40 Hz or 50 Hz, and the amplitude is set to 1.5 Vpp. In the power amplifier, the amplification ratio is set to 40%. - Set the function generator to work in the trigger mode. Connect the trigger line to the external trigger port of the MRI machine.

- Set the MRE scanning (actuator) frequency the same as that from the function generator, so that the motion encoding gradient is synchronized with the motion of the vibration plate.

- Set the waveform, vibration frequency, and amplitude in the function generator. Set the desired vibration amplitude by adjusting the power amplifier.

- Data measurement and analysis

- Follow the routine imaging positioning procedures. Use a 2D gradient-echo (GRE) based MRE sequence for imaging of the gelatin phantom20. Set the GRE-MRE imaging parameters as follows: Flip-angle = 30°; TR/TE = 50/31 ms; Field-of-view = 300 mm; Slice thickness = 5 mm; Voxel size = 2.34 x 2.34 mm2.

- Measure the phase images at four temporal points in one sinusoidal cycle. Apply both positive and negative motion encoding gradients at each time point.

- Based on the phase image acquired, remove the background phase by subtracting the positive and negative encoded phase images. Unwrap the phase with a reliability sorting-based algorithm21.

- Extract the principal component of the motion by applying fast Fourier Transform to the unwrapped phase images. Filter the phase image with a digital bandpass filter. Estimate the shear modulus with a 2D direct inversion (DI) algorithm to obtain storage modulus G' and loss modulus G''13,14.

NOTE: The cut-off frequency of the bandpass filter is [0.04 0.08]. The size of the fitting window of the DI algorithm is 11 x 11.

3. Indentation test

- Use a circular punch or surgical blade to trim the gelatin phantom into a cylindrical or cuboid sample, respectively. Make sure that the sample thickness is between 3 and 10 mm and the diameter of the cylindrical sample or the long side of the cuboid is larger than 4 mm. Use a sharp blade to trim the surface of the sample to make it as smooth as possible for indentation.

- Turn on the power of the indentation tester. Perform the following using the indenter control program designed to automate the indenter contact procedure (custom program; see Table of Materials).

- Click on the Back off button in the GUI to initialize the calibration process (Figure 2B). Read the value from the laser sensor and type the value in the BaseLine box.

NOTE: During the calibration process, the distance between the laser sensor and the baffle plate is adjusted to a specific pre-defined value. - Place a glass slide on the baffle plate and record the value shown by the laser sensor. Next, put the sample on the glass slide and place them together on the baffle plate. Read the value from the laser sensor and type this value in the Sample+Slide box.

NOTE: The laser sensor is used to record the displacement of the indentation, but it is also used to measure the sample thickness before the test. - Take the difference between the two values obtained in step 3.2.2 as the sample thickness at the region of interest (ROI).

- Carefully place the sample along with the underlying glass slide right below the indenter, and then click on the Contact button to initiate automatic contact between the indenter and the sample surface.

NOTE: If the automatic contact is not satisfactory, i.e., the indenter presses deep into the sample or does not have a contact, adjust the indenter position by typing a value in the range of 0.05-0.1 mm in the Offset box and repeat steps 1.2.1-1.2.4. - Based on the measured sample thickness (step 3.2.3), estimate the indentation displacement (i.e., total indentation depth) by multiplying the thickness with the indented testing strain (here, it is set to ≤8% to keep the indentation within the small strain assumption).

- Type the displacement values (step 3.2.5) in the Displacement (mm) box. Set the relaxation time to 180 s in the Dwell Time box. Click on the Indentation button. The displacement and reactive force during the ramp-hold procedure will be automatically recorded and saved in a file at the specified File Path.

NOTE: The File Path can be pre-defined as the path for saving testing data.

- Click on the Back off button in the GUI to initialize the calibration process (Figure 2B). Read the value from the laser sensor and type the value in the BaseLine box.

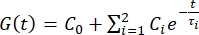

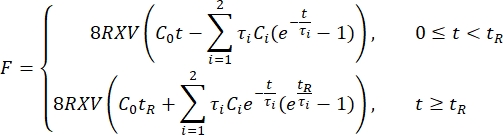

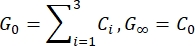

- Export the indentation data to a spreadsheet. Use a two-term Prony series

to fit the force relaxation curve1,3,11:

to fit the force relaxation curve1,3,11:

- Estimate the instantaneous shear modulus (G0) and long-term shear modulus (G∞) based on the fitted parameters:

NOTE: In the above equations, C0, Ci, and τi are model parameters of the Prony series, F is the indentation force, R is the radius of the indenter, X is the compensation factor for the infinite half space assumption, V is the indentation velocity, t is the time variable, and tR is the ramp time.

Wyniki

Following the MRE protocol, a clear shear wave propagation in the gelatin phantoms at 40 and 50 Hz were observed (Figure 3). The viscoelastic properties measured from MRE, and indentation tests are shown in Figure 4. The estimated G' and G" values at each testing for each phantom are summarized in Table 2. Following the indentation protocol, the viscoelastic properties of each phantom at each test point are summarized in Table 3<...

Dyskusje

Gelatin phantoms are commonly used as tissue-mimicking materials for testing and validation of algorithms and devices17,19,22,23,24,25,26,27. One of the pioneering studies using the gelatin phantom to compare MRE and dynamic shear testing was presented by O...

Ujawnienia

Authors declare no conflicts of interest.

Podziękowania

Funding support from the National Natural Science Foundation of China (grant 31870941), Natural Science Foundation of Shanghai (grant 22ZR1429600), and the Science and Technology Commission of Shanghai Municipality (grant 19441907700) is acknowledged.

Materiały

| Name | Company | Catalog Number | Comments |

| 24-channel head & Neck coil | United Imaging Healthcare | 100120 | Equipment |

| 3T MR Scanner | United Imaging Healthcare | uMR 790 | Equipment |

| Acquisition board | Advantech Co | PCI-1706U | Equipment |

| Computer-Windows | HP | 790-07 | Equipment |

| Electromagnetic actuator | Shanghai Jiao Tong University | Equipment | |

| Function generator | RIGOL | DG1022Z | Equipment |

| Gelatin | CARTE D’OR | Reagent | |

| Glycerol | Vance Bioenergy Sdn.Bhd | Reagent | |

| Indenter control program | custom-designed | Software; accessed via: https://github.com/aaronfeng369/FengLab_indentation_code. | |

| Laser sensor | Panasonic | HG-C1050 | Equipment |

| Load cell | Transducer Technique | GSO-10 | Equipment |

| MATLAB | Mathworks | Software | |

| Power amplifier | Yamaha | A-S201 | Equipment |

| Voice coil electric motor | SMAC Corporation | DB2583 | Equipment |

Odniesienia

- Qiu, S., et al. Viscoelastic characterization of injured brain tissue after controlled cortical impact (CCI) using a mouse model. Journal of Neuroscience Methods. 330, 108463 (2020).

- Garcia, K. E., et al. Dynamic patterns of cortical expansion during folding of the preterm human brain. Proceedings of the National Academy of Sciences of the United States of America. 115 (12), 3156-3161 (2018).

- Qiu, S., et al. Characterizing viscoelastic properties of breast cancer tissue in a mouse model using indentation. Journal of Biomechanics. 69, 81-89 (2018).

- Yin, Z., et al. A new method for quantification and 3D visualization of brain tumor adhesion using slip interface imaging in patients with meningiomas. European Radiology. 31 (8), 5554-5564 (2021).

- Streitberger, K. -. J., et al. How tissue fluidity influences brain tumor progression. Proceedings of the National Academy of Sciences of the United States of America. 117 (1), 128 (2020).

- Bunevicius, A., Schregel, K., Sinkus, R., Golby, A., Patz, S. REVIEW: MR elastography of brain tumors. NeuroImage: Clinical. 25, 102109 (2020).

- Namani, R., et al. Elastic characterization of transversely isotropic soft materials by dynamic shear and asymmetric indentation. Journal of Biomechanical Engineering. 134 (6), 061004 (2012).

- Potter, S., et al. A novel small-specimen planar biaxial testing system with full in-plane deformation control. Journal of Biomechanical Engineering. 140 (5), 0510011 (2018).

- Zhang, W., Feng, Y., Lee, C. -. H., Billiar, K. L., Sacks, M. S. A generalized method for the analysis of planar biaxial mechanical data using tethered testing configurations. Journal of Biomechanical Engineering. 137 (6), 064501 (2015).

- Delaine-Smith, R. M., Burney, S., Balkwill, F. R., Knight, M. M. Experimental validation of a flat punch indentation methodology calibrated against unconfined compression tests for determination of soft tissue biomechanics. Journal of the Mechanical Behavior of Biomedical Materials. 60, 401-415 (2016).

- Chen, Y., et al. Comparative analysis of indentation and magnetic resonance elastography for measuring viscoelastic properties. Acta Mechanica Sinica. 37 (3), 527-536 (2021).

- Garteiser, P., Doblas, S., Van Beers, B. E. Magnetic resonance elastography of liver and spleen: Methods and applications. NMR in Biomedicine. 31 (10), 3891 (2018).

- Arani, A., Manduca, A., Ehman, R. L., Huston Iii, J. Harnessing brain waves: a review of brain magnetic resonance elastography for clinicians and scientists entering the field. British Journal of Radiolology. 94 (1119), 20200265 (2021).

- Qiu, S., et al. An electromagnetic actuator for brain magnetic resonance elastography with high frequency accuracy. NMR in Biomedicine. 34 (12), 4592 (2021).

- Hiscox, L. V., et al. Standard-space atlas of the viscoelastic properties of the human brain. Human Brain Mapping. 41 (18), 5282-5300 (2020).

- Seyedpour, S. M., et al. Application of magnetic resonance imaging in liver biomechanics: A systematic review. Frontiers in Physiology. 12, 733393 (2021).

- Okamoto, R. J., Clayton, E. H., Bayly, P. V. Viscoelastic properties of soft gels: comparison of magnetic resonance elastography and dynamic shear testing in the shear wave regime. Physics in Medicine and Biology. 56 (19), 6379-6400 (2011).

- Feng, Y., et al. A multi-purpose electromagnetic actuator for magnetic resonance elastography. Magnetic Resonance Imaging. 51, 29-34 (2018).

- Zeng, W., et al. Nonlinear inversion MR elastography with low-frequency actuation. IEEE Transactions on Medical Imaging. 39 (5), 1775-1784 (2020).

- Wang, R., et al. Fast magnetic resonance elastography with multiphase radial encoding and harmonic motion sparsity based reconstruction. Physics in Medicine and Biology. 67 (2), (2022).

- Herraez, M. A., Burton, D. R., Lalor, M. J., Gdeisat, M. A. Fast two-dimensional phase-unwrapping algorithm based on sorting by reliability following a noncontinuous path. Applied Optics. 41 (35), 7437-7444 (2002).

- Gordon-Wylie, S. W., et al. MR elastography at 1 of gelatin phantoms using 3D or 4D acquisition. Journal of Magnetic Resonance. 296, 112-120 (2018).

- McGarry, M., et al. Uniqueness of poroelastic and viscoelastic nonlinear inversion MR elastography at low frequencies. Physics in Medicine and Biology. 64 (7), 075006 (2019).

- Zampini, M. A., Guidetti, M., Royston, T. J., Klatt, D. Measuring viscoelastic parameters in Magnetic Resonance Elastography: a comparison at high and low magnetic field intensity. Journal of the Mechanical Behavior of Biomedical Materials. 120, 104587 (2021).

- Ozkaya, E., et al. Brain-mimicking phantom for biomechanical validation of motion sensitive MR imaging techniques. Journal of the Mechanical Behavior of Biomedical Materials. 122, 104680 (2021).

- Guidetti, M., et al. Axially- and torsionally-polarized radially converging shear wave MRE in an anisotropic phantom made via Embedded Direct Ink Writing. Journal of the Mechanical Behavior of Biomedical Materials. 119, 104483 (2021).

- Badachhape, A. A., et al. The relationship of three-dimensional human skull motion to brain tissue deformation in magnetic resonance elastography studies. Journal of Biomechanical Engineering. 139 (5), 0510021 (2017).

Przedruki i uprawnienia

Zapytaj o uprawnienia na użycie tekstu lub obrazów z tego artykułu JoVE

Zapytaj o uprawnieniaPrzeglądaj więcej artyków

This article has been published

Video Coming Soon

Copyright © 2025 MyJoVE Corporation. Wszelkie prawa zastrzeżone