Microfluidic Preparation of Liquid Crystalline Elastomer Actuators

In This Article

Summary

This article describes the microfluidic process and parameters to prepare actuating particles from liquid crystalline elastomers. This process allows the preparation of actuating particles and the variation of their size and shape (from oblate to strongly prolate, core-shell, and Janus morphologies) as well as the magnitude of actuation.

Abstract

This paper focuses on the microfluidic process (and its parameters) to prepare actuating particles from liquid crystalline elastomers. The preparation usually consists in the formation of droplets containing low molar mass liquid crystals at elevated temperatures. Subsequently, these particle precursors are oriented in the flow field of the capillary and solidified by a crosslinking polymerization, which produces the final actuating particles. The optimization of the process is necessary to obtain the actuating particles and the proper variation of the process parameters (temperature and flow rate) and allows variations of size and shape (from oblate to strongly prolate morphologies) as well as the magnitude of actuation. In addition, it is possible to vary the type of actuation from elongation to contraction depending on the director profile induced to the droplets during the flow in the capillary, which again depends on the microfluidic process and its parameters. Furthermore, particles of more complex shapes, like core-shell structures or Janus particles, can be prepared by adjusting the setup. By the variation of the chemical structure and the mode of crosslinking (solidification) of the liquid crystalline elastomer, it is also possible to prepare actuating particles triggered by heat or UV-vis irradiation.

Introduction

Microfluidic syntheses have become a well-known method for the fabrication of liquid crystalline elastomer (LCE) actuators in the last few years1,2,3. This approach not only enables the production of a large number of well-actuating particles but also allows the fabrication of shapes and morphologies which are not accessible by other methods. Since LCE actuators are promising candidates for an application as artificial muscles in micro-robotics, new methods to synthesize such particles are of great importance for this future technology4.

In LCEs, the mesogens of a liquid crystal (LC) are attached to the polymer chains of an elastomeric network5,6,7,8. The linkage of the mesogens to the polymer chain can thereby happen in the form of a side-chain, a main-chain, or a combined LC-polymer9,10,11. The distance between the crosslinking points should be far enough to allow a free reorientation of the polymer chain in between (in fact, this is true for any elastomer, which differentiates them from "thermosets"). Thereby, crosslinking can be permanent or reversible due to strong non-covalent interactions12,13,14. This kind of material combines the properties of both, the anisotropic behavior of a liquid crystal with the entropic elasticity of an elastomer. In the temperature range of its liquid crystalline phase, the polymer chains adopt a (more or less) stretched conformation caused by the anisotropy of the liquid crystalline phase, which is quantified by the nematic order parameter. When the sample is brought above the nematic-to-isotropic phase transition temperature, the anisotropy disappears, and the network relaxes to the energetically favored random coil conformation. This leads to a macroscopic deformation and thus actuation5,15. Besides the heating of the sample, this phase transition can also be induced by other stimuli such as light or solvent diffusion in the LCEs16,17,18,19.

In order to obtain a strong deformation, it is necessary that the sample either forms a monodomain or features at least a preferred orientation of the single domain's directors during the crosslinking step20. For the production of LCE films, this is often achieved by the stretching of a pre-polymerized sample, via the orientation of the domains in an electric or magnetic field, with the aid of photo-alignment layers or via 3D-printing21,22,23,24,25,26.

A different approach is the continuous preparation of LCE particles with capillary-based microfluidic droplet generators. Liquid crystalline monomer droplets are dispersed in a highly viscous continuous phase, which flows around the droplets and applies a shear rate on the droplets' surface. Therefore, a circulation inside the monomer droplet is observed, which causes an overall alignment of the liquid crystalline phase27. Thereby, the magnitude of the shear rates acting on the droplets has a strong influence on both the droplet's shape and the size, as well as on the orientation of the liquid crystalline director field. These well-oriented droplets can then be polymerized further downstream in the microfluidic setup. Thus, the preparation of actuators with varying shapes (e.g., particles and fibers) and more complex morphologies like core-shell and Janus particles are possible28,29,30,31. It is even possible to prepare oblate particles, which extend along their symmetry axis and highly prolate, fiber-like particles, which shrink at the phase transition. Both types of particles can be made with the same kind of microfluidic setup, just by varying the shear rate27. Here, we present the protocol of how to produce such LCE actuators of different morphologies in self-manufactured capillary-based microfluidic devices.

Besides the effect of mesogen alignment in LCE droplets and the accessibility of polymers with varying shapes, microfluidic approaches have further advantages. Compared to other particle fabrication methods like precipitation in a non-solvent or suspension polymerization32 (which leads to particles with a broad size-distribution), monodisperse particles (the coefficient of variation of the particle size is <5%) can be synthesized using microfluidics33,34. In addition, it is easy to break the sphere symmetry of the droplets by a flow. Thus, large particles with a cylindrical symmetry are accessible, which is needed for actuators. This is different from LC-particles made by suspension polymerization32. Furthermore, the particle size is well adjustable by microfluidics in a range from several micrometers to hundreds of microns, and additives can easily be brought into the particles or at their surface. This is why microfluidic particle preparation is often used in topics like drug delivery35 or the manufacturing of cosmetics36.

The microfluidic setups used in this article were introduced by Serra et al.33,37,38. These are self-manufactured and consist of high-performance liquid chromatography (HPLC) polytetrafluorethylene (PTFE) tubes and T-junctions, as well as fused silica capillaries that provide the single phases. Thus, the setup can easily be modified, and single parts can simply be exchanged as they are commercially available. A photoinitiator is added to the monomer mixtures, which enables the use of an appropriate light source to induce the polymerization of the droplets on-the-fly, after they left the capillary. Irradiation aside from the capillaries is necessary to prevent a clogging of the setup. Other types of the polymerization only start the polymerization after the droplet has left the capillary (e.g., with initiators based on redox processes)39. However, due to the quickness of the photo-induced crosslinking polymerization and the ability to be remotely controlled, photoinitiation is the most advantageous one.

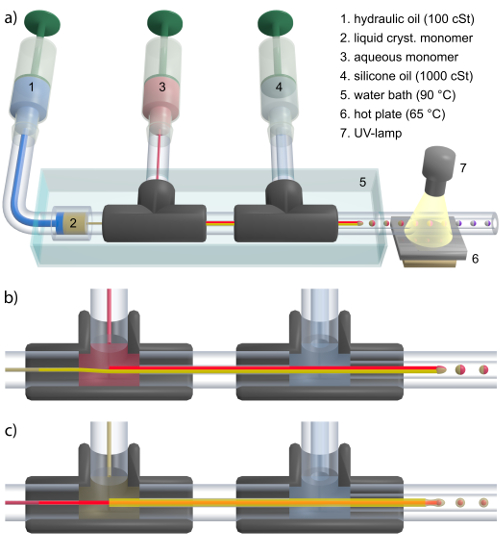

Since the LCE's monomer mixture is crystalline at room temperature, a careful temperature control of the whole microfluidic setup is necessary. Therefore, the part of the setup in which the droplet formation occurs is placed in a water bath. Here, the droplets are formed at high temperatures in the isotropic melt of the mixture. For the orientation, the droplets must be cooled into the liquid crystalline phase. Therefore, the polymerization tube is placed on a hot plate which is set to the lower temperature range of the LC-phase (Figure 1).

Here, we describe a flexible and straightforward method for the fabrication of LCE actuators in a flow. This protocol provides the steps required to build the microfluidic setup for the synthesis of single particles as well as Janus and core-shell particles in a few minutes. Next, we describe how to run a synthesis and show the typical outcome as well as the properties of the actuating particles. Finally, we discuss the advantages of this method and why we think it might bring progress to the field of LCE actuators.

Protocol

1. Synthesis of Single Actuating LCE Particles

- Mounting the device

NOTE: All materials used for the microfluidic setup are HPLC supply and commercially available.- Equip a glass water bath dish [diameter (D): 190 mm, connections: two 29/24 ground glass joints flange-mounted] with two septa. Broach both septa with an awl to fit a tube with an outer diameter (OD) of 1/16 inch through the opening hole.

- Attach a fitting for 1/16 inch OD tubing and the corresponding ferrule to the end of a PTFE tube (tube 1.1; OD: 1/16 inch, inner diameter (ID): 0.17 mm, length (L): 5 cm) and stick the tip (ca. 1 cm) of a polyimide-coated silica capillary (ID: 100 µm, OD: 165 µm, L: 7 cm) into it.

- Screw the tube onto one of the opposing arms of a polyether ether ketone (PEEK) T-junction for 1/16 inch OD tubes, which is mounted on a small metal table. Now, the capillary should protrude a few centemeters out of the T-junction.

NOTE: PTFE tubes are best cut with the aid of a tube cutter. For the capillaries, a cleaving stone is best to use. - Attach a suitable fitting and ferrule to the end of a second PTFE tube (tube 1.2; OD: 1/16 inch, ID: 0.75 mm), which is long enough to reach a syringe pump outside the water bath, and screw it onto the lateral arm of the T-junction.

- Stick a third PTFE tube (tube 1.3; OD: 1/16 inch, ID: 0.17 mm) through one of the septa. Tube 1.3 should be long enough to connect a second syringe pump with tube 1.1 inside the water bath. Add two female luer locks for 1/16 inch OD tubing to the spare end of tubes 1.1 and 1.3, respectively.

- Prepare a fourth PTFE tube (polymerization tube 1.4; OD: 1/16 inch, ID: 0.75 mm) with a fitting plus ferrule and stick it through the second septum. Tube 1.4 should be long enough to leave the water bath and pass a precision heating plate. Connect tube 1.4 via its fitting to the remaining arm of the T-junction and place the end of the glass capillary inside the tube.

- Put the water bath on a hot plate equipped with a thermometer, use adhesive tape to fix tube 1.4 on top of the precision heating plate and attach a 5 mL glass vial to the end of tube 1.4. Connect the end of tube 1.2 to a syringe filled with the continuous phase (silicone oil; viscosity: 1.000 m2/s), connect tube 1.3 to a syringe filled with the hydraulic oil for the monomer phase (silicone oil; viscosity: 100 m2/s) and plug both syringes in a syringe pump.

NOTE: In order to connect the tubes to the syringes, barb-to-female-luer-lock connectors for use with 3/32 inch ID tubes are best to use. - Install a stereomicroscope with the focus being set on the capillary's tip to enable the observation of the droplet formation and mount a UV-light source (e.g., a 500 W-mercury vapor lamp) with the light cone focused on tube 1.4.

- Preparation of the monomer mixture

- To prepare the monomer mixture40, add 200 mg of (4-acryloyloxybutyl)-2,5-di(4-butyloxybenzoyloxy)benzoate to a 50 mL pear-shaped flask.

- Add 7.2 mg of 1,6-hexanediol dimethacrylate (10 mol%) and 6.2 mg of ethyl(2,4,6-trimethylbenzoyl) phenylphosphinate (photoinitiator, 3 w%) to the flask. Dissolve the mixture in about 1 mL of dichloromethane.

NOTE: Starting from step 1.2.2., all steps should be performed under UV light-free conditions (e.g., under yellow light). - Remove the solvent completely under vacuum at 313 K and melt the residual solid at 383 K in an oil bath.

- Prepare a syringe with a barb-to-female-luer-lock connector for use with 3/32 inch ID tubing and attach a PTFE tube (tube 1.5; OD: 1/8 inch, ID: 1.65 mm) via a connecting tube (OD: 1/16 inch, ID: 0.75 mm). Draw up the monomer mixture into the tube 1.5 with the aid of the syringe.

NOTE: The amount of monomer should not be less than 70 mg. Otherwise, it becomes very difficult to draw enough monomer mixture into tube 1.5. The protocol can be paused here. If so, store the tube in a refrigerator.

- Preparation of the particles

- Attach a male luer lock for 1/8 inch OD tubing to both ends of tube 1.5 containing the monomer mixture. Afterwards, connect both ends of tube 1.5 with the female luer locks on the ends of tubes 1.1 and 1.3.

NOTE: The tubes should be rinsed with the liquids provided by the syringe pumps prior to the synthesis. - Set the water bath's temperature to 363 K and set the precision heating plate's temperature to 338 K.

- Make sure the capillary's tip is in the center of the polymerization tube 1.5 and does not touch the wall.

NOTE: The temperatures given here are optimized for this monomer mixture. In general, the water bath's temperature should be high enough to melt the monomer mixture and the heating plate's temperature should be in the temperature range of the liquid crystalline phase. - After the monomer mixture is melted, set the flow rate of the continuous phase (Qc) to a value between 1.5 and 2.0 mL/h and choose flow rate ratios of Qc/Qd (Qd = the flow rate of the hydraulic oil/monomer phase) between 20 and 200.

NOTE: For flow rates of Qc = 1.75 mL/h and Qd = 0.35 mL/h, well-actuating particles with a D of 270 µm are observed, for example. - After the droplet formation begins, wait until the droplets are all the same size before switching on the UV-light. For the described monomer mixture, position the UV source 1 cm above polymerization tube 1.4 at the right end of the precision heating plate. Collect the different fractions of the polymerized particles in the 5-mL glass vial at the end of tube 1.4. While flowing under the UV-light, the droplets' color should change from transparent to white.

Caution: Wear UV-protection goggles to protect eyes. - Put a shield (e.g., a paper box) between the light source and the water bath, in order to prevent any clogging of the capillary.

NOTE: In case of a clogging polymerization tube, it might help to heat the clogged part with a heat gun. - After all the monomer is consumed, clean the setup by injecting acetone into tube 1.3.

- Attach a male luer lock for 1/8 inch OD tubing to both ends of tube 1.5 containing the monomer mixture. Afterwards, connect both ends of tube 1.5 with the female luer locks on the ends of tubes 1.1 and 1.3.

2. Synthesis of Core-shell LCE Particles

- Mounting of the device

- Follow step 1.1.1. but use a water bath dish with a D of 190 mm instead.

- Attach a fitting and ferrule to both ends of a fluorinated ethylene propylene (FEP) tubing sleeve (ID: 395 µm, OD: 1/16 inch, L: 1.55 inch), respectively. First, stick a fused silica capillary (ID: 280 µm, OD: 360 µm, L: 8 cm) through the sleeve, in such a way that it protrudes about 3 mm out of one side. Then stick a thinner capillary (ID: 100 µm, OD: 165 µm, L: 11 cm) through the bigger one, so that it protrudes a few millimeters out of its longer side.

- Screw the sleeve onto one of the opposing arms of a PEEK T-junction for 1/16 inch OD tubes (T-junction 1) which is mounted on a small metal table, with the shorter end of the bigger capillary reaching into the T-junction.

- Stick a PTFE tube (tube 2.1; OD: 1/16 inch, ID: 0.17 mm) that is long enough to connect a syringe pump with T-junction 1 through one of the water bath's septa. Attach a fitting and ferrule to the tube's end inside the water bath, connect it to the free lateral arm of T-junction 1, and stick the thinner capillary inside tube 2.1.

- Prepare a second PTFE tube (tube 2.2; OD: 1/16 inch, ID: 0.5 mm) with a fitting and a ferrule and connect it to the spare arm of T-junction 1. Stick another PTFE tube (tube 2.3; OD: 1/16 inch, ID: 0.5 mm) through a second hole in the septum next to tube 2.1. Tube 2.3 should be long enough to connect another syringe pump with tube 2.2.

- Add two female luer locks for 1/16 inch OD tubing to the free ends of tubes 2.2 and 2.3 inside the water bath, respectively.

- Connect the free end of the sleeve to one of the opposing arms of a second PEEK T-junction (T-junction 2) which is also mounted on the small metal table. Prepare a fourth PTFE tube (tube 2.4; OD: 1/16 inch, ID: 0.75 mm) with a fitting plus ferrule. Tube 2.4 is long enough to reach a third syringe pump outside the water bath and connect it to the lateral arm of T-junction 2.

- Prepare a fifth PTFE tube (polymerization tube 2.5; OD: 1/16 inch, ID: 0.75 mm) with a fitting plus ferrule and stick it through the other septum. Tube 2.5 should be long enough to leave the water bath and pass a high precision heating plate. Connect the fitting of tube 2.5 with the remaining arm of the T-junction. Now the glass capillaries' tips should be located inside tube 2.5.

- Put the water bath on a hot plate equipped with a thermometer, use adhesive tape to fix tube 2.5 on top of a precision heating plate and attach a 5 mL glass vial to the tube's end. Connect the end of tube 2.1 to a syringe filled with glycerol (inner phase), connect tube 2.3 to a syringe filled with the hydraulic oil for the monomer phase (silicone oil; viscosity: 100 m2/s), connect tube 2.4 to a syringe filled with the continuous phase (silicone oil; viscosity: 1.000 m2/s) and plug all syringes in syringe pumps.

- Follow step 1.1.7., but read tube 2.5 instead of tube 1.4.

- Preparation of the monomer mixture

- Follow all steps of 1.2.

- Preparation of the core-shell particles

- Attach a male luer lock for 1/8 inch OD tubes to both ends of the tube containing the monomer mixture, respectively. Afterwards, connect both ends of this tube with the female luer locks on the ends of the tubes 2.2 and 2.3.

- Follow steps 1.3.2-1.3.4.

- Observe the droplet formation via a stereo microscope.

3. Synthesis of Janus LCE Particles

- Mounting of the device

- Follow step 1.1.1.

- Attach a fitting and ferrule to both ends of an FEP tubing sleeve (ID: 395 µm, OD: 1/16 inch, L: 1.55 inch), respectively. Stick two parallelly aligned fused silica capillaries (ID: 100 µm, OD: 165 µm, L1: 8 cm, L2: 11 cm) through the sleeve. The short capillary protrudes about 3 mm out of one side of the sleeve. On the other side of the sleeve, both capillaries have the same length.

- Super-glue the capillaries by putting some glue on one end of the sleeve and wait until it is cured.

- Connect two PEEK T-junctions by screwing the sleeve onto one of the opposing arms, respectively, and mount both on a small metal table.

- Follow steps 2.1.4-2.1.7.

- Prepare a fifth PTFE tube (tube 3.5; OD: 1/16 inch, ID: 0.75 mm, L: 5 cm) with a fitting plus ferrule and connect it with the remaining arm of T-junction 2. Both tips of the glass capillaries are located inside tube 3.5.

- Stick another PTFE tube (tube 3.6; OD: 1/16 inch, ID: 0.5 mm) through the other septum. Tube 2.6 should be long enough to leave the water bath and pass a precision heating plate. Connect tubes 3.5 and 3.6 via fitting systems for 1/16 inch OD tubing.

- Put the water bath on a hot plate equipped with a thermometer, use adhesive tape to fix tube 3.6 on top of a precision heating plate and attach a 5 mL glass vial to the tube's end. Connect the end of tube 3.1 to a syringe filled with an aqueous monomer mixture (aq. monomer phase), connect tube 3.3 to a syringe filled with the hydraulic oil for the LC-monomer phase (silicone oil; viscosity: 100 m2/s), connect tube 3.4 to a syringe filled with the continuous phase (silicone oil; viscosity: 1.000 m2/s) and plug all syringes in syringe pumps.

- Follow step 1.1.8, but read tube 3.6 instead of tube 1.4.

- Preparation of the liquid crystalline (LC) monomer mixture

- Follow all steps of 1.2.

- Preparation of the aqueous monomer mixture

- Prepare a solution of 40 wt% acrylamide in distilled water. Add 10 mol% of the crosslinking agent N,N'-methylenebis(acrylamide) and 2 wt% of the initiator 2-hydroxy-2-methylpropiophenone to the solution. (Both amounts are with respect to the acrylamide.)

NOTE: In order to raise the viscosity of the aqueous monomer mixture, polyacrylamide can be added. - Stir the mixture for 24 h at RT and fill it into a 1 mL syringe, afterward.

- Prepare a solution of 40 wt% acrylamide in distilled water. Add 10 mol% of the crosslinking agent N,N'-methylenebis(acrylamide) and 2 wt% of the initiator 2-hydroxy-2-methylpropiophenone to the solution. (Both amounts are with respect to the acrylamide.)

- Preparation of the Janus particles

- Attach a male luer lock for 1/8 inch OD tubes to both ends of the tube containing the LC monomer mixture, respectively. Afterwards, connect both ends of this tube with the female luer locks on the ends of tubes 3.2 and 3.3.

- Follow steps 1.3.2-1.3.4.

- Observe the droplet formation via a stereo microscope.

4. Analysis of the Particles

- Put the particles on a hot-stage under an optical microscope connected to a computer with imaging software. To analyze the particles' actuation, take pictures at temperatures above and below their phase transition temperature, and measure their D.

NOTE: A drop of silicon oil prevents the particles from sticking on the object slide. - To estimate the particles' clearing temperature, determine the temperature at which the particles lose their birefringence under a polarized optical microscope (POM).

Representative Results

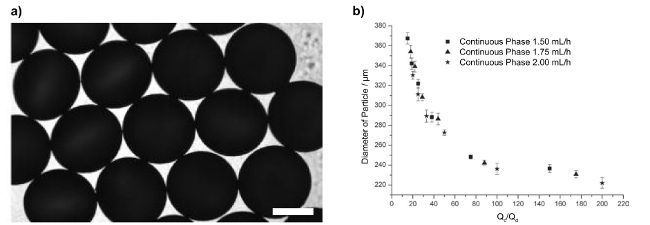

In this protocol, we present the synthesis of LCE particles with different morphologies via a microfluidic approach. The microfluidic setups for the fabrication of single, core-shell, and Janus particles are shown in Figure 129,38,41. One advantage of the continuous flow production is the very good control over both size and shape of the particles. Figure 2a illustrates the advantage of the single droplet setup: a very narrow size distribution with all particles having the same shape41. Hereby, the size of the spheres can easily be adjusted by changing the ratio of flow rates of the different phases. Following the protocol, particle diameters between 200 and 400 µm can be produced in a well-controlled manner by choosing the flow rate ratios, as shown in Figure 2b1. The best results are obtained for flow rates of the continuous phase (Qc) between 1.5 and 2.0 mL/h and for flow rate ratios of QC/Qd (Qd = the flow rate of the monomer phase) between 20 and 200. For the flow rates of Qc = 1.75 mL/h and Qd = 0.35 mL/h, well-actuating particles with a diameter of 270 µm are observed, for example. If higher ratios Qc/Qd are selected, the droplet formation is less controlled and the particles' size distribution becomes much broader. For lower ratios, the particles are not spherical anymore. In addition to the flow rate adjustments, the distance of the UV-lamp to the polymerization tube as well as the position between the left and the right end of the precision hot plate can change the actuation properties of LCE particles, which happens, for example, if the polymerization kinetics change by reason of choosing monomer mixture compositions or applied polymerization temperatures different from the values described here.

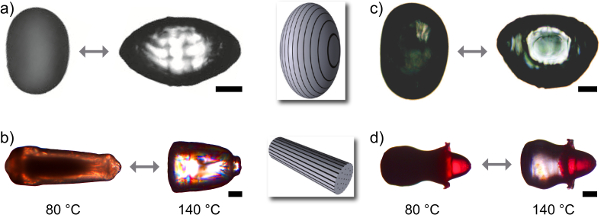

Figure 3a shows an actuating particle which elongates up to 70% when it is heated above its phase transition temperature, which proves that the requirement of inducing an orientation of the liquid crystalline director before polymerization is fulfilled. This alignment of the mesogens results from the shear between the highly viscous continuous phase and the monomer droplets' surface. If silicon oils of lower viscosity are used, the particle's actuation is reduced.

Furthermore, the microfluidic device allows the control over different kinds of actuation patterns, such as elongation or contraction during the phase transition, by varying the shear rate acting on the droplets during the polymerization. This can be processed easily at constant flow rates of the continuous phase by using different inner diameters of the polymerization tube. Figure 3a shows a prolate shaped particle, which elongates along its rotational axis and was synthesized at lower shear rates in a broader polymerization tube (ID: 0.75 mm). The liquid crystalline molecules (mesogens) are aligned along a concentric director field in this case. On the other side, rod-like particles (as illustrated in Figure 3b) feature a contraction during the phase transition and a bipolar alignment of the mesogens' director field. This particle was produced at higher shear rates in a thinner polymerization tube (ID: 0.5 mm).

The protocol describes another advantage of the microfluidic process. Besides single particles, samples of more complex morphologies can also be synthesized. Figure 3c shows an actuating core-shell particle and Figure 3d a Janus particle which both were produced following part 2 and 3 of the protocol29,30.

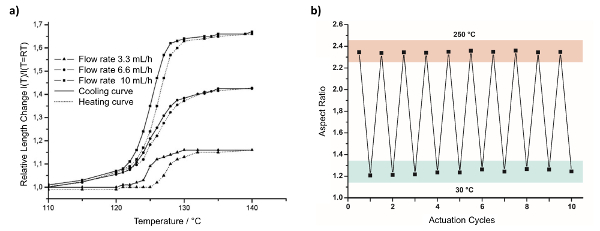

If all steps of the protocol are done correctly, particles having the properties shown in Figure 4 should be obtained3,41. In Figure 4a, the heating and cooling curves are plotted for single particles synthesized at different flow rates. By heating the particle from room temperature, the liquid crystalline order is - at first - reduced for a little bit, resulting in a small deformation of the particle. However, close to the phase transition temperature, all orientation is suddenly lost and the particle shows a strong elongation just by heating it up for a few degrees. By cooling the particle down, a hysteresis can be observed, and the original shape is obtained. This process is reversible over many actuation cycles, as shown in Figure 4b.

Figure 1: Microfluidic setups. (a) The general setup includes three syringes, which contain the hydraulic silicone oil (1), the aqueous monomer mixture (3), and the continuous phase silicone oil (4). The liquid crystalline monomer mixture (2) is placed in the water bath (5) at 363 K, which heats up the liquid crystal to the isotropic state. The droplet's polymerization is initiated on the hot plate (6) at 338 K in the nematic state of the liquid crystal by UV-irradiation (7). (The single particle setup equals the general setup, but lacks the second capillary, syringe (3) and the second T-junction). (b) This panel shows a setup containing two capillaries side by side to each other, which allows the Janus droplet formation. (c) The core-shell setup is composed of a capillary which is telescoped into a broader second capillary. Please click here to view a larger version of this figure.

Figure 2: Representative particles obtained in the microfluidic single particle setup. (a) This panel shows a microscopy image of monodisperse LCE particles prepared in the microfluidic single particle setup. Scale bar = 200 µm. (b) This panel shows the dependence of the particles' diameter with respect to the ratio of the oil's flow rate (Qc) to the monomer mixture's flow rate (Qd). The size of the obtained particles is only dependent on the velocity ratio of both phases and not on their absolute values. (This figure has been modified from Ohm, Fleischmann, Kraus,Serra, and Zentel1 and Ohm, Serra, and Zentel41.) Please click here to view a larger version of this figure.

Figure 3: Optical microscopy images of four different particle morphologies in the nematic state (at 353 K) and after phase transition in the isotropic state (at 413 K). These panels show (a) the elongation of an oblate-shaped LCE particle (concentric director field), (b) the contraction of a rod-like shaped LCE-particle (bipolar director field), (c) the elongation of an oblate-shaped core-shell particle, and (d) the contraction of a prolate-shaped Janus particle (left part: LCE, right part: acrylamide hydrogel). Scale bars = 100 µm. Please click here to view a larger version of this figure.

Figure 4: Actuation properties of representative single particles. (a) This panel shows the heating and cooling curves of LCE particles being prepared in the single particle microfluidic setup at different flow rates for the continuous phase. The particles prepared at the highest flow rate show the strongest actuation (about 70%) and both curves form a hysteresis, respectively. (b) This is a plot of 10 actuation cycles of LCE particles showing no decrease of their actuation over the cycle number. This proves that the particles are crosslinked, and the actuation is completely reversible. Note: This graph was drawn for a particle made from a main-chain LCE system but looks the same for the LCE system used in this article. (This figure has been modified from Ohm, Serra, and Zentel41.) Please click here to view a larger version of this figure.

Discussion

We have described the fabrication of particles with different morphologies via a microfluidic approach to produce LCE microactuators. For this purpose, capillary-based microfluidic setups were built which allow droplet formation followed by photopolymerization at defined temperatures.

Here, one critical aspect of a successful synthesis is the correct mounting of the setup. All connections between the single parts must be fixed properly to prevent any leaking of the liquids, and the device must be clean before every synthesis to prevent clogging. It is also crucial that the experiment is performed under UV-free conditions, since, otherwise, premature polymerization of the monomer mixture and thus again clogging of the setup would be the result.

To this day, the microfluidic approach described here is the only method able to produce actuating LCE particles. Hereby, the microfluidic process fulfills two requirements at the same time. Besides the fabrication of a multitude of equally sized micro-objects, an orientation of the liquid crystalline director is induced in these particles. In addition, it is a quite simple procedure since a large number of actuators can be synthesized in a single step. Applying other methods, the orientation of the mesogens usually requires an additional step like the stretching of the sample or the application of photo-alignment layers. Additionally, these processes are manual, which means the production of many actuators is very time-consuming. Furthermore, the LCE morphology is-in most cases-limited to polymer films. Drawbacks of the microfluidic approach are the limitation of the particle size (as the diameter is restricted to values between 200 and 400 µm), the vulnerability to clogging the capillary, and the necessity of UV-free conditions during the particle preparation in the setup.

On-chip systems are often used for microfluidic particle fabrications since they can easily be produced and are made of just one piece. These setups, however, not only lack the necessary adjustability of different temperatures during the flow but also are not flexible enough to easily exchange clogged or broken parts of the microreactor. Hence, the capillary-based setups we use are more suitable for the synthesis of LCE actuators, as they fulfill the crucial requirements.

Aside from our presented results of actuating Janus-particles and core-shell micropumps, more complex actuating particles featuring new properties could be synthesized in the future and open new possibilities for soft actuator applications. The further modification of Janus particles to multi-responsive particles is already in progress. Therefore, we are aiming for the introduction of a second temperature responsive polymer besides the actuating LCE. Further possibilities for new particle designs can also arise from the use of liquid crystalline azo-monomers, which results in the light-driven actuation of LCE-particles17,18. In that case, we can think of Janus particles containing both a temperature-responsive as well as a photo-actuating part. The synthesis of light-driven core-shell particles or pipe-like structures offers another possible particle design, which would lead to photo-responsive micropumps. The modification of the principle microfluidic procedures which we presented above should allow a variety of new actuators.

Acknowledgements

The authors thank the German Science Foundation for funding this work (Ze 230/24-1).

Materials

| Name | Company | Catalog Number | Comments |

| NanoTight fitting for 1/16'' OD tubings | Postnova_IDEX | F-333N | |

| NanoTight ferrule for 1/16'' OD tubings | Postnova_IDEX | F-142N | |

| PEEK Tee for 1/16” OD Tubing | Postnova_IDEX | P-728 | T-junction |

| Female Fitting for 1/16” OD Tubing | Postnova_IDEX | P-835 | female luer-lock |

| Male Fitting for 1/8” OD Tubing | Postnova_IDEX | P-831 | male luer-lock |

| Female Luer Connectors for use with 3/32” ID tubings | Postnova_IDEX | P-858 | for the syrringe's tip |

| NanoTight FEP tubing sleeve ID: 395 µm OD: 1/16'' | Postnova_IDEX | F-185 | |

| Fused Silica Capillary Tubing ID: 100 µm OD: 165 µm | Postnova | Z-FSS-100165 | glass capillary |

| Fused Silica Capillary Tubing ID: 280 µm OD: 360 µm | Postnova | Z-FSS-280360 | glass capillary |

| ‘‘Pump 33’’ DDS | Harvard Apparatus | 70-3333 | syringe pump |

| Precision hot plate | Harry Gestigkeit GmbH | PZ 28-2 | |

| Stereomicroscope stemi 2000-C | Carl Zeiss Microscopy GmbH | 455106-9010-000 | |

| Mercury vapor lamp Oriel LSH302 | LOT | Intensity: 500 W | |

| Teflon Kapillare, 1/16'' x 0,75mm | WICOM | WIC 33104 | teflon tube |

| Teflon Kapillare, 1/16'' x 0,50mm | WICOM | WIC 33102 | teflon tube |

| Teflon Kapillare, 1/16'' x 0,17mm | WICOM | WIC 33101 | teflon tube |

| Silicion oil 1.000 cSt | Sigma Aldrich | 378399 | |

| Silicion oil 100 cSt | Sigma Aldrich | 378364 | |

| 1,6-hexanediol dimethacrylate | Sigma Aldrich | 246816 | Crosslinker |

| Lucirin TPO | Sigma Aldrich | 415952 | Initiator |

| Polarized optical microscope BX51 | Olympus | For analysis | |

| Hotstage TMS 94 | Linkam | For analysis | |

| Imaging software Cell^D | Olympus | For analysis |

References

- Ohm, C., Fleischmann, E. K., Kraus, I., Serra, C., Zentel, R. Control of the properties of micrometer-sized actuators from liquid crystalline elastomers prepared in a microfluidic setup. Advanced Functional Materials. 20 (24), 4314-4322 (2010).

- Urbanski, M., et al. Liquid crystals in micron-scale droplets, shells and fibers. Journal of Physics: Condensed Matter. 29 (13), 133003 (2017).

- Hessberger, T., Braun, L., Zentel, R. Microfluidic synthesis of actuating microparticles from a thiol-ene based main-chain liquid crystalline elastomer. Polymers (Basel). 8 (12), (2016).

- Palagi, S., et al. Structured light enables biomimetic swimming and versatile locomotion of photoresponsive soft microrobots. Nature Materials. , 1-8 (2016).

- Ohm, C., Brehmer, M., Zentel, R. Liquid crystalline elastomers as actuators and sensors. Advanced Materials. 22, 3366-3387 (2010).

- White, T. J., Broer, D. J. Programmable and adaptive mechanics with liquid crystal polymer networks and elastomers. Nature Materials. 14 (11), 1087-1098 (2015).

- Liu, D., Broer, D. J. Liquid crystal polymer networks: preparation, properties, and applications of films with patterned molecular alignment. Langmuir. 30 (45), 13499-13509 (2014).

- Ube, T., Ikeda, T. Photomobile polymer materials with crosslinked liquid-crystalline structures: molecular design, fabrication, and functions. Angewandte Chemie International Edition in English. 53 (39), 10290-10299 (2014).

- Zentel, R., Schmidt, G. F., Meyer, J., Benalia, M. X-ray investigations of linear and cross-linked liquid-crystalline main chain and combined polymers. Liquid Crystals. 2 (5), 651-664 (1987).

- Kapitza, H., Zentel, R. Combined liquid-crystalline polymers with chiral phases, 2 Lateral substituents. Macromolecular Chemistry and Physics. 189, 1793 (1988).

- Li, M. -. H., Keller, P. Artificial muscles based on liquid crystal elastomers. Philosophical Transactions of the Royal Society A. Mathematical, Physical, and Engineering Sciences. 364 (1847), 2763-2777 (2006).

- Wiesemann, A., Zentel, R., Pakula, T. Redox-active liquid-crystalline ionomers: 1. Synthesis and rheology. Polymer (Guildford). 33 (24), 5315-5320 (1992).

- Pei, Z., Yang, Y., Chen, Q., Terentjev, E. M., Wei, Y., Ji, Y. Mouldable liquid-crystalline elastomer actuators with exchangeable covalent bonds. Nature Materials. 13 (1), 36-41 (2014).

- Wang, Z., Tian, H., He, Q., Cai, S. Reprogrammable, reprocessible, and self-healable liquid crystal elastomer with exchangeable disulfide bonds. ACS Applied Materials & Interfaces. 9 (38), 33119-33128 (2017).

- Chambers, M., Finkelmann, H., Remškar, M., Sánchez-Ferrer, A., Zalar, B., Žumer, S. Liquid crystal elastomer-nanoparticle systems for actuation. Journal of Materials Chemistry. 19 (11), 1524-1531 (2009).

- Braun, L. B., Linder, T., Hessberger, T., Zentel, R. Influence of a crosslinker containing an azo group on the actuation properties of a photoactuating LCE system. Polymers.(Basel). 8 (12), 435 (2016).

- Braun, L. B., Hessberger, T., Zentel, R. Microfluidic synthesis of micrometer-sized photoresponsive actuators based on liquid crystalline elastomers. Journal of Materials Chemistry C. 4, 8670-8678 (2016).

- Ikeda, T., Mamiya, J. I., Yu, Y. Photomechanics of liquid-crystalline elastomers and other polymers. Angewandte Chemie International Edition. 46, 506-528 (2007).

- Zeng, H., Wani, O. M., Wasylczyk, P., Kaczmarek, R., Priimagi, A. Self-regulating iris based on light-actuated liquid crystal elastomer. Advanced Materials. 29 (30), 1-7 (2017).

- Küpfer, J., Finkelrnann, H. Nematic liquid single crystal elastomers. Macromolecular Rapid Communications. 12, 717-726 (1991).

- Bergmann, G. H. F., Finkelmann, H., Percec, V., Zhao, M. Y. Liquid-crystalline main-chain elastomers. Macromolecular Rapid Communications. 18 (5), 353-360 (1997).

- Li, M. H., Keller, P., Yang, J., Albouy, P. A. An artificial muscle with lamellar structure based on a nematic triblock copolymer. Advanced Materials. 16 (21), 1922-1925 (2004).

- Brehmer, M., Zentel, R., Wagenblast, G., Siemensmeyer, K. Ferroelectric liquid-crystalline elastomers. Macromolecular Chemistry and Physics. 195 (6), 1891-1904 (1994).

- Beyer, P., Terentjev, E. M., Zentel, R. Monodomain liquid crystal main chain elastomers by photocrosslinking. Macromolecular Rapid Communications. 28 (14), 1485-1490 (2007).

- Ditter, D., et al. MEMS analogous micro-patterning of thermotropic nematic liquid crystalline elastomer films using a fluorinated photoresist and a hard mask process. Journal of Materials Chemistry C. 5, 12635-12644 (2017).

- Lopez-Valdeolivas, M., Liu, D., Broer, D. J., Sánchez-Somolinos, C. 4D printed actuators with soft-robotic functions. Macromolecular Rapid Communications. 1700710, 3-9 (2017).

- Ohm, C., Kapernaum, N., Nonnenmacher, D., Giesselmann, F., Serra, C., Zentel, R. Microfluidic synthesis of highly shape-anisotropic particles from liquid crystalline elastomers with defined director field configurations. Journal of the American Chemical Society. 133 (14), 5305-5311 (2011).

- Ohm, C., et al. Preparation of actuating fibres of oriented main-chain liquid crystalline elastomers by a wetspinning process. Soft Matter. 7, 3730 (2011).

- Hessberger, T., et al. Co-flow microfluidic synthesis of liquid crystalline actuating Janus particles. Journal of Materials Chemistry C. 4, 8778-8786 (2016).

- Fleischmann, E. -. K., Liang, H. -. L., Kapernaum, N., Giesselmann, F., Lagerwall, J., Zentel, R. One-piece micropumps from liquid crystalline core-shell particles. Nature Communications. 3, 1178 (2012).

- Khan, I. U., et al. Microfluidic conceived drug loaded Janus particles in side-by-side capillaries device. International Journal of Pharmaceutics. 473 (1-2), 239-249 (2014).

- Vennes, M., Martin, S., Gisler, T., Zentel, R. Anisotropic particles from LC polymers for optical manipulation. Macromolecules. 39 (24), 8326-8333 (2006).

- Serra, C. a., et al. Engineering polymer microparticles by droplet microfluidics. Journal of Flow Chemistry. 3 (3), 66-75 (2013).

- Seo, M., Nie, Z., Xu, S., Lewis, P. C., Kumacheva, E. Microfluidics: from dynamic lattices to periodic arrays of polymer disks. Langmuir. 21 (11), 4773-4775 (2005).

- Kim, K., Pack, D. Microspheres for drug delivery. BioMEMS and Biomedical Nanotechnology. 2, 19-50 (2006).

- Kim, J. -. W., et al. Titanium dioxide/poly(methyl methacrylate) composite microspheres prepared by in situ suspension polymerization and their ability to protect against UV rays. Colloid and Polymer Science. 280 (6), 584-588 (2002).

- Serra, C., Berton, N., Bouquey, M., Prat, L., Hadziioannou, G. A predictive approach of the influence of the operating parameters on the size of polymer particles synthesized in a simplified microfluidic system. Langmuir. 23 (14), 7745-7750 (2007).

- Chang, Z., Serra, C. a., Bouquey, M., Prat, L., Hadziioannou, G. Co-axial capillaries microfluidic device for synthesizing size- and morphology-controlled polymer core-polymer shell particles. Lab on a Chip. 9, 3007-3011 (2009).

- Braun, L. B., Hessberger, T., Serra, C. A., Zentel, R. UV-free microfluidic particle fabrication at low temperature using ARGET-ATRP as the initiator system. Macromolecular Reaction Engineering. 10 (6), 611-617 (2016).

- Thomsen, D. L., et al. Liquid crystal elastomers with mechanical properties of a muscle. Macromolecules. 34, 5868-5875 (2001).

- Ohm, C., Serra, C., Zentel, R. A continuous flow synthesis of micrometer-sized actuators from liquid crystalline elastomers. Advanced Materials. 21 (47), 4859-4862 (2009).

This article has been published

Video Coming Soon

ABOUT JoVE

Copyright © 2024 MyJoVE Corporation. All rights reserved