A subscription to JoVE is required to view this content. Sign in or start your free trial.

Determination of Aggregate Surface Morphology at the Interfacial Transition Zone (ITZ)

In This Article

Summary

Hereby, we proposed a protocol to illustrate the effect of aggregate surface morphology on the ITZ microstructure. The SEM-BSE image were quantitatively analyzed to obtain ITZ's porosity gradient via digital image processing and a K-means clustering algorithm was further employed to establish a relationship between porosity gradient and surface roughness.

Abstract

Here, we present a comprehensive method to illustrate the uneven distribution of the interfacial transition zone (ITZ) around the aggregate and the effect of aggregate surface morphology on the formation of ITZ. First, a model concrete sample is prepared with a spherical ceramic particle in roughly the central part of the cement matrix, acting as a coarse aggregate used in common concrete/mortar. After curing until the designed age, the sample is scanned by X-ray computed tomography to determine the relative location of the ceramic particle inside the cement matrix. Three locations of the ITZ are chosen: above the aggregate, on the side of the aggregate, and below the aggregate. After a series of treatments, the samples are scanned with a SEM-BSE detector. The resultant images were further processed using a digital image processing method (DIP) to obtain quantitative characteristics of the ITZ. The surface morphology is characterized at the pixel level based on the digital image. Thereafter, K-means clustering method is used to illustrate the effect of surface roughness on ITZ formation.

Introduction

At the mesoscopic scale, cement-based materials can be regarded as a three-phase composite comprised of the cement paste, the aggregate, and the interfacial transition zone (ITZ) between them1,2. The ITZ is often treated as a weak link since its increased porosity could act as channels for the ingress of aggressive species3,4 or provide easier pathways for crack growth5,6,7,8,9,10,11. Subsequently, it is of great interest to precisely characterize the properties of the ITZ to evaluate and predict the macro performance of the cement-based materials.

To investigate the ITZ, there has been excessive research on its microstructural features, forming mechanisms, and influencing factors12,13,14 using both experimental and numerical methods. Various techniques have been coupled for ITZ characterization including: mechanical tests, transport tests, mercury intrusion porosimetry (MIP) tests15,16 and nano-indentation17. It is widely accepted that the ITZ is mainly caused by the wall effect, as well as water film, micro-bleeding, one side growth, and gel syneresis18.

With the development of digital image processing method (DIP) in the last two decades19, the morphological characteristics of the ITZ (e.g., volume fraction, thickness, and porosity gradient) can be quantitatively determined. Based on examination of the plane sections using scanning electron microscopy (SEM) with a backscattered electron detector (BSE), the three dimensional (3D) features of ITZ can be derived from the 2D results via stereology theory20. Like the SEM-BSE technique, the nano-indentation technique is also based on the examination of polished surfaces, but it more focuses on the elastic modulus of the existing phases21. However, in both SEM-BSE analysis and the nano-indentation test, the ITZ thickness may be overestimated as the examined cross section rarely goes through the normal direction from an aggregate surface22. However, coupling this with fluorescent 3D confocal microscopy, the overestimation of ITZ could be eliminated and a real ITZ porosity and anhydrous cement content could be obtained23.

Previous studies of influencing factors mainly focused on the cement paste, ignoring the role of the aggregate and its surface texture24,25,26. Since the shape and morphological properties of the aggregate have been extensively described based on quantitative analysis of digital slices obtained from SEM or X-ray computed tomography (X-CT)27,28. However, no research focusing on the effect of the aggregate surface texture on the formation of ITZ region has been performed.

Hereby, we present a protocol to investigate the effect of aggregate surface morphology on the ITZ microstructure formation based on quantitative analysis of SEM-BSE images and a K-means clustering algorithm. A model concrete sample was prepared with spherical ceramic particle acting as the coarse aggregate. X-CT was used to roughly determine the relative location of the particle in the opaque cement matrix before halving the sample. After processing to obtained SEM-BSE images, the uneven distribution of ITZ around single aggregate was observed. Also, an index surface roughness (SR) describing the aggregate surface texture at the pixel level was defined. The K-means clustering algorithm, originally used in the area of signal processing and now widely used for image clustering29,30, was introduced to established a relationship between surface roughness (SR) and porosity gradient (SL).

Protocol

1. Preparation of the model concrete with a single ceramic particle

- Mold preparation

- Use a brush to clean the mold (25 mm x 25 mm x 25 mm) and ensure that the inner surfaces of the mold are impurity-free.

- Use another brush to uniformly apply diesel oil on the inner surfaces of the mold for easier mold-release.

NOTE: Here, we did not use the common mold for mortar or concrete preparation. As the ceramic particle is around 15 mm in diameter, a cubic plastic mold around 30 mm in length is used for sample preparation. Ensure that the size of plastic mold is larger than the ceramic particle.

- Molding the model concrete

- Weigh 1,000 g of cement and 350 g of water with an electronic balance (the designed water to cement mass ratio is 0.35).

- Wipe the 5 L mixing pot with a wet towel to moisten it. Add 350 g of water and 1,000 g of cement into the mixing pot sequentially. Place the mixing pot on the mixer and raise it to the stirring position.

- Mix at 65 rpm for 90 s, and let the mixture stand still for 30 s. During this period, scrape off the paste on the inner wall of the pot. Then, mix at 130 rpm for another 60 s.

- Remove the pot from the mixer and put the ceramic particle into the paste, manually mixing it with the cement paste thoroughly.

- Half fill the mold with well mixed fresh cement paste.

- Place the ceramic particle on the top surface of the cement paste and fill the rest of the mold with cement paste. Wipe off excess cement paste with a scraper knife and vibrate the mold on a vibrating table for 1 min at 50 ± 3 Hz.

- Seal the mold surface with cling film to prevent moisture evaporation.

- Curing

- Cure the specimen in a curing room for 24 h (20 ± 1 °C and 95% ± 5% relative humidity).

- Remove the specimen from the mold and further cure the specimen for 28 d under the same environmental conditions.

2. Scanning electron microscopy preparation

- Determination of the ceramic particle inside the matrix

- Scan the specimen with X-ray computed tomography to obtain a stack of slices31.

- Roughly choose the slice where the ceramic particle appears to be largest. Fit the boundary of the ceramic particle with a circle and determine the center of the circle as the geometrical center of the ceramic particle. Due to the gray value difference between cement matrix and ceramic particle, a rough boundary of the particle appears on each CT slice (Figure 1).

- Cutting

- Cut the cubic specimen into two parts through the geometrical center of the ceramic particle in a cutting machine. Figure 132 is a schematic map showing the cutting direction.

NOTE: The ceramic particle was split into two equal parts, while the specimen was not cut into two exactly equal halves. If the ceramic particle is in the exact center of the cubic specimen, the specimen will be split into two equal halves. However, in a real situation, the ceramic particle typically is not in the exact center of the specimen.

- Cut the cubic specimen into two parts through the geometrical center of the ceramic particle in a cutting machine. Figure 132 is a schematic map showing the cutting direction.

- Hydration termination

- Immerse the two parts into isopropyl alcohol (≥99.5%) for 3 days at room temperature to remove the unbounded water and terminate the internal hydration process. Replace the isopropyl alcohol solution every 24 h.

- Place the two parts in the vacuum drying even for 7 days to dry the sample at temperature of 40 °C.

- Solidifying the microstructure

- Use a finger to smear the inner surface of two cylindrical plastic molds (31 mm in diameter and 25 mm in height) with demolding paste. The molds are all bottom removable.

- Place each piece of the sample into each mold with the surface to be examined facing downward.

- In a paper cup, weigh 50 g of low viscosity epoxy resin and add another 5 g of hardener. Manually stir the mixture with a wooden stick for 2 min.

- Put the mold into the cold mounting machine along with the paper cup with the mixture.

- Start the vacuum on the cold mounting machine and pour the epoxy resin into the mold until it merges with each sample.

- Keep the mold in the cold mounting machine for 24 h until the epoxy resin hardens.

- Remove the bottom of each mold and squeeze out the sample. Store the sample in a vacuum drying oven.

- Grinding and polishing

- Grind the sample with SiC paper and alcohol as a lubricant on an automatic polishing machine at the speed of 300 rpm in the following sequence for 3 min each: 180 grit, 300 grit, 600 grit, and 1200 grit.

- Attach the flannelette to the turntable of the automated polishing machine.

- Polish the sample on the flannelette with diamond paste of 3 μm, 1 μm, and 0.25 μm for 15 min at the speed of 150 rpm, each.

- Remove the debris in an ultrasonic cleaner with alcohol as the cleaning solvent after each grinding and polishing step.

- Store each sample in a plastic box of similar size to the sample with each surface to be examined facing up to avoid cause any scratches on the testing surface.

- Keep the boxes containing the samples in a vacuum dry oven32.

NOTE: The grinding and polishing process could be completed on an automated polishing machine and at most 6 samples could be polished at the same time. The grinding and polishing time should be carefully chosen to obtain an extremely smooth surface for the SEM without creating height differences between the cement paste and the aggregate. A typical sample is shown in Figure 232.

3. Backscattered image acquisition and processing

- Acquisition

- Spray a thin layer of gold foil on the surface to be examined in a vacuum environment with an automatic sputter coater.

- Place a strip of adhesive tape on the side of the sample to connect the testing surface and opposite surface and place the sample on the test bench with the testing surface facing upward.

- Move the sample to focus the lens on region 1 as labelled in Figure 232.

- Vacuum the SEM and change to backscattered electron mode. Set the magnification at 1,000x and carefully adjust the brightness and contrast before capturing images.

- Move the lens along the direction of the aggregate boundary to another position of the aggregate and take another image. Repeat this moving and imaging process at least 15 times so that enough images can be obtained for statistical analysis.

- Move the lens to region 2 and region 3 and repeat the imaging process.

NOTE: Each image should include three phases: the matrix, the aggregate, and the ITZ. Since ITZ is a narrow section existing between another two phases and hard to be distinguished, each image should include both the cement matrix and the aggregate.

- Processing

- Pre-treat the image with a best fit and 3 x 3 median filter three times to reduce the noise and enhance the boundary of different phases on ImageJ.

- Manually capture the boundary of the ceramic particle and cut off this part from the original image using ImageJ.

- Roughly determine the upper threshold value of pore phases by setting different threshold values and segmenting the image to compare with the original one.

- Obtain the gray-scale distribution of the remaining part of the image. Choose two approximatively linear parts of the distribution curve just around the roughly determined upper threshold value of pore phases. Fit these two parts with linear curve and the intersection point will be set as the exact upper threshold value of this image (see Figure 3c32).

- Use this value to do the segmentation and compare the binary image with original gray-scale image for final threshold value determination.

- Convert the gray-scale image to a binary image with white (gray value = 255) representing pore phase and black (gray value = 0) representing solid phases.

NOTE: The exact determination of threshold value is called the overflow point method33 since the brightness and contrast are kept the same for different images obtained from same sample. Once the upper threshold value is precisely determined, this value could be applied to other images obtained from the same sample.

4. Data processing

- ITZ thickness determination

- Delineate twenty 20 successive strips that are 5 μm in width (use the included strip_delineation.m file), along the captured boundary in the direction of starting from aggregate surface and going into the bulk paste (see Figure 3d32).

- Count the number of pixels with a gray value lower than the threshold in each strip and normalize the values by the number of total voxels contained in each strip. Each normalized value will be viewed as the porosity of each strip.

- Repeat the counting and normalization process for all the images. Average the porosity profiles of the same strip number from different images.

- Draw the porosity distribution graph as a function of distance away from aggregate surface. Determine the inflection point on the curve where porosity become stable as the thickness of the ITZ.

NOTE: The number of strips and width of each strip could vary; make sure that the total width of the delineated strips includes all of the ITZ. According to previous research, the ITZ thickness ranges between 20-50 μm13. Even in some model concrete samples with an enlarged ITZ, this value does not exceed 70 μm34,35.

- Aggregate surface roughness (SR) characterization

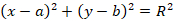

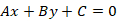

- Save the manually captured boundary as a curve. Fit the irregular boundary with both straight line and circle arc according to the Eq. (1) and Eq. (2) based on least square algorithm.

(1)

(1)

(2)

(2)

with (a,b) being the center of the fitting circle. - Define the deviations between original irregular boundary and fitting smooth curve as the surface roughness (SR).

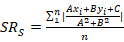

- For straight line, calculate the SRs by averaging the absolute value of the perpendicular distance of the center of each pixel on the boundary to the fitting line:

(3)

(3)

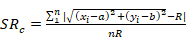

with n being the number of pixels included in each boundary and (xi, yi) being the coordinates of the ith pixel on the boundary. - For a circle arc, define SRC as:

(4)

(4) - Compare the value of SRS and SRC for each boundary and determine the minimum value as the final surface roughness for this curve (use the included surface_roughness_calculation.m file).

NOTE: The surface roughness of boundary should be defined against a smooth baseline curve. Both straight line and circle line were used for the following reason. Though the boundary of the spherical ceramic particle appears like a circle in 2D, some local regions appear to be more appeal to a straight line.

- Save the manually captured boundary as a curve. Fit the irregular boundary with both straight line and circle arc according to the Eq. (1) and Eq. (2) based on least square algorithm.

- K-means clustering

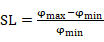

- Define a slope index (SL) to describe the porosity gradient within the interfacial transition zone according to the Eq. (5).

(5)

(5)

where φmax is the value of the porosity in the first strip (0 μm to 5 μm) and φmin is the value of the porosity in the sixth strip (25 μm to 30 μm). - Combine the SR and SL of each boundary to be an observation. And for total n boundaries and ITZs, there exist n observations to be saved as a cluster {(SR1,SL1),(SR2,SL2), ... , (SRn,SLn)}.

- Apply a K-means clustering36,37 algorithm (use the included k_means_clustering.m file) to all the observations and subdivide them into 2 clusters: rough and smooth aggregate surface group, respectively.

- Average the porosity distributions of ITZ in rough and smooth cluster, respectively. Compare the average porosity distribution between two clusters.

NOTE: Herein, K-means clustering is a method of vector quantization, which is originally used in signal processing and currently widely applied to cluster analysis in data mining. The aim of the method is to subdivide the observations into 2 or more subgroups.

- Define a slope index (SL) to describe the porosity gradient within the interfacial transition zone according to the Eq. (5).

Results

The porosity distribution of ITZ regions above the aggregate, on the side of the aggregate, and below the aggregate are compared and shown in Figure 432. The porosity of the ITZ above the upper surface appears to be smaller than that on the side or above the aggregate, indicating a denser ITZ microstructure, while the ITZ below the aggregate is always the most porous due to micro-bleeding. Figure 432 shows that eve...

Discussion

The X-CT technique was applied to roughly determine the geometrical center of the ceramic particle to ensure that the analyzed surface is through the equator of the particle. Thus, the overestimation of the ITZ thickness caused by the 2D artifacts could be avoided38. Herein, the accuracy of obtained results is highly dependent on the flatness of the examined surfaces. Generally, a longer grinding and polishing time contributes to an adequately smooth surface for testing. However, due to the varyin...

Disclosures

We hereby confirm that this manuscript is our original work and all the authors listed have approved the manuscript and have no interest conflicts on this paper.

Acknowledgements

The authors gratefully acknowledge the financial support from the National Key R&D Program of China (2017YFB0309904), National Natural Science Foundation of China (Grant Nos. 51508090 and 51808188), 973 Program (2015CB655100), State Key Laboratory of High-Performance Civil Engineering Materials (2016CEM005). Also, greatly appreciate Jiangsu Research Institute of Building Science Co., Ltd and the State Key Laboratory of High-Performance Civil Engineering Materials for funding the research project.

Materials

| Name | Company | Catalog Number | Comments |

| Auto Sputter Coater | Cressington | 108 Auto/SE | |

| Automatic polishing machine | Buehler | Phoenix4000 | |

| Brush | Huoniu | 3# | |

| Cement | China United Cement Corporation | P.I. 42.5 | |

| Cement paste mixer | Wuxi Construction and Engineering | NJ160 | |

| Ceramic particle | Haoqiang | Φ15 mm | |

| Cling film | Miaojie | 65300 | |

| Cold mounting machine | Buehler | Cast N' Vac 1000 | |

| Conductive tape | Nissin Corporation | 7311 | |

| Cup | Buehler | 20-8177-100 | |

| Cutting machine | Buehler | Isomet 4000 | |

| Cylindrical plastic mold | Buehler | 20-8151-100 | |

| Diamond paste | Buehler | 00060210, 00060190, 00060170 | |

| Diesel oil | China Petroleum | 0# | |

| Electronic balance | Setra | BL-4100F | |

| Epoxy resin | Buehler | 20-3453-128 | |

| Hardener | Buehler | 20-3453-032 | |

| High precision cutting machine | Buehler | 2215 | |

| Image J | National Institutes of Health | 1.52o | |

| Isopropyl alcohol | Sinopharm | M0130-241 | |

| Matlab | MathWorks | R2014a | |

| Paper | Deli | A4 | |

| Plastic box | Beichen | 3630 | |

| Plastic mold | Youke | a=b=c=25mm | |

| Polished flannelette | Buehler | 242150, 00242050, 00242100 | |

| Release agent | Buehler | 20-8186-30 | |

| Scanning Electron Microscopy | FEI | Quanta 250 | |

| Scrape knife | Jinzheng Building Materials | CD-3 | |

| SiC paper | Buehler | P180, P320, P1200 | |

| Ultrasonic cleaner | Zhixin | DLJ | |

| Vacuum box | Heheng | DZF-6020 | |

| Vacuum drying oven | ZK | ZK30 | |

| Vibrating table | Jianyi | GZ-75 | |

| Wooden stick | Buehler | 20-8175 | |

| X-ray Computed Tomography | YXLON | Y.CT PRECISION S |

References

- Scrivener, K. L., Crumbie, A. K., Laugesen, P. The Interfacial Transition Zone (ITZ) Between Cement Paste and Aggregate in Concrete. Interface Science. 12 (4), 411-421 (2004).

- Scrivener, K. L. Backscattered electron imaging of cementitious microstructures: understanding and quantification. Cement and Concrete Composites. 26 (8), 935-945 (2004).

- Houst, Y. F., Sadouki, H., Wittmann, F. H. Influence of aggregate concentration on the diffusion of CO2 and O2. Concrete. , 279-288 (1993).

- Halamickova, P., Detwiler, R. J., Bentz, D. P., Garboczi, E. J. Water permeability and chloride ion diffusion in portland cement mortars: Relationship to sand content and critical pore diameter. Cement & Concrete Research. 25 (4), 790-802 (1995).

- Yang, Z., et al. In-situ X-ray computed tomography characterisation of 3D fracture evolution and image-based numerical homogenisation of concrete. Cement and Concrete Composites. 75, 74-83 (2017).

- Skarżyński, &. #. 3. 2. 1. ;., Nitka, M., Tejchman, J. Modelling of concrete fracture at aggregate level using FEM and DEM based on X-ray µCT images of internal structure. Engineering Fracture Mechanics. 147, 13-35 (2015).

- Königsberger, M., Pichler, B., Hellmich, C. Micromechanics of ITZ-Aggregate Interaaction in Concrete Part II: Stength Upscaling. Journal of the American Ceramic Society. 97 (2), 543-551 (2014).

- Shahbazi, S., Rasoolan, I. Meso-scale finite element modeling of non-homogeneous three-phase concrete. Case Studies in Construction Materials. 6, 29-42 (2017).

- Akçaoğlu, T., Tokyay, M., Çelik, T. Assessing the ITZ microcracking via scanning electron microscope and its effect on the failure behavior of concrete. Cement and Concrete Research. 35 (2), 358-363 (2005).

- Chang, H., Feng, P., Lyu, K., Liu, J. A novel method for assessing C-S-H chloride adsorption in cement pastes. Construction & Building Materials. 225, 324-331 (2019).

- Wang, P., Jia, Y., Li, T., Hou, D., Zheng, Q. Molecular dynamics study on ions and water confined in the nanometer channel of Friedel's salt: structure dynamics and interfacial interaction. Physical Chemistry Chemical Physics. 20, 27049-27058 (2018).

- Ma, H., Li, Z. A Multi-Aggregate Approach For Modeling The Interfacial Transition Zone In Concrete. ACI Materials Journal. 111 (2), (2014).

- Yun, G., et al. Characterization of ITZ in ternary blended cementitious composites: Experiment and simulation. Construction & Building Materials. 41 (2), 742-750 (2013).

- Garboczi, E. J., Bentz, D. P. In Digital simulation of the aggregate-cement paste interfacial zone in concrete. International Conference on Electric Information and Control Engineering (ICEICE), 2011. , 196-201 (2011).

- Winslow, D. N., Cohen, M. D., Bentz, D. P., Snyder, K. A., Garboczi, E. J. Percolation and pore structure in mortars and concrete. Cement & Concrete Research. 24 (1), 25-37 (1994).

- Simões, T. . Mechanical Characterization of Fiber/Paste and Aggregate/Paste Interfaces (ITZ) in Reinforced Concrete with Fibers. , (2018).

- Xiao, J., Li, W., Sun, Z., Lange, D. A., Shah, S. P. Properties of interfacial transition zones in recycled aggregate concrete tested by nanoindentation. Cement and Concrete Composites. 37, 276-292 (2013).

- Bentz, D. P., Garboczi, E. J., Stutzman, P. E. Computer Modelling of the Interfacial Transition Zone in Concrete. Interfaces in Cementitious Composites. , 107-116 (1993).

- Kai, L., Wei, S., Changwen, M., Honglei, C., Yue, G. Quantitative characterization of pore morphology in hardened cement paste via SEM-BSE image analysis. Construction & Building Materials. 202, 589-602 (2019).

- Ondracek, G., Underwood, E. Quantitative stereology. Journal of Nuclear Materials. 42 (2), 237-237 (1972).

- Xu, J., Wang, B., Zuo, J. Modification effects of nanosilica on the interfacial transition zone in concrete: A multiscale approach. Cement and Concrete Composite. 81, 1-10 (2017).

- Zhu, Z., Chen, H. . Overestimation of ITZ thickness around regular polygon and ellipse aggregate. , 205-218 (2017).

- Head, M. K., Wong, H. S., Buenfeld, N. R. Characterising aggregate surface geometry in thin-sections of mortar and concrete. Cement and Concrete Research. 38 (10), 1227-1231 (2008).

- Gao, Y., De Schutter, G., Ye, G., Tan, Z., Wu, K. The ITZ microstructure, thickness and porosity in blended cementitious composite: Effects of curing age, water to binder ratio and aggregate content. Composites Part B: Engineering. 60, 1-13 (2014).

- Erdem, S., Dawson, A. R., Thom, N. H. Influence of the micro- and nanoscale local mechanical properties of the interfacial transition zone on impact behavior of concrete made with different aggregates. Cement and Concrete Research. 42 (2), 447-458 (2012).

- Elsharief, A., Cohen, M. D., Olek, J. Influence of aggregate size, water cement ratio and age on the microstructure of the interfacial transition zone. Cement & Concrete Research. 33 (11), 1837-1849 (2003).

- Pan, T., Tutumluer, E. Quantification of Coarse Aggregate Surface Texture Using Image Analysis. Journal of Testing & Evaluation. 35 (2), 177-186 (2006).

- Erdogan, S. T., et al. Three-dimensional shape analysis of coarse aggregates: New techniques for and preliminary results on several different coarse aggregates and reference rocks. Cement & Concrete Research. 36 (9), 1619-1627 (2006).

- Santos, B. O., Valença, J., Fowler, D. W., Saleh, H. A. Livings patterns on concrete surfaces with biological stains using hyperspectral images processing. Structural Control and Health Monitoring. , (2019).

- Santos, B. O., Valença, J., Júlio, E. In Classification of biological colonization on concrete surfaces using false colour HSV images, including near-infrared information. Optical Sensing and Detection V, International Society for Optics and Photonics. , 106800 (2018).

- Stock, S. R. Recent advances in X-ray microtomography applied to materials. International Materials Reviews. 53 (3), 129-181 (2013).

- Lyu, K., Garboczi, E. J., She, W., Miao, C. The effect of rough vs. smooth aggregate surfaces on the characteristics of the interfacial transition zone. Cement and Concrete Composites. 99, 49-61 (2019).

- Wong, H. S., Head, M. K., Buenfeld, N. R. Pore segmentation of cement-based materials from backscattered electron images. Cement & Concrete Research. 36 (6), 1083-1090 (2006).

- Liao, K. -. Y., Chang, P. -. K., Peng, Y. -. N., Yang, C. -. C. A study on characteristics of interfacial transition zone in concrete. Cement and Concrete Research. 34 (6), 977-989 (2004).

- Barnes, B. D., Diamond, S., Dolch, W. L. The contact zone between portland cement paste and glass “aggregate” surfaces. Cement & Concrete Research. 8 (2), 233-243 (1978).

- Hamerly, G., Elkan, C. Alternatives to the k-means algorithm that find better clusterings. Proceedings of the eleventh international conference on Information and knowledge management, ACM. , 600-607 (2002).

- Celebi, M. E., Kingravi, H. A., Vela, P. A. . A comparative study of efficient initialization methods for the k-means clustering algorithm. , 200-210 (2013).

- Lu, Y., et al. Three-dimensional mortars using real-shaped sand particles and uniform thickness interfacial transition zones: Artifacts seen in 2D slices. Cement and Concrete Research. , (2018).

- Gao, Y., De Schutter, G., Ye, G., Huang, H., Tan, Z., Wu, K. Porosity characterization of ITZ in cementitious composites: Concentric expansion and overflow criterion. Construction and Building Materials. 38, 1051-1057 (2013).

- Celebi, M. E., Kingravi, H. A., Vela, P. A. A comparative study of efficient initialization methods for the k-means clustering algorithm. Expert Systems with Applications. 40 (1), 200-210 (2013).

Reprints and Permissions

Request permission to reuse the text or figures of this JoVE article

Request PermissionExplore More Articles

This article has been published

Video Coming Soon

Copyright © 2025 MyJoVE Corporation. All rights reserved