Non-destructive SPE-UPLC-based Quantification of Aflatoxins and Stilbenoid Phytoalexins in Single Peanut (Arachis spp.) Seeds

In This Article

Summary

We demonstrate a medium-throughput method for quantification of aflatoxins and stilbenoid phytoalexins in single peanut seeds using ultra performance liquid chromatography. This method was specifically developed for the analyses of wild Arachis species challenged by the aflatoxigenic Aspergillus species.

Abstract

Aflatoxins are highly carcinogenic secondary metabolites of some fungal species, particularly Aspergillus flavus. Aflatoxins often contaminate economically important agricultural commodities, including peanuts, posing a high risk to human and animal health. Due to the narrow genetic base, peanut cultivars demonstrate limited resistance to fungal pathogens. Therefore, numerous wild peanut species with tolerance to Aspergillus have received substantial consideration by scientists as sources of disease resistance.

Exploring plant germplasm for resistance to aflatoxins is difficult since aflatoxin accumulation does not follow a normal distribution, which dictates the need for the analyses of thousands of single peanut seeds. Sufficiently hydrated peanut (Arachis spp.) seeds, when infected by Aspergillus species, are capable of producing biologically active stilbenes (stilbenoids) that are considered defensive phytoalexins. Peanut stilbenes inhibit fungal development and aflatoxin production. Therefore, it is crucial to analyze the same seeds for peanut stilbenoids to explain the nature of seed resistance/susceptibility to the Aspergillus invasion. None of the published methods offer single-seed analyses for aflatoxins and/or stilbene phytoalexins.

We attempted to fulfill the demand for such a method that is environment-friendly, uses inexpensive consumables, and is sensitive and selective. In addition, the method is non-destructive since it uses only half of the seed and leaves the other half containing the embryonic axis intact. Such a technique allows germination and growth of the peanut plant to full maturity from the same seed used for the aflatoxin and stilbenoid analysis. The integrated part of this method, the manual challenging of the seeds with Aspergillus, is a limiting step that requires more time and labor compared to other steps in the method. The method has been used for the exploration of wild Arachis germplasm to identify species resistant to Aspergillus and to determine and characterize novel sources of genetic resistance to this fungal pathogen.

Introduction

Peanut (Arachis hypogaea L.) is one of the major food crops in the world. It is cultivated in more than 100 countries with total production exceeding 45 million tons1. Agricultural commodities, such as peanut, corn, and cottonseed are often invaded by species of Aspergillus, soil-born fungi that produce aflatoxins2. These commodities are particularly susceptible to preharvest aflatoxin contamination when environmental conditions are characterized by high temperatures and drought. Aflatoxins are among the most potent carcinogens known3. They contaminate a quarter of the agricultural commodities in the world4 making about half of the world's population chronically exposed to aflatoxins5. Due to their high carcinogenicity and toxicity, aflatoxin presence in food is regulated at the lowest practically acceptable limits in most countries of the world6.

The European Union (EU) has legislated a maximum level of 2 ng/g for aflatoxin B1 and 4 ng/g for total aflatoxins (B1, B2, G1, and G2) in products for human consumption7. Such low limits put substantial pressure on agriculture and the food industry that processes commodities contaminated with aflatoxins. Aflatoxin monitoring and reprocessing of contaminated peanuts may be considered a passive and costly strategy to prevent aflatoxins from entering the food chain. That is why all major segments of the peanut industry experience tremendous profit losses due to the aflatoxin contamination of current peanut cultivars that often demonstrate limited resistance to fungal diseases. A prospective approach to resolve the aflatoxin problem is to obtain fungus-resistant peanut cultivars through gene introgression, that is, the transfer of genetic information from resistant wild peanut species to elite cultivars. In recent years8,9, wild peanut species have received substantial consideration as sources of genetic disease resistance because the narrow genetic base of cultivated peanuts can no longer provide the needed level of resistance traits to the peanut plant10,11. Successful introgression from wild peanut species requires the analyses of thousands of single small and scarce seeds (Figure 1A) 12.

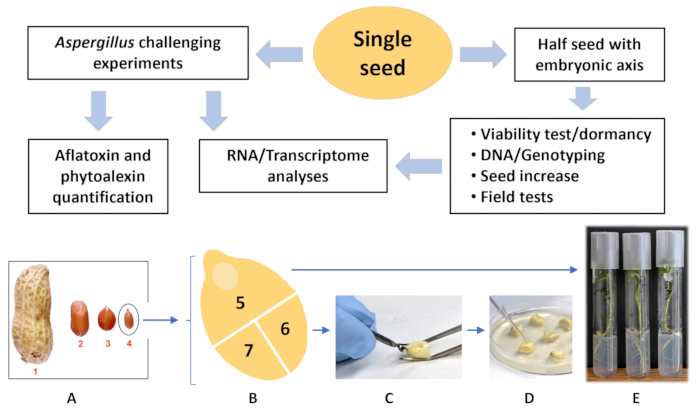

Figure 1: Single-seed analysis flowchart. (A) Comparative size of different market-type peanut cultivars vs. wild Arachis spp. (1) Virginia; (2) runner; (3) Spanish; (4) wild Arachis spp. (B) Wild Arachis spp. (plate A, seed 4) cut into three sections, (5) half seed with embryonic axis; this portion of the seed is used to grow a plant (E). (C) Parts (6) and (7) are drilled with a drill bit and (D) inoculated with fungal spores. After incubation for 72h at 30 °C, one of the seed parts, (6) or (7) is used for aflatoxin and phytoalexin analyses, and another is used for RNA/transcriptome sequencing. Please click here to view a larger version of this figure.

Peanut resistance to fungal pathogens is strongly associated with phytoalexins13,14,15,16,17. Peanut phytoalexins are represented by antimicrobial stilbenoids that are biosynthesized and accumulated in plant tissues after exposure to exogenous stimuli, particularly, to fungal invasion16,17,18. Rapid accumulation of sufficient concentrations of phytoalexins at the site of fungal invasion is inhibitory to fungal growth and is critical for plant defense19,20,21. Pathogen stops growing when phytoalexins accumulate to inhibitory concentrations16,22. The role of stilbenoids as defensive compounds against aflatoxigenic fungi in peanut was evaluated over 30 years ago in field experiments13. Those experiments clearly supported the hypothesis that peanut stilbenoids are a crucial resistance factor in preharvest aflatoxin contamination. Such evidence is based on the facts that stilbenes are naturally produced in field-damaged peanuts; stilbenes demonstrate appreciable biological activity against aflatoxigenic fungi; and aflatoxin contamination in seeds was detected only when peanuts lost the capacity for phytoalexin synthesis due to drought-induced seed dehydration. Another set of field experiments confirmed the association between phytoalexin production and peanut genotype resistance to agriculturally important peanut diseases17.

A better understanding of the natural phytoalexin-based mechanism of peanut resistance to fungal invasion is a promising strategy for the control of aflatoxin contamination15,17. Therefore, in addition to the aflatoxin analyses, it is important to quantitatively analyze the same seeds for phytoalexins. Although this mechanism for resistance is not fully researched and understood, yet it is crucial for breeding and genetically modifying peanut plants for new fungal-resistant cultivars23. Despite the existence of various analytical procedures for aflatoxin determination in different commodities, there is still a need for simple methods for specific research, particularly when traditional methods do not satisfy analytical and cost-effective requirements. Most modern cleanup methods used by the peanut industry, agriculture, and private laboratories are antibody-based24 and immunoassay25,26,27devices. They are selective and sensitive but substantially more expensive than minicolumns packed with common adsorbents. In addition, none of those methods were designed for the analyses of few-milligram-weight samples. Based on our previous research on the analytical use of magnesium silica gel (Florisil)-packed minicolumns28, we modified this procedure to suit the needs of ongoing and prospective pre-breeding and breeding programs.

The purpose of this work was to develop a non-destructive, medium throughput, environment-friendly method for the quantitative determination of aflatoxins and phytoalexins in single peanut seeds. Such a method has been developed. Its advantages over published methods are higher sensitivity, the ability to analyze aflatoxins and phytoalexins in a single-seed extract, lack of the need to weigh samples, and lower cost thanks to smaller volumes of consumables. The flow chart of the integrated method is shown in Figure 1. The genetic analyses and other steps are mentioned in this text and demonstrated in the figure to show the importance of the suggested method and how it is integrated with the entire procedure.

Protocol

1. Preparation of seeds for fungal challenge

- Incubate the aflatoxigenic Aspergillus flavus NRRL 3357 on a slant of Potato Dextrose Agar (PDA) in a test tube for 6 days at 30 °C. Harvest fungal spores from the test tube with 10 mL of water with Tween 20 (100 μL of Tween in 1 L of distilled sterile water), filter through glass wool placed in a funnel and count the spores with a hemocytometer referring to the user manual.

- Dilute the spore suspension with sterile water to 1,000 spores/μL concentration. Confirm the concentration with a hemocytometer.

NOTE: Prepare the spore suspension no earlier than 2 h before the challenging experiments. - Gently crack the peanut pods and remove the hulls. Place the seeds in a sterile beaker so that the volume of seeds does not exceed 1/5 of the beaker volume, add 0.05% hydrogen peroxide solution to approximately 70% of the beaker volume, and allow the seeds to imbibe water for 3 h.

- Decant the hydrogen peroxide solution from the seeds and add approximately 3x the amount of 80% ethanol-water mixture (v/v) to the beaker to cover the seeds. Allow to stand for 1 min and then rinse the seeds 2x with equal volumes of sterile distilled water.

- Add 5-fold volume of 3% hydrogen peroxide to the beaker with the ethanol-sterilized seeds and allow to stand for 5 min, then decant the liquid and rinse the seeds twice with equal volumes of sterile water (Figure 2A).

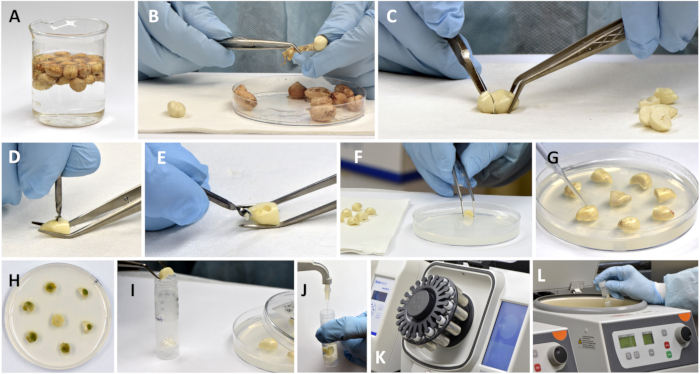

Figure 2: Preparation of peanut seeds for inoculation, incubation, and extraction of aflatoxin and phytoalexin fractions. (A) Sterilizing imbibed seeds with 3% hydrogen peroxide; (B) removing testa (skin) from seeds; (C) cutting off the embryonic axis part; (D,E) drilling cavity in a half cotyledon with a drill bit; (F) placing drilled parts of seeds on agar; (G) applying fungal spores into the drilled cavity. (H) Petri dish with seeds after incubation; (I) placing incubated single seeds (photo of control samples) into reinforced bead tubes; (J) adding measured volume of extracting solvent; (K) pulverizing samples in a bead ruptor; (L) centrifugation of pulverized slurry. Please click here to view a larger version of this figure.

- Place the seeds on a sterile paper towel, remove the seed testa with forceps, and cut about 1/3 of the seed containing the embryonic axis with a scalpel (Figure 2B,C).

- Discard this part of the seed or use it to grow a plant in a test tube with growth medium (Figure 1B,E).

- Split the remaining portion of the seed into two cotyledons, place them in a Petri dish, cover the seed parts with moist sterile filter paper, replace the lid to avoid dehydration and promptly proceed to the inoculation step.

- Before performing the challenging experiments, prepare a sufficient number of Petri dishes with seed incubation medium by pouring 26 mL of 1.5% sterile agar in water into the 100 x 15 mm dishes and allow them to solidify overnight.

- In the middle of the outer side of each remaining cotyledon, make a 1.5-2 mm deep cavity by manually drilling the seed with a 1.6-2.34 mm diameter sterile sharp drill bit. It takes ~2-5 s to make a cavity (Figure 2D,E).

- Place 4 to 6 "drilled" pieces of the seeds into a Petri dish with agar and apply 2 μL of the 1,000 spores/μL suspension into the drilled cavity of each half-cotyledon piece with a 10 μL pipetter. Instead of the spore suspension, apply sterile water to the control seeds (Figure 2F,G).

- Cover all Petri dishes with lids and incubate at 30 °C without light for 72 h.

2. Sampling and preparation of the incubated seed pieces for aflatoxin and phytoalexin analysis

- Collect seed pieces at 72 h by removing them from agar with forceps and placing each of them into labeled 7 mL bead vials with 13 zirconium ceramic beads (12 of 2.8 mm diameter and 1 of 6.5 mm diameter) (Figure 2H,I).

NOTE: At this point, if not processed immediately, the vials can be placed into a -80 °C freezer and kept for up to 2 months before further processing . - Phytoalexins and aflatoxins are determined in the same seed extract. For the extraction, depending on the visual seed size (small, medium, or large), add 2 or 4 mL of precisely measured methanol-water mixture (90:10, v/v) to the bead vials and pulverize at 5.5 m/sec for 45 s. Place the vials with pulverized seeds into a centrifuge and centrifuge at 1,860 × g for 3 min (Figure 2J - L).

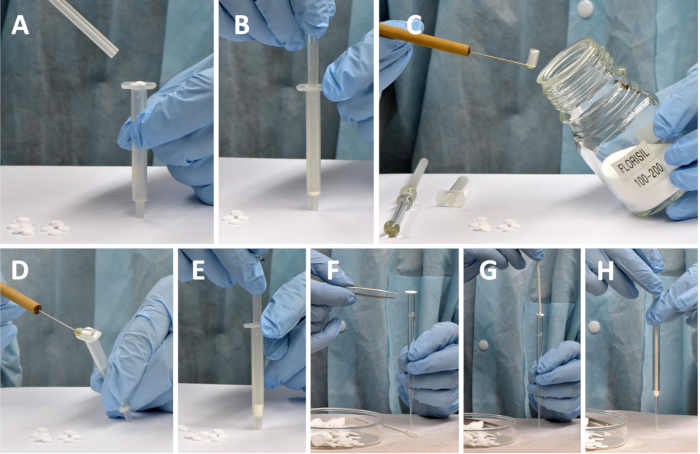

NOTE: The following important17,22 stilbenoid derivatives are determined (all in trans-configuration): resveratrol, arachidin-1, arachidin-2, arachidin-3, 3′-isopentadienyl-3,5,4′-trihydroxystilbene (IPD), and SB-1. - For aflatoxin analyses, before running the challenging experiments, prepare a sufficient number of cleanup columns as follows. Place a matching polyethylene porous (20 μL) frit into a 1.5 mL polypropylene column with the help of a glass rod cut at a 90o angle. Place 50 mg of the magnesium silica gel (100-200 mesh) into the column with a custom-made scoop and cap the column with an identical frit by pushing it down with a glass rod (Figure 3A - E).

NOTE: This amount of magnesium silica gel occupies 75 μL volume, and the height of the adsorbent layer is 3 mm.

Figure 3: Preparation of cleanup columns and filters. (A,B) Placing a porous frit into barrel; (C,D) filling barrel with magnesium silica gel; (E) packing the adsorbent and inserting a top porous frit into barrel. (F) Placing an 11.5 mm dia. glass fiber circle on top of a Pasteur pipette. (G,H) Pushing the center of the circle with a plastic or wooden rod down to the bottom of the Pasteur pipette barrel and firmly compacting the glass fiber. Please click here to view a larger version of this figure.

- At this point, prepare a matching number of custom-made filters as shown in Figure 3F - H.

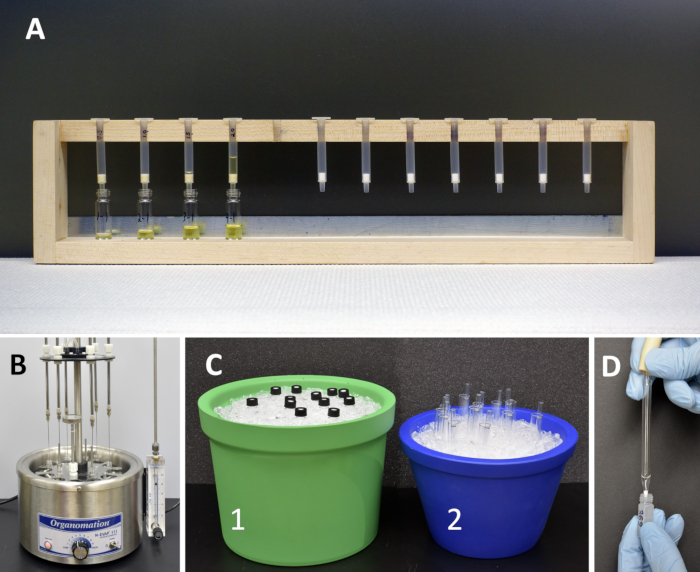

- For aflatoxin analyses, precisely measure up to 0.5 mL aliquot of the supernatant (obtained as described in step 2.2), transfer it into the custom-packed minicolumn, and allow the extract to drain by gravity into a 4-mL glass vial. Transfer 1.0 mL of methanol-water (90:10, v/v) mixture to the column to wash out impurities by gravity into the same 4 mL vial (Figure 4A).

Figure 4: Purification of seed extracts and preparation for the UPLC analyses. (A) Rack with packed columns. (B) Evaporating solvent with N2 gas from six 4-mL vials with purified extract eluted from cleanup columns. (C) Bringing vials and filters to a subzero temperature in foam containers (1 and 2) with ice before and after addition of the injection solvent (MeOH-H2O 9:1, v/v) to the 4-mL vials. (D) Filtering cooled extract from a 4-mL vial into a 400 µL autosampler vial. Please click here to view a larger version of this figure.

- Discard the combined eluates. Elute the aflatoxin fraction by gravity from the column into a clean 4 mL glass vial with 1.2 mL acetone-acetonitrile-water-88% formic acid (65:31:3.5:0.5, v/v) mixture (Figure 4A).

- Alternatively, elute aflatoxins from the column with 2.0 mL of acetonitrile-water-88% formic acid (96:3.5:0.5, v/v) mixture, and inject an aliquot of the eluate, up to 2 μL, directly into the ultra performance liquid chromatography (UPLC) system (without evaporation of the solvent with N2).

NOTE: In this case, expect up to 10-fold lower quantitation limit for aflatoxins; in the majority of the cases such a drop of sensitivity is acceptable since aflatoxin concentrations in challenged seed are often high. - Remove the solvent from the vials in a stream of N2 in a heated block at 45 °C. Cap the vial and place it in a container with crushed ice for 30-45 s to minimize evaporation of the solvent that is added in the following step. Place custom-made filters into disposable test tubes and insert the tubes into ice in another container to minimize evaporation of solvent upon filtration (Figure 4B,C).

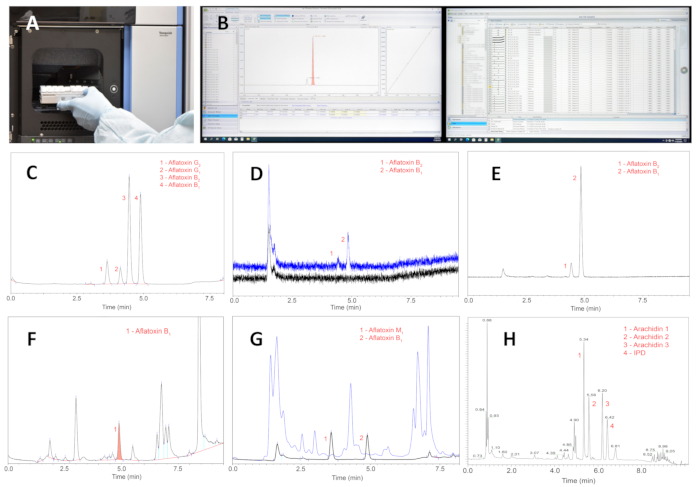

- After evaporation of the solvent, dissolve the dry residue in precisely measured 0.25-1.0 mL of methanol-water mixture (90:10, v/v) and vortex for 1-2 s. Place vials with purified extracts into the UPLC autosampler and inject 0.1 to 3.0 μL into the UPLC system (Figure 5A,B).

NOTE: If the solution after vortexing is suspected to have some suspended particles, filter the solution through the cooled filter (Figure 4D).

Figure 5: The process and results of UPLC analyses of purified extracts. (A) Placing a rack with purified sample extracts into UPLC autosampler. (B) Performing the instrumental analyses, obtaining data, and interpreting results. (C) UPLC of four major aflatoxins; the major peaks of interest, aflatoxins B1 and B2 represent 0.04 and 0.004 ng, respectively. (D) UPLC of aflatoxins B1 and B2; peak 2 represents aflatoxin B1 at a 2 pg level (with an 8 µL flow cell). (E) UPLC of purified extract of a seed harvested from a local peanut field with a wild Arachis species. (F) UPLC of the extract of a challenged peanut seed purified with a basic aluminum oxide minicolumn. (G) UPLC of the extract of challenged peanut seed purified with a Florisil column; blue chromatogram presents impurities that are washed from the column with 1 mL of methanol-water (90:10 v/v) mixture; black chromatogram shows peaks of aflatoxins M1 and B1. The level of aflatoxin B1 is 48 ng/g. (H) A typical chromatogram of peanut stilbenoids from a challenged seed; abbreviation: IPD = 3′-isopentadienyl-3,5,4′-trihydroxystilbene. Note: All stilbenoids in seed extracts are in trans-configuration. Please click here to view a larger version of this figure.

- For phytoalexin analyses, from each bead vial, transfer 200 μL of supernatant into the above Pasteur pipette filter. Use N2 gas from a compressed nitrogen tank to expedite filtration into a 400 μL UPLC autosampler vial and cap the vial with a matching cap with a PTFE septum (Figure 4D).

3. Aflatoxin analyses

- For separations of aflatoxins in seed extracts, use a UPLC system equipped with an autosampler, a quaternary pump, a fluorescent detector, a UPLC BEH C18 3.0 mm x 100 mm, 1.7 µm column with a matching precolumn, and a postcolumn photochemical reactor (PHRED) with a standard knitted PTFE coil 0.25 internal diameter cut to 25% of its original length.

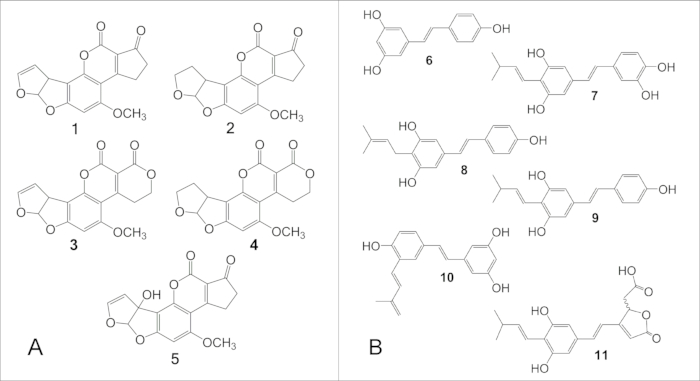

NOTE: UPLC instrument and associated equipment used by the authors are listed in the Table of Materials. - Use water (A), methanol (B), and acetonitrile (C) in the following gradient: initial conditions, 62.7% A, 24% B, 13.3% C, changed linearly to 30% A, 45% B, 25% C in 3.75 min, changed to 0% A, 64.4% B, 35.6% C in 3.751 min, held isocratic for 3.249 min, then changed to initial conditions in 0.01 min and held isocratic for 2.499 min before next injection. Set the flow rate to 0.45 mL/min and run time to 9.5 min. Maintain the column at 40 °C in the system column heater. Use 362 nm and 440 nm as the excitation and emission wavelengths, respectively, for aflatoxins B1, B2, G1, G2, and M1 quantification. The structures of major aflatoxins are shown in Figure 6A.

NOTE: Under the experimental conditions, only aflatoxins B1 and B2 are expected to be produced by A. flavus NRRL 3357; if an A. parasiticus strain is used for seed challenging, the production of aflatoxins B1, B2, G1, and G2 is expected. - Determine concentrations of aflatoxins by reference to peak areas of corresponding authentic standards (calibration curve) as described in the software user manual.

NOTE: Since the UPLC procedure exhibits baseline noise at the high sensitivity settings for the fluorescent detector, Detection Limit (LOD) and Quantitation Limit (LOQ) for aflatoxins are evaluated using the widely accepted Signal-to-Noise ratio of 3:1 for LOD and 10:1 for LOQ. In the routine experimental setup for peanut seed analysis, described in sections 2 and 3, the quantitation limits for aflatoxins G1 and B1 are expected to be less or equal to 0.8 and 0.08 ng/g for aflatoxins G2 and B2, respectively.

4. Stilbenoid phytoalexin analyses

- For separation of stilbenoids, use water (A), methanol (B), and 88% formic acid (C) in the following gradient: initial conditions, 53% A, 42% B, 5% C, changed linearly to 35% A, 60% B, 5% C in 2.0 min, held isocratic for 4 min, changed to 0% A, 95% B, 5% C in 0.5 min, held isocratic for 2.5 min, then changed to initial conditions in 0.1 min and held isocratic for 2.9 min before next injection. Set flow rate to 0.5 mL/min and run time to 12.0 min.

- Determine concentrations of stilbenoids by reference to peak areas of corresponding authentic standards (calibration curve) and/or to published coefficients of molar extinctions as described in the software user manual. The structures of major stilbene-derived phytoalexins are shown in Figure 6B.

NOTE: Separation of phytoalexins is achieved using the same system but without a fluorescent detector and a PHRED reactor. Instead, a Diode Array Detector is used for the detection and quantification of peanut stilbenoids. Quantitation Limit (LOQ) for the major stilbenoid phytoalexins does not have a practical meaning as stilbenoid concentrations exceed concentrations of aflatoxins in the same extract by some orders of magnitude; after 3 days of incubation, stilbenoids are reliably quantitated.

Results

The developed method for aflatoxin quantitation in seeds is the core of the entire procedure of evaluation of wild peanut species for resistance to aflatoxin accumulation. Custom-packed minicolumns and filters provide substantial savings and simplify the overall procedure due to the lack of large volumes of solvents, costly and unnecessary 0.22 or 0.45 µm commercial filters, and pumping devices. The method for aflatoxin analyses provides high recoveries, accuracy, and precision within the tested range of 1.0-50.0 ng/g of aflatoxins from ground seeds as seen in Table 1. Highly contaminated samples were diluted to the linear tested value. Figure 5C shows a baseline separation of four major aflatoxins, B1, B2, G1, and G2 within 5 min elution time, which is acceptable since the fungal challenging of peanut seeds is the limiting stage of the procedure and not UPLC analyses.

The proposed method is sufficiently sensitive with a quantitation limit of 2 pg for aflatoxin B1 (Figure 5D). The high purity of the extracts allows for unambiguous quantification of aflatoxins as seen from an UPLC (Figure 5E) of purified extract of seeds harvested from a field with a wild Arachis species. An earlier published minicolumn method29 is not capable of achieving satisfactory purity for fungus-challenged peanut seeds (Figure 5F) compared to the proposed method (Figure 5G). From Figure 5F it is obvious that aflatoxins B2, G1, and G2 cannot be reliably detected and quantitated due to the presence of high concentrations of interfering impurities, many of which, eluted after aflatoxins, are stilbenoid phytoalexins and fungal metabolites. In contrast, Figure 5G demonstrates the high efficiency of the magnesium silica gel column in removing impurities from the aflatoxin fraction. Blue chromatogram presents interfering impurities that are washed from the column with 1 mL of methanol-water (90:10) mixture; black chromatogram shows unobscured peaks of aflatoxins M1 and B1. This chromatogram represents the extract of a challenged wild species seed. The level of aflatoxin B1 is 48 ng/g.

Quantitation of peanut phytoalexins is a valuable addition to the analyses of aflatoxins in the same seed, which may be a natural seed from a field or a fungus-challenged seed. Figure 5H shows a typical chromatogram of peanut defensive stilbenoids from a challenged seed. Separation of the compounds is achieved using the same analytical column that is used for aflatoxin analyses. The column and chosen chromatographic conditions provide satisfactory separation of the peaks allowing for reliable quantitation of the stilbenoids. Evaluation of the aflatoxin-phytoalexin relationship in challenged seeds is outside the scope of this presentation and the method is suggested here as a potential research tool, which has been used at the authors' laboratory for several years and has proved to be useful.

Figure 6: Structures of major aflatoxins and stilbene-derived peanut phytoalexins. (A) Structures of major aflatoxins: 1, B1; 2, B2; 3, G1; 4, G2. (B) Structures of major stilbene-derived peanut phytoalexins: 6, resveratrol; 7, arachidin-1; 8, arachidin-2; 9, arachidin-3; 10, IPD (3′-isopentadienyl-3,5,4′-trihydroxystilbene); 11, SB-1. Please click here to view a larger version of this figure.

| Spike levela (ng/g) | Aflatoxins | |||

| B1 | B2 | G1 | G2 | |

| 50 | 85.87 (0.97) | 82.33 (0.67) | 86.63 (2.89) | 84.01 (0.86) |

| 5 | 91.43 (2.76) | 87.32 (0.47) | 88.08 (2.08) | 87.73 (0.77) |

| 1 | 81.21 (3.16) | 85.33 (1.98) | 81.76 (4.66) | 88.46 (3.24) |

Table 1: Recovery of aflatoxins from peanut seeds using the Florisil column and 1.2 mL of the aflatoxin fraction elution mixture. [mean (SD), %; n = 5]. Aflatoxin-free ground samples (50 g) of Georgia 06G peanut cultivar were evenly spiked with the help of a micro syringe with aflatoxin stock solution at 50, 5, or 1 ng/g level, and left at room temperature for 16 h. a Spike levels are given for aflatoxins B1 and G1; for aflatoxins B2 and G2 the multiplication factor of 0.33 should be used.

Discussion

Based on our previous experience28, we have developed a simple, inexpensive, environment-friendly, chemical procedure suitable for the exploration of wild Arachis germplasm collections to identify species resistant to Aspergillus and to determine and characterize novel sources of genetic resistance to this opportunistic fungus. This method is based on seed extract purification by a solid phase extraction (SPE) technique and aflatoxin quantification by Ultra Performance Liquid Chromatography (UPLC) and is characterized by sufficiently high recovery, precision, and accuracy. The proposed "Florisil" method is a modification of the single minicolumn cleanup procedure that is based on the unique property of Florisil (magnesium silica gel) to strongly and selectively retain aflatoxins28. As in the original method, seed samples were extracted with MeOH-H2O mixture but at a different proportion of 90:10 (v/v) compared to the published 80:20 (v/v). This change has increased the flow rate of solvents through the cleanup column up to 2.5x with the same aflatoxin recovery rate. This 90:10 (v/v) methanol-water mixture provided nearly 100% recovery of aflatoxins B1, B2, G1, and G2 standards added to extracting solvent at spike levels equivalent to 5-50 ng of aflatoxin concentrations in 1 g of a substrate, as well as provided sufficiently high recoveries from the spiked peanut seed samples (Table 1).

It has been shown that aflatoxins can be eluted from the Florisil adsorbent only with large volumes of acetone30, acetone-methanol31,32, and acetone-water mixtures33,34,35,36. In the course of the present research, we discovered that acidified acetonitrile behaves similarly to acetone in its ability to elute aflatoxins from Florisil. To our knowledge, this property of acetonitrile has not been reported in the literature. The discovery of this property allows injecting purified extract directly into the UPLC system omitting the solvent evaporation step, which substantially reduces the preparation time. Even when acetonitrile was mixed with acetone (acetone-acetonitrile-water-88% formic acid (65:31:3.5:0.5, v/v)), it provided smooth, complete, and fast removal of water from the purified eluates substantially reducing solvent evaporation time. The presence of acetonitrile allowed for the use of a single solvent, methanol-water (90:10, v/v) mixture to effectively remove impurities from the Florisil column compared to a published method, where two additional washing solvents, methanol and chloroform-methanol mixture, was required.28

On average, aflatoxin B1 standard recovery was ~98% when using 1.2 mL for the elution of aflatoxins. The amount of 50 mg of Florisil was selected so that 1.2 mL of the elution solvent filled the minicolumn to the top of the barrel and, at the same time, provided satisfactory recovery (Table 1). This approach expedites the cleanup procedure as the column barrel needs to be filled only once. In the early stages of this project, it was not clear whether a commercial Florisil fraction with a relatively large particle size, 100-200 mesh, would be appropriate for a small column holding only a 3 mm layer of the adsorbent. Therefore, we explored different Florisil fractions obtained from a commercial 100-200 mesh product using U.S.A. standard test sieves 120-140, 140-170, 170-200, 200-270, 270-400, and >400 mesh. All these fractions provided reproducible, nearly matching results with satisfactory recovery. Although smaller particle-size fractions demonstrated narrower aflatoxin bands in the column under UV light, those fractions were not superior in any respect to the commercial 100-200 mesh product. In addition, the 100-200 mesh fraction demonstrated the shortest elution times (8-12 min) for the entire procedure.

Gradient UPLC solvent delivery allowed for satisfactory separation of aflatoxins as well as for complete removal of non-polar impurities from the column (Figure 5G). This approach led to flawless column operation and reproducible results of the analyses of hundreds of samples. The identity of aflatoxins eluted from the Florisil column was confirmed as previously described.28 The 3-mm diameter analytical UPLC column used here demonstrated higher selectivity and more reliable separation of aflatoxins B1, B2, G1, and G2 at higher concentrations compared to the 2.1-mm diameter column of the same chemistry. Moreover, the longevity of the 3 mm column (over 1,200 injections) was substantially higher than that of the 2.1-mm column (up to 800 injections). Even though the 3 mm column required a higher rate of the mobile phase (40% more), this drawback was outperformed by the above advantages of the column.

The Florisil minicolumn was effective for the purification of extracts of peanut seeds heavily contaminated with Aspergillus metabolites (Figure 5G); such seeds also contained high levels of stilbenoid phytoalexins that were produced by seeds in response to the fungal invasion. All those impurities may exceed aflatoxin concentration in the seeds up to 106-fold22, which makes these seeds challenging objects for aflatoxin analyses. Figure 5G shows the lack of interfering peaks in the chromatogram within aflatoxin retention times, which made aflatoxin detection and quantitation uncompromised at all levels tested (Table 1). As seen in Table 1, the accuracy and precision of the method were sufficiently high within the tested range of 1.0-50.0 ng/g, which is also the most critical range for aflatoxin detection. The recoveries at different levels for various wild peanut genotypes were uniform and the standard deviations for five different extractions were essentially low.

The method was also tested on peanut, cotton, corn, and rice seeds naturally contaminated from zero to extremely high levels-over 10,000 ng/g of total aflatoxins. Recovery of aflatoxins B1, B2, G1, and G2 from corn, cottonseed, and rice at the 5 ng/g level varied from 76.1% to 93.7%, 77.1% to 86.6%, and 90.5% to 96.2%, respectively. The highest recovery of aflatoxins from rice was accompanied by the eluent's "purity", that is, virtually the lack of any impurities. Further, rice represented the smallest single object tested, on average, 19 mg/seed.

The total preparation time for a single peanut seed (including shelling, weighing, extraction, centrifugation, and purification) using a Florisil column did not exceed 20 min. The cost of the Florisil minicolumn is >10x less than that of commercial cleanup columns. Additional savings derive from using lower volumes of adsorbents, solvents, and nitrogen gas compared to the published procedure28. The minicolumn does not require pumping or vacuum devices to operate and has an indefinite shelf life.

Exploring plant germplasm for resistance to aflatoxins is exceptionally difficult because mycotoxin accumulation does not follow a normal distribution37,38; a large number of aflatoxin analyses in single seeds is needed to overcome this phenomenon. In addition to aflatoxin content, information on quantitative phytoalexin composition is highly valuable in the light of a large body of information that can be obtained from a single seed (Figure 1A) and tracked to a specific plant (Figure 1E). The method has been successfully used for screening hundreds of accessions including landraces, advanced breeding lines, and elite peanut varieties. The method is suggested for use in peanut prebreeding and breeding research programs and may help in the characterization of peanut genes for fungal resistance.

Disclosures

The authors have no conflicts of interest to disclose.

Acknowledgements

This work received the financial support of USDA-ARS CRIS project 6044-42000-011-00D and CRIS project 6044-21000-005-000-D. We thank Dan Todd for making the minicolumn-holding rack. The mention of trade names or commercial products in this article is solely for the purpose of providing specific information and does not imply recommendation or endorsement by the US Department of Agriculture.

Materials

| Name | Company | Catalog Number | Comments |

| Acetone, Optima | Fisher Scientific | A929-4 | |

| Acetonitrile, Optima | Fisher Scientific | A996-4 | |

| Acquity BEH C18 2.1 x 5mm Van-Guard pre-column | Waters Corporation | 186003975 | |

| Acquity BEH C18 3 x 100mm column | Waters Corporation | 186004661 | |

| Acquity BEH C18 2.1 x 100mm column | Waters Corporation | 186002352 | |

| Aflatoxins B1, B2, G1, and G2 | Sigma-Aldrich | A9441-1VL | Dissolve the contents of the commercial vial in 5 mL of methanol to obtain 5 µg/mL for aflatoxins B1 and G1 and 1.5 µg/mL for B2 and G2 |

| Aflatoxin B1 (1mg) | Sigma-Aldrich | A6636-1MG | |

| Aflatoxin B2 (1mg) | Sigma-Aldrich | A9887-1MG | |

| Aflatoxin G1 (1mg) | Sigma-Aldrich | A0138-1MG | |

| Aflatoxin G2 (1mg) | Sigma-Aldrich | A0263-1MG | |

| Aflatoxin M1 (10 µg) | Sigma-Aldrich | CRM46319 | |

| Agar, Granulated (2kg) | Becton Dickinson | BD214510 | |

| Alumina oxide basic (60-325 mesh) | Fisher Scientific | A941-500 | |

| Basal medium | Murashige and Skoog | M5519 | |

| Bead Ruptor 24 | Omni International | 19-042E | |

| Beaker (1000mL) | Corning (Pyrex) | 10001L | |

| Beaker (250mL) | Corning (Pyrex) | 1000250 | |

| Beaker (400mL) | Corning (Pyrex) | 1000400 | |

| Beaker (600mL) | Corning (Pyrex) | 1000600 | |

| Blade, scalpel | Feather | #10 | |

| Centrifuge (LSE Compact) | Corning | Model: 6755 | |

| Centrifuge, micro | Corning | Model: 6770 | |

| Ceramic beads (2.8 mm) | Omni International | 19-646 | |

| Ceramic beads (6.5 mm) | Omni International | 19-682 | |

| Chromeleon 7 series Software | Thermo Scientific | ||

| Drill bit | Kyocera | 07896 | 1.6 mm |

| Drill bit | Kyocera | 07357 | 2.0 mm |

| Drill bit | Kyocera | 07985 | 2.34 mm |

| Ethanol (200 proof) | Decon Labs | 2805M | |

| Evaporator, nitrogen | organimation | 11106 | 6-position |

| Excel, Microsoft | Microsoft | Office 365 | |

| Filter paper (#4) | Cytiva Whatman | 1004-090 | |

| Filter paper cutter, stainless steel (ID 11.5mm) | Unknown | ||

| Filter paper, glass fibre | Cytiva Whatman | 934-AH | |

| Flask (2800mL) | Corning (Pyrex) | 44202XL | |

| Florisil (100-200 mesh) | Fisher Scientific | F101-500 | |

| Forceps | Integra Lifescience (Miltex) | PM-0300 | |

| Formic acid (88%, ACS) | Fisher Scientific | A118P-500 | |

| Freezer (-80oC) | Fisher Scientific | TSX70086D | |

| Funnel (15 x 80mm) | DWK Life Sciences (Kimax) | 2902060 | |

| Gelzan (medium) | Caisson Labs | G024 | |

| Glass rod (custom) | Custom made | ||

| Glass wool | Corning (Pyrex) | 3950 | |

| Handle, scalpel | Feather | #7 | |

| Hemocytometer | Hausser Scientific | 3100 | |

| Hydrogen peroxide | Fisher Scientific | H325-4 | 30%, Certified ACS |

| Ice bucket, round with lid | Corning | 432122 | |

| Incubator | Percival | 136VL | |

| Kimtech SCIENCE Brand Kimwipes | Kimtech | 34120 | 8.2" x 4.39" |

| Kimtech SCIENCE Brand Kimwipes | Kimtech | 34256 | 16.4" x 14.43" |

| Lab coat | Cenmed | B113660SBXL | |

| Methanol, Optima | Fisher Scientific | A454-4 | |

| Mini column rack (custom) | Custom made | ||

| Mixer, touch (maxi mix II) | Thermolyne | 37600 (model 231) | |

| Nitrile gloves | Microflex | XC310M | |

| Nitrogen gas, compressed (ultra high purity) | Jones Welding | ||

| Paper towel | Georgia-Pacific | 20023 (D400) | |

| pH meter | Fisher Scientific (Accumet) | 13-636-AB15 | |

| pH/ATC electrode | Fisher Scientific (Accumet) | 13-620-111 | |

| PhCR Photochemical Reactor | Waters (Vicam) | 600001222 | |

| Pipette, pasteur | Fisher Scientific | 13-678-20D | 9" |

| Pipettor (1 mL) (Reference 2) | Eppendorf | 4924000088 | |

| Pipettor (10 μL) (Reference) | Eppendorf | 022470051D | |

| Pipette tips: 10 μL, 200 μL, 1 mL | Eppendorf | F144054M | |

| Pipettor (200 µL)(Ergofit) | Fisher Scientific | 12-146-679 | |

| Plates, petri (100x15mm) | Fisher Scientific | FB0875713 | |

| Potato Dextrose Agar (500g) | Becton Dickinson | BD213400 | |

| Reinforced bead tube (2 mL) | Omni International | 19-660 | |

| Reinforced bead tube (7 mL) | Omni International | 19-651 | |

| Repipettor, Dispensette III (10mL) | Brandtech | 4701141 | |

| Resveratrol | Sigma-Aldrich | R5010-100MG | |

| Scoop (custom) | Custom made | ||

| screwcap jar (250 mL) | Corning (Pyrex) | 1395250 | |

| Silica gel, spherical (200-400 mesh) | Supelco | 97727-U | 100 g |

| Sodium Hydroxide | Fisher Scientific | S318-500 | |

| SPE extract clean 1.5-mL polypropylene column | American Chromotography Supplies | SP-5122382 | |

| SPE extract clean PP frits (for 1.5 mL minicolumn) | American Chromotography Supplies | SP-3119414 | |

| Spectrophotometer, UV-visible | Fisher Scientific | 14-385-351 (Genesys 50) | |

| Test tube | Corning (Pyrex) | 982516X | 16x125mm |

| Test tube (Disposable)(16x125mm) | Fisher Scientific | 14-961-31 | |

| Test tube (Disposable)(150x250mm) | Fisher Scientific | 14-961-34 | |

| Thermo Vanquish DAD detector (UPLC) | Thermo Scientific | VF-D11-A-01 | |

| Thermo Vanquish Fluourescense detector (UPLC) | Thermo Scientific | VF-D51-A | |

| Thermo Vanquish quaternary pump F (UPLC) | Thermo Scientific | VF-P20-A | |

| Thermo Vanquish Split Sampler FT (UPLC) | Thermo Scientific | VF-A10-A-02 | |

| Tween 20 (polysorbate 20) (enzyme grade) | Fisher Scientific | BP337-500 | |

| Vial caps (4mL) | Fisher Scientific | C4015-75A | |

| Vial caps (autosampler) | Fisher Scientific | C4010-60A | |

| Vials & caps (16 mL) | Thermo Scientific | B7800-4 | |

| Vials, glass (4mL) | Fisher Scientific | C4015-1 | |

| Vials, polypropylene (autosampler) (400mL) | Fisher Scientific | C4010-11 | |

| Water, Optima | Fisher Scientific | W6-4 |

References

- Janila, P., et al. Molecular breeding for introgression of fatty acid desaturase mutant alleles (ahFAD2A and ahFAD2B) enhances oil quality in high and low oil containing peanut genotypes. Plant Sci. 242, 203-213 (2016).

- Rasooly, R., Hernlem, B., He, X., Friedman, M. Non-linear relationships between aflatoxin B1 levels and the biological response of monkey kidney vero cells. Toxins (Basel). 5 (8), 1447-1461 (2013).

- American Association for Cancer Research: AACR. An evaluation of chemicals and industrial processes associated with cancer in humans based on human and animal data: IARC Monographs Volumes 1 to 20. Cancer Res. 40 (1), 1-12 (1980).

- Turner, P. C. The molecular epidemiology of chronic aflatoxin driven impaired child growth. Scientifica. , 21 (2013).

- Williams, J. H., et al. Human aflatoxicosis in developing countries: a review of toxicology, exposure, potential health consequences, and interventions. Am. J. Clin. Nutr. 80 (5), 1106-1122 (2004).

- van Egmond, H. P., Jonker, M. A., Abbas, H. K. Worldwide regulations on aflatoxins. Aflatoxinandfood safety. , 77-93 (2005).

- European Commission. Commission Regulation (EC) 1525/98. Off. J. Eur. Comm. L. 201, 43-46 (1998).

- Bressano, M., et al. Introgression of peanut smut resistance from landraces to elite peanut cultivars (Arachis hypogaea L). PLoS ONE. 14 (2), e0211920 (2019).

- de Blas, F. J., et al. Identification of smut resistance in wild Arachis species and its introgression into peanut elite lines. Crop Sci. 59 (4), 1657-1665 (2019).

- Mallikarjuna, N., Pande, S., Jadhav, D. R., Sastri, D. C., Rao, J. N. Introgression of disease resistance genes from Arachis kempff-mercadoi into cultivated groundnut. Plant Breeding. 123 (6), 573-576 (2004).

- Moretzsohn, M. C., et al. Genetic diversity of peanut (Arachis hypogaea L.) and its wild relatives based on the analysis of hypervariable regions of the genome. BMC Plant Biol. 4, 1-10 (2004).

- Arias, R. S., et al. New tools to screen wild peanut species for aflatoxin accumulation and genetic fingerprinting. BMC Plant Biol. 18 (1), 170 (2018).

- Dorner, J. W., Cole, R. J., Sanders, T. H., Blankenship, P. D. Interrelationship of kernel water activity, soil temperature, maturity, and phytoalexin production in preharvest aflatoxin contamination of drought-stressed peanuts. Mycopathologia. 105 (2), 117-128 (1989).

- Paxton, J. D., Sharma, R. P., Salunkhe, D. K. Biosynthesis and accumulation of legume phytoalexins. Mycotoxins and phytoalexins. , 485-499 (1991).

- Cole, R. J., Dorner, J. W., Sharma, R. P., Salunkhe, D. K. Peanut phytoalexins. Mycotoxins and phytoalexins. , 501-509 (1991).

- Subba Rao, P. V., Strange, R. N., Daniel, M., Purkayastha, R. P. Chemistry, biology, and role of groundnut phytoalexins in resistance to fungal attack. Handbook of phytoalexin metabolism and action. , 199-227 (1995).

- Sobolev, V. S., Guo, B. Z., Holbrook, C. C., Lynch, R. E. Interrelationship of phytoalexin production and disease resistance in selected peanut genotypes. J. Agric. Food. Chem. 55 (6), 2195-2200 (2007).

- Paxton, J. Phytoalexins: a working redefinition. J. Phytopathol. 101, 106-109 (1981).

- Mansfield, J. W., Bailey, J. A., Mansfield, J. W. The role of phytoalexins in disease resistance. Phytoalexins. , 153-288 (1982).

- Strange, R. N., Ayers, P. G. Resistance: the role of the hypersensitive response and phytoalexins. Plant response to foliar pathogens. , 39-56 (1992).

- Sobolev, V. S., et al. Biological activity of peanut (Arachis hypogaea) phytoalexins and selected natural and synthetic stilbenoids. J. Agric. Food Chem. 59 (5), 1673-1682 (2011).

- Sobolev, V. S. Localized production of phytoalexins by peanut (Arachis hypogaea) kernels in response to invasion by Aspergillus Species. J. Agric. Food Chem. 56 (6), 1949-1954 (2008).

- Sobolev, V. S., Neff, S. A., Gloer, J. B. New stilbenoids from peanut (Arachis hypogaea) seeds challenged by an Aspergillus caelatus strain. J. Agric. Food Chem. 57 (1), 62-68 (2009).

- Trucksess, M. W., et al. Immunoaffinity column coupled with solution fluorometry or liquid chromatography postcolumn derivatization for determination of aflatoxins in corn, peanuts, and peanut butter: collaborative study. J. AOAC Int. 74 (1), 81-88 (1991).

- Dorner, J. W., Blankenship, P. D., Cole, R. J. Performance of two immunochemical assays in the analysis of peanuts for aflatoxin at 37 field laboratories. J. AOAC Int. 76 (3), 637-643 (1993).

- Stroka, J., Anklam, E. Immunoaffinity column cleanup with liquid chromatography using post-column bromination for determination of aflatoxins in peanut butter, pistachio paste, fig paste, and paprika powder: collaborative study. J. AOAC Int. 83 (2), 320-340 (2000).

- Pal, A., Acharya, D., Saha, D., Roy, D., Dhar, T. K. In situ sample cleanup during immunoassay: a simple method for rapid detection of aflatoxin B1 in food samples. J. Food Prot. 68 (10), 2169-2177 (2005).

- Sobolev, V. S. Simple, rapid, and inexpensive cleanup method for quantitation of aflatoxins in important agricultural products by HPLC. J. Agric. Food Chem. 55 (6), 2136-2141 (2007).

- Sobolev, V. S., Dorner, J. W. Cleanup procedure for determination of aflatoxins in major agricultural commodities by liquid chromatography. J. AOAC Int. 85 (3), 642-645 (2002).

- Levi, C. P., Borker, E. Survey of green coffee for potential aflatoxin contamination. J. AOAC. 51 (3), 600-602 (1968).

- Levi, C. P. Collaborative study on a method for detection of aflatoxins B1 in green coffee beans. J. AOAC. 52 (6), 1300-1303 (1969).

- Scott, P. M. Note on analysis of aflatoxins in green coffee. J. AOAC. 51, 609 (1968).

- Bicking, M. K. L., Kniseley, R. N., Svec, H. J. Coupled-column system for quantitating low levels of aflatoxins. J. AOAC. 66 (4), 905-908 (1983).

- Kamimura, H., et al. Simple, rapid cleanup method for analysis of aflatoxins and comparison with various methods. J. AOAC. 68 (3), 458-461 (1985).

- Hoogenboom, L. A., et al. Genotoxicity testing of extracts from aflatoxin-contaminated peanut meal, following chemical decontamination. Food Addit. Contam. 18 (4), 329-341 (2001).

- Castro, L., Vargas, E. A. Determining aflatoxins B1, B2, G1 and G2 in maize using Florisil clean up with thin layer chromatography and visual and densitometric Quantitation. Cienc. Tecnol. Ailment. Campinas. 21, 115-122 (2001).

- Arias, R. S., Dang, P. M., Sobolev, V. S. RNAi-mediated Control of Aflatoxins in Peanut: Method to Analyze Mycotoxin Production and Transgene Expression in the Peanut/Aspergillus Pathosystem. J. Vis. Exp. (106), e53398 (2015).

- Whitaker, T. B., Dorner, J. W., Giesbrecht, F. G., Slate, A. B. Variability among aflatoxin test results on runner peanuts harvested from small field plots. Peanut Sci. 31 (1), 59-63 (2004).

Reprints and Permissions

Request permission to reuse the text or figures of this JoVE article

Request PermissionThis article has been published

Video Coming Soon

Copyright © 2025 MyJoVE Corporation. All rights reserved