JoVE Science Education

Materials Engineering

A subscription to JoVE is required to view this content.

Nanocrystalline Alloys and Nano-grain Size Stability

Source: Sina Shahbazmohamadi and Peiman Shahbeigi-Roodposhti-Roodposhti, School of Engineering, University of Connecticut, Storrs, CT

Alloys with grain size less than 100 nm are known as nanocrystaline alloys. Due to their enhanced physical and mechanical properties, there is an ever-increasing demand to employ them in various industries such as semiconductor, biosensors and aerospace.

To improve the processing and application of nanocrystalline alloys, it is necessary to develop close to 100% dense bulk materials which requires a synergistic effect of elevated temperature and pressure. By increasing the applied temperature and pressure, small grains start to grow and lose their distinguished properties. Thus, it is technologically important to reach a compromise between inter-particle bonding with minimum porosity and loss of nano-scale grain size during consolidating at elevated temperatures.

In this study we aim to eliminate oxygen from solid solution to improve the nano-grain size stability at elevated temperatures. Nano-crystalline Fe-14Cr-4Hf alloy will be synthesized in a protected environment to avoid oxide particles formation.

- File the high purity low oxygen content bulk materials (Fe, Cr and Hf targets) in the glove box using a reciprocating mechanical filing machine in order to minimize oxygen contamination in the starting powders.

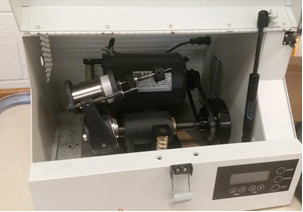

- Load the powder mixture for a specific alloy (Fe14Cr4Hf wt.% in this study) into a stainless-steel vial along with 440C stainless steel milling balls (Fig. 1). The diameters of the milling balls are 6.4 and 7.9 mm and the ball powder-to-weight ratio is 10:1. The sealed vial needs to be kept under prot

Fig. 3 shows the XRD data for ball-milled OF-Fe14Cr4Hf annealed for one hour at 900°C. There is sharpening of the peaks along with slight peak shifts. It is due to relaxation of lattice strain as the annealing temperature rises. When the annealing temperature rises, several small peaks are revealed between the four major BCC peaks. These would indicate the formation of secondary phases.

Fig. 4a-c shows TEM images and diffraction pattern for OF-Fe14Cr4Hf annealed for 1 hour at

The experiment demonstrates how the nano-grain size stability of the nominally oxygen free nanocrystalline materials may improves compare to the alloys with significant amount of oxygen. In this study the OF powders synthesized in a protected atmosphere to minimize the interaction between oxygen and solid solution leads to increase the segregation of alloying elements to the grain boundaries and improve the thermodynamic grain size stability. TEM microscope introduced itself as a cost-effective, time-saving and powerful

Skip to...

Videos from this collection:

Now Playing

Nanocrystalline Alloys and Nano-grain Size Stability

Materials Engineering

5.1K Views

Optical Materialography Part 1: Sample Preparation

Materials Engineering

15.3K Views

Optical Materialography Part 2: Image Analysis

Materials Engineering

10.9K Views

X-ray Photoelectron Spectroscopy

Materials Engineering

21.4K Views

X-ray Diffraction

Materials Engineering

87.6K Views

Focused Ion Beams

Materials Engineering

8.8K Views

Directional Solidification and Phase Stabilization

Materials Engineering

6.5K Views

Differential Scanning Calorimetry

Materials Engineering

36.3K Views

Thermal Diffusivity and the Laser Flash Method

Materials Engineering

13.1K Views

Electroplating of Thin Films

Materials Engineering

19.5K Views

Analysis of Thermal Expansion via Dilatometry

Materials Engineering

15.5K Views

Electrochemical Impedance Spectroscopy

Materials Engineering

22.9K Views

Ceramic-matrix Composite Materials and Their Bending Properties

Materials Engineering

8.0K Views

Hydrogel Synthesis

Materials Engineering

23.4K Views

ISSN 2640-0510

Copyright © 2025 MyJoVE Corporation. All rights reserved

We use cookies to enhance your experience on our website.

By continuing to use our website or clicking “Continue”, you are agreeing to accept our cookies.