A subscription to JoVE is required to view this content. Sign in or start your free trial.

Method Article

Design and Control of a High-Dynamic Modular Reconfigurable Legged Robotic System

In This Article

Summary

Here, we present a protocol to enable beginners to replicate a highly dynamic bipedal robotic system and a modular quadrupedal robot composed of bipeds as the smallest units.

Abstract

Legged robots possess exceptional terrain adaptability, making them an ideal platform for outdoor exploration and cargo transport across complex terrains. The number and configuration of legs play a crucial role in their performance; however, most current designs are monolithic, lacking the flexibility for reconfiguration. The protocol presented in this paper details the design and fabrication of a modular legged robot system with robust walking capabilities and flexible reconfiguration between bipedal and quadrupedal configurations. First, various functional modules are mechanically assembled to complete the construction of the bipedal platform and the assembly of the modular connecting device. Subsequently, using debugging software, we configured the inertial measurement unit and motors, including set controller area network (CAN) identity (ID), baud rate, and other working parameters to ensure they are in the correct working state. Then, we designed a whole-body control strategy and a distributed control framework to ensure stable walking of the bipedal unit and coordinated movement of the assembled structure, respectively. Finally, we validated the system's effectiveness on both bipedal and quadrupedal configurations, enabling the robot to achieve stable outdoor walking.

Introduction

Legged robots, utilizing a discrete support mechanism, exhibit superior terrain adaptability and agility1,2. In recent years, legged robots have been deployed in scenarios such as rescue and search operations, achieving favorable results3,4,5. Legged robots of various configurations offer distinct advantages for different tasks. Bipedal robots, with their simple design, can navigate narrow spaces but have limited load capacity. Quadrupedal robots are more complex but can carry heavier loads and move faster. Robots with six or more legs provide greater stability but are harder to maintain. However, existing legged robots generally employ an integrated design characterized by a singular configuration that lacks the flexibility to adapt or switch between different configurations6,7,8. This design approach results in a high incidence of faults and presents significant maintenance challenges, as single points of failure may lead to system collapse. In contrast, robots designed with the modular assembly concept can easily reconfigure to meet different task requirements9,10. When facing rugged terrain, they can enhance their traversability by increasing the number of legs or modules11.

Currently, research on modular legged robots is still in the exploratory stage, primarily focusing on small or miniature-legged platforms, which mainly move by crawling or slithering11,12,13,14,15. Some assembly sub-modules even lack independent movement capabilities and can only achieve mobility when combined16,17. This makes them difficult to deploy in practical scenarios for tasks such as transportation and reconnaissance. To address these challenges, this paper proposes a modular-legged robotic system with flexible mobility capabilities. Distinct from previous methods, the legs of the assembly sub-modules in this paper are inspired by the mammalian leg configuration, providing rapid running capabilities. We select the bipedal robot as the smallest splicing module due to its simple structure, stable walking capability, and more human-like walking style18,19.

Additionally, some of the modular legged robots mentioned above use latches or fasteners to connect modules12, weakening their rapid connection and disconnection capabilities. To simplify the connection process and avoid the use of clips and fasteners, we employ an electromagnetic attachment mechanism between modules, with controllable and flexible activation/deactivation of the magnetic force. To fully leverage the advantages of the modular legged robot, we employ a distributed control approach to manage the locomotion of the robot discussed in this paper. The effectiveness of the constructed system and the control method has been validated through prototype experiments. The proposed system may assist in addressing the needs of large-scale material transport in unstructured terrains or rapid reconnaissance in unknown environments.

The objective of this protocol is to thoroughly present the design and manufacturing process of the system described in this paper, enabling interested parties to replicate or create robots with similar functionality to meet their needs. The bipedal module in this paper is based on our previous work. We have installed a docking mechanism on it and performed parameter fine-tuning20.

Protocol

1. Construction of the machine

- Assemble the linkage, housing, and calf using screws and fasteners, and then connect the assembled linkage to the motor output shaft's key pin using fasteners (Figure 1).

NOTE: The leg, which comprises the linkage, motor, bearings, etc., is the primary component of the robot responsible for its motion. - Initialize the motors using the software provided by the motor manufacturer. This includes the calibration of Hall sensors and encoders.

- Fasten the two assembled legs with carbon fiber plates and appropriate connectors to create a bipedal structure, as illustrated (Figure 2).

- Fix the carbon fiber tube to both sides of the docking device with screws and secure the electromagnet in its central groove (see Figure 3).

2. Building the control box

- Assemble the power board based on the circuit schematic and physical diagram shown in Figure 4.

- Position and secure the power management module, inertial measurement unit (IMU), microcontroller unit (MCU), and other components in their designated locations as illustrated (Figure 5).

- Connect the universal serial bus (USB) port of the MCU to the IMU using the JT30-USB connector.

- Link the Ethernet port of the MCU to the router using an Ethernet cable.

- Use wiring to connect the motor switch, MCU switch, and main switch to their corresponding interfaces on the power management module.

- Connect the serial peripheral interface (SPI) board's CAN1 and CAN2 interfaces to the power management module's CAN1 and CAN2 interfaces, respectively.

- Link all motors to the power and CAN interfaces on the power management module via their corresponding interfaces.

NOTE: The left leg's motors are linked to the left-side power and CAN interfaces on the power management module via the left-side connector on the control box; the right side is connected similarly.

3. Debugging the motors

- Open the motor debugging software. Connect the computer to the debug motor with a USB-CAN module.

- Assign the motor's CAN ID. Set the value of ab/ad to 1, hip to 2, and knee to 3.

- Set the joint zero position and positive direction sequentially, as shown in Figure 6.

4. Control scheme

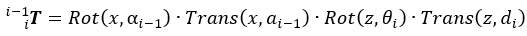

- Establish the kinematic transmission relationship between the robot's links as given by

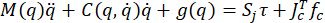

NOTE: The z axis aligns with the joint axis i while the axis aligns along the common perpendicular between joint axes i and i + 1, directed from joint i to i + 1. If the axes intersect, xi is perpendicular to the plane of intersection. ai-1 is the rotation angle about xi-1 from zi-1 to zi; ai-1 is the distance along xi-1 from zi-1 to zi; θi is the rotation angle about zi from xi-1 to xi; and di is the distance along zi from xi-1 to xi. - Establish full body dynamic equation given by

NOTE: Jc and fc denote the Jacobian matrix mapping foot forces to joint space and the foot contact force, respectively. M(q) is the inertia matrix, represents centrifugal and Coriolis terms, and g(q) is the gravitational force on the robot.

represents centrifugal and Coriolis terms, and g(q) is the gravitational force on the robot. - Establish whole-body balance control equations.

NOTE: The control law for the bipedal module integrates virtual model control (VMC) and whole-body control (WBC). For detailed control equations, refer to a previous work20.

5. Write the program

- Use ST-LINK to import the binary (BIN) file of the communication program between the MCU and the motor into the SPI board.

NOTE: The SPI board serves as the communication module between the MCU and the motors, with the STM32 as the control core. - Transmit the compiled robot locomotion control program from the PC to the MCU via an Ethernet cable.

6. Starting the bipedal robot module

- Set the robot to the initial posture, as illustrated (Figure 7A).

- Launch the executable file compiled from the control code on the MCU.

- Send the stand command to the robot using the remote control (Figure 7B).

NOTE: The remote control buttons can be configured as needed. It is recommended that the joystick be used to control speed and the buttons switch between different states. - Activate the robot's locomotion mode via the remote control (Figure 7C).

- Use the remote control's joystick to maneuver the robot forward, backward, and steer.

7. Starting the modulary reconfigured quadruped robot

- Configure the routers of the two bipedal modules to be on the same network segment.

- Establish the distributed control framework based on Lightweight Communications and Marshalling (LCM)21.

- Install the assembled splicing device components on the head of the biped robot.

- Position the two bipedal modules in the initial state as specified and activate the magnetic force of the splicing device.

- Launch the executable programs of the two bipedal modules separately.

- Transmit the standing command to the robot via the remote control.

- Activate the robot's locomotion mode via the remote control.

- Use the remote control's joystick to maneuver the splicing robot forward, backward, and steer.

Results

To validate the effectiveness of the proposed system, we conducted outdoor walking tests on multiple terrains. Initially, a single bipedal module was selected as the test subject, and motion tests were conducted on both artificial grass and a synthetic track. As shown in Figure 8, the robot demonstrated stable locomotion on both terrains. The posture and joint torque data of the robot during locomotion are shown in Figure 9. The amplitude of the robot's roll...

Discussion

The modular legged robot proposed in this paper offers a new perspective on legged robot design, where reconfiguration and coordinated movement are achieved through the combination of multiple distributed leg modules. This approach presented in this paper has been experimentally validated, confirming its capability for configuration reconfiguration and coordinated movement. Sections 1, 2, 4, and 5 in this protocol represent the critical stages in the implementation of this design, covering the development of both the rob...

Disclosures

The authors declare that they have no competing financial interests.

Acknowledgements

The authors would like to express their gratitude to Mr. Xianwu Zeng for his assistance in performing the experiments reported in this paper. This work was supported in part by the National Natural Science Foundation of China (62373223) and the Natural Science Foundation of Shandong Province (ZR2024ZD06).

Materials

| Name | Company | Catalog Number | Comments |

| Battery | YOBOTICS | https://yobotics.cn/ | |

| Electromagnet | Kaka Electric | H25 | |

| Electronic component | JLC | https://yobotics.cn/ | Including commonly used components such as resistors, capacitors, inductors, etc |

| IMU | LORD | 3DM-GX5-45 | |

| Motor | YOBOTICS | https://yobotics.cn/ | |

| Power Management Module | JLC | P1 | |

| Remote control | Ledi | https://yobotics.cn/ | |

| Router | linwlan | GX30 | |

| SPI | YOBOTICS | https://yobotics.cn/ | |

| Structural parts | 3D printing service | N/A | M1-1, M1-2, M1-3, M1-4, M1-5, M1-6, U1, U2, LX1, LX2,LX3, LX4 |

References

- Hutter, M., et al. Anymal-a highly mobile and dynamic quadrupedal robot. , (2016).

- Bledt, G., et al. Mit cheetah 3: Design and control of a robust, dynamic quadruped robot. , (1109).

- Jung, T., et al. Development of the humanoid disaster response platform DRC-HUBO+. IEEE Trans Robot. 34 (1), 1-17 (2018).

- Kaneko, K., et al. Humanoid robot HRP-5P: An electrically actuated humanoid robot with high-power and wide-range joints. IEEE Robot Autom Lett. 4 (2), 1431-1438 (2019).

- Bernreiter, L., et al. A framework for collaborative multi-robot mapping using spectral graph wavelets. Int J Rob Res. 43 (13), 2070-2088 (2024).

- . Atlas, the next generation Available from: https://bostondynamics.com/atlas/ (2016)

- Hubicki, C., et al. Atrias: Design and validation of a tether-free 3D-capable spring-mass bipedal robot. Int J Rob Res. 35 (12), 1497-1521 (2016).

- Huang, Q., et al. . Historical Development of BHR Humanoid Robots. Explorations in the History and Heritage of Machines and Mechanisms. History of Mechanism and Machine Science. , (2019).

- Wang, J., Hu, C., Zhu, Y. J. I. R., Letters, A. CPG-based hierarchical locomotion control for modular quadrupedal robots using deep reinforcement learning. IEEE Robot Autom Lett. 6 (4), 7193-7200 (2021).

- Daudelin, J., et al. An integrated system for perception-driven autonomy with modular robots. Sci Robot. 3 (23), eaat4983 (2018).

- Chong, B., et al. Multilegged matter transport: A framework for locomotion on noisy landscapes. Science. 380 (6644), 509-515 (2023).

- Mahkam, N., Bakir, A., Özcan, O. Miniature modular legged robot with compliant backbones. IEEE Robot Autom Lett. 5 (3), 3923-3930 (2020).

- Ohira, M., Chatterjee, R., Kamegawa, T., Matsuno, F. Development of three-legged modular robots and demonstration of collaborative task execution. , 3895-3900 (2007).

- Yang, Z., et al. A unit-compressible modular robotic system and its self-configuration strategy using meta-module. Robot Comput-Integr Manuf. 49, 39-53 (2018).

- Ozkan-Aydin, Y., Goldman, D. I. Self-reconfigurable multilegged robot swarms collectively accomplish challenging terradynamic tasks. Sci Robot. 6 (56), eabf1628 (2021).

- Kim, J., Alspach, A., Yamane, K. Snapbot: A reconfigurable legged robot. , (1109).

- Gim, K. G., Kim, J. Snapbot v2: A reconfigurable legged robot with a camera for self configuration recognition. , (1109).

- Li, J., Nguyen, Q. Force-and-moment-based model predictive control for achieving highly dynamic locomotion on bipedal robots. , (1109).

- Gong, Y., et al. Feedback control of a cassie bipedal robot: Walking, standing, and riding a segway. , (2019).

- Zhu, Z., et al. Design and control of braver: A bipedal robot actuated via proprioceptive electric motors. Auton Robots. 47 (8), 1229-1243 (2023).

- Huang, A. S., Olson, E., Moore, D. C. Lcm: Lightweight communications and marshalling. , (2010).

- Yoshiike, T., et al. Development of experimental legged robot for inspection and disaster response in plants. , (1109).

- Kumagai, I., et al. Toward industrialization of humanoid robots: Autonomous plasterboard installation to improve safety and efficiency. IEEE Robot Autom Mag. 26 (4), 20-29 (2019).

Reprints and Permissions

Request permission to reuse the text or figures of this JoVE article

Request PermissionThis article has been published

Video Coming Soon

Copyright © 2025 MyJoVE Corporation. All rights reserved