Aby wyświetlić tę treść, wymagana jest subskrypcja JoVE. Zaloguj się lub rozpocznij bezpłatny okres próbny.

Method Article

A Rapid Method for Modeling a Variable Cycle Engine

W tym Artykule

Podsumowanie

Here, we present a protocol to build a component-level mathematical model for a variable cycle engine.

Streszczenie

The variable cycle engines (VCE) that combine the advantages of turbofan and turbojet engines, are widely considered to be the next generation aircraft engines. However, developing VCE requires high costs. Thus, it is essential to build a mathematical model when developing an aircraft engine, which may avoid a large number of real tests and reduce the cost dramatically. Modeling is also crucial in control law development. In this article, based on a graphical simulation environment, a rapid method for modeling a double bypass variable cycle engine using object-oriented modeling technology and modular hierarchical architecture is described. Firstly, the mathematical model of each component is built based on the thermodynamic calculation. Then, a hierarchical engine model is built via the combination of each component mathematical model and the N-R solver module. Finally, the static and dynamic simulations are carried out in the model and the simulation results prove the effectiveness of the modeling method. The VCE model built through this method has the advantages of clear structure and real-time observation.

Wprowadzenie

Modern aircraft demands bring great challenges to the propulsion system, which need more intelligent, more efficient or even more versatile aircraft engines1. Future military propulsion systems also require both higher thrust at high speed and lower specific fuel consumption at low speed1,2,3,4. In order to meet the technical requirements of future flight missions, General Electric (GE) put forward the variable cycle engine (VCE) concept in 19555. A VCE is an aircraft engine that can perform different thermodynamic cycles by changing the geometry size or position of some components6. The Lockheed SR-71 "Blackbird" powered by a J58 turboramjet VCE has held the world record for the fastest air-breathing manned aircraft since 19767. It also proved many potential advantages of supersonic flight. In the past 50 years, GE has improved and invented several other VCEs, including a double bypass VCE8, a controlled pressure ratio engine9 and an adaptive cycle engine10. These studies involved not only the general structure and performance verification, but also the control system of the engine11. These studies have proven that the VCE can work like a high bypass ratio turbofan at subsonic flight and like a low bypass ratio turbofan, even like a turbojet at supersonic flight. Thus, the VCE can realize performance matching under different flight conditions.

When developing a VCE, a large amount of necessary verification works will be carried out. It may cost a large amount of time and outlay if all these works are performed in a physical way12. Computer simulation technology, which has already been adopted in developing a new engine, can not only reduce the cost greatly, but also avoid the potential risks13,14. Based on computer simulation technology, the development cycle of an engine will be reduced to nearly half, and the number of equipment required will be reduced dramatically15. On the other hand, simulation also plays an important role in the analysis of the engine behavior and control law development. For simulating the static design and off-design performance of engines, a program called GENENG16 was developed by the NASA Lewis Research Center in 1972. Then the research center developed DYNGEN17 derived from GENENG, and DYNGEN could simulate the transient performance of a turbojet and the turbofan engines. In 1989, NASA put forward a project, called Numerical Propulsion System Simulation (NPSS), and it encouraged researchers to construct a modular and flexible engine simulation program through the use of object-oriented programming. In 1993, John A. Reed developed the Turbofan Engine Simulation System (TESS) based on the Application Visualization System (AVS) platform through object-oriented programing18.

Meanwhile, rapid modeling based on graphical programming environment is being used gradually in simulation. The Toolbox for the Modeling and Analysis of Thermodynamic Systems (T-MATS) package developed by NASA is based on Matlab/Simulink platform. It is open source and allows users to customize built-in component libraries. T-MATS offers a friendly interface to users and it is convenient to analyze and design the built-in JT9D model19.

In this article, the dynamic model of a type of VCE has been developed here using Simulink software. The modeling object of this protocol is a double bypass VCE. Its schematic layout is shown in Figure 1. The engine can work in both single and double bypass modes. When the Mode Select Valve (MSV) is open, the engine performs better at subsonic conditions with a relatively large bypass ratio. When the Mode Select Valve is closed, the VCE has a small bypass ratio and a better supersonic mission adaptability. To further quantize performance of the engine, a double bypass VCE model is built based on component-level modeling method.

Access restricted. Please log in or start a trial to view this content.

Protokół

1. Preparation before modeling

- Obtain design point performance.

- Open Gasturb 13. Select Variable Cycle Engine.

- Click on Basic Thermodynamics. Select Cycle Design. Open DemoVarCyc.CVC.

- Obtain the engine design point performance. These are shown on the right side of the window.

- Obtain component maps.

- Open Gasturb 13. Select Variable Cycle Engine.

- Click on Off Design. Select Standard Maps. Open DemoVarCyc.CVC.

- Click on Off Design Point. Then select LPC, IPC, HPC, HPT and LPT; thus, all components maps are obtained.

2. Model each component of the VCE20,21,22

- Model a single component of a VCE. Take the high-pressure compressor as an example.

- Open Matlab. Click on Simulink. Double click on Blank Model.

- Click on Library, and place function to model.

- Double click on Function. According to the working principle of the compressor, the thermodynamic equation of the compressor is described. Then describe the equation with the MATLAB function.

- After finishing the MATLAB function, obtain the input and output of the compressor.

- Use Subsystem to mask the module. Then rename it with “compressor”. Thus far, a subsystem module called “compressor” is established.

- Use the same steps to get the subsystems of all components including inlet, fan, duct, core driven fan stage(CDFS), bypass mixer, compressor, burner, high-pressure turbine, low-pressure turbine, mixer, afterburner and nozzle.

- Combine output of each component with input of the next component.

3. Solution of the whole model

- Construct dynamic co-working equations of whole model.

- Construct dynamic co-working equations. Construct the following 6 independent co-working equations.

- Determine the flow balance equation for inlet and outlet of burner:

Wa3: compressor outlet section air flow, Wf: burner fuel flow, Wg44: high-pressure turbine inlet gas flow. - Determine the flow balance equation for inlet and outlet of low-pressure turbine:

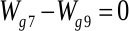

Wg44: low-pressure turbine inlet section gas flow, Wg5: low-pressure turbine outlet gas flow. - Determine the flow balance equation for inlet and outlet of nozzle:

Wg7: nozzle inlet gas flow, Wg9: nozzle outlet gas flow. - Determine the static pressure balance equation for inlet of rear mixer:

Ps163: static pressure of main outer bypass outlet, Ps63: static pressure of inner bypass outlet. - Determine the flow balance equation of fan inlet and outlet:

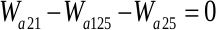

Wa2: fan inlet air flow, Wa21: CDFS inlet air flow, Wa13: sub-outer bypass inlet air flow - Determine the flow balance equation of CDFS outlet:

Wa21: CDFS inlet air flow, Wa125: CDFS bypass inlet air flow, Wa25: compressor inlet air flow. - The above 6 independent equations constitute the following equations.

- Use the N-R iteration solver in TMATS to solve the above equations.

- Before using the solver to solve the co-working equations, set the N-R iteration solver. According to the modeling process, select the following 6 initial guesses: component map auxiliaries line of fan, CDFS, high-pressure compressor, high-pressure turbine and low-pressure turbine β1, β2, β3, β4, β5, sub-outer bypass inlet flow.

Access restricted. Please log in or start a trial to view this content.

Wyniki

In order to prove the validity of the simulation model, several typical performance parameters selected in static and dynamic simulations are compared with the data in Gasturb.

In a static simulation, we compare several key performance parameters of the model with these parameters in Gasturb to verify the accuracy of the static model. Table 2 shows the result of the comparison at the design point with H=0 m, Ma=0, Wf=0.79334 kg/s under a double bypass ope...

Access restricted. Please log in or start a trial to view this content.

Dyskusje

Based on a graphical simulation environment, a VCE component-level model can be built rapidly through modular hierarchical architecture and object-oriented modeling technology. It offers a friendly interface to users and it is convenient to analyze and design the model19.

The main limitation of this method is the execution efficiency of the model. Because the model is written in scripting language, the model needs to be recompiled every time it runs. Thus, the execution...

Access restricted. Please log in or start a trial to view this content.

Ujawnienia

We have nothing to disclose.

Podziękowania

This research was funded by the Fundamental Research Funds for the Central Universities, grant number [No. NS2018017].

Access restricted. Please log in or start a trial to view this content.

Materiały

| Name | Company | Catalog Number | Comments |

| Gasturb | GasTurb GmbH | Gasturb 13 | |

| MATLAB | MathWorks | R2017b | |

| TMATS | NASA | 1.2.0 |

Odniesienia

- Bin, L., Min, C., Zhili, Z. Steady Performance Investigation on Various Modes of an Adaptive Cycle Aero-Engine [J]. Propulsion Technology. 34 (8), 1009-1015 (2013).

- Junchao, Z., Min, C., Hailong, T. Matching mechanism analysis on an adaptive cycle engine. Chinese Journal of Aeronautics. (2), 22(2017).

- Lyu, Y., Tang, H., Chen, M. A study on combined variable geometries regulation of adaptive cycle engine during throttling. Applied Sciences. 6 (12), 374(2016).

- Ruffles, P. C. Aero engines of the future. Aeronautical Journal. 107 (1072), 307-321 (2003).

- Johnson, J. Variable cycle engine developments at General Electric 1955-1995. Developments In High-Speed Vehicle Propulsion Systems. , 105-158 (1995).

- NASA VCE test bed engine aerodynamic performance characteristics and test results. French, M., Allen, C. The 17th Joint Propulsion Conference in Colorado Springs, CO, , 1594(1981).

- Variable-cycle engines for supersonic cruising aircraft. Willis, E., Welliver, A. The 12th Propulsion Conference in Palo Alto, CA, , 759(1976).

- Allan, R. General Electric Company variable cycle engine technology demonstrator programs. The 15th Joint Propulsion Conference in Las Vegas, NV, , 1311(1979).

- Keith, B. D., Basu, D. K., Stevens, C. Aerodynamic Test Results of Controlled Pressure Ratio Engine (COPE) Dual Spool Air Turbine Rotating Rig. ASME Turbo Expo 2000: Power for Land, Sea, and Air. , American Society of Mechanical Engineers. V001T003A105-V001T003A105 (2000).

- US Patent. , 10/719,884 (2005).

- Study of an Airbreathing Variable Cycle Engine. Vyvey, P., Bosschaerts, W., Fernandez Villace, V., Paniagua, G. The 47th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit in, San Diego, CA, , 5758(2011).

- LIU, Z., WANG, Z., HUANG, H., Cai, Y. H. Numerical simulation on performance of variable cycle engines. Journal of Aerospace Power. 25 (6), 1310-1315 (2010).

- Loftin, L. K. Toward a second-generation supersonic transport. Journal of Aircraft. 11 (1), 3-9 (1974).

- Mavris, D. N., Pinon, O. J. Complex Systems Design & Management. , Springer. 1-25 (2012).

- Reed, J. A., Follen, G. J., Afjeh, A. A. Improving the aircraft design process using Web-based modeling and simulation. ACM Transactions on Modeling and Computer Simulation (TOMACS). 10 (1), 58-83 (2000).

- Koenig, R. W., Fishbach, L. H. GENENG: A Program for calculating design and off-design performance for turbojet and turbofan engines. NASA Technical Note TN. D-6552. , (1972).

- Sellers, J. F., Daniele, C. J. DYNGEN: A program for calculating steady-state and transient performance of turbojet and turbofan engines. NASA Technical Note TN. D-7901. , (1975).

- Development of an interactive graphical propulsion system simulator. The 30th Joint Propulsion Conference and Exhibit in Indianapolis, IN. Reed, J., Afjeh, A. , (1994).

- Chapman, J. W., Lavelle, T. M., May, R., Litt, J. S., Guo, T. H. Propulsion System Simulation Using the Toolbox for the Modeling and Analysis of Thermodynamic Systems (T MATS). 50th AIAA/ASME/SAE/ASEE Joint Propulsion Conference 2014, Cleveland, Ohio, , (2014).

- Camporeale, S., Fortunato, B., Mastrovito, M. A modular code for real time dynamic simulation of gas turbines in simulink. Journal of Engineering for Gas Turbines and Power. 128 (3), 506-517 (2006).

- Tsoutsanis, E., Meskin, N. Dynamic performance simulation and control of gas turbines used for hybrid gas/wind energy applications. Applied Thermal Engineering. 147, 122-142 (2019).

- Reed, J., Afjeh, A. An extensible object-oriented framework for distributed computational simulation of gas turbine propulsion systems. The 34th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit in Cleveland, OH, , 3565(1998).

- Muir, D. E., Saravanamuttoo, H. I., Marshall, D. Health monitoring of variable geometry gas turbines for the Canadian Navy. Journal of Engineering for Gas Turbines and Power. 111 (2), 244-250 (1989).

Access restricted. Please log in or start a trial to view this content.

Przedruki i uprawnienia

Zapytaj o uprawnienia na użycie tekstu lub obrazów z tego artykułu JoVE

Zapytaj o uprawnieniaThis article has been published

Video Coming Soon

Copyright © 2025 MyJoVE Corporation. Wszelkie prawa zastrzeżone