É necessária uma assinatura da JoVE para visualizar este conteúdo. Faça login ou comece sua avaliação gratuita.

Method Article

A purificação Protocolo Tailored HPLC que os rendimentos de alta pureza beta-amilóide 42 e beta-amilóide 40 Peptides, capaz de Formação Olig�ero

Neste Artigo

Resumo

Herein we report a tailored HPLC purification protocol that yields high-purity amyloid beta 42 (Aβ42) and amyloid beta 40 (Aβ40) peptides, capable of oligomer formation. Amyloid beta is a highly aggregation prone, hydrophobic peptide implicated in Alzheimer's disease. The amyloidogenic nature of the peptide makes its purification a challenge.

Resumo

Amyloidogenic peptides such as the Alzheimer's disease-implicated Amyloid beta (Aβ), can present a significant challenge when trying to obtain high purity material. Here we present a tailored HPLC purification protocol to produce high-purity amyloid beta 42 (Aβ42) and amyloid beta 40 (Aβ40) peptides. We have found that the combination of commercially available hydrophobic poly(styrene/divinylbenzene) stationary phase, polymer laboratory reverse phase - styrenedivinylbenzene (PLRP-S) under high pH conditions, enables the attainment of high purity (>95%) Aβ42 in a single chromatographic run. The purification is highly reproducible and can be amended to both semi-preparative and analytical conditions depending upon the amount of material wished to be purified. The protocol can also be applied to the Aβ40 peptide with identical success and without the need to alter the method.

Introdução

A doença de Alzheimer é uma doença neurodegenerativa que os efeitos de mais de 35 milhões de pessoas em todo o mundo. 1 Implicado fortemente no início e desenvolvimento da doença, é altamente propensos a agregação, peptídeo hidrofóbico beta-amilóide (Ap). Ap 2 varia de 36 a 43 aminoácidos de comprimento, no entanto, pensa-se que o 42-amino ácido variante, beta amilóide 42 (Aβ42), é a forma mais tóxica da proteína. 3 Isto é devido em grande parte à capacidade de Aβ42 para formar prontamente difus�eis, espécies oligoméricas que se acredita ser entidades particularmente neurotóxicos. 4 A fim de promover nossa compreensão do peptídeo Aâ, é essencial para obter rotineiramente material de alta pureza. A presença de vestígios de impurezas foi mostrado para alterar drasticamente as propriedades de agregação propensão do péptido. 5

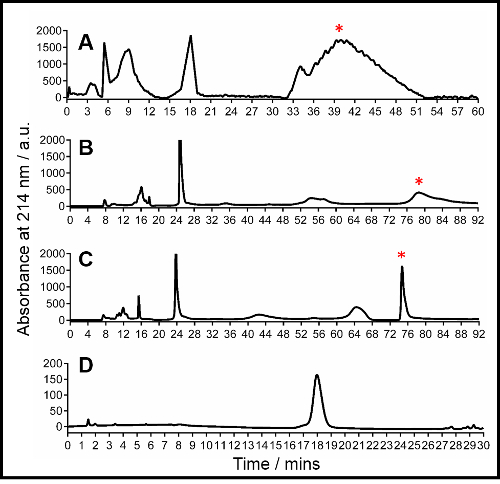

Traditionally, a cromatografia líquida (HPLC) de separação dos péptidos hidrofóbicos, tais como Ap alto desempenho tem sido feito através da utilização de uma combinação de C 4 ou C 8 fases estacionárias à base de sílica e uma fase móvel de ácido. 6 No entanto, tais condições podem apresentar um desafio para a purificação do péptido. O ponto isoeléctrico baixo do péptido Ap (pi de aproximadamente 5,5) 7 significa que, sob condições ácidas, a agregação peptídica é aumentada e, como resultado grandes picos de HPLC, não resolvidas que são muitas vezes difíceis de isolar são produzidas (Figura 2A). Além disso, esses picos largos contêm frequentemente impurezas que podem ter impacto no perfil de agregação do peptídeo, e geralmente requerem ciclos subsequentes de purificação, que podem ter impacto dramaticamente a quantidade de péptido produzida.

O poli (estireno / divinilbenzeno) de fase estacionária, PLRP-S, representa um meio alternativo de PurifYing péptidos hidrofóbicos. A fase estacionária foi utilizado na purificação de um número de diferentes proteínas e ácidos ribonucleicos mensageiro (mRNA). 8, 9 A fase estacionária PLRP-S requer nenhum ligando de alquilo adicional para a separação de fase reversa, e o mais importante é quimicamente estável a um pH elevado, que leva a desagregação do péptido. 7 Relata-se um protocolo de purificação HPLC adaptado que produz alta pureza amyloid beta 42 (Aβ42) e beta 40 peptídeos amilóides (Aβ40).

Protocolo

1. Preparative HPLC Purification of the Aβ40 or Aβ42 Peptide

- Prepare the following buffers for the HPLC purification.

- Prepare buffer A (20 mM NH4OH) by adding 1.3 mL of NH4OH (28% solution) to 1,000 mL of ultrapure water.

- Prepare buffer B (80% acetonitrile with 20 mM NH4OH) by adding 1.3 mL of NH4OH (28% solution) to a solution of 800 mL of HPLC-grade acetonitrile and 200 mL of ultrapure water.

- Prepare sample dissolution buffer (0.1% NH4OH) by adding 100 µL of NH4OH (28% solution) to 100 mL of ultrapure water.

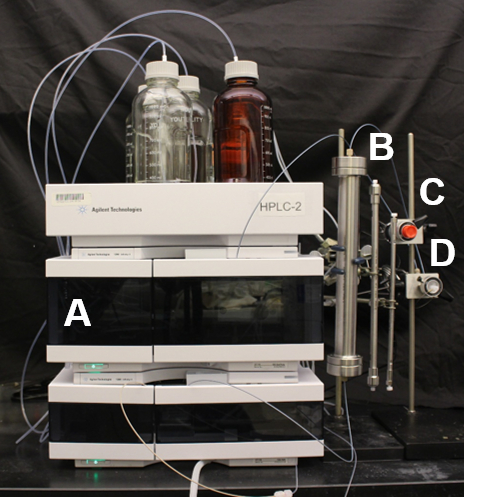

- Setup the HPLC instrument as shown in Figure 1.

- Fit the solvent bottles that contain buffer A and buffer B to the inlets of the HPLC pump using polymer tubing. Attach the polymer tubing to the HPLC pump with a one-piece fitting. Ensure that the polymer tubing of each buffer is fitted to the correct inlet valve of the instrument. Fit the HPLC pump with a degasser.

- Couple the HPLC pump with the inlet of the 300 Å 8 µm 25 mm х 300 mm preparative column (Figure 1B, far left column, see Materials List) using polymer tubing.

- Attach the polymer tubing to the preparative column with a one-piece finger tight fitting. Ensure that the polymer column is orientated in the correct manner.

NOTE: The stationary phase of the preparative column is comprised of poly(styrene-divinylbenzene) particles. The correct orientation of the polymer column is marked on the outer casing with a single directional arrow.

- Attach the polymer tubing to the preparative column with a one-piece finger tight fitting. Ensure that the polymer column is orientated in the correct manner.

- Connect the outlet of the column to the dual wavelength detector using polymer tubing and set the wavelength detector to 214 nm and 280 nm.

- Alter the wavelength by changing the detection wavelength parameters in the setup instrument method option of the built-in HPLC software.

- Attach the polymer tubing to the inlet of the wavelength detector with a one-piece finger tight fitting. Attach polymer tubing to the output valve of the wavelength detector. Attach the polymer tubing to the outlet valve of the HPLC detector with a one-piece finger tight fitting. This will be the sample collection tubing.

NOTE: The lack of a strong chromophore on the Aβ peptide dictates that 214 nm be used as the primary ultraviolet (UV) wavelength for peak collection.

Figure 1: Experimental setup of the HPLC instrument used for purification of the amyloid beta peptides. (A) The quaternary HPLC pump fitted with a degasser and variable wavelength detector set to 214 nm and 280 nm; (B) HPLC columns used for purification of the amyloid beta peptides, from left to right, 25 x 300 mm2 preparative column, 7.5 x 300 mm2 semi preparative column and 4.6 x 250 mm2 analytical column; (C) Manual injector with 20 µL stainless steel injection loop used for analytical HPLC; (D) Manual injector with 10 mL stainless steel injection loop used for preparative and semi preparative purification. Please click here to view a larger version of this figure.

- Program the HPLC software to run the purification method as shown in Table 1. Enter the purification method by changing the solvent timetable parameter (in the setup instrument method option built into the HPLC software). Turn on the HPLC pump by clicking the "on" button on the HPLC software.

NOTE: The pump will begin supplying starting ratio of buffer A and buffer B through the preparative column and the HPLC instrument.- Leave the system for 30 min to fully equilibrate.

| Time / min | % of Buffer Aa | % of Buffer Bb | Flow Rated / mL min-1 |

| 0 | 80 | 20 | 6 |

| 45 | 75.5 | 24.5 | 6 |

| 45.01 | 80 | 20 | 6 |

| 52.01 | 80 | 20 | 6 |

| 52.02 | 73 | 27 | 6 |

| 85 | 73 | 27 | 6 |

| 92 | 5 | 95c | 6 |

Table 1: Timetable for the purification of the Aβ42 and Aβ40 peptides using the 25 × 300 mm polymer column. aBuffer A - H2O with 20 mM NH4OH; b80% MeCN / 20% H2O with 20 mM NH4OH; cRan for 15 min to wash the column prior to the next injection of sample; dIn order to run a flow rate of 6 mL/min on the HPLC instrumentation, the pressure limit needs to be reduced to 200 bar.

- Purification of the Aβ peptide sample

Note: The crude peptide was obtained through automated solid-phase peptide synthesis.10- Dissolve 3 mg of crude Aβ peptide in 4 mL of the sample dissolution buffer. Sonicate the sample for 30-60 s at room temperature and at a frequency of 40 kHz to aid dissolution.

- Inject the entire sample onto the HPLC column using a 5 mL plastic syringe fitted with a 16-gauge stainless steel needle. Run the purification method as outlined in sub-step 1.3.

NOTE: The system enables sample injection to be done through the use of a manual injector fitted with a 10 mL stainless steel injection loop (Figure 1D). The desired Aβ peptide will elute between 72 and 74 min as a sharp resolved peak (Figure 2C). - Collect the sample into a 50 mL conical centrifuge tube. Confirm the identity of the Aβ peak through direct injection mass spectrometry of the collected eluent.11 Store the eluent for up to 12 h at -20 °C.

NOTE: Storage of the solution for periods longer than 12 h is not advised due to the potential for oxidation of the peptide. - Isolate the purified peptide by flash freezing the collected aliquot/aliquots of the Aβ peptide in liquid nitrogen and lyophilize. Perform lyophilization by freeze-drying the sample at a temperature of -60 °C and a pressure of 20 mTorr for a period of 24 h.

- Run the analytical HPLC protocol as outlined below to determine the purity of the Aβ peptide. Store peptides in their lyophilized form at -20 °C for a period of up to 6 months.

2. Analytical HPLC Analysis of the Purified Aβ Protein

- Prepare the HPLC buffers as outlined in sub-section 1.1. of the above protocol.

- Setup the analytical HPLC as per step 1.2.1 and as depicted in Figure 1 with the 4.6 × 250 mm analytical column (Figure 1B, far right column) and the manual injector with 20 µL stainless steel injection loop (Figure 1C) fitted to the instrument.

- Program the HPLC software to run the analytical method as shown in Table 2 following instructions similar to those in step 1.3.

| Time / min | % of Buffer Aa | % of Buffer Bb | Flow Rate / mL min-1 |

| 0 | 95 | 5 | 1 |

| 30 | 50 | 50 | 1 |

Table 2: Timetable for the HPLC purity analysis of the Aβ peptide. aBuffer A - H2O with 20 mM NH4OH; b80% MeCN / 20% H2O with 20 mM NH4OH.

- Purity analysis of the Aβ peptide

- Prepare a 1 mg/mL solution of the purified peptide through dissolution of the peptide in the sample buffer solution.

NOTE: The buffer recipe can be found in sub-section 1.1. Protein concentration is determined by measuring the protein absorption at 280 nm (A280nm).12 The molar extinction coefficient (ε) used to determine concentration is ε = 1,490 dm3 mol-1 cm-1.13 - Inject 20 µL of the 1 mg/mL (222 µM) solution onto the HPLC column and run the analytical method that was setup in step 2.3.

NOTE: The remaining solution not used for analysis can be flash frozen in liquid nitrogen and lyophilized to recover the Aβ peptide. Lyophilization details can be found in sub-section 1.4.4. The Aβ peptide will elute from the analytical column between 16 and 18 min (Figure 2D). Use the built-in integration analysis software that accompanies the HPLC instrument to determine the purity of the Aβ peptide. Purity is determined by integrating each of the individual peaks on the spectrum and calculating peptide-peak percentage area. Typically, a purification of >95% should be ascertained.

- Prepare a 1 mg/mL solution of the purified peptide through dissolution of the peptide in the sample buffer solution.

Figure 2: Representative HPLC traces of Aβ42. (A) Traditional C4 silica purification, conditions: Buffer A: H2O with 0.1% trifluoroacetic acid (TFA), buffer B: MeCN (acetonitrile) with 0.1% TFA, gradient: 20 to 27% buffer B over 40 min followed by isocratic 27% buffer B; (B) Preparative purification using the 25 x 300 mm2 polymer column, conditions: Buffer A: H2O with 20 mM NH4OH, buffer B: 80% MeCN / 20% H2O with 20 mM NH4OH, gradient: 20 to 27% buffer B over 70 min followed by isocratic 27% buffer B; (C) Optimized preparative purification using the 25 x 300 mm2 polymer column, conditions are described in Table 1 located in sub-section 1.3 of the protocol description text; (D) Analytical HPLC using the 4.6 x 250 mm2 polymer column, conditions: Buffer A: H2O with 20 mM NH4OH, buffer B: 80% MeCN / 20% H2O with 20 mM NH4OH, gradient-5 to 50% buffer B over 30 min. For parts A, B and C the peak corresponding to Aβ42 is marked by an asterisk. Collection of the marked Aβ42 peak in part C reveals a purity of >95% as shown in part D. Mass spectrometry was used to determine the identity of the Aβ42 peak. Please click here to view a larger version of this figure.

Resultados

The purification of the Aβ42 peptide using a combination of the PLRP-S stationary phase and a high pH mobile phase results in the formation of a sharp, resolved peak for the Aβ peptide at a retention time between 72 and 74 min (Figure 2C). Confirmation of the identity of the peak is done through direct injection mass spectrometry of the collected eluent. The eluent can be stored at -20 °C in solution for up to 12 h. Longer periods of storage may result in o...

Discussão

The HPLC purification of the Aβ peptide is highly dependent upon the choice of both the stationary phase employed in the purification and the mobile phase chosen to elute the peptide. The low isoelectric point of the peptide and high propensity for aggregation render traditional chromatographic conditions for the separation of hydrophobic proteins (C4 or C8 stationary phase coupled with an acidic mobile eluent) challenging, with the Aβ peptide eluting as a prolonged broad, non-resolved peak (Figure 2A

Divulgações

The authors have nothing to disclose.

Agradecimentos

The authors would like to thank Agilent for their technical assistance. Kate Markham and Rafael Palomino are credited for their initial help in the synthesis and purification of the Aβ peptide and Dr Hsiau-Wei Lee is thanked for his help in preparing Figure 1 of the manuscript.

Materiais

| Name | Company | Catalog Number | Comments |

| Agilent 1260 Infinity II quarternary pump | Agilent | G7111B | http://www.agilent.com/en-us/products/liquid-chromatography/lc-pumps-vacuum-degassers/1260-infinity-ii-quaternary-pump |

| Agilent 1260 Infinity II Dual variable wavelength detector | Agilent | G7114A | http://www.agilent.com/en-us/products/liquid-chromatography/lc-detectors/1260-infinity-ii-variable-wavelength-detector |

| Agilent 1260 Infinity II Manual Injector fitted with 10 mL stainless steel sample loop | Agilent | 0101-1232 | http://www.agilent.com/en-us/products/liquid-chromatography/lc-injection-systems/1260-infinity-ii-manual-injector |

| Agilent 1260 Infinity II Manual Injector fitted with 20 µL stainless steel sample loop | Agilent | G1328C | http://www.agilent.com/en-us/products/liquid-chromatography/lc-injection-systems/1260-infinity-ii-manual-injector |

| Ring Stand Mounting Bracket | Agilent | 1400-3166 | |

| Agilent PLRP-S 300 Å 5 µm 4.6 x 250 mm (Analytical) | Agilent | PL1512-5501 | http://www.agilent.com/en-us/products/liquid-chromatography/lc-columns/biomolecule-separations/plrp-s-for-biomolecules#features |

| Aβ42 or Aβ40 peptide | Synthesized in-house using a CEM liberty automated peptide synthesizer. | ||

| Ammonium Hydroxide (NH4OH, 28% solution) | Fisher Scientific | A669-500 | |

| Acetonitrile | Fisher Scientific | A998-4 | |

| HPLC grade water | Fisher Scientific | W5-4 | |

| Falcon 50 mL conical centrifuge tube | Fisher Scientific | 14-954-49A | |

| Supelco PEEK Fitting One-piece fingertight, pkg of 5 ea | Sigma-Aldrich | Z227250 | |

| Normject 5 cc sterile syringe | Fisher Scientific | 1481729 | |

| 16 Gauge SS Needle | Rheodyne | 3725-086 |

Referências

- Querfurth, H. W., LaFerla, F. M. Alzheimer's Disease. N. Engl. J. Med. 362 (4), 329-344 (2010).

- McGowan, E., et al. Aβ42 Is Essential for Parenchymal and Vascular Amyloid Deposition in Mice. Neuron. 47 (2), 191-199 (2005).

- Gong, Y., et al. Alzheimer's disease-affected brain: Presence of oligomeric Aβ ligands (ADDLs) suggests a molecular basis for reversible memory loss. Proc. Natl. Acad. Sci. USA. 100 (18), 10417-10422 (2003).

- Selkoe, D. J. Soluble Oligomers of the Amyloid β-Protein Impair Synaptic Plasticity and Behavior. Behav Brain Res. 192 (1), 106-113 (2008).

- Zagorski, M. G., Yang, J., Shao, H., Ma, K., Zeng, H., Hong, A. Methodological and Chemical Factors Affecting Amyloid β Peptide Amyloidogenicity. Methods Enzymol. 309, 189-204 (1999).

- Kim, W., Hecht, M. H. Mutations Enhance the Aggregation Propensity of the Alzheimer's Aβ Peptide. J Mol Bio. 377 (2), 565-574 (2008).

- Fezoui, Y., et al. An improved method of preparing the amyloid beta-protein for fibrillogenesis and neurotoxicity experiments. Amyloid. 7 (3), 166-178 (2000).

- Zhelev, N. Z., Barratt, M. J., Mahadevan, L. C. Use of reversed-phase high-performance liquid chromatography on polystyrene-divinylbenzene columns for the rapid separation and purification of acid-soluble nuclear proteins. J Chromatogr A. 763 (1-2), 65-70 (1997).

- Thess, A., et al. Sequence-engineered mRNA Without Chemical Nucleoside Modifications Enables an Effective Protein Therapy in Large Animals. Mol Ther. 23 (9), 1456-1464 (2015).

- Warner, C. J. A., Dutta, S., Foley, A. R., Raskatov, J. A. Introduction of D-glutamate at a critical residue of Aβ42 stabilizes a pre-fibrillary aggregate with enhanced toxicity. Chem Eur J. 22 (34), 11967-11970 (2016).

- Thompson, J. A., Lim, T. K., Barrow, C. J. On-line High-performance Liquid Chromatography/Mass Spectrometric Investigation of Amyloid-β Peptide Variants Found in Alzheimer's Disease. Rapid Commun. Mass Spectrom. 13 (23), 2348-2351 (1999).

- Layne, E. Spectrophotometric and turbidimetric methods for measuring proteins. Met. Enzymology. 3, 447-455 (1957).

- Ioannou, J. C., Donald, A. M., Tromp, R. H. Characterizing the secondary structure changes occurring in high density systems of BLG dissolved in aqueous pH 3 buffer. Food Hydro. 46, 216-225 (2015).

- Rahimi, F., Maiti, P., Bitan, G. Photo-Induced Cross-Linking of Unmodified Proteins (PICUP) Applied to Amyloidogenic Peptides. J. Vis. Exp. (23), e1071 (2009).

- Bitan, G., Kirkitadze, M. D., Lomakin, A., Vollers, S. S., Benedek, G. B., Teplow, D. B. Amyloid β-protein (Aβ) assembly: Aβ40 and Aβ42 oligomerize through distinct pathways. Proc. Natl. Acad. Sci. USA. 100 (1), 330-335 (2003).

Reimpressões e Permissões

Solicitar permissão para reutilizar o texto ou figuras deste artigo JoVE

Solicitar PermissãoThis article has been published

Video Coming Soon

Copyright © 2025 MyJoVE Corporation. Todos os direitos reservados