A subscription to JoVE is required to view this content. Sign in or start your free trial.

Ultrasound-Induced Neuromodulation Using a Microelectrode Array System

In This Article

Overview

This video demonstrates the method for inducing the modulation of neural activity in cultured human iPSC-derived neurons in a multi-well microelectrode array, or MEA system using a focused ultrasound transducer.

Protocol

1. Preparation of materials

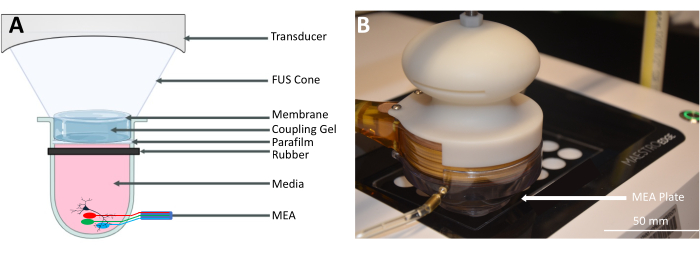

- Aspirate the culture medium and use it to fill a single well in a 24-well neuron culture plate with an embedded microelectrode array (MEA) (Figure 1A).

- Sterilize the parafilm interface, the rubber band, and the focused ultrasound (FUS) cone with its rubber membrane using 70% ethanol for 10 min, and place them in the fume hood for later assembly.

- Degas 300 mL of deionized water and 50 mL of coupling gel. Centrifuge the water and gel at 160 x g for 5 min to avoid inducing cavitation within the coupling medium.

NOTE: The original source of the human induced pluripotent stem cells (HiPSCs) is from GM01582 and CIPS cell lines. On average, a density of 5 x 104 motor neurons and 2.5 x 104 astrocytes per well can be achieved.

2. Connection and setup of the peripherals

- Secure the FUS cone to the transducer using screws, and seal the cone with a flexible rubber membrane in a ventilated sterile hood. Fill the cone with the degassed and deionized (DG-DI) water from step 1.3, and ensure the absence of bubbles in the cone to avoid cavitation.

- Use a customized threaded rod to secure the 3D-printed holder to a frame (Figure 1B). Position the frame such that the head of the FUS transducer is over the well that will be stimulated.

- Use a rubber band to secure parafilm over the well on the 24-well MEA plate containing the medium and the HiPSCs.

- Prepare the FUS system by connecting the ultrasound transducer's back-end driver electronics, in this case, the transducer power output (TPO), to a 100-240 V power outlet and connecting the matching network to the TPO and the FUS transducer. The matching network ensures efficient electrical coupling between the transducer and the TPO.

- Connect the MEA system to a power outlet (100-240 V) (Figure 2B, Connection 5). Connect the MEA system synchronization port to the TPO (Figure 2B, Connection 3). This connection will synchronize the data acquisition by the MEA system with the FUS stimulation.

- Place the 24-well MEA plate in the MEA system, and remove the lid to enable direct contact between the transducer and the well. Place the transducer 5-10 mm above the well plate to allow room for the degassed coupling gel, as described in step 3.2 (Figure 2A and Figure 1B).

3. Stimulation and neuronal signal acquisition

- Set the FUS parameters on the TPO control panel (Table 1).

- Apply the coupling gel on top of the parafilm, and lower the FUS transducer into the coupling gel, ensuring contact with the gel with minimal air bubbles (Figure 1A).

- Start the MEA system recording by clicking on the Start button on the user interface.

- Start the FUS sonication by pressing the bottom right button on the TPO (Figure 2A, Label 7), and wait at least 5 min between each round of sonication to allow the neurons to return to a baseline state.

- Use the trigger pulse generated by the FUS system to align the FUS stimulation sequence to the MEA recording (Figure 1B, Connection 3).

Table 1: Focused ultrasound (FUS) parameters set on the TPO

| Parameter | Value |

| Max Power/Ch | 1.200 W |

| Pactual | 0.749 W/channel |

| ISPPA | 10.79 W/cm2 |

| ISPTA | 0.05 W/cm2 |

| Burst Length | 0.100 ms |

| Frequency | 250.00 kHz |

| Focus | 39.800 mm |

| Period | 20.000 ms |

| Timer | 60.000 s |

Access restricted. Please log in or start a trial to view this content.

النتائج

Figure 1: FUS neuromodulation with a multi-well microelectrode array (MEA). (A) Schematic of the setup for FUS neuromodulation with a multi-well MEA. The acoustic waves generated by the FUS transducer propagate through an FUS cone filled with degassed water and are coupled using ultrasound gel. The parafilm is secured to the well using a rubber band to prevent contamination. The MEA plate sends electrical recordings from the neurons to the MEA system. (B) A photograph of the FUS transducer on the multi-well plate contained in the MEA system.

Figure 2: In vitro platform setup. (A) The front of the in vitro platform setup. The transducer power output (TPO; left) is used to program the FUS parameters. The MEA system (right) records electrical activity from the neurons in the well plate, which are neuromodulated by the FUS transducer. (B) The back of the in vitro platform is set up with connections from the matching network (1) to the TPO and (2) to the transducer. (3) The connection from the MEA system to the TPO synchronizes the data acquisition. (4) The connection from the MEA system to the computer for data transfer. (5) The power connection to the MEA system. (6) The power connection to the FUS system. (7) The sonication button.

Access restricted. Please log in or start a trial to view this content.

Disclosures

Materials

| Name | Company | Catalog Number | Comments |

| MEA System | Axion Biosystem Inc. | Maestro Edge | Sampling Rate: 11500 Hz |

| MEA Plate | Axion Biosystem Inc. | CytoView MEA | Electrode and Well: 16 electrodes in 24 wells |

| Well plate Interface | Amcor Inc. | Parafilm PM996; P7793 | Thickness: 127 µm |

| CO2 Tank and Regulator for culture | AirGas Inc./ Harris Inc. | 9296NC | Concentration: 5% |

| Culture Media | ThermoFisher Inc. | Laminin; 23017-015 | Concentration: 1 µg/mL |

| HiPSC Neurons | Peprotech | CIPS and GM01582 Derived; 450-10 | Concentration: 10 ng/mL (Refer Taga et al [2021]13) |

| Transducer | Sonic Concepts Inc. | CTX250; 008 | Center Frequency: 250 kHz |

| Matching Network | Sonic Concepts Inc. | CTX250; NFS102v2 | Impedance: 50 Ω |

| Transducer Power Output (TPO) | Sonic Concepts Inc. | Version 4.1; 020 | Frequency: From 250 kHz to 2.5 MHz |

| Membrane | McMaster Inc. | Silicone Rubber; 5542N115 | Thickness: 0.0127 cm |

| Coupling Gel | Parker Laboratory Inc. | Aquasonic 100; B08DDWG GXB | Viscosity: 130,000–185,000 cops |

| Connection to Probe holder | McMaster Inc. | Steal Threaded Rod; 90322A661 | Length: 1–1/2" Long |

| Hydrophone | Sonic Concepts Inc. | Y-104; 009 | Range: 50 kHz–1.9 MHz |

| Water Tank | Sonic Concepts Inc. | WT | Size: 30 cm x 30 cm x 30 cm |

| Water Conditioning Unit | Sonic Concepts Inc. | WCU; SN006 | Flow Velocity: 50 mL/s maximum |

| Oscilloscope | Rohde-Schwarz Inc. | RTC1002 | Sampling rate: Up to 50 MHz |

| Stage | Sonic Concepts Inc. | MicroStage; 2 | Accuracy: 1 µm |

| Thermochromic sheet | TIPTEMP Inc. | Liquid Crystal Sheet; TLCSEN337 | Range: 22–24 °C |

| Computer | Microsoft Surface | Surface Pro | CPU i5 1035G4: 3.7 GHz |

| Data Transfer Software | Mathworks Inc. | MATLAB | Version 2021b |

| Processing Software | Python Software Foundation | Python | Version 3.7.10 |

References

Access restricted. Please log in or start a trial to view this content.

This article has been published

Video Coming Soon

Source: Liang, R. et al., Focused Ultrasound Neuromodulation of Human In Vitro Neural Cultures in Multi-Well Microelectrode Arrays. J. Vis. Exp. (2024)

Copyright © 2025 MyJoVE Corporation. All rights reserved