Method Article

高性能炸药的研究与发展

Erratum Notice

摘要

Developmental testing of high explosives for military applications involves small-scale formulation, safety testing, and finally detonation performance tests to verify theoretical calculations. This paper will share typical development tests associated with the measurement of detonation velocity and detonation pressure.

摘要

高爆炸药军事应用的发展测试包括小规模的配方,安全测试,终于引爆性能测试,以验证理论计算。小规模对于新开发的配方中,该过程开始于小规模的混合物,热测试,并冲击和摩擦的灵敏度。才做后续较大规模的制剂进行爆震检测,这将在本文中被覆盖。在表征技术的最新进展已经导致了爆炸的早时间演化的表征无双精度。光多普勒测速仪(PDV)为爆轰压力和速度的测量的新技术将被共享,并与引爆压力的传统的光纤爆速和板状凹痕计算比较。特别是,铝在炸药配方中的作用将被讨论。最近的事态发展导致爆炸性f的发展在爆炸产品扩张很早导致铝反应ormulations。这种增强的反应导致在爆轰速度和压力由于与在膨胀的气体的产品氧的铝的反应的变化。

引言

高爆炸药用于军事用途的开发涉及广泛的安全考虑,由于测试设施要求的资源限制。在美国陆军军备研究开发和工程司令部(ARDEC)皮卡汀尼兵工厂,炸药等从整个生命周期的监测和非军事化的研究水平评估。对于处理,储存,和装载有更安全的新的炸药在努力提供对战士有效和安全的弹药连续评估。最近的法律规定,只要有可能,钝感弹药(IM)准则和要求得到遵守。因此,每当新的炸药被合成和配方,性能测试是至关重要的,以确保它们符合用户的要求。在这种情况下,新研制的PAX-30的爆轰性能的测量是用PBXN-5,一个传统高性能炸药相比。在其引爆VELO特别,测量城市和爆轰压力,这是理论模型和性能计算的验证重要,是共享的。在PAX-30的开发利用无铝来代替传统炸药如PBXN-5。

铝具有氧化作用的高焓铝在每摩尔的基础:

2AL + 3/2 O 2 - > 的 Al 2 O 3(1670千焦/摩尔)

通过代替震动敏感炸药成分加入铝,制剂呈现更安全的外部冲击和危险损伤。这有效地帮助实现钝感弹药(IM)联合国要求,而在同一时间保持必要的军事应用的性能。2,3.4

这些设施,以测试这些项目是独一无二的,专业性强。一些初步试验进行大批量使用前筛查炸药。 ŧHESE测试包括用差示扫描量热法(DSC)和冲击和摩擦试验热特性。对于在DSC测试中,一个小的测试样品在惰性气氛中以恒定速率加热,以及金额和热流的方向被监测。冲击和摩擦试验,将样品经受从标准化落锤(Bundesanstalt献给Materialprufung,或BAM影响)辱骂,和用于摩擦试验的标准化陶瓷销和板(Bundesanstalt献给Materialprufung,或BAM摩擦)。5

一旦配方被视为对处理安全,进一步扩大规模是由专有的混合技术来实现的。总之,高能炸药分为三类:

熔融流延,其中,所述粘合剂是熔融相材料如蜡,三硝基甲苯(TNT),dintroanisole(DNAN),或其它可熔化材料。精力充沛或燃料固体可以认真考虑齐名被纳入视察员大小和兼容性。

浇铸固化,其中,所述粘合剂是可浇注的聚合物,如羟基封端聚丁二烯(HTPB),聚丙烯酸酯,或其它环氧型的塑料,处于其未反应的状态的液体,但在起始固化成固体。固体其液体状态期间并入基质。

压,其中,所述固体负荷非常高,经常达到了将近95%(重量),条件是加入到涂层用漆或挤压过程中的固体粘合剂。

一旦按下或铸造,材料使用标准的方法,以获得正确的几何形状为期望的测试加工。在本文中,大同-30和PBXN-5是高性能炸药压制。该制剂通过浆料涂布方法,其中高能硝胺晶体(HMX,RDX,或CL-20)和铝粒子悬浮在水溶液中进行。与专有粘合剂我的漆记者随后补充道。在漆此外,聚合物涂层的炸药的结晶,将悬浮液真空下加热以驱除溶剂,然后过滤,并干燥所述颗粒。然后将颗粒样颗粒被压到所期望的配置。

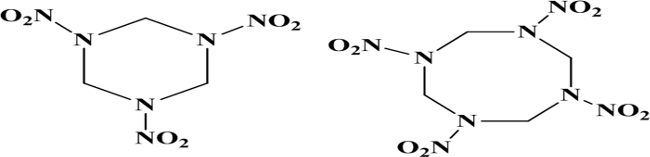

爆速

为了确定爆速,必须监视爆轰前的材料中的到来。一个暴炸被定义为压力和温度的自我维持的瞬时上升比材料中的声音速度。一旦温度和压力足以提供传播反应前后面的放热反应就变成自持。这种行为是通过将氧化部分如在地层的某些材料硝酸盐基团来实现。称为RDX(环-1,3,5-三亚甲基-2,4,6- trinitramine)和HMX(环四)的两个实例示我Q图1,它大体上是美国国防部最常用的含能材料(国防部)。注意分子的氧平衡,这导致在冲击前后面的自蔓延放热反应。

图1. RDX(环-1,3,5-三亚甲基-2,4,6- trinitramine,左)和HMX(环四,右)。 请点击此处查看该图的放大版本。

确定爆震前的速度的一种方法是监控其作为时间的函数的位置。光纤爆速(FODV)测试被执行以确定爆炸材料的爆速。丙烯酸夹具的目的是要保持炸药样品,并找到光在纤维已知的距离下充电长度。标准测试采用的是5英寸长,有五个总光纤0.75英寸直径的爆炸样本;底部纤维从电荷的底部位于0.50英寸和每个连续纤维位于1英寸以上的下一个。在丙烯酸类夹具钻出孔有两个阶梯孔。的较大直径的孔的尺寸以适合光纤的纤芯和包层和较小直径孔用作密闭空气空间。作为爆震前进通过爆炸物样品,所产生的冲击波激励产生可与光导纤维观察短,明亮的闪光的密闭空气空间。

用于此测试的光导纤维具有便宜的塑料芯。由于测试的破坏性质和空气震动的一致性,均未发现更高品质的纤维是必要的,以保持高质量的速度数据。在皮卡汀尼兵工厂的试验设施使用求和光电二极管的光从爆震成电压转换。电压尖峰的幅度是不重要此测试的目的。 A 1 GHz的示波器连接到光电二极管求和中,尽管这采样率是远远超出了必要的测试。光纤"峰",可以由信号或峰值的第一上升被任一确定。定光纤和爆轰到达之间的时间差之间的距离,爆速然后确定。

爆压

爆轰压力是通过测量从炸药的爆轰标准钢板所得的凹痕深度估计。登特深度以及相关的已知的压力值,各种易燃易爆化合物。一般,由于大多数炸药满足发生爆震查普曼-Jouguet(CJ)条件,爆轰压力通常被称为作为CJ压力,这将是从这个角度提出在这篇文章。充电组件被放置在一个钢板,称为"验证板",并且在该板的凹痕的爆轰结果的顶部。在标准的0.75英寸装药直径为已知爆轰压力许多炸药材料的凹痕深度然后比较测试凹痕深度。由板凹痕爆压是具有多年可接受相关记录的数据的可靠的方法。然而,爆轰是一个动态的,快速化学反应,并在近几年已成为需要利用工具以更高的分辨率观察压力 - 时间历史记录。

直接测量炸药的爆轰压力,光子多普勒测速(PDV)也可以使用。该激光干涉仪系统是由劳伦斯·利弗莫尔国家实验室开发和利用1550nm波长连续激光源。通过在移动目标的引导激光Ð收集多普勒频移的光,所产生的拍频进行分析,以提供所述目标的速度轨迹。不同于传统的高速摄影技巧,这些速度痕迹提供目标的速度为时间的函数的连续记录。这种测量技术取得了显著的关注,在过去几年中,并正在成为美国国防部和能源部(DOE)炸药实验室表征无所不在。

为了计算新的炸药的CJ压力,一个PDV系统可用于测量炸药和聚甲基丙烯酸甲酯(PMMA)窗口之间的粒子速度。一个非常薄的金属箔,通常是铝或铜,被放置在该界面充当反射表面。在这些研究中,使用铜。此箔片应该足够薄,以防止显著冲击波衰减同时又足够厚,以防止穿过爆轰的光。通常情况下,箔的厚度为1000埃是理想的最具实验性的设置。定在聚甲基丙烯酸甲酯粒子的速度和炸药的爆轰速度,爆轰压力可以与雨贡纽休克匹配方程来计算。6

而在0.75"充电直径FODV测试是在ARDEC一个既定的标准,基于PDV-测试不断进行完善。根据不同的炸药配方,任一种或两种测试可以用来表征爆速和爆轰压力。

研究方案

警告!加工,处理和高爆炸药试验(危害司1级材料)只能由经过培训合格的人员进行。高爆炸药是撞击,摩擦,静电放电和冲击敏感。仅使用批准的研究和开发设施,可处理大量的1级材料。

1. ARDEC光纤爆速测试

- 切割光纤使用光纤切割长度和套五类电缆捆绑。基于位点特异性测试室的几何形状,通常使用15米长度。条带电缆护套材料上的束的一个端部5毫米的束的另一端部背面15mm以下。抛光光导纤维用P800砂纸的切割端,以消除任何毛刺。

注意:由于此测试的破坏性质,塑料光纤是优选的。光纤的性能如下;聚甲基丙烯酸甲酯树脂甲酯(PMMA)的芯材(直径980微米),含氟聚合物包层材料(直径1000微米),1.49芯折射率,0.5数值孔径。 - 使用高精度卡尺测量平衡试验样品和成分A-3型II助推器颗粒的直径,长度和群众。

注意:虽然典型的测试2.54厘米长粒料使用1.905厘米直径,试验程序也可以与任何尺寸的颗粒可以使用,只要该塑料夹具保持集中在每个粒料的光纤电缆。在本研究的试验中,使用1.905厘米直径的颗粒。 - 经由撬槽开扩管的内径装载炸药颗粒,逐一放入塑料夹具。记录炸药粒料号码和在夹具的位置。然后升压粒料从夹具顶部装入管中。

- 放置丙烯酸雷管夹持器上增压粒料的顶部。

注:RP-502爆炸的雷管桥丝(EBWs)通常使用。其它雷管可以被取代,虽然试验的重新校准是必要的。 - 插入光纤的较短暴露端(5毫米)浸入在爆速测试夹具的两阶梯孔。

注意:两步孔确保在引爆前这导致一个强烈的信号的通道有足够的空气电离。对于夹具孔的直径应0.021英寸由对炸药0.020长度内孔和用于光纤插入一0.042英寸直径的孔。如果使用塑料纤维,光纤的外径的光砂磨可以根据两者的纤维直径和测试夹具的公差是必要的。确保该光纤被完全插入(坐在在两台阶孔的步骤)。 - 胶/环氧树脂代替纤维。使用5分钟环氧这个协议。

- 当环氧捧在纤维已完全固化,定位压克力含在钢证人板顶部的爆炸性颗粒IC管。固定文本夹具钢板或在它的上面或磁带的重量。确保有不是最后的炸药颗粒的底表面和钢证人板之间的空气间隙。

- 环氧围绕测试夹具360°,它秉承了验证板。环氧树脂完全固化后,将雷管在雷管夹持器即在测试夹具的顶部,并用胶带将其固定在适当位置。

- 传输测试夹具到测试室和光纤的较长暴露端(15毫米)插入到光电二极管求和框。连接光电二极管求和框,或其他数据采集方法,酌情示波器(1 GHz带宽是绰绰有余)。

- 连接火线到RP-80雷管。关闭所有必需的门/端口/ 等 ,每个工厂的爆炸试射进行区域锁定操作(STANDARD操作程序)标准操作程序。

- 确认示波器的触发电压/格,时间/格设置。从高电压点火器与3.0 V至一个信道在示波器的触发阈连接触发的。光电二极管总结盒连接到示波器的第二通道。将两个通道5 V /格和时基为5微秒/格,具有-20微秒延迟设置。

- 通过引爆高能点火器的项目。

- 测量从光电二极管求和盒的输出对应于时间的峰。从示波器屏幕迹,使用峰值电压来确定具体的时间,但首次上升可能会因所用的设备上一个更好的指标。

- 计算从示波器获得的五个时间点爆速。由于每个光纤的间隔是已知的,通过将各销之间的距离由时间各峰之间计算爆速(二姿态/次=速度)。都报告的平均值和标准偏差。

- 通过将校准钢轴承在凹痕找到的最低水平计算在钢证人板的凹痕的深度,然后用来确定深度的深度计。

2.照片多普勒测速

- 机的PMMA窗口尺寸设置成炸药约6.5毫米厚的直径。确保窗口是任何加工缺陷光学透明和自由。要做到这一点需要铸造丙烯酸和加工的光学透明板材使用了激光切割机或类似的加工过程中的磁盘。接着,利用水枪获得光学透明的表面。

- 确保铝箔厚度不超过0.005"每个制造商的规格。如果箔面是纯净的(镜面),辊用砂磨不锈钢球轴承的表面上。漫面效果最优激光BACķ反射,即使在对准稍微偏离。

- 使用薄的,光学透明的,基于丙烯酸的胶带的铝箔粘贴到PMMA窗口。确保有聚甲基丙烯酸甲酯和铝之间没有气泡。

- 测量炸药测试样品粒料直径,长度和质量。使用高精度卡钳和平衡。

- 加盖炸药测试样品粒料彼此以形成连续的电荷,包括任何助推器(如有必要)。在组装过程中每个爆炸性接口涂上润滑脂,以尽量减少在颗粒界面的空气间隙。

- 摩爆速销到丙烯酸夹具。这些可以是光纤或压电销。销的相对于该电荷的位置必须是已知的。

- 贴上丙烯酸爆速销座的电荷。胶带足以丙烯酸销钉保持器保持的电荷。通常情况下,光纤/引脚位置最靠近爆炸通道的底部ARGE这样稳态爆轰可以观察到。

- 附加雷管到电荷。反转组装费和稳定在这个方向,以用于固定PMMA窗口准备。放置在炸药面油脂的少量,以防止气泡在铝/炸药接口。

- 聚甲基丙烯酸甲酯窗口的箔侧贴在炸药。如果窗口和充电是同心,用胶布圆周上。如果不是这样,胶带向下炸药的轴线。

- 一旦PMMA窗口被牢固地连接到可爆炸的炸药,贴上所述丙烯酸PDV探头支架与胶带PMMA窗口。将PDV探头插入PDV探头支架。

- 对准PDV探针与背反射计的持有人。该器件输出低功率的激光束,并测量背反射振幅。 -10 dBm至-20 dBm的背面反射是可取的。环氧树脂的PDV探针代替一次背反射已被确定为最佳。

- 放置测试项目中的腔室,并连接两个爆速线(光纤或压电)和PDV纤维。一个火线连接到RP-80雷管。关闭所有必需的门/端口/等。每设施的爆炸式点火试验标准操作规程进行区域锁定操作。

- 确认示波器的触发电压/格,时间/格设置。确认PDV系统设置。观察信号激光基准激光振幅和作必要的修改。

- 通过引爆高能点火器的项目。保存示波器的痕迹为PDV数据和爆轰速度的数据。

- 分析相关数据分析程序对PDV数据。原始PDV信号必须使用快速傅立叶变换(FFT)为基础的分析包进行处理。

注意:通过查看这个原始信号的频率内容,并且知道该光源(1,550nm处)的初始频率,FFT分析包产生一个速度谱图该曲线所记录的速度为时间的函数。在这种情况下,PlotData,能源的图形用户界面(GUI)的一个专有美国部,是配合使用的LabView软件进行所述FFT。然而,许多可商购的分析软件包存在能够执行这些任务。 - 计算从示波器获得的五个时间点爆速。由于每个光纤中的间隔已知,爆轰速度除以每个销之间的距离由每个峰(距离/时间=速度)之间的时间来计算。报告的平均值和标准偏差。

结果

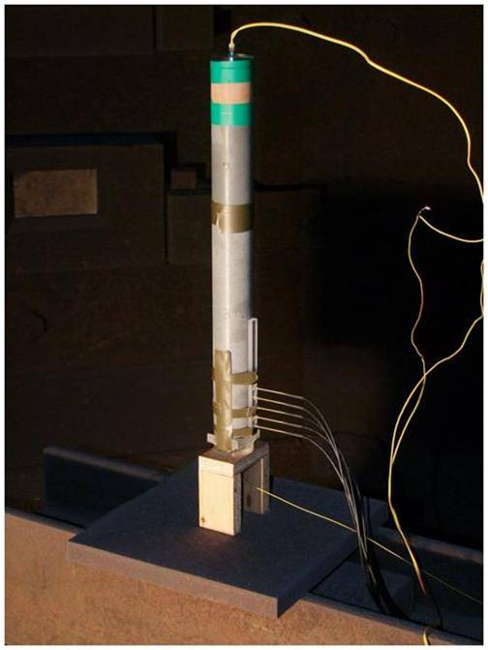

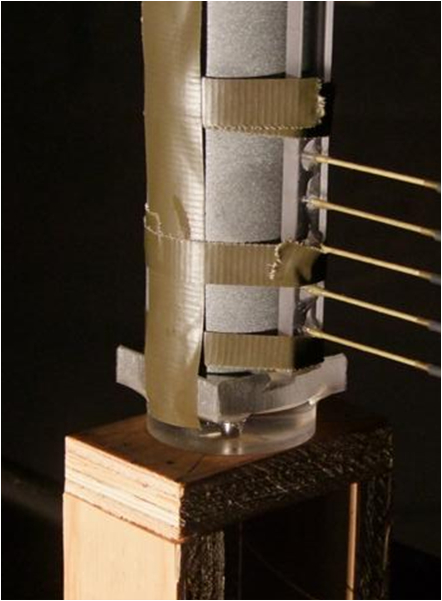

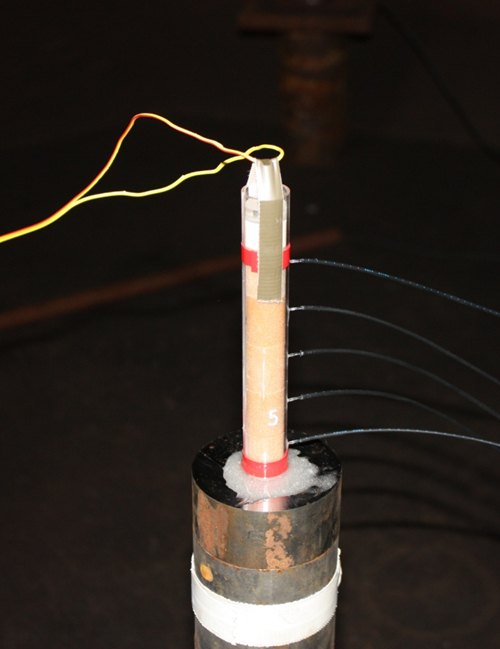

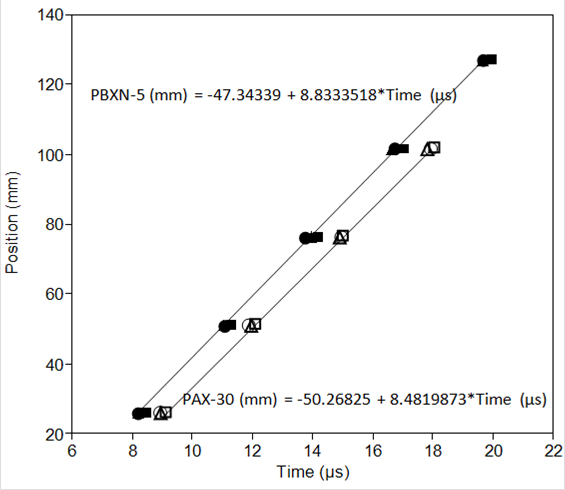

对于PDV典型的设置示出在图2和3中, 而在图4示出了FODV设置。一旦爆轰,从传统FODV拍摄所得凹痕板示于图5中,与PAX-30的位置/时间的结果和PBXN-5 在图6中。这两种材料具有相似的爆轰速度(线的斜率),以PAX-30〜0.4微秒/毫米慢。虽然它可能似乎不是一个显著的差异,这的确是在那个PAX-30具有重量炸药填少了近20%的事实光。爆轰速度是不确凿试验以量化在或引爆前后立即铝反应,但是它可以赋予铝反应的初步评估。

图2。一个典型的PDV设置。爆炸球或棒铸造堆叠。 请点击此处查看该图的放大版本。

图3. PDV设置(近景)的PDV设置在那里的飞板所在的基地。 请点击此处查看该图的放大版本。

图4. FODV设置该棒用环氧树脂的钢验证板,以确保安装过程中固体接触和正直的立场。雷管和助推器是在棒的顶部。 ="https://www.jove.com/files/ftp_upload/52950/52950fig4large.jpg"目标="_空白">点击此处查看该图的放大版本。

图 5. FODV测试凹痕。凹痕与校准深度计或轮廓仪测定。 请点击此处查看该图的放大版本。

图6。 爆轰速度的计算。每个数据点是从FODV设置光纤引脚。 PAX-30 R 2 = 0.999717,RMSE(均方根误差)= 0.519693; PBXN-5 R 2 = 0.998778,RMSE = 1.342272。OM /文件/ ftp_upload / 52950 / 52950fig6large.jpg"TARGET ="_空白">点击此处查看该图的放大版本。

| 爆炸物 | ñ | 爆速(毫米/微秒) | CJ压力 (GPA,板凹痕) | CJ压力 (GPA,PDV) |

| PBXN-5 | 3 | 8.83±0.12 | 37.9±1.4 | 34.7±0.0 |

| PAX-30 | 3 | 8.48±0.04 | 32.3±1.3 | 30.5±0.3 |

表1中。从实验性能数据。n为试验总次数,每次用5光纤引脚。该PDV CJ压力只由一个考验。

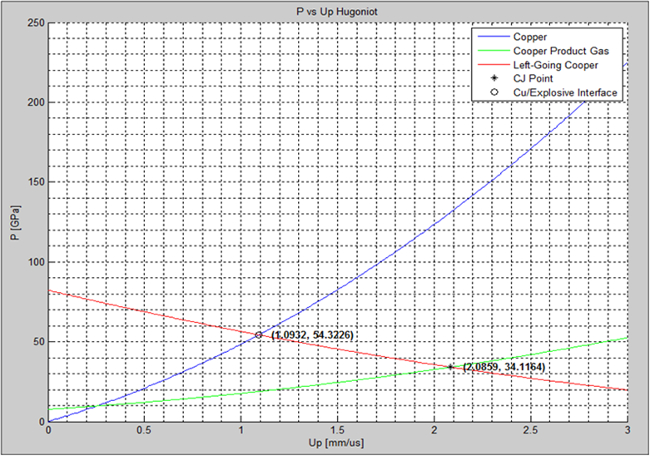

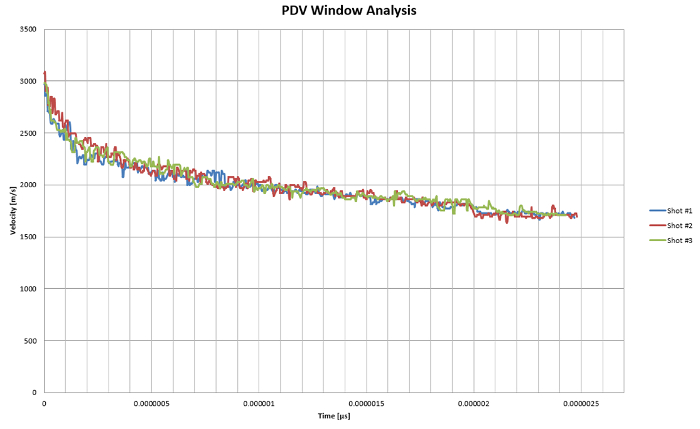

该从炸药图2-3的底部的飞板的PDV跟踪输出示于图7。从在从快速加速的板振铃近4-5千米/秒产生的振荡。在CJ压力从造型与库珀的逼近,6产品气冲击压缩,然后外推CJ点,一旦铝爆炸冲击压缩匹配计算。从这样的计算的典型屏幕打印示于图8。该技术仍然有一定的局限性,因为计算假定从传单速度的开始的线性加速度推断。这导致略微低估的压力,由结果(表1)所证明。目前正在努力开发新的公式,以适应飞板的初期加速。

上传/ 52950 / 52950fig7.jpg"/>

图7. 板速度作为时间在CJ压力的测量功能PBXN-5的爆发力。注意两个不同的镜头,那里的痕迹几乎落在彼此之间的良好的协议。 请点击此处查看大图这个数字。

图8.计算从上PDV实验铜飞板的数据CJ压力。需要注意的是外推假设在目前导致CJ压力的低估了飞板的最初推动线性加速度。 请点击这里查看该图的放大版本。</ A>

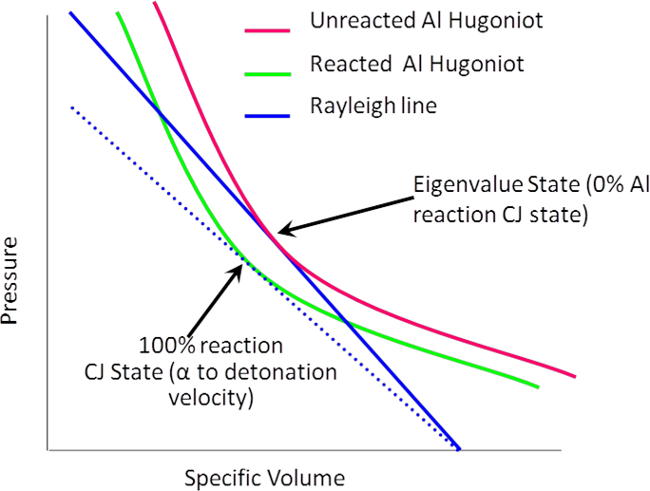

图9.描写膨胀isentropes在爆轰产物反应和未反应的铝。蓝色直线是正切的解决方案,是成正比的爆速。注意反应阿尔产品解决方案,迫使爆轰速度比未反应的铝液低。 请点击此处查看该图的放大版本。

讨论

注意两个爆炸配方之间的计算压力差。的含铝炸药展品压力以下时,部分是由于以下硝胺(HMX)装载,而且还因为铝与氧在不断扩大的爆轰气体,这导致从下爆轰压力较小的凹痕反应。该PBXN-5施加更高的爆压,由于爆炸后其较高的气体含量相比,PAX-30(36.2摩尔/千克PBXN-5对33.1摩尔/千克PAX-30)。从壁速度测量得到的状态(EOS)的更先进的方程来描述炸药产品的条件在这种极端的温度和压力。-10,11-这将是未来的手稿的主题。

很明显,当在爆炸性的金属的早期反应发生时,所检测的爆轰速度比如果金属不反应降低。这是违反直觉有点;一期望的速度,以增加当更多的能量沉积到扩大爆轰前由于铝的放热反应。在爆速的降低起因于到压力密度Hugoniots解决方案。比容(逆密度) -压力等熵线表示在从爆轰产物扩大(从左至右,如图9)的变化。6的扩张等熵线表示那些爆轰的产品,可以在热力学形成并沿特定压力-容积曲线展开。在扩张的过程中,如果铝反应形成氧化物质,它会导致在气体浓度整体减少并导致较低的速度。这表现在对非反应性铝(图9)的溶液在下面的膨胀等熵线。因为爆速是切线相交从x轴的起始密度的等熵线,显然爆轰v当在制剂中的铝反应elocity必须降低。

综上所述,国防部的美国国防部继续积极开展应用研究和与传统和新技术新高能材料的表征。在PDV的情况下,它是一种有价值的工具,特征与极端精度炸药,并提供了有价值的洞察炸药效力的研究人员。这种快速的测试周期大大降低了成本和所需的配方优化和要求核查的时间。

披露声明

A级发行:获准公开发行;分布是无限的。作者什么都没有透露。

致谢

The authors would like to thank the Future Requirement of Enhanced Energetics for Decisive Munitions (FREEDM) Program for funding, Mike Van De Waal and Gerard Gillen for their assistance in testing, Paula Cook for formulations assistance, and Ralph Acevedo and Brian Travers for pressing of the samples.

材料

| Name | Company | Catalog Number | Comments |

| cylcotetramethylenetetranitramine | BAE | Class 5 | 1.1D, High Explosive |

| Aluminum | Valimet | Proprietary | |

| Viton | 3M | ||

| Grease | Dow Corning | Sylgard 182 | Gap sealer |

参考文献

- . Title 10, Chapter 141, Section 2389. United States Code. , (2001).

- Anderson, P. E., Cook, P., Davis, A., Mychajlonka, K. The Effect of Binder Systems on Early Aluminum Reaction in Detonations. Propellants, Explosives, and Pyrotechnics. 38 (4), 486-494 (2013).

- Trzcinski, W. A., Cudzilo, S., Paszula, J. Studies of Free Field and Confined Explosions of Aluminum Enriched RDX Compositions. Propellants, Explosives, Pyrotechnics. 32 (6), 502-508 (2007).

- Volk, F., Schedlbauer, F. Products of Al Containing Explosives Detonated in Argon and Underwater. , (1995).

- United Nations. . Recommendations on the Transport of Dangerous Goods—Tests and Criteria, revisions adopted by reference (A.1), ST/SG/AC.10/11. , (2013).

- Cooper, P. W. . Explosives Engineering. , (1996).

- Chapman, D. L. On the rate of explosion in gases. Philosophical Magazine Series 5. 47 (284), 90-104 (1899).

- OT, S. t. r. a. n. d., Goosman, D. R., Martinez, C., Whitworth, T. L., Kuhlow, W. W. Compact system for high-speed velocimetry using heterodyne techniques. Review of Scientific Instruments. 77 (8), (2006).

- Manner, V. W., Pemberton, S. J. The role of Aluminum in the Detonation and Post-detonation expansion of Selected Cast HMX-Based Explosives. Propellants, Explosives, and Pyrotechnics. 37 (2), 198-206 (2012).

- Baker, E. L., Stiel, L., Balas, W., Capellos, C., Pincay, J. Combined Effects Aluminized Explosives. , (2008).

- Stiel, L. I., Baker, E. L., Capellos, C., Furnish, M. D., Elert, M., Russell, T. P., White, C. T. Study of Detonation and Cylinder Velocities for Aluminized Explosives. Shock Compression of Condensed Matter - 2005. AIP Conference Proceedings. 845, 475-478 (2006).

Erratum

Formal Correction: Erratum: Research and Development of High-performance Explosives

Posted by JoVE Editors on 6/30/2016. Citeable Link.

An erratum was issued for Research and Development of High-performance Explosives. The abstract, introduction, protocol, representative results, and acknowledgments sections were updated.

The Abstract was updated from:

Developmental testing of high explosives for military applications involves small-scale formulation, safety testing, and finally detonation performance tests to verify theoretical calculations. small-scale For newly developed formulations, the process begins with small-scale mixes, thermal testing, and impact and friction sensitivity. Only then do subsequent larger scale formulations proceed to detonation testing, which will be covered in this paper. Recent advances in characterization techniques have led to unparalleled precision in the characterization of early-time evolution of detonations. The new technique of photo-Doppler velocimetry (PDV) for the measurement of detonation pressure and velocity will be shared and compared with traditional fiber-optic detonation velocity and plate-dent calculation of detonation pressure. In particular, the role of aluminum in explosive formulations will be discussed. Recent developments led to the development of explosive formulations that result in reaction of aluminum very early in the detonation product expansion. This enhanced reaction leads to changes in the detonation velocity and pressure due to reaction of the aluminum with oxygen in the expanding gas products.

to:

Developmental testing of high explosives for military applications involves small-scale formulation, safety testing, and finally detonation performance tests to verify theoretical calculations. For newly developed formulations, the process begins with small-scale mixes, thermal testing, and impact and friction sensitivity. Only then do subsequent larger scale formulations proceed to detonation testing, which will be covered in this paper. Recent advances in characterization techniques have led to unparalleled precision in the characterization of early-time evolution of detonations. The new technique of Photonic Doppler Velocimetry (PDV) for the measurement of detonation pressure will be shared and compared with traditional fiber-optic detonation velocity and plate-dent calculation of detonation pressure. In particular, the role of aluminum in explosive formulations will be discussed. Recent developments led to the development of explosive formulations that result in reaction of aluminum very early in the detonation product expansion. This enhanced reaction leads to changes in the detonation velocity and pressure due to reaction of the aluminum with oxygen in the expanding gas products.

The Introduction's second to last paragraph was updated from:

In order to calculate the CJ pressure of a new explosive, a PDV system can be used to measure the particle velocity between the explosive and a polymethyl methacrylate (PMMA) window. A very thin foil, usually aluminum or copper, is placed at this interface to act as a reflective surface. In these studies, copper was used. This foil should be thin enough to prevent significant shock wave attenuation while being thick enough to prevent detonation light from passing through. Typically, a foil thickness of 1,000 angstroms is ideal for most experimental setups. Given the particle velocity in the PMMA and the detonation velocity of the explosive, the detonation pressure can be calculated with Hugoniot shock matching equations.6

to:

In order to calculate the CJ pressure of a new explosive, a PDV system can be used to measure the particle velocity between the explosive and a polymethyl methacrylate (PMMA) window. A very thin foil, usually aluminum or copper, is placed at this interface to act as a reflective surface. This foil should be thin enough to prevent significant shock wave attenuation while being thick enough to prevent detonation light from passing through. Typically, a foil thickness of 1,000 angstroms is ideal for most experimental setups. Given the particle velocity in the PMMA and the detonation velocity of the explosive, the detonation pressure can be calculated with Hugoniot shock matching equations.6

Step 2.1 in the Protocol was updated from:

Machine a PMMA window sized to the diameter of the explosive charge approximately 6.5mm thick. Ensure that the window is optically clear and free of any machining defects. To accomplish this take an optically clear sheet of cast acrylic and machining out the disks using a laser cutter or similar machining process. Then, utilize water jets to obtain an optically clear surface.

to:

Machine a PMMA window sized to the diameter of the explosive charge approximately 6.5mm thick. Ensure that the window is optically clear and free of any machining defects. To accomplish this take an optically clear sheet of cast acrylic and machining out the disks using a laser cutter or similar machining process. Then, polish the PMMA to obtain an optically clear surface.

In the Representative Results Figure 3's capation was updated from:

Figure 3. PDV setup (close view). The PDV setup at the base where the flyer plate is located.

to:

Figure 3. PDV setup (close view). The PDV setup at the base.

In the Representative Results, the paragraph between table 1 and figure 7 has been updated from:

The output from the PDV trace of the flyer plate from the bottom of the explosive charge of Figures 2-3 is shown in Figure 7. The oscillations arise from the ringing in the plate from the rapid acceleration to nearly 4-5 km/sec. The CJ pressure is calculated from modeling the product gas Hugoniot with Cooper’s approximation,6 and then extrapolating the CJ point once the aluminum-explosive Hugoniot is matched. A typical screen print from such a calculation is shown in Figure 8. The technique still has some limitations since the calculations assume a linear acceleration extrapolation from the beginning of the flyer velocity. This results in slightly underestimating the pressure, as evidenced by the results (Table 1). Work is ongoing to develop new equations to fit the early acceleration of the flyer plate.

to:

The output of the PDV trace from the bottom of the explosive charge of Figures 2-3 is shown in Figure 7. The CJ pressure is calculated from modeling the product gas Hugoniot with Cooper’s approximation,6 and then extrapolating the CJ point once the PMMA-explosive Hugoniot is matched. A typical screen print from such a calculation is shown in Figure 8. The technique still has some limitations since the calculations assume a linear extrapolation from the beginning of the window velocity trace. This results in slightly underestimating the pressure, as evidenced by the results (Table 1).

In the Representative Results Figure 7 and its caption were updated from:

Figure 7. Plate velocity as a function of time for the measurement of CJ pressure in the PBXN-5 explosive. Note the excellent agreement between two different shots, where the traces practically fall on one another.

to:

Figure 7. Window velocity as a function of time for the measurement of CJ pressure. Note the excellent agreement between the different shots, where the traces practically fall on one another.

Also in the Representative Results, Figure 8 had its caption update from:

Figure 8. Calculation of the CJ pressure from the copper flyer plate data on the PDV experiment. Note that the extrapolation assumes a linear acceleration in the initial push of the flyer plate which currently leads to an underestimation of the CJ pressure.

to:

Figure 8. Calculation of the CJ pressure from the PDV experiment. Note that the extrapolation assumes a linear acceleration in the initial push of the window which currently leads to an underestimation of the CJ pressure.

The Acknowledgments section was updated from:

The authors would like to thank the Future Requirement of Enhanced Energetics for Decisive Munitions (FREEDM) Program for funding, Mike VanDeWal and Gerard Gillen for their assistance in testing, Paula Cook for formulations assistance, and Ralph Acevedo and Brian Travers for pressing of the samples.

to:

The authors would like to thank the Future Requirement of Enhanced Energetics for Decisive Munitions (FREEDM) Program for funding, Mike Van De Waal and Gerard Gillen for their assistance in testing, Paula Cook for formulations assistance, and Ralph Acevedo and Brian Travers for pressing of the samples.

转载和许可

请求许可使用此 JoVE 文章的文本或图形

请求许可探索更多文章

This article has been published

Video Coming Soon

版权所属 © 2025 MyJoVE 公司版权所有,本公司不涉及任何医疗业务和医疗服务。