需要订阅 JoVE 才能查看此. 登录或开始免费试用。

Method Article

表面上的纳米硅聚酯涂料暴露在阳光下的演变

摘要

两种类型的表面,涂覆有二氧化硅纳米颗粒的层的聚酯涂层钢板及聚酯,进行了研究。两面暴露在阳光下,将其发现导致在表面的化学性质和纳米形貌实质性的变化。

摘要

金属表面的腐蚀是在环境中普遍存在,并在许多领域,包括军事,交通,航空,建筑,食品等行业,除其他外的极大关注。聚酯和含有聚酯和二氧化硅纳米粒子的涂层(SiO 2的纳米颗粒)已经被广泛地用于保护钢基质免受腐蚀。在这项研究中,我们利用X射线光电子能谱,衰减全反射红外微光谱,水接触角的测量,光分析和原子力显微镜,以提供深入了解暴露于阳光下如何导致在微米和纳米级的完整性的改变的涂层。使用光学轮廓检测在表面微地形无显著变化,然而,使用原子力显微镜进行检测统计学显著纳米变化到表面。 X射线光电子能谱分析和衰减全反射红外微光谱数据表明,已通过暴露于紫外线光发生酯基的降解以形成COO·,-H 2 C·,-O·, - CO·自由基。在降解过程,CO和CO 2的也被生产。

引言

Environmental corrosion of metals in the environment is both prevalent and costly1-3. A recent study conducted by the Australasian Corrosion Association (ACA) reported that corrosion of metals resulted in a yearly cost of $982 million, which was directly associated with the degradation of assets and infrastructure through metallic corrosion within the water industry4. From an international perspective, the World Corrosion Organization estimated that metallic corrosion was responsible for a direct cost of $3.3 trillion, over 3% of the world's GDP5. The process of galvanizing as a corrosion preventative method has been widely used to increase the lifespan of steel material6. In humid and subtropical climates, however, water tends to condense into small pockets or grooves within the surface of the galvanized steel, leading to the acceleration of corrosion rates through pit corrosion7,8. Thermosetting polymer coatings based on polyesters have been developed to coat the galvanized steel substrata increasing their ability to withstand humid weathering conditions for items such as satellite dishes, garden furniture, air-conditioning units or agricultural construction equipment9-11. Unfortunately polymer coatings on steel surfaces have been found to be considerably adversely affected by the presence of high levels of ultraviolet (uv) radiation12-14. Coatings comprised of silica nanoparticles (SiO2) spread over a polymer layer have been widely used with a view to increasing their corrosion-, wear-, tear- and degradation-resistance15,16. The tendency of the protective polymeric coatings to form pores and cracks can be reduced by incorporating nanoparticles (NPs), which contribute to the passive obstruction of corrosion initiation17,18. Also, the mechanical stability of the protective polymeric layer can be improved by NPs inclusion. However, these coatings act as passive physical barriers and, in comparison to the galvanization approach, cannot inhibit corrosion propagation actively.

An in-depth understanding of the effect that high-levels of ultraviolet light exposure under humid conditions upon these metal coatings is yet to be obtained. In this paper, a wide range of surface analytical techniques, including X-ray photoelectron spectroscopy (XPS), attenuated total reflection infrared micro-spectroscopy (ATR IR), contact angle goniometry, optical profiling and atomic force microscopy (AFM) will be employed to examine the changes in the surface of steel coatings prepared from polyester- and silica nanoparticle-coated polyester (silica nanoparticles/polyester) after exposure to sunlight. Furthermore, the aim of this work is to give a concise, practical overview of the overall characterization techniques to examine weathered samples.

研究方案

1.钢铁样品

- 从商业供应商获得厚度为1毫米的钢试样。

注:样品涂覆有聚酯或聚酯涂覆有二氧化硅纳米粒子。 - 样品暴露在罗克汉普顿,澳大利亚昆士兰州的阳光:收集了总共5年的时间后,一年期和五年期的时间间隔采样。切样片到用打孔器直径1厘米的圆形光盘。

- 前表面表征,用双蒸水漂洗样品,然后干燥用氮气(99.99%)。保持在所有样品中的气密容器以防止任何空气污染物吸附到表面上( 图1)。

图1的金属圆盘制备聚酯系涂料。将样品储存在容器中,直到需要。OM /文件/ ftp_upload / 54309 / 54309fig1large.jpg"目标="_空白">点击此处查看该图的放大版本。

2.表面的化学和理化性质

- 利用X射线光电子能谱法分析表面化学。

- 执行使用在150瓦操作的单色X射线源(铝Kα,hν= 1486.6电子伏特)的X射线光电子光谱法(XPS)

注意:利用X射线束的光点大小为400微米的直径。 - 在样品板负载的样品。放置样品板到的XPS真空室,然后泵室中。等待室中的真空达到约1×10 -9毫巴。

- 在光电子能谱软件,按"洪水枪"的选项涌入样品低能电子抵消表面充电。

- 按"插入">"点">"点"插入一个分析POIN吨。

注意:这将是在其中进行分析的位置。启用自动高度函数来获得收购的最佳高度。 - 按"插入">"频谱">"多光谱"来扫描添加到这一点。

注意:这将打开一个周期表的窗口;通过点击它以突出显示它选择一个元素。 - 设立试验后,按"播放"命令进行扫描。

- 按"曲线拟合"命令,然后按"添加峰"和"适合所有级别"命令来解决高分辨率光谱,化学性质不同的物种。

注:此步骤将收购雪莉算法消除背景和高斯-洛伦兹拟合解卷积光谱19。 - 选择所有高清晰度和调查谱。按"Shift键充电"选项,使用hydroca纠正谱的C 1s峰(结合能285.0 eV)的作为参考的rbon组件。

- 后电荷修正,按"导出"选项生成的峰面积的基础上,元件的相对原子浓度的数据表。

- 执行使用在150瓦操作的单色X射线源(铝Kα,hν= 1486.6电子伏特)的X射线光电子光谱法(XPS)

- 表面化学

注:红外光谱(IR)光束线在澳大利亚同步加速器如下使用衰减全反射红外显微光谱(ATR-IR)分析表面化学:- 关于显微镜的阶段负荷样品。打开"开始视频辅助测量"或"开始测量没有3D"选项。打开"可见"模式。使用目标集中在样品表面。按"快照/概览"采取所需的图像。

注:0.5毫米厚的CaF 2板可以用作背景。 - 在ATR目标更改为样本。小心地移动舞台放置一个45°的多反射GERmanium水晶(4折射率)1-2毫米以上的表面。实况视频窗口上单击鼠标右键。按"开始测量">"更改测量参数。"选择选项"不要使用现有的BG所有职位"。

注意:这将选择不采取背景光谱对每个测量点。 - 绘制视频屏幕上的地图来选择感兴趣的区域。按下一个红色的方形孔,然后选择"光圈">"更改光圈"。更改实际的"刀锋光圈"设置X = 20微米和Y = 20微米。

- 在新尺寸的方形孔径右键点击并进入"光圈">"设置所有光圈选定的孔径。"按"测量"图标启动扫描。保存数据。

注:戈晶体的折射率为4,所以为20μm×20μm的孔将定义为5μm×5μm的光点尺寸。氏S步进将允许通过20微米,其对应于5微米5微米的光斑通过横跨4,000-850厘米,最大波数范围的晶体用20的孔径设定FTIR制图- 1。 - 使用光谱软件打开主文件。选择对红外光谱目标峰。感兴趣的峰值单击鼠标右键。选择"集成">"集成"。它将允许创建二维伪彩色图

- 关于显微镜的阶段负荷样品。打开"开始视频辅助测量"或"开始测量没有3D"选项。打开"可见"模式。使用目标集中在样品表面。按"快照/概览"采取所需的图像。

- 表面润湿性测量

注意:使用装备有纳米分配器19的接触角测角器进行润湿的测量。- 在舞台上放置样品。使针的底部会出现大约四分之一的方式在实时视频窗口屏幕朝下调整微量组件的位置。

- 利用Z轴直到样品和表面之间的距离提高样品是约5毫米。移动至注射器,直到DOUB的液滴乐蒸馏水接触的表面上。移动注射器到原来的位置。

- 按"运行"命令,记录水滴在表面上影响了使用它与硬件集成在一个黑白CCD摄像机20秒的时间。

- 按下"停止"命令来获得一系列图像。

- 按"接触角"命令来测量获得的图像接触角。重复该接触角测量在每个样品三个随机的位置。

3.表面形貌的可视化

- 光学仿形测量。

注:该仪器是白光垂直扫描干涉模式下工作。- 在显微镜的阶段处的样品。

注:确保有物镜和舞台之间有足够的间隙( 例如 ,"15毫米)。 - 专注于表面使用5×目标通过控制Z轴直到条纹出现在屏幕上。按"自动"命令优化力度。按"测量"命令开始扫描。保存主文件。

- 重复步骤3.1.2为20×和50×的目标。

- 此前统计分析粗糙,按下"删除倾斜"选项去除表面波纹度。按"轮廓"选项来分析粗糙度参数。点击"3DI"选项生成使用兼容的软件20倍光学分析文件的三维图像。

- 在显微镜的阶段处的样品。

- 原子力显微镜

- 上钢盘将样品。将钢盘到磁持有人。

- 在轻敲模式21进行AFM扫描。机械负载磷掺杂的硅探针为0.9牛顿/米,具有8毫微米半径约20千赫表面成像的共振频率前端曲率的弹簧常数。

- 手动调整悬臂的激光反射。选择"自动调整"命令,然后按"调"命令来调整AFM悬臂达到制造商报告的最佳共振频率。

- 重点在表面上。移动靠近样品表面的提示。点击命令搞搞表面上的针尖。

- 输入"1赫兹"到扫描速度框。选择扫描区域。按"运行"命令来执行扫描。至少重复扫描的每个的每个条件的五个样品的十个方面。

- 选择找平选项处理所得的地形数据。保存主文件。

- 打开兼容的AFM软件。加载AFM主文件。按"平"命令删除面的倾斜。按"平滑化"命令删除背景。

- 按"统计参数分析"生成的统计粗糙度21。

4.统计分析

- 表达在平均值和其标准偏差方面的结果。使用配对Student的双尾T-测试,以评估结果的一致性进行统计的数据处理。集合P -值在<0.05指示统计显着性水平。

结果

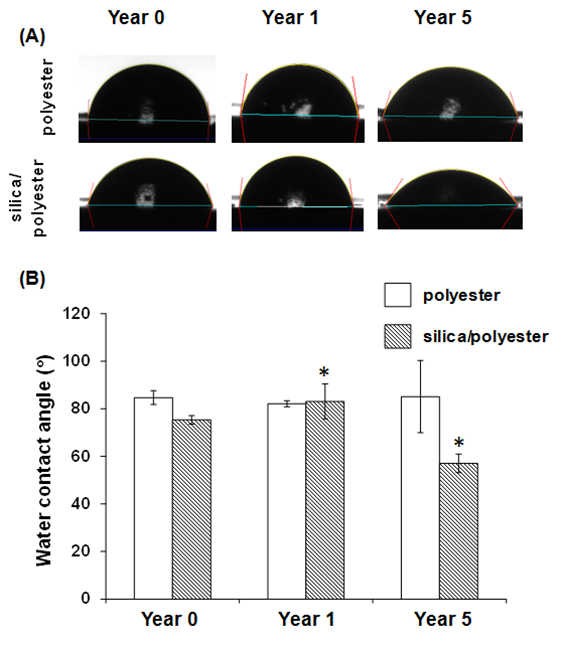

已被经受暴露于阳光下一个或五年涂覆的钢样品收集,与水的接触角测量进行了决定曝光是否已导致在所述表面的表面疏水性的改变( 图2 )。

图2.润湿与聚酯或二氧化硅纳米微粒/聚酯涂料(硅胶/聚酯)在五年内暴露于阳光的表面的变化 (A)的测角的图?...

讨论

聚酯涂料已被广泛地用于保护钢基质从上未涂布表面将发生因水分和污染物的积累的腐蚀。的聚酯涂料的应用可以保护钢免受腐蚀;然而这些涂料的长期效力,如果它们暴露于高水平的潮湿条件下的紫外光,损害作为在热带气候发生。二氧化硅纳米粒子可被施加到聚酯的表面以改善这些环境内的这些涂层的坚固性,对这些含二氧化硅的涂层材料的环境因素然而效果,到现在为止,未知的,特别是关...

披露声明

The authors have nothing to disclose.

致谢

Funding from the Australian Research Council Industrial Transformation Research Hubs Scheme (Project Number IH130100017) is gratefully acknowledged. Authors gratefully acknowledge the RMIT Microscopy and Microanalysis Facility (RMMF) for providing access to the characterisation instruments. This research was also undertaken on the Infrared Microscopectroscopy beamline at the Australian Synchrotron, Victoria, Australia.

材料

| Name | Company | Catalog Number | Comments |

| polyester-coated steel silica nanoparticle-polyester coated steel substrata | BlueScope Steel | Samples provided by company | |

| Millipore PetriSlideTM | Fisher Scientific | PDMA04700 | Storing samples |

| Thermo ScientificTM K-alpha X-ray Photoelectron Spectrometer | Thermo Fisher Scientific, Inc. | IQLAADGAAFFACVMAHV | Acquire XPS spectra |

| Avantage Data System | Thermo Fisher Scientific, Inc. | IQLAADGACKFAKRMAVI | Analyse XPS spectra |

| A Bruker Hyperion 2000 microscope | Bruker Corporation | Synchrotron integrated instrument | |

| Bruker Opus v. 7.2 | Bruker Corporation | ATR-IR analysis software | |

| Contact angle goniometer, FTA1000c | First Ten Ångstroms Inc., VA, USA | Measuring the wettability of surfaces | |

| FTA v. 2.0 | First Ten Ångstroms Inc., VA, USA | Anaylyzing water contact angle | |

| Optical profiler, Wyko NT1100 | Bruker Corporation | Measure surface topography | |

| Innova atomic force microscope | Bruker Corporation | Measure surface topography | |

| Phosphorus doped silicon probes, MPP-31120-10 | Bruker Corporation | AFM probes | |

| Gwyddion software | http://gwyddion.net/ | Software used to measure optical profiling and AFM data |

参考文献

- Fathima Sabirneeza, A. A., Geethanjali, R., Subhashini, S. Polymeric corrosion inhibitors for iron and its alloys: A review. Chem. Eng. Commun. 202 (2), 232-244 (2015).

- Gupta, R. K., Birbilis, N. The influence of nanocrystalline structure and processing route on corrosion of stainless steel: A review. Corros. Sci. 92, 1-15 (2015).

- Lee, H. S., Ismail, M. A., Choe, H. B. Arc thermal metal spray for the protection of steel structures: An overview. Corros. Rev. 33 (1-2), 31-61 (2015).

- Moore, G. . Corrosion challenges - urban water industry. , (2010).

- Hays, G. F. . World Corrosion Organization. , (2013).

- Koch, G. H., Brongers, M. P. H., Thompson, N. G., Virmani, P. Y., Payer, J. H. Corrosion cost and preventive strategies in the United States. CC Technologies Laboratories, Incorporated; NACE International; Federal Highway Administration, NACE International. , (2002).

- Pojtanabuntoeng, T., Singer, M., Nesic, S. . Corrosion 2011. , (2011).

- Jas̈niok, T., Jas̈niok, M., Tracz, T., Hager, I. . 7th Scientific-Technical Conference on Material Problems in Civil Engineering, MATBUD 2015. , 316-323 (2015).

- Cambier, S. M., Posner, R., Frankel, G. S. Coating and interface degradation of coated steel, Part 1: Field exposure. Electrochim. Acta. 133, 30-39 (2014).

- Barletta, M., Gisario, A., Puopolo, M., Vesco, S. Scratch, wear and corrosion resistant organic inorganic hybrid materials for metals protection and barrier. Mater. Des. 69, 130-140 (2015).

- Fu, J., et al. Experimental and theoretical study on the inhibition performances of quinoxaline and its derivatives for the corrosion of mild steel in hydrochloric acid. Ind. Eng. Chem. Res. 51 (18), 6377-6386 (2012).

- Hattori, M., Nishikata, A., Tsuru, T. EIS study on degradation of polymer-coated steel under ultraviolet radiation. Corros. Sci. 52 (6), 2080-2087 (2010).

- Yang, X. F., et al. Weathering degradation of a polyurethane coating. Polym. Degrad. Stab. 74 (2), 341-351 (2001).

- Armstrong, R. D., Jenkins, A. T. A., Johnson, B. W. An investigation into the uv breakdown of thermoset polyester coatings using impedance spectroscopy. Corros. Sci. 37 (10), 1615-1625 (1995).

- Zhou, W., Liu, M., Chen, N., Sun, X. Corrosion properties of sol-gel silica coatings on phosphated carbon steel in sodium chloride solution. J. Sol. Gel. Sci. Technol. 76 (2), 358-371 (2015).

- Hollamby, M. J., et al. Hybrid polyester coating incorporating functionalized mesoporous carriers for the holistic protection of steel surfaces. Adv. Mater. 23 (11), 1361-1365 (2011).

- Borisova, D., Möhwald, H., Shchukin, D. G. Mesoporous silica nanoparticles for active corrosion protection. ACS Nano. 5 (3), 1939-1946 (2011).

- Wang, M., Liu, M., Fu, J. An intelligent anticorrosion coating based on pH-responsive smart nanocontainers fabricated via a facile method for protection of carbon steel. J. Mater. Chem. A. 3 (12), 6423-6431 (2015).

- Truong, V. K., et al. The influence of nano-scale surface roughness on bacterial adhesion to ultrafine-grained titanium. Biomaterials. 31 (13), 3674-3683 (2010).

- Nečas, D., Klapetek, P. Gwyddion: An open-source software for SPM data analysis. Cent. Eur. J. Phys. 10 (1), 181-188 (2012).

- Crawford, R. J., Webb, H. K., Truong, V. K., Hasan, J., Ivanova, E. P. Surface topographical factors influencing bacterial attachment. Adv. Colloid Interface Sci. 179-182, 142-149 (2012).

- Allen, N. S., Edge, M., Mohammadian, M., Jones, K. Physicochemical aspects of the environmental degradation of poly(ethylene terephthalate). Polym. Degrad. Stab. 43 (2), 229-237 (1994).

- Newman, C. R., Forciniti, D. Modeling the ultraviolet photodegradation of rigid polyurethane foams. Ind. Eng. Chem. Res. 40 (15), 3346-3352 (2001).

- Ivanova, E. P., et al. Vibrio fischeri and Escherichia coli adhesion tendencies towards photolithographically modified nanosmooth poly (tert-butyl methacrylate) polymer surfaces. Nanotechnol. Sci. Appl. 1, 33-44 (2008).

- Biggs, S., Lukey, C. A., Spinks, G. M., Yau, S. T. An atomic force microscopy study of weathering of polyester/melamine paint surfaces. Prog. Org. Coat. 42 (1-2), 49-58 (2001).

- Signor, A. W., VanLandingham, M. R., Chin, J. W. Effects of ultraviolet radiation exposure on vinyl ester resins: Characterization of chemical, physical and mechanical damage. Polym. Degrad. Stab. 79 (2), 359-368 (2003).

- Wang, H., et al. Corrosion-resistance, robust and wear-durable highly amphiphobic polymer based composite coating via a simple spraying approach. Prog. Org. Coat. 82, 74-80 (2015).

- Liszka, B. M., Lenferink, A. T. M., Witkamp, G. J., Otto, C. Raman micro-spectroscopy for quantitative thickness measurement of nanometer thin polymer films. J. Raman Spectrosc. 46 (12), 1230-1234 (2015).

- Alghunaim, A., Kirdponpattara, S., Newby, B. M. Z. Techniques for determining contact angle and wettability of powders. Powder Technol. 287, 201-215 (2016).

- Treviño, M., et al. Erosive wear of plasma electrolytic oxidation layers on aluminium alloy 6061. Wear. 301 (1-2), 434-441 (2013).

转载和许可

请求许可使用此 JoVE 文章的文本或图形

请求许可探索更多文章

This article has been published

Video Coming Soon

版权所属 © 2025 MyJoVE 公司版权所有,本公司不涉及任何医疗业务和医疗服务。