Aby wyświetlić tę treść, wymagana jest subskrypcja JoVE. Zaloguj się lub rozpocznij bezpłatny okres próbny.

Method Article

Microparticle Manipulation by Standing Surface Acoustic Waves with Dual-frequency Excitations

W tym Artykule

Podsumowanie

A protocol for manipulating the microparticles in a microfluidic channel with a dual-frequency excitation is presented.

Streszczenie

We demonstrate a method for increasing the tuning ability of a standing surface acoustic wave (SSAW) for microparticles manipulation in a lab-on-a-chip (LOC) system. The simultaneous excitation of the fundamental frequency and its third harmonic, which is termed as dual-frequency excitation, to a pair of interdigital transducers (IDTs) could generate a new type of standing acoustic waves in a microfluidic channel. Varying the power and the phase in the dual-frequency excitation signals results in a reconfigurable field of the acoustic radiation force applied to the microparticles across the microchannel (e.g., the number and location of the pressure nodes and the microparticle concentrations at the corresponding pressure nodes). This article demonstrates that the motion time of the microparticle to only one pressure node can be reduced ~2-fold at the power ratio of the fundamental frequency greater than ~90%. In contrast, there are three pressure nodes in the microchannel if less than this threshold. Furthermore, adjusting the initial phase between the fundamental frequency and the third harmonic results in different motion rates of the three SSAW pressure nodes, as well as in the percentage of microparticles at each pressure node in the microchannel. There is a good agreement between the experimental observation and the numerical predictions. This novel excitation method can easily and non-invasively integrate into the LOC system, with a wide tenability and only a few changes to the experimental set-up.

Wprowadzenie

LOC technology integrates one or several functions on a microchip for biology, chemistry, biophysics, and biomedical processes. LOC allows a laboratory set-up on a scale smaller than sub-millimeters, fast reaction rates, a short response time, a high process control, a low volume consumption (less waste, lower reagents cost, and less required sample volume), a high throughput due to parallelization, a low cost in the future mass production and cost-effective disposables, a high safety for chemical, radioactive, or biological studies, and the advantages of a compact and portable device1,2. Precise cell manipulation (i.e., accumulation and separation) is critical in an LOC-based analysis and diagnosis3,4. However, the accuracy and reproducibility of microparticle manipulation have a variety of challenges. Many techniques, such as electro-osmosis5, dielectrophoresis (DEP)6, magnetophoresis7, thermophoresis8,9, an optical approach10, an optoelectronic approach11, a hydrodynamic approach12, and acoustophoresis13,14,15, have been developed. In comparison, acoustic approaches are appropriate for a LOC application because, theoretically, many types of microparticles/cells can be manipulated effectively and noninvasively with a sufficiently high contrast (density and compressibility) compared with the surrounding fluid. Therefore, compared to their counterparts, acoustic approaches are inherently eligible for most microparticles and biological objects, no matter their optical, electrical, and magnetic properties16.

Surface acoustic waves (SAWs) from the IDTs propagate mostly on the surface of a piezoelectric substrate at the thickness of several wavelengths and then leak at the Rayleigh angle into the fluid in the microchannel, according to the Snell's law17,18,19,20,21,22. They have the technical advantages of a high energy efficiency along the surface due to their localization of the energy, a great design flexibility at high frequency, a good system integration with the microfluidic channel and miniaturization using micro-electronic-mechanical system (MEMS) technology, and a high potential of mass production23. In this protocol, SAWs are generated from a pair of identical IDTs and propagated in the opposite direction to generate a standing wave, or SSAW, in the microchannel, where the suspended microparticles are pushed to pressure nodes, mostly by the applied acoustic radiation force24. The amplitude of such resultant force is determined by the excitation frequency, microparticle size, and its acoustic contrast factor22,25.

Such acoustophoresis has the limitation of predetermined manipulating patterns that are not easily adjustable. The excitation frequency of the IDTs is determined by their periodic distance, so the bandwidth is quite limited. Several strategies have been developed to enhance the tunability and manipulation capability. The first and second modes of acoustic standing waves applied in different parts of the microchannel could separate microparticles more effectively according to different motion speeds toward the nodal lines26. These two modes could also be applied to the whole part of the microchannel and switched alternatively27,28,29. However, for this, a large number of equipment (i.e., three function generators, two impedance matching units, and an electromagnetic relay) is required, with the increased cost and control complexity of the experimental set-up owing to the different electrical impedances at the fundamental frequency and third harmonic of the piezoceramic plate30. Furthermore, slanted-finger interdigital transducers (SFITs) could be applied to adjust the cells and the microparticles patterning by exciting a period of the slanted fingers for a certain resonance20,31. However, then, the bandwidth is inversely proportional to the number of slanted fingers. Multiple pressure nodal lines have a higher separation efficiency and sensitivity in comparison to the single nodal line in the conventional SSAW-based microparticle separator. Alternatively, the location of the pressure nodes could also be changed simply by adjusting the phase difference applied to the two IDTs in the design32,33.

The fundamental frequency and the third harmonic of IDTs have similar frequency responses so that they can be excited simultaneously, which provides more tunability for the microparticles manipulation34. In comparison to the conventional IDT excitation at a single frequency, adjusting the acoustic pressures of the dual-frequency excitation and the phase between them provides technical uniqueness, such as the up to ~2-fold reduced motion time to the pressure nodal line or the center of the microchannel, the varied number and location of the pressure nodal lines, and the microparticle concentrations.

Protokół

1. Preparation of the Microfluidic Channel

- Mix poly-dimethylsiloxane (PDMS) with an elastomer base in a ratio of 10:1.

- Degas the mixture in a vacuum oven and pour it on a silicon wafer with a negative tone photoresist pattern on the top.

- Degas the patterned silicon wafer again and heat it at 70 °C for 3 h in an incubator for solidification.

2. Fabrication of the Interdigital Transducers

- Deposit 20 nm of Cr and 400 nm of Al on a LiNbO3 wafer; pattern 20 strips with a width of 150 µm and an aperture of 2 cm on a plastic mask for photolithography by depositing the positive photoresist on the substrate.

- Remove the Cr-Al layer on the non-exposed area with acetone.

- Treat the surface of them with oxygen plasma (with a nitrogen and oxygen ratio of 2:1) at the power of 30 W for 60 s.

- Align the PDMS microchannel and bond it to the LiNbO3 substrate by pressing it with a thumb for a few seconds.

- Place the integrated device in the heating chamber at 60 °C for 3 h.

3. Dual-frequency Excitation

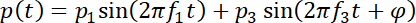

- Simultaneously apply two frequency components (f1 and f3, the fundamental frequency and its third harmonic of the fabricated IDT, respectively) with the phase difference φ between them to the pair of IDTs, so that the produced SAW may be expressed as follows.

Here,

and

and  = the acoustic pressures.

= the acoustic pressures. - Synthesize the dual-frequency waveform using the Equation Editor of the ArbExpress Application software at the sampling frequency of 100 MS/s and then store it to the function generator as arbitrary input for the SAW excitation in the experiment via a USB cable.

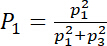

- Vary the power of the fundamental frequency to the total emitted power

from 100% (excitation at the purely fundamental frequency) to 0% (excitation at the purely third harmonic); for a good comparison, change but keep the total power the same.

from 100% (excitation at the purely fundamental frequency) to 0% (excitation at the purely third harmonic); for a good comparison, change but keep the total power the same. - Vary the phase difference of the dual-frequency excitation from 0° to 360°.

4. Numerical Simulation

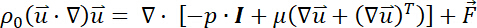

- Describe the motion of the incompressible laminar flow with low Reynolds (i.e., Re = 0.55) and Mach numbers as follows35.

Here,

= the fluid velocity,

= the fluid velocity,

= the dynamic viscosity,

= the dynamic viscosity,

= the fluid density,

= the fluid density,

= the pressure on the fluid,

= the pressure on the fluid,

= the identity matrix, and

= the identity matrix, and

= an external force.

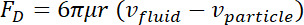

= an external force. - Describe the produced Stoke drag force on the object as follows36.

Here,

= the radius of the microparticle,

= the radius of the microparticle,

= the velocity of the fluid, and

= the velocity of the fluid, and

= the velocity of the microparticle.

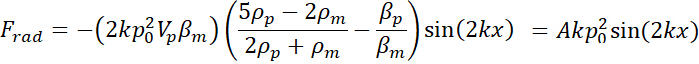

= the velocity of the microparticle. - Derive the acoustic radiation force applied to the microparticle in the microchannel along the x-axis (across the microchannel width) at a single frequency as follows16 .

Here,

= the volume of the microparticle,

= the volume of the microparticle,

= the density of the microparticle,

= the density of the microparticle,

= the density of the medium,

= the density of the medium,

= the compressibility of the microparticle, and

= the compressibility of the microparticle, and

= the compressibility of the medium.

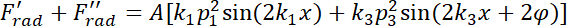

= the compressibility of the medium. - Derive the resultant acoustic radiation force of the dual-frequency excitation as follows.

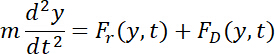

- Express the transverse motion across the channel width (along the y-axis) under both the acoustic radiation force and the Stokes drag force governed by Newton's second law as follows.

- Solve the ordinary differential equations (ODEs) above using the fourth order Runge-Kutta method on a personal computer.Set the time step and total duration as 1 µs and 20 s, respectively.

5. Experimental Observation

- Spin the solution in the concentration of 5.9 x 107 with 4 µm green fluorescent polystyrene beads per 1 mL by vortex for about 2 - 3 min and then immerse it in an ultrasound sonicator for 10 min to disrupt any agglomeration before each testing.

- Fill the mixture into a 3 mL syringe and then drive it with a syringe pump at a flow rate of 3 - 5 µL/min.

- Drive the IDT with the dual-frequency signal from a function generator followed by a power amplifier.

- Observe the stabilized microparticles in the downstream microchannel under a light microscope at a 40X magnification and record the image with a digital camera.

- Measure the location of the accumulated microparticles in the captured digital images using ImageJ and the established scale, and then quantitatively determine the concentration of the accumulated microparticle with the normalized fluorescence brightness at each pressure node.

Wyniki

The distributions of the acoustic pressure and the acoustic radiation force of an SSAW at the dual-frequency excitation (6.2 and 18.6 MHz) are shown in Figure 1. Here, the dual-frequency excitation occurs on polystyrene microparticles (4 µm in diameter) in a microchannel with a width of 300 µm at an acoustic power of 146 mW. The resultant acoustic pressure is always in phase when P1 > 90% so that only one pressure node is pre...

Dyskusje

The microparticle motion in the microchannel by an SSAW at the dual-frequency excitation was extensively investigated in this study, and an effectively tunable patterning technique by varying the dual-frequency excitation signals was developed and tested. The production of such a waveform is easily realized by most function generators, and the adjusting approach is very convenient. Both the S12- and S11-frequency responses of the fabricated IDTs illustrate several resonant modes34<...

Ujawnienia

The authors have nothing to disclose.

Podziękowania

This work was sponsored by the Academic Research Fund (AcRF) Tier 1 (RG171/15), Ministry of Education, Singapore.

Materiały

| Name | Company | Catalog Number | Comments |

| poly-dimethylsiloxane | Dow Corning | Sylgard 184 | |

| poly-dimethylsiloxane elastomer base | Dow Corning | Sylgard 184 | |

| silicon wafer | Bonda Technology | SI8PSPD | |

| negative tone photoresist | Microchem | SU-8 | |

| double-side polished LiNbO3 wafer | University Wafer | Y-128° | |

| positive photoresist | Nicolaus-Otto-Straße | AZ 9260 | |

| oxygen plasma | Harrick Plasma | ||

| plastic mask | Infinite Graphics |

Odniesienia

- Chin, C. D., Linder, V., Sia, S. K. Commercialization of microfluidic point-of-care diagnostic devices. Lab on a Chip. 12 (12), 2118-2134 (2012).

- Figeys, D., Pinto, D. Lab-on-a-chip: a revolution in biological and medical sciences. Analytical Chemistry. 72 (9), 330 A-335 A (2000).

- den Toonder, J. Circulating tumor cells: the Grand Challenge. Lab on a Chip. 11 (3), 375-377 (2011).

- Yu, L., et al. Advances of lab-on-a-chip in isolation, detection and post-processing of circulating tumour cells. Lab on a Chip. 13 (16), 3163-3182 (2013).

- Jorgenson, J. W., Lukacs, K. D. High-resolution separations based on electrophoresis and electroosmosis. Journal of Chromatography A. 218, 209-216 (1981).

- Gascoyne, P. R., Vykoukal, J. Particle separation by dielectrophoresis. Electrophoresis. 23 (13), 1973 (1973).

- Xia, N., et al. Combined microfluidic-micromagnetic separation of living cells in continuous flow. Biomedical Microdevices. 8 (4), 299-308 (2006).

- Garcés-Chávez, V., et al. Extended organization of colloidal microparticles by surface plasmon polariton excitation. Physical Review B. 73 (8), 085417 (2006).

- Zhu, T., Ye, W. Origin of Knudsen forces on heated microbeams. Physical Review E. 82 (3), 036308 (2010).

- Ashkin, A., Dziedzic, J., Yamane, T. Optical trapping and manipulation of single cells using infrared laser beams. Nature. 330 (6150), 769-771 (1987).

- Chiou, P. Y., Ohta, A. T., Wu, M. C. Massively parallel manipulation of single cells and microparticles using optical images. Nature. 436 (7049), 370-372 (2005).

- Yamada, M., Seki, M. Hydrodynamic filtration for on-chip particle concentration and classification utilizing microfluidics. Lab on a Chip. 5 (11), 1233-1239 (2005).

- Burguillos, M. A., et al. Microchannel acoustophoresis does not impact survival or function of microglia, leukocytes or tumor cells. PLoS One. 8 (5), e64233 (2013).

- Lin, S. -. C. S., Mao, X., Huang, T. J. Surface acoustic wave (SAW) acoustophoresis: now and beyond. Lab on a Chip. 12 (16), 2766-2770 (2012).

- Petersson, F., Åberg, L., Swärd-Nilsson, A. -. M., Laurell, T. Free flow acoustophoresis: microfluidic-based mode of particle and cell separation. Analytical Chemistry. 79 (14), 5117-5123 (2007).

- Ding, X., et al. On-chip manipulation of single microparticles, cells, and organisms using surface acoustic waves. Proceedings of the National Academy of Sciences. 109 (28), 11105-11109 (2012).

- Friend, J., Yeo, L. Y. Microscale acoustofluidics: Microfluidics driven via acoustics and ultrasonics. Reviews of Modern Physics. 83 (2), 647 (2011).

- Destgeer, G., Lee, K. H., Jung, J. H., Alazzam, A., Sung, H. J. Continuous separation of particles in a PDMS microfluidic channel via travelling surface acoustic waves (TSAW). Lab on a Chip. 13 (21), 4210-4216 (2013).

- Guo, F., et al. Controlling cell-cell interactions using surface acoustic waves. Proceedings of the National Academy of Sciences. 112 (1), 43-48 (2015).

- Ding, X., et al. Cell separation using tilted-angle standing surface acoustic waves. Proceedings of the National Academy of Sciences. 111 (36), 12992-12997 (2014).

- Roshchupkin, D., et al. X-ray diffraction by standing surface acoustic waves. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms. 142 (3), 432-436 (1998).

- Shi, J., Mao, X., Ahmed, D., Colletti, A., Huang, T. J. Focusing microparticles in a microfluidic channel with standing surface acoustic waves (SSAW). Lab on a Chip. 8 (2), 221-223 (2008).

- Ding, X., et al. Surface acoustic wave microfluidics. Lab on a Chip. 13 (18), 3626-3649 (2013).

- King, L. V. On the acoustic radiation pressure on spheres. Proceedings of the Royal Society of London A: Mathematical, Physical and Engineering Sciences. , 212-240 (1934).

- Yosioka, K., Kawasima, Y. Acoustic radiation pressure on a compressible sphere. Acta Acustica United with Acustica. 5 (3), 167-173 (1955).

- Ratier, C., Hoyos, M. Acoustic programming in step-split-flow lateral-transport thin fractionation. Analytical Chemistry. 82 (4), 1318-1325 (2010).

- Mandralis, Z., Feke, D., Bolek, W., Burger, W., Benes, E. Enhanced synchronized ultrasonic and flow-field fractionation of suspensions. Ultrasonics. 32 (2), 113-122 (1994).

- Laurell, T., Petersson, F., Nilsson, A. Chip integrated strategies for acoustic separation and manipulation of cells and particles. Chemical Society Reviews. 36 (3), 492-506 (2007).

- Liu, Y., Lim, K. -. M. Particle separation in microfluidics using a switching ultrasonic field. Lab on a Chip. 11 (18), 3167-3173 (2011).

- Brissaud, M. Characterization of piezoceramics. IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control. 38 (6), 603-617 (1991).

- Ding, X., et al. Tunable patterning of microparticles and cells using standing surface acoustic waves. Lab on a Chip. 12 (14), 2491-2497 (2012).

- Jo, M. C., Guldiken, R. Particle manipulation by phase-shifting of surface acoustic waves. Sensors and Actuators A: Physical. 207, 39-42 (2014).

- Meng, L., et al. Transportation of single cell and microbubbles by phase-shift introduced to standing leaky surface acoustic waves. Biomicrofluidics. 5 (4), 044104 (2011).

- Sriphutkiat, Y., Zhou, Y. Particle manipulation using standing surface acoustic waves (SSAW) at dual frequency excitation: effect of power ratio. Sensors and Actuators A: Physical. 263, 521-529 (2017).

- Batchelor, G. K. . An Introduction to Fluid Dynamics. , (2000).

- Glynne-Jones, P., Hill, M. Acoustofluidics 23: acoustic manipulation combined with other force fields. Lab on a Chip. 13 (6), 1003-1010 (2013).

- Winkler, A., Brünig, R., Faust, C., Weser, R., Schmidt, H. Towards efficient surface acoustic wave (SAW)-based microfluidic actuators. Sensors and Actuators A: Physical. 247, 259-268 (2016).

- Chen, Y., et al. Standing surface acoustic wave (SSAW)-based microfluidic cytometer. Lab on a Chip. 14, 916-923 (2014).

- Devendran, C., et al. The importance of travelling wave components in standing surface acoustic wave (SSAW) systems. Lab on a Chip. 16, 3756-3766 (2016).

- Destgeer, G., et al. Submicron separation of microspheres via travelling surface acoustic waves. Lab on a Chip. 14, 4665-4672 (2014).

- Ding, X., et al. Standing surface acoustic wave (SSAW) based multichannel cell sorting. Lab on a Chip. 12, 4228-4231 (2012).

- Chen, Y., et al. Continuous enrichment of low-abundance cell samples using standing surface acoustic waves (SSAW). Lab on a Chip. 14, 924-930 (2014).

Przedruki i uprawnienia

Zapytaj o uprawnienia na użycie tekstu lub obrazów z tego artykułu JoVE

Zapytaj o uprawnieniaThis article has been published

Video Coming Soon

Copyright © 2025 MyJoVE Corporation. Wszelkie prawa zastrzeżone