A subscription to JoVE is required to view this content. Sign in or start your free trial.

Method Article

A Versatile Kit Based on Digital Microfluidics Droplet Actuation for Science Education

In This Article

Summary

We describe an educational kit that allows users to execute multiple experiments and gain hands-on experience on digital microfluidics.

Abstract

This paper describes an educational kit based on digital microfluidics. A protocol for luminol-based chemiluminescence experiment is reported as a specific example. It also has fluorescent imaging capability and closed humidified enclosure based on an ultrasonic atomizer to prevent evaporation. The kit can be assembled within a short period of time and with minimal training in electronics and soldering. The kit allows both undergraduate/graduate students and enthusiasts to obtain hands-on experience in microfluidics in an intuitive way and be trained to gain familiarity with digital microfluidics.

Introduction

Microfluidics is a highly interdisciplinary field combing physics, chemistry, biology, and engineering for the manipulation of small volume of liquids ranging from femtoliter to microliters1. Microfluidics is also a very broad and active field; a Web of Science search returns nearly 20,000 publications and yet there is insufficient literature and review papers on the usage of microfluidics as educational tool2. There are two insightful, albeit outdated review articles by Legge and Fintschenko3,4. Legge introduces educators to the idea of a lab on a chip3. Fintschenko pointed out the role of microfluidics teaching lab in Science Technology Engineering Mathematics (STEM) education and simplified the philosophies into "teach microfluidics" and "use microfluidics"4. A more recent review by Rackus, Ridel-Kruse and Pamme in 2019 points out that in addition to being interdisciplinary in nature, microfluidics is also a very hands-on subject2. The hands-on activity related to the practice of microfluidics lends students to inquiry-based learning and makes it an engaging tool for science communication and outreach. Microfluidics indeed offers much potential for science education in both formal and informal settings and is also an ideal "tool" to enthuse and educate the general public about the interdisciplinary aspect of modern sciences.

Examples such as low-cost microchannel devices, paper microfluidics, and digital microfluidics are ideal tools for educational purposes. Among these platforms, digital microfluidics remains esoteric and peer-reviewed reports based on digital microfluidics are lacking2. Here we propose to use digital microfluidics as an educational tool for several reasons. First, digital microfluidics is very distinct from microchannel-based paradigm because it is based on manipulation of the droplets and usage of the droplets as discrete microvessels. Second, droplets are manipulated on relatively generic electrode-array platforms so digital microfluidics can be intimately coupled with microelectronics. Users can leverage on an extended set of electronic components, now highly accessible for do-it-yourself applications to electronically interface with droplets. Hence, we argue that digital microfluidics can let students to experience these unique aspects and be open-minded not overly to stick to microchannel-based low Reynold number microfluidics1.

Briefly, the field of digital microfluidics is largely based on the electrowetting phenomena, which was first described by Gabriel Lippmann5,6. The recent developments were initiated by Berge in the early 1990s7. His key contribution is the idea of introducing a thin insulator to separate the conductive liquid from metallic electrodes to eliminate the problem of electrolysis. This idea has been termed as electrowetting on dielectric (EWOD). Subsequently, the digital microfluidics was popularized by several pioneering researchers8,9. Now a comprehensive list of applications for example, in clinical diagnostics, chemistry and biology, has been proven on digital microfluidics10,11,12 and, therefore, plenty of examples are available for an educational setting. In particular, along the line of low cost, do-it-yourself digital microfluidics, Abdelgawad and Wheeler have previously reported low-cost, rapid prototyping of digital microfluidics13,14. Fobel et al., has also reported DropBot as an open source digital microfluidic control system15. Yafia et al., also reported a portable digital microfluidics based on 3D printed parts and smaller phone16. Alistar and Gaudenz have also developed the battery powered OpenDrop platform, which is based on the field effect transistor array and dc actuation17.

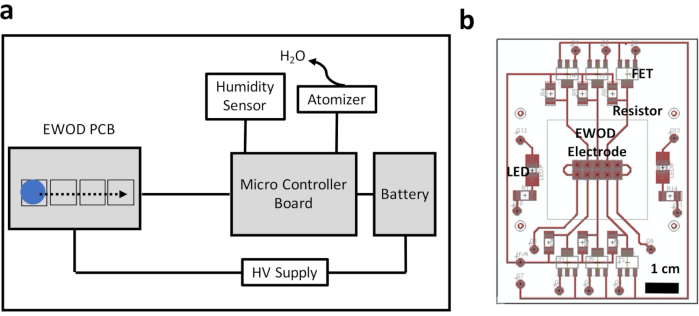

Here, we present a digital microfluidics educational kit based on commercially sourced printed circuit board (PCB) that allows the user to assemble and get hands-on experience with digital microfluidics (Figure 1). Fee-for-service to create PCB from digital design files is widely available, and hence we think it is a viable low-cost solution for education provided that digital design files can be shared. Meticulous choice of components and system design is made to simplify the assembly process and make an interface with the user's intuitive. Hence, a one-plate configuration is used instead of a two-plate configuration to avoid the need for a top plate. Both the components and the test chemicals need to be easily available. For example, food wrap from the supermarket is used as the insulator in our kit.

To prove feasibility of our kit, we suggest a specific chemistry experiment based on chemiluminescence of luminol and provide the protocol. The hope is that visual observation of chemiluminescence can enthuse and excite students. Luminol is a chemical that exhibits a blue glow when mixed with an oxidizing agent such as H2O2 and is typically used in forensics to detect blood18. In our laboratory setting, potassium ferricyanide serves as the catalyst. Luminol reacts with the hydroxide ion and forms a dianion. The dianion subsequently reacts with oxygen from hydrogen peroxide to form 5-aminophthalic acid with electrons in an excited state, and relaxation of electrons from the excited state to the ground state results in photons visible as a burst of blue light.

We also report a fluorescent imaging experiment with a smart phone to demonstrate the integration of a light-emitting diode (LED) as an excitation light source. Finally, droplet evaporation is a problem in microfluidics but is rarely being addressed. (A 1 μL of water droplet is lost within 1 h from an open substrate3.) We use an atomizer based on a high-frequency piezo transducer to convert water into fine mist. This creates a humidified environment to prevent droplet evaporation and demonstrates long-term (~1 h) droplet actuation.

Figure 1: Schematics of EWOD set up. (a) A microcontroller is used to provide a control sequence to the EWOD electrode. Also, the humidity is controlled. (b) Schematics of PCB layout. Electrodes, LED for fluorescent imaging, resistor, and field effect transistors (FET) are labeled. Scale bar of 1 cm is also shown. Please click here to view a larger version of this figure.

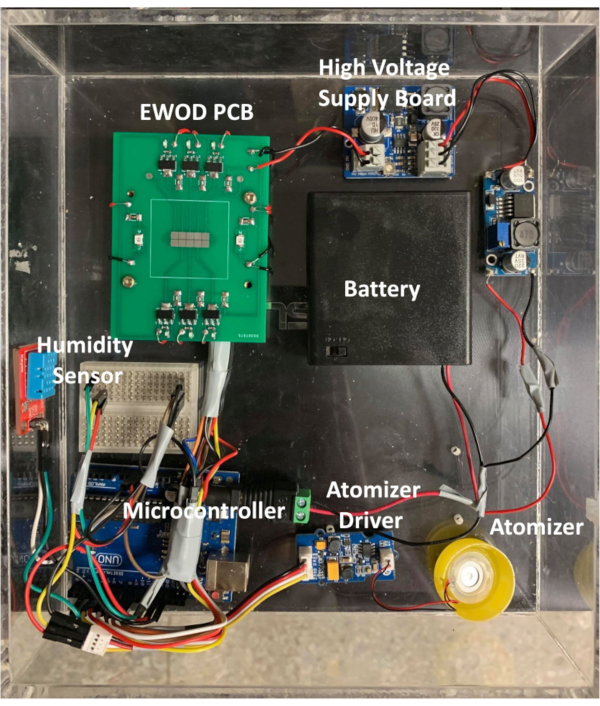

Figure 2: Top view of the kit. Microcontroller board, high voltage supply board, EWOD PCB, humidity sensor, and atomizer are labeled. Please click here to view a larger version of this figure.

Protocol

1) Assembling the digital microfluidics kit

- Solder the surface mount resistors, transistors, and light-emitting diodes onto the PCB board according to the schematics in Figure 1b.

- Connect the output of the high-voltage power supply board to the PCB board with soldered components (Figure 2 and Supplementary Figure 1).

- Connect the battery to the voltage booster board to boost the voltage from 6 V to 12 V (Figure 2 and Supplementary Figure 1).

- Connect the high-voltage supply board to the voltage booster board to boost the voltage from 12 V to ~230 V (Figure 2 and Supplementary Figure 1).

- Connect the humidity sensor to the microcontroller board. Connect the ultrasonic piezo atomizer and the atomizer driver board to the microcontroller board (Figure 2 and Supplementary Figure 1).

- Place the whole assembly into the acrylic enclosure of dimensions 23 cm x 20.5 cm x 6 cm.

- Turn on the microcontroller with the code (Supplementary Code) and use the digital multimeter to measure the voltage of the EWOD electrode to make sure the output voltage is ~230 V. Adjust the variable resistor of the high-voltage supply board such that the output voltage is ~230 V (Supplementary Figure 2).

2) Preparation of insulator on the electrode array

- Wear clean nitrile gloves. Use a micropipette to apply ~10 μL of 5 cSt silicone oil on the electrode area and use a finger to spread the silicone oil evenly on the electrode area. Note that the silicone oil serves as the filling between electrode and food wrap insulator and to avoid any airgap.

- Cut a piece of food wrap with dimensions of approximately 2.5 cm x 4 cm and place it on top of the electrode. Use the micropipette to apply ~10 μL of 5 cSt silicone oil on the electrode area and use a finger to spread the silicone oil evenly. Note that the silicone oil serves as a hydrophobic layer on top of the insulator.

3) Chemiluminescence experiment based on luminol

- Mix 0.25 g of luminol and 1.6 g of NaOH in 25 mL of deionized water in a beaker with a glass stirrer to obtain a solution.

- Mix 20 mL of the solution from the previous step with 20 mL of 3% hydrogen peroxide.

- Use a micropipette to place 2-5 μL of the luminol solution from the previous step on the target electrode.

- Use a micropipette to place 10 μL of 0.1% w/w potassium ferricyanide on the electrode. Note that this is the droplet to be moved for electrowetting.

- Turn on the microcontroller to move the 10 μL droplet of potassium ferricyanide to merge with the luminol.

4) Fluorescent imaging experiment

- Cut a piece of semi-transparent tape with dimensions of ~1 cm x 1 cm. Place the semi-transparent tape between the excitation light-emitting diode and EWOD electrodes.

- Attach the emission color glass filter on the camera of the smart phone with tape.

- Mix 2.5 mg of fluorescein isothiocyanate in aqueous ethanol (3% w/w) solution.

- Pipette ~10 μL of the solution from the previous step on one of the electrodes.

- Turn on the microcontroller.

- Use the smart phone to record a video of droplet actuation.

5) Long-term droplet actuation experiment with ultrasonic atomizer

- Place 1 mL of water onto the ultrasonic atomizer. Note that the code is written to use a threshold feedback algorithm to maintain a humidity level over 90%.

- Place a 10 μL droplet with a micropipette. Turn on the microcontroller and immediately close the lid of the enclosure.

- Wait for ~1 h. Visually check droplet actuation.

Results

The droplet actuation is recorded with a smart phone. Representative results for chemiluminescence and fluorescent imaging are displayed in Figure 3 and Figure 4. For the chemiluminescence experiment, the droplet of 10 μL ferricyanide is actuated to move and mix with pre-deposited 2 μL droplet on the target electrode as shown in Figure 3. The time period between successive movement is set t...

Discussion

The procedure described here allows the reader to assemble and test a working EWOD system for droplet actuation and gain hands-on experience with microfluidics. We intentionally avoid expensive components and chemical samples. Currently, one kit can be constructedfor ~$130 with the most expensive component being optical color glass for fluorescent imaging and microcontroller excluding the custom acrylic enclosure (Supplementary Table 1). For such a cost, a fluorescent imaging capability and an active hum...

Disclosures

The authors have nothing to disclose.

Acknowledgements

Y. T. Y. would like to acknowledge funding support from the Ministry of Science and Technology under grant numbers MOST 107-2621-M-007-001-MY3 and National Tsing Hua University under grant number 109Q2702E1. Mark Kurban from Edanz Group (https://en-author-services.edanzgroup.com/ac) edited a draft of this manuscript.

Materials

| Name | Company | Catalog Number | Comments |

| Acrylic enclosure | LOCAL vendor | 23cm x 20.5 cm x 6cm | |

| Ardunion Uno | Arduino | UNO | microcontroller board |

| acetic acid | Sigma Alrich | 695092-100ML | |

| Breadboard | MCIGICM | 400tie | 4 cm x 7 cm, 400 Points Solderless Breadboard, a pack of 4 |

| BSP89 H6327 Infineon MOSFET | Mouser | 726-BSP89H6327 | drain soure breakdown voltage 240V,on resistance 4.2 ohm |

| citrid acid | sigma Alrich | 251275-100G | |

| Color glass filter | Thorlabs | FGL 530 | color glass filter for fluorescent imaging |

| DHT11 temperature & humidity sensor | adafruit | ||

| Digital multimeter | Fluke | 17B | |

| Fluorescein isothiocyanate isomer I | sigma Alrich | F7250-50MG | 50 mg price, fluorescent imaging |

| Glycerol | Sigma Alrich | G9012-500ML | |

| High voltage power supply for Nixe tube | Vaorwne | NCH6100HV | High voltage power max dc 235V |

| LM2596 voltage booster circuit | boost voltage from 5V to 12 V | ||

| Luminol | Sigma Alrich | 123072-5G | 5 g for $110 |

| Pippet | Thermal Fisher | 1- 10 ul | |

| Printed circuit board | Local vender | 10 piece for $60 | |

| Plastic food wrap | Kirkland | Stretch-tite | food wrap Plastic food wrap |

| Potassium ferricynide | Merck | 104982 | 1 kg |

| 1N Potassium hydroxide solution (1 mol/l) | Scharlau | 1 Liter | |

| Clear Office tape 3mm | 3M Scotch | semi-transparent, used as diffuser for illumination | |

| salt | Great Value Iodized Salt | 6 oz for $7 salt from supermarket | |

| Silicone oil (5Cst) | Sigma Alrich | 317667-250ML | top hydrophobic layer & filling layer between electrode and insulator |

| sucrose | table sugar from any supermarket, 6 dollar per pound | ||

| Surface mount blue LED | oznium | 3528 | Oznium 20 Pieces of PLCC-2 Surface Mount LEDs, 3528 Size SMD SMT LED - Blue |

| Surface mount resistor 180k Ohm | Balance World Inc | 3mm x 6 mm 1watt | |

| Surface mount resistor 510Ohm | Balance World Inc | bias resistor for LED, 3mmx6mm 1watt | |

| Water atomizer | Grove | operating frequency 100 kHz supply votage 5V max 2W The kit comes with ultrasonic transducer | |

| high voltage transistor | |||

References

- Convery, N., Gadegaard, N. 30 years of microfluidics. Micro and Nano Engineering. 2, 76-91 (2019).

- Rackus, D. G., Ridel-Kruse, I. H., Pamme, N. Learning on a chip: Microfluidics for formal and informal science education. Biomicrofluidics. 13, 041501 (2019).

- Legge, C. H. Chemistry under the microscope-Lab on a chip technologies. Journal of Chemical Education. 79, 173 (2002).

- Fintschenko, Y. Education: a modular approach to microfluidics in the teaching laboratory. Lab On A Chip. 11, 3394 (2011).

- Mugele, F., Baret, J. -. C. Electrowetting: from basics to applications. Journal of Physics: Condensed Matter. 17, 705-774 (2005).

- Lippmann, G. Relations entre les phenomenes electriques et capillary. Ann. Chim. Phys. 6, 494 (1875).

- Berge, B. Electrocapillarite et mouillge de films isolant par l'eau. C. R. Acad. Sci. II. 317, 157 (1993).

- Pollack, M. G., Fair, R. B., Shenderov, A. D. Electrowetting-based actuation of liquid droplets for microfluidics applications. Applied Physics Letters. 77, 1725 (2000).

- Lee, J., Kim, C. J. Surface-tension-driven microactuation based on continuous electrowetting. Journal of Microelectromechanical Systems. 9 (2), 171 (2000).

- Choi, K., Ng, A. H. C., Fobel, R., Wheeler, A. R. Digital Microfluidics. Annual Review of Analalytical Chemistry. 5, 413-440 (2012).

- Jebrail, M. J., Wheeler, A. R. Let's get digital: digitizing chemical biology with microfluidics. Current Opinion in Chemical Biology. 14, 574-581 (2000).

- Pollack, M. G., Pamula, V. K., Srinivasan, V., Eckhardt, A. E. 2011. Applications of electrowetting-based digital microfluidics in clinical diagnostics. Expert Review of Molecular Diagnostics. 11, 393-407 (2011).

- Abdelgawad, M., Wheeler, A. R. Rapid prototyping in copper substrates for digital microfluidics. Advanced Materials. 19 (1), 133-137 (2007).

- Abdelgawad, M., Wheeler, A. R. Low-cost, rapid-prototyping of digital microfluidics devices. Microfluidics and Nanofluidics. 4, 349-355 (2008).

- Fobel, R., Fobel, C., Wheeler, A. R. DropBot: an open-source digital microfluidic control system with precise control of electrostatic driving force and instantaneous drop velocity measurement. Applied Physics Letters. 102, 193513 (2013).

- Yafia, M., Ahmadi, A., Hoorfar, M., Najjaran, H. Ultra-portable smartphone controlled integrated digital microfluidic system in a 3D-printed modular assembly. Micromachines. 6 (9), 1289-1305 (2015).

- Alistar, M., Gaudenz, U. OpenDrop: an integrated do-it-yourself platform for personal use of biochips. Bioengineering. 4 (2), 45 (2017).

- Khan, P., et al. Luminol-based chemiluminescent signals: clinical and non-clinical application and future uses. Applied Biochemistry and Biotechnology. 173 (2), 333-355 (2014).

- Agresti, J. J., et al. Ultrahigh-throughput screening in drop-based microfluidics for directed evolution. Proceedings of the National Academy of Sciences of the United States of America. 107 (9), 4004-4009 (2010).

- . Microfluidics Available from: https://microfluidics.utoronto.ca/dropbot/ (2020)

- Busnel, J. M., et al. Evaluation of capillary isoelectric focusing in glycerol-water media with a view to hydrophobic protein applications. Electrophoresis. 26, 3369-3379 (2005).

- Chatterjee, D., Shepherd, H., Garrell, R. L. Electromechanical model for actuating liquids in a two plate droplet microfluidic device. Lab On A Chip. 9, 1219-1229 (2009).

Reprints and Permissions

Request permission to reuse the text or figures of this JoVE article

Request PermissionExplore More Articles

This article has been published

Video Coming Soon

Copyright © 2025 MyJoVE Corporation. All rights reserved