Method Article

Preparation of Free-Surface Hyperbolic Water Vortices

In This Article

Summary

This paper describes how three different water vortex regimes in a hyperbolic Schauberger funnel can be created, their most important characteristics, and how associated parameters such as the oxygen transfer rates can be calculated.

Abstract

Free surface vortices are present in industry in flow regulation, energy dissipation, and energy generation. Although investigated extensively, detailed experimental data regarding free surface vortices are lacking, particularly regarding the turbulence at the interface. The present paper reports on a special type of free surface vortex first proposed by Walter Schauberger in the 1960s that has an oxygen volumetric mass transfer coefficient exceeding the value of similar systems. This special type of vortex forms in a hyperbolic funnel. Different stable regimes can be stabilized with different hydraulic characteristics. Other advantages of this technology are its energy efficiency, simple design, and scalability. The flow in this hyperbolic funnel is characterized by strong turbulence and an increased surface area of the air-water interface. The local pressure strongly varies along the surface, resulting in a pronounced wavey air-water boundary layer. Due to the helical flow, these perturbations move inward, pulling the boundary layer with them. The resultant pressure gradient draws a certain air volume into the water vortex. The construction of the basic hyperbolic funnel setup and operational examples, including high-speed visualization for three different stable regimes, are presented in this work.

Introduction

Our lives are closely connected with spiral structures. They exist in almost everything and everywhere, including the structure of shells and ammonites and the formation of hurricanes, tornadoes, and whirlpools1,2. On a cosmological scale, galaxies form and evolve according to the principle of the logarithmic spiral3. The best-known spirals are the golden and the Fibonacci spirals4, which have many applications ranging from describing plant growth and the crystallographic structure of certain solids to developing computer database search algorithms. The Fibonacci sequence is characterized as a numerical series that starts with 0 and 1 and has subsequent numbers corresponding to the sum of the previous two. This sequence can also be found when counting the reproduction rate of rabbits. Spirals are among some of the oldest geometric shapes drawn by Homo sapiens, such as the concentric circles found in Colombia and Australia (40,000-20,000 BC1). Leonardo da Vinci5 tried to create a helicopter-shaped flying machine using a spiral blade (from the Greek word ἕλιξ πτερόν, or helix pteron, meaning spiral wing). Following the same principle, an aircraft designer, Igor Sikorsky, constructed the first helicopter in series production 450 years later6.

Many other examples point to the fact that helical flow structures might be very efficient and expense-saving because this type of flow is preferentially seen in nature. At the beginning of the 20th century, the Austrian forester and philosopher Viktor Schauberger realized this. He said that humans should study nature and learn from it rather than trying to correct it. Based on his ideas, he built rather unusual log flumes to float timber; the flumes did not take the straightest path between two points but followed the meandering of valleys and streams. This design made the water flow by twisting in a spiral along its axis, thus forming a vortex, which thereby reduced the amount of water used and produced a transport rate that significantly exceeded what was considered normal7.

Following his father's footsteps, Viktor's son Walter developed new technologies using the water vortex8 for various purposes: the treatment of drinking water, industrial process, the restoration of ponds and water courses, the oxygenation of ponds and little lakes, and river regulation and restoration. One of these ideas has recently gained considerable interest, namely water treatment using a hyperbolic funnel8, in which a vortex is created only by the flow of water without any stirring devices. It has been proven to be a very effective method for oxidizing iron in groundwater9,10. A limitation of this technology is that it is less efficient for low-pH water11.

Large amounts of drinking water in the Netherlands are obtained from underground sources12, in which the concentration of iron can reach several tens of milligrams per liter13, whereas 0.2 mg/L is considered acceptable by the standards14. Most drinking water plants use aeration as one of the first steps to reduce the iron concentration in the water purification process. In most cases, the purpose of aeration is to increase the dissolved oxygen content, to remove gases and other related substances from the water, or both15. There are various methods by which aeration can introduce oxygen into liquid media. These methods include agitating the liquid surface using a mixer or turbine and releasing air through either macroscopic orifices or porous materials16.

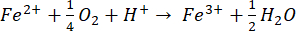

The chemical process of iron oxidation was demonstrated by van de Griend17, in which an oxygen molecule takes an electron from ferrous iron and reacts with a free proton to form water, while the iron ion is oxidized (equation [1]):

, (1)

, (1)

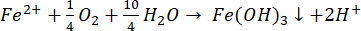

The iron ion then precipitates as Fe(OH)3 because of its reaction with water, which releases protons (equation [2]):

(2)

(2)

The total reaction is given by equation (3):

. (3)

. (3)

In aeration, the techniques most often applied are cascades, tower, spray, and plate aeration systems18,19. The disadvantage of these technologies is that they consume from 50% to 90% of all energy20 and up to 40% of the budget for the operation and maintenance of the treatment facilities21.

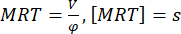

Using a hyperbolic funnel for aeration can significantly decrease the costs and increase the efficiency of this process. Hyperbolic funnels are less sensitive to clogging due to their geometry and the fact that there are no moving parts, meaning the energy is spent only on pumping water. Such a system can be characterized by several parameters, such as the water flow rate of the funnel per hour (φ), the mean residence time (MRT), the hydraulic retention time (HRT), the oxygen volumetric mass transfer coefficient (KLa20) (corrected to a standardized temperature of 20°C), the standard oxygen transfer rate (SORT), and the standard aeration efficiency (SAE). The flow rate of the funnel is needed to calculate the volume of water that can be processed in a certain time. The MRT is calculated from the ratio of the water flow rate to its volume in the funnel for a certain regime using equation (4):

(4)

(4)

where V represents the liquid volume in the reactor.

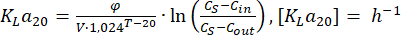

The HRT can be determined experimentally using tracer technologies22 via its residence time distribution function. HRT provides fundamental insight into mixing processes, hold-ups, and segregation phenomena23. It was shown by Donepudi24 that the farther away the water jet is from the inlet, the faster it moves toward the outlet. At the initial moment, water is pumped tangentially to the upper cylindrical part of the funnel. Then, under the influence of gravity, together with the system's geometry, the tangential velocity decreases, and the axial velocity increases. The oxygen volumetric mass transfer coefficient, KLa20 (unit reciprocal time), indicates the capability of a system to facilitate oxygen transfer to the liquid phase10. It can be calculated25,26 according to equation (5):

(5)

(5)

where Cout is the dissolved oxygen (DO) concentration in the bulk liquid, Cin is the DO concentration in the feed, Cs is the DO concentration at saturation, and T is the water temperature.

The SORT value is the standard rate of oxygen transferred to the liquid phase by the system and is determined by equation (6)27:

(6)

(6)

where  is the DO at saturation for a temperature of 20 °C. The SOTR value can be defined for a certain process, in which case the volume used in equation (6) is normalized by assuming 1 h of treatment time (process-specific SOTR), so that pilot scale aeration methods can be compared with real-scale systems. For the capability of a certain regime in the funnel, the system-specific SOTR must be calculated, which uses the volume of water inside the funnel for a (regime-specific) hydraulic retention time. This value is important when calculating the actual aeration capabilities of a regime in a given funnel.

is the DO at saturation for a temperature of 20 °C. The SOTR value can be defined for a certain process, in which case the volume used in equation (6) is normalized by assuming 1 h of treatment time (process-specific SOTR), so that pilot scale aeration methods can be compared with real-scale systems. For the capability of a certain regime in the funnel, the system-specific SOTR must be calculated, which uses the volume of water inside the funnel for a (regime-specific) hydraulic retention time. This value is important when calculating the actual aeration capabilities of a regime in a given funnel.

The SAE is the ratio between the SOTR and the power expended for aeration. Since energy is spent only on pumping water to the top of the funnel and giving it the necessary flow to form a vortex, it is calculated as the sum of the potential energy of the volume of water pumped per hour at a height corresponding to the length of the funnel and the kinetic energy needed by the water to create a vortex27 using equation (7):

(7)

(7)

where Pp is the potential power (in kW) required to lift the water pumped to the height of the funnel, and Pk is kinetic power (in kW) required for the water pumped at the top of the funnel to gain enough flow to create a vortex. Normally, for equation (7), the system-specific SOTR should be used. If the process-specific SOTR is applied instead, it yields the energy consumption of a (theoretical) system with 1 h of hydraulic retention time.

These parameters are sufficient to assess the effectiveness and feasibility of using this technology but not to describe the process itself. It should be mentioned that vortices are among the least understood phenomena in fluid dynamics. Therefore, a lot of research efforts are invested in this direction. One of the main challenges in finding the general laws and rules of vortices in fluid dynamics is that there are always variations in the geometric boundary conditions, which influence the development of vortices and significantly influence their formation and dynamics. Thus, it is reasonable to assume that a free-surface vortex (FSV) cannot be considered analogously to a laboratory-type confined one. However, it was shown by Mulligan et al.28 for the Taylor-Couette flow (TCF) that if the air-core of the FSV is considered as a virtual inner cylinder rotating at the same speed as the air core, both can be treated similarly. By doing so, equations that represent the free-surface vortex flow field can be substituted with the angular velocity conditions of the virtual cylinder, resulting in equations for the TCF system. It was also demonstrated that if the rotation speed of an imaginary cylinder is increased, at some point, Taylor-like vortices28 appear as a secondary flow field and then disappear when approaching the walls.

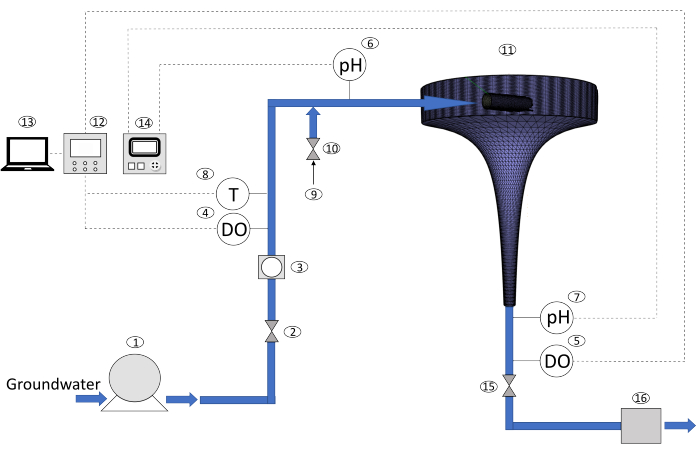

After it was shown by Niemeijr29 that it is possible to obtain three different types of water vortices in a Schauberger funnel (twisted, straight, and restricted) (Figure 1 and Figure 2), which are characterized by other hydraulic parameters, Donepudi24 used the same approach as Mulligan et al.28 to simulate vortex regimes using computational fluid dynamics (CFD) and thereby analyze the organization of their flow field to understand the underlying physical mechanisms. The system is very turbulent, and the secondary flow field is very unstable and is characterized by the appearance of a large number of Taylor-like vortices. Gas transport from the gas phase into the liquid phase is governed by diffusion, advection, and reaction. Therefore, to increase the efficiency of this process, it is necessary either to increase the gas concentration gradient or the volumetric motion of the liquid. The latter directly depends on the turbulence of the system in the form of Taylor-like vortices, which facilitate the transport of saturated fluid elements from the interface into the bulk liquid. In another work on this topic9, the main parameters for different vortex regimes, such as the water flow rate, KLa20, and SOTR, were compared. This study showed great promise for this technology because the system enables very fast gas transfer compared to other methods that are used for water aeration.

The purpose of this article is to provide and demonstrate this method for creating different water vortex regimes in hyperbolic Schauberger funnels (small: 26 cm high and 15 cm top diameter; medium: 94 cm high and 30 cm top diameter; large: 153 cm high and 59 cm top diameter) with the goal of efficient water aeration.

Protocol

1. General recommendations

- Check all the pipe connections for leaks before starting the setup.

- Check that the funnel lid is in place, and secure.

- Clean the funnel before and after each experiment with a brush and glass cleaner, as it may turn yellow due to the high concentration of iron in the groundwater.

2. Experimental setup

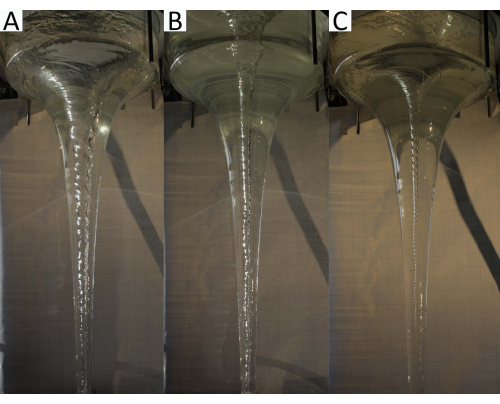

- Water vortex system (Figure 3)

- Securely fix the glass funnel (Figure 4) in a vertical position on a special frame - a board with four legs and a slot in the middle, which corresponds to the diameter of the cylindrical part of the funnel and is big enough for the funnel to fit in but not too big for it to fall through. Securely fasten the frame so that it does not shake.

- Put a rubber gasket between the lid and the funnel to avoid leaks. Attach the funnel lid, and tighten it using the bolts.

- Connect the groundwater pump to the tangential inlet in the top cylindrical part of the funnel using hoses and hose connectors.

- Connect a special control valve to adjust the water flow rate between the pump and the funnel. Connect a water flow meter between the control valve and the funnel.

- Connect the outlet of the funnel to the drain with a hose. On the drainage hose, near the outlet of the funnel, install a clamp to create back pressure during the unit's operation.

NOTE: The clamp should be installed immediately after all the other adapters and connectors required for the experiments.

- System for tracer experiments (Figure 3)

- Install special adapters for installing probes near the inlet and outlet. Install pH probes in these adapters, and connect them to the data logger.

- Install sensors as close as possible to the funnel to reduce error in the HRT calculations.

- Prepare 1 mL of NaOH solution (concentration: 0.2 M) to be used as a chemical tracer that is injected into the water flow of the jet.

NOTE: As sodium hydroxide aqueous solution is a strong base, it is displayed as a peak-like increase in the pH30. - Install an adapter with three openings for connecting the tracer-injection system, which consists of a valve and a syringe before the pH probe near the inlet.

- System for DO experiments (Figure 3)

- Glue two oxygen sensor spots to the inside wall of the two different glass adapters, placing them as close as possible to the inlet and outlet of the funnel and connecting them to the water pipeline.

NOTE: During operation, the water must completely cover the stickers. - Install the glass adapter with the oxygen sensor spot near the inlet and outlet of the funnel, and fix the tip of the polymer optical fiber (which is 2 m long) over the sticker on the other side of the glass.

- Install the water temperature sensor near the funnel inlet in the same adapter as for the pH probe. Ensure that it is close to the fiber, since the water temperature is used to correlate the DO measurements.

- Connect the polymer optical fiber and temperature sensor to the fiber-optic oxygen transmitter.

- Connect the fiber-optic oxygen transmitter to a laptop with special software installed to display the signal from the sensor, which is related to the concentration of dissolved oxygen and the water temperature.

- Glue two oxygen sensor spots to the inside wall of the two different glass adapters, placing them as close as possible to the inlet and outlet of the funnel and connecting them to the water pipeline.

3. Operation (medium funnel)

- Vortex regimes

- Turn on the flow meter. Start the underground water pump, and fully open the control valve. Make sure that the water flow is significantly higher than the maximum flow required to form a water vortex (1338 L/h for the medium funnel).

- Adjust the desired value of the water flow by turning the control valve. If necessary, squeeze the clamp near the outlet of the funnel to allow water to be blocked in the funnel, which causes the water level to rise in the upper cylindrical part of the funnel.

- To set different regimes, adjust the values of the water flow and the water level in the upper cylindrical part of the funnel (Table 1), sequentially in one experiment. Check the water vortex for stability for 15 min. In stable mode, the water level should not change.

- For the twisted regime, adjust the flow rate to 1194 L/h and the water level to 2 cm and the flow rate to 1218 L/h and the water level to 5 cm.

- For the straight regime, adjust the flow rate to 1314 L/h and water level to 11 cm and the flow rate to 1338 L/h and the water level to 11.7 cm.

- For the restricted regime, as opposed to the twisted and straight regimes, create back pressure by squeezing the clamp near the outlet of the funnel. Set the flow rate to 882 L/h and the water level to 3 cm and the flow rate to 936 L/h and the water level to 9 cm.

- Tracer experiment

- Using a data logger, calibrate the pH probes to ensure the validity and accuracy of the data obtained.

- Prepare two standard solutions, one with a pH that is higher than the pH of the operating range (6-10), and one with a pH that is lower than the pH of the operating range. Set their values in the data logger and measure them one by one during the calibration. After that, the data logger calibrates the pH probes.

- Install pH probes at the inlet and outlet of the funnel, connect them to the data logger, and start the recording mode.

- Start the setup.

- Start the setup, and make sure that the water vortex is stable.

- Fill the syringe with the prepared tracer mixture of NaOH and connect it to the tracer injection line. Quickly unscrew the valve in the injection system, inject the tracer liquid, and then quickly screw the valve.

- Perform the saving and analysis.

- When the pH stabilizes, save the pH peaks recorded during the passage of the tracer liquid through a glass funnel.

- Analyze the entry and exit peaks as described in a previous work22 for HRT calculation. To do this, take the point at the beginning of the first peak for the countdown, and take the point on the second peak, which divides it into two figures of equal area, for the end of the countdown.

- Using a data logger, calibrate the pH probes to ensure the validity and accuracy of the data obtained.

- DO experiment

- Calibrate the DO sensor using software with a laptop and the fiber-optic oxygen transmitter. Use two fluids: one oxygen-free (mix 0.1 L of water and 1 g of sodium sulfite), and the other saturated with oxygen (to do this, aerate it with air for 15 min). Then, select the calibration function in the software, and measure both liquids in turn.

- Perform the installation and recording.

- Install the DO sensor at the inlet and outlet of the funnel. Additionally, install the temperature sensor near the funnel inlet. Connect them to the fiber-optic oxygen transmitter, and start the recording mode.

- Start the setup, and make sure the water vortex is stable. Reach the mode in which the value of the concentration of DO is stable and record the data.

NOTE: If the readings are not stable, the data are not valid, and the experiment must be repeated.

Results

The water vortex in the Schauberger hyperbolic funnel is formed in different regimes (twisted, straight, and restricted) (Figure 1). As a result, the water is enriched with atmospheric oxygen, and oxidation of chemical species in the water is fostered. The system does not require energy except for pumping water into the upper part of the hyperbolic funnel.

The twisted regime has a double-helix shape and the largest interface between water and air. For its creation, it is necessary to apply an average water flow (75-78 L/h for the small funnel, 1,194-1,218 L/h for the medium funnel, and 4,834-5,032 L/h for the large funnel). Its height in the upper cylindrical part of the funnel should not be more than 2 cm for the small funnel, 7 cm for the medium funnel, and 16 cm for the large funnel.

The straight regime has a smooth straight shape and a smaller interface between water and air. This regime requires maximum water flow (93-100 L/h for the small funnel, 1,314-1,338 L/h for the medium funnel, and 5,102-5,289 L/h for the large funnel). Its height can reach the cover for all the funnels.

Depending on the water level, the restricted regime can take the form of both twisted and straight vortices. However, the peculiarity of this regime is that its length changes depending on the application of back pressure, unlike in the previous modes, for which no pressure is applied. It is also formed at the top of the funnel; however, with increasing back pressure, its tail begins to shorten, and the vortex gradually disappears from the bottom part. Its water flow is extremely small (58-70 L/h for the small funnel, 882-936 L/h for the medium funnel, and 2,351-2,634 L/h for the large funnel), and its height can be both minimal and maximal depending on the funnel geometry.

The different regimes can be stabilized and transformed into each other depending on the water flow rate, back pressure, and system geometry. Parameters such as the water flow rate, oxygen volumetric mass transfer coefficient, and standard oxygen transfer rate characterize the aeration efficiency. It can be seen that for the twisted vortex with a low water flow rate, the KLa20 was the highest (Figure 4), several times higher than the KLa20 for straight and restricted regimes and dozens of times higher than the same indicator for conventional systems, which are also used for the aeration of lakes and rivers (Air Jet, Impeller, Paddle) and are much more energy intensive. With further increases in water flow, the KLa20 gradually decreased, but the water level, that is, the volume of water in the system, increased. After some threshold value, the twisted regime switched to the straight regime. For each regime, there were stationary conditions when their volume and hydraulic parameters do not change.

However, when comparing similar regimes for small, medium, and large funnels, the differences between the systems' water flow rates and volumes were significant. However, at the same time, the ratios of the KLa20 values did not change much. The maximum values of 83 h-1 for the small funnel, 60 h-1 for the medium funnel, and 79 h-1 for the large funnel were achieved in the twisted regime.

At the same time, when the KLa20 decreased with increasing water flow, the MRT increased, indicating that the water took more time to pass through the funnel, as described in detail by Donepudi24. However, as for KLa20, the value of MRT was approximately the same for the twisted and straight regimes in different funnels. The MRT varied from 10 s to 43 s for the small funnel, from 14 s to 30 s for the medium funnel, and from 24 s to 43 s for the large one (Table 1).

Figure 1: Water vortex regimes in a 26 cm high glass hyperbolic Schauberger funnel. (A) Twisted (75 L/h), (B) straight (100 L/h), (C) restricted (70 L/h). Please click here to view a larger version of this figure.

Figure 2: Water vortex regimes in a 94 cm high glass hyperbolic Schauberger funnel. (A) Twisted (1,194 L/h), (B) straight (1,314 L/h), (C) restricted (882 L/h). Please click here to view a larger version of this figure.

Figure 3: Sketch of the setup used for the experiments described in protocol steps 3.1-3.3. (1) Groundwater pump; (2) control valve; (3) water flow meter; (4, 5) polymer optical fibers for DO detection; (6, 7) pH probes; (8) temperature sensor; (9) syringe with tracer; (10) valve; (11) Schauberger hyperbolic funnel; (12) fiber-optic oxygen transmitter; (13) laptop; (14) data logger; (15) clamp; (16) water drain. Please click here to view a larger version of this figure.

Figure 4: Photo of the large funnel setup. (1) Groundwater reservoir; (2) water pump; (3) water flow meter; (4) syringe with tracer; (5, 6) glass adapters with the oxygen sensor spot; (7), (8) pH probes; (9) Schauberger hyperbolic funnel; (10) water drain. Please click here to view a larger version of this figure.

| Funnel | Regime | φ (L/h) | HRT (s) | MRT (s) | KLa20 (h-1) | V (L) | Level (cm) | Cin (mg/L) | Cout (mg/L) | SOTR (g O2/h) | SAE (g O2/kWh) |

| Small | Twisted | 75 | 10 | 15 | 83 | 0.2 | 0.5 | 0.0 | 1.8 | 0.2 | 2801 |

| 78 | 20 | 24 | 41 | 0.4 | 2 | 0.0 | 1.9 | 0.2 | 2932 | ||

| Straight | 93 | 31 | 24 | 25 | 0.8 | 4 | 0.0 | 1.8 | 0.2 | 2688 | |

| 100 | 43 | 32 | 18 | 1.2 | 6 | 0.0 | 1.7 | 0.2 | 2635 | ||

| Restricted | 58 | 18 | 23 | 14 | 0.3 | 1 | 0.0 | 0.6 | 0.0 | 872 | |

| 70 | 53 | 31 | 2 | 1.0 | 5 | 0.0 | 0.3 | 0.0 | 459 | ||

| Medium | Twisted | 1194 | 14 | 13 | 60 | 4.5 | 2 | 0.0 | 1.8 | 2.4 | 784 |

| 1218 | 19 | 19 | 37 | 6.3 | 5 | 0.0 | 1.6 | 2.1 | 667 | ||

| Straight | 1314 | 29 | 29 | 18 | 10.7 | 11 | 0.0 | 1.2 | 1.8 | 509 | |

| 1338 | 30 | 31 | 18 | 11.0 | 11.7 | 0.0 | 1.2 | 1.8 | 500 | ||

| Restricted | 882 | 21 | 24 | 17 | 5.1 | 3 | 0.0 | 0.9 | 0.8 | 348 | |

| 936 | 37 | 36 | 5 | 9.7 | 9 | 0.0 | 0.5 | 0.4 | 180 | ||

| Large | Twisted | 4834 | 24 | 23 | 79 | 32 | 11 | 0.7 | 4.1 | 22.9 | 1113 |

| 5032 | 34 | 26 | 52 | 48 | 16 | 0.6 | 4.0 | 22.6 | 1054 | ||

| Straight | 5102 | 38 | 29 | 31 | 54 | 19.5 | 0.7 | 3.0 | 15.0 | 690 | |

| 5289 | 43 | 30 | 19 | 64 | 22.5 | 0.6 | 2.3 | 10.8 | 479 | ||

| Restricted | 2351 | 58 | 43 | 16 | 38 | 7 | 0.6 | 2.6 | 5.5 | 557 | |

| 2634 | 95 | 50 | 7 | 70 | 19 | 0.6 | 2.0 | 4.2 | 380 |

Table 1: Basic hydraulic characteristics and aeration efficiency parameters for small (Figure 1), medium (Figure 2), and large funnels.

Discussion

If the groundwater pump is too powerful and the system cannot hold the pressure, an additional drain can be added before the control valve to reduce it. It is very important to calibrate the sensors for reliable results and for the tracer experiment to ensure fast probes. If the probes are slow, then this will distort the HRT measurements. Further, if the HRT is much smaller than the MRT for the straight regime, this may indicate that the tangential entrance to the funnel is significantly below the water level and that part of the tracer liquid is going down to the drain after entering the funnel, thus causing a decrease in HRT.

The water vortex in a hyperbolic Schauberger funnel is very sensitive to the water flow rate. The smaller the system, the more it depends on flow changes. If the regime is stable, then the water level in the funnel should not change with time. If this is not the case, it will rise or fall. Therefore, it is worth paying attention to the water level to avoid water overflow, cracks due to increased pressure inside the funnel, or an unwanted regime change.

To determine the regime of the vortex (protocol steps 3.1.3.1-3.1.3.3) and its stability, it is advantageous for the funnel to be transparent. For this reason, a glass funnel was used in this work. It is imperative to be very careful when transporting, handling, and installing it, and one should pay attention not to tighten the screws of the lid too much so as not to damage it (protocol step 2.1.2).

To determine the HRT, protocol steps 3.2.2-3.2.3 should be repeated as many times as possible (at least 10x) because, due to the high turbulence of the system and the presence of secondary flows (Taylor-like vortices), the tracer jet can separate and travel different ways through the funnel. For example, it was shown by Donepudi et al.24 and Mulligan et al.28 that the closer the water layer is to the glass wall, the faster it will move to the drain. The probes should always be washed with deionized water and wiped to avoid mixing the sample and the storage solution, which can spoil the data and deteriorate the quality of the electrode storage.

For the DO experiment, it is important to achieve a stable oxygen concentration value at the output of the system (protocol step 3.3.2.2). If the regime is not stable but the fluctuations in the system are not significant, then the obtained value should be averaged. It is also necessary to have a hole in the lid for ventilation to allow airflow into the system for further aeration.

Despite the high values of KLa20 and energy efficiency of this system, the SOTR value is low compared to other methods26 because of the low water flow rates of the available funnels; this is currently a limitation for the industrial use of the hyperbolic funnel for water aeration. However, it has been demonstrated that high efficiency of the system can be achieved for different scales with large, medium, and small funnels. From this, we can conclude that by changing the geometry (dimensions, diameters of the inlet and outlet, curvature of the walls), it is possible to significantly increase the speed and volume of water treatment without reducing the aeration efficiency. Moreover, in Table 1, it can be seen that an increase in the funnel length by 1.1 m led to a more than 100-fold rise in the SOTR. Taking into account the fact that in some water treatment plants, the water level difference can reach several meters, (partial) aeration could be achieved at much lower costs than at present. Thus, determining how different geometric parameters of the funnel affect the water flow rate and KLa20 for vortex regimes can provide a cheap and competitive technology for the aeration of groundwater. Alternatively, as shown by Schauberger31, aeration can be used to improve the quality of water reservoirs, lakes, and rivers.

Disclosures

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

This work was performed in the cooperation framework of Wetsus European Center of Excellence for Sustainable Water Technology (www.wetsus.eu) within the Applied Water Physics theme. Wetsus is cofounded by the Dutch Ministry of Economic Affairs and Ministry of Infrastructure and Environment, The Province of Friesland and the Northern Netherlands Provinces. This research has received funding from the European Union’s Horizon 2020 research and innovation program under the Marie Sklodowska-Curie grant agreement No. 665874 and the Gilbert- Armstrong lab. We highly appreciate Maarten V. van de Griend's support of this work.

Materials

| Name | Company | Catalog Number | Comments |

| 1-/2-channel transmitter | Endress+Hauser | CM442 | Data logger |

| Control valve | +GF+ | 625DN20 | Typ514 |

| Data Logger | Endress+Hauser | CM442 | Liquiline |

| Fiber Optic Oxygen Transmitter | PreSens | SACN0002000005 | Fibox 3 |

| Glass Elbow Connector | Custom made | - | Adapter for the pipeline |

| Groundwater pump | SAER | 3637899 | H/150 |

| Laptop | any | any | Windows 10 or higher |

| Large glass funnel | Custom made | - | 94 cm high |

| Oxygen Calculator | PreSens | v. 3.1.1 | Software |

| Oxygen Sensor Spots | PreSens | NAU-D5-YOP | SP-PSt3 |

| pH connector | Custom made | - | Adapter for the pH probe |

| pH sensor | Endress+Hauser | CPS11 | Orbisint CPS11 |

| Polymer Optical Fiber | PreSens | POF-L2.5-2SMA | OXY-1 SMA |

| Rubber gasket | ERIKS | 11535207 | 141x197x2mm |

| Rubber gasket | ERIKS | 12252766 | 273x340x3mm |

| Small glass funnel | Custom made | - | 26 cm high |

| Water flow meter | Endress+Hauser | P7066819000 | Picomag |

| Water flow meter | Kobolt | 5NA15AC34P | MIK |

| Water Temperature Connector | PreSens | - | Pt100 |

References

- Tsuji, K., Muller, S. C. . Spirals and Vortices in Culture, Nature, and Science. , (2019).

- Uchiyama, Y., Zhang, X., Yanase, S. Generation mechanism of Tidally-driven whirlpools at a narrow strait in an estuary. IOP Conference Series: Earth and Environmental Science. 945, 012028 (2021).

- Vallee, J. P. Metastudy of the spiral structure of our home galaxy. The Astrophysical Journal. 566 (261), 261-265 (2002).

- Dunlap, R. A. . The Golden Ratio and Fibonacci Numbers. , (1997).

- Da Vinci, L., Manuscript B, L. P. a. r. i. s. Paris Manuscript B. Folio 83v. Collection of Institute de France. , (2023).

- Johnson, W. . Helicopter Theory. , (1980).

- Johansson, L., Ovesen, M., Hallberg, C. Self-organizing flow technology In Viktor Schauberger's footsteps. Institute of Ecological Technology Scientific and Technical Reports. , (2002).

- Sarafzadeh, M. Design and analysis of sustainable ways for water purification. Polytechnic University of Turin, Italy. , (2022).

- Agostinho, L. L. F. Enhanced oxygen volumetric mass transfer in a geometrically constrained vortex. Water. 14 (5), 771 (2022).

- de Kroon, E. Iron oxidation in groundwater using a hyperbolic water vortex system. Graduation Internship. Van Hall Larenstein University of Applied Sciences. , (2021).

- Sharma, K. S. Adsorptive iron removal from groundwater. Wageningen University. , (2001).

- . Compendium voor de Leefomgeving. Waterwinning en watergebruik in Nederland 1976-2018 Available from: https://clo.nl/indicatoren/nl0057-waterwinning-en-verbruik-nederland (2022)

- vanden Brink, C., Frapporti, G., Griffioen, J., Zaadnoordijk, J. W. Statistical analysis of anthropogenic versus geochemical-controlled differences in groundwater composition in The Netherlands. Journal of Hydrology. 336 (3-4), 470-480 (2007).

- Besluit kwaliteit drinkwater BES. Wettenbank Available from: https://wetten.overheid.nl/BWBR0028642/2010-10-10 (2010)

- Thakre, S. B., Bhuyar, L. B., Deshmukh, S. J. Effect of different configurations of mechanical aerators on oxygen transfer and aeration efficiency with respect to power consumption. International Journal of Aerospace and Mechanical Engineering. 2 (2), 100-107 (2008).

- Rosso, D., Larson, L. E., Stenstrom, M. K. Aeration of large-scale municipal wastewater treatment plants: state of the art. Water Science & Technology. 57 (7), 973-978 (2008).

- van de Griend, M. V., et al. Vortex impeller-based aeration of groundwater. Water. 14 (5), 795 (2022).

- Aeration and gas stripping. TU Delft OpenCourseWare Available from: https://ocw.tudelft.nl/wp-content/uploads/Aeration-and-gas-stripping-1.pdf (2015)

- Popel, H. J. Aeration and Gas Transfer. Delft University of Technology. , (1976).

- Drewnowski, J., Remiszewska-Skwarek, A., Duda, S., Lagod, G. Aeration process in bioreactors as the main energy consumer in a wastewater treatment plant. Review of solutions and methods of process optimization. Processes. 7 (5), 311 (2019).

- Hydro International's Wastewater Division. Wastewater treatment: Bubbling up for major energy saving. Filtration + Separation. 48 (2), 42-43 (2011).

- Levenspiel, O. . Tracer Technology, Modeling the Flow of Fluids. , (2012).

- Danckwerts, P. V. Continuous flow systems - Distribution of residence times. Chemical Engineering Science. 2, 1-13 (1953).

- Donepudi, T. Vortices in hyperbolic funnels as aeration systems. Delft University of Technology. , (2021).

- Benjamin, M. M., Lawler, D. F. . Water Quality Engineering - Physical/Chemical Treatment Processes. , (2013).

- Marappan, J. Assessment of the new generation aeration systems efficiency and water current flow rate, its relation to the cost economics at varying salinities for Penaeus vannamei culture. Aquaculture Research. 51 (5), 2112-2124 (2020).

- American Society of Civil Engineers. Measurement of Oxygen Transfer in Clean Water. American Society of Civil Engineers. , (1992).

- Mulligan, S., de Cesre, G., Casserly, J., Sherlock, R. Understanding turbulent free-surface vortex flows using a Taylor-Couette flow analogy. Scientific Reports. 8 (1), 824 (2018).

- Niemeijer, C. Simulation of a hyperbolic water vortex. Grenoble Institute of Technology. , (2019).

- Fabienne, A. Design and characterization of a rotating bed system bioreactor for tissue engineering applications. Biotechnology Progress. 24, 140-147 (2008).

- Hyperbolic Cone Fountains and Spiral Pipes. TrueSpring Available from: https://truespring.wordpress.com/w013/05/10/hyperbolice-cone-fountain-and-spiral-pipes/ (2013)

Reprints and Permissions

Request permission to reuse the text or figures of this JoVE article

Request PermissionExplore More Articles

This article has been published

Video Coming Soon

Copyright © 2025 MyJoVE Corporation. All rights reserved