Method Article

Advanced Workflow for Taking High-Quality Increment Cores - New Techniques and Devices

In This Article

Summary

Here, we present a protocol on how to avoid micro cracks in increment cores by applying a cordless drill with a torque multiplier to minimize problems when coring trees, as well as its effect on preparing long micro sections. This protocol also includes a procedure to sharpen corers in the field.

Abstract

In dendroecological research, precise dating of each single growth ring is a basic requirement for all studies, focusing on ring-width variations only, chemical or isotope analyses, or wood anatomical studies. Independent of the sampling strategy for a certain study (e.g., climatology, geomorphology), the way samples are taken is crucial for their successful preparation and analyses.

Until recently, it was sufficient to use a (more or less) sharp increment corer to obtain core samples that could be sanded for further analyses. Since wood anatomical characteristics can be applied to long time series, the need to obtain high-quality increment cores has taken on a new meaning. Essentially, the corer needs to be sharp(ened) when used. When coring a tree by hand, there are some problems in handling the corer, resulting in the hidden occurrence of micro cracks along the entire core: When starting to drill by hand, the drill bit is strongly pressed against the bark and the outermost ring until the thread has fully entered the trunk. At the same time, the drill bit is moved up and down as well as sideward. Then, the corer is drilled all the way into the trunk; however, it is necessary to stop after each turn, change the grip, and turn again. All these movements, as well as the start/stop-coring, puts mechanical stress on the core. The resulting micro cracks make it impossible to create continuous micro sections, as they fall apart along all these cracks.

We present a protocol to overcome these obstacles by applying a new technique using a cordless drill to minimize these problems when coring a tree, as well as its effect on the preparation of long micro sections. This protocol includes the preparation of long micro sections, as well as a procedure to sharpen corers in the field.

Introduction

Dendroecological research is based on various characteristics of growth rings in trees, both annual and otherwise. "Precursory" discipline dendrochronology was established using ring-width variations as a parameter to simply date the rings and, as a result, establish long chronologies. Therefore, manifold other characteristics, such as density variations, isotopic concentrations, or wood anatomical characteristics, are used to correlate single rings or their structure and content to environmental parameters to better understand the impact of environmental conditions on tree growth over time.

Dendroecology, as well as dendroclimatology, has gained in importance in environmental research, mainly in reconstructing past climate conditions1,2,3. For this, the rings of countless trees have to be analyzed in detail. Although some techniques exist to determine tree-ring width and density (e.g., by acoustic wave technology4 or drilling resistance5,6), to date, there is no reliable "non-destructive" method to extract the characteristics of rings from trees. For very detailed analyses of ring characteristics within a tree, or to estimate basal area increment, it would be best to cut disks from the trees of interest7. This would require cutting down all potential trees of interest for specific analyses. Bearing in mind the huge number of trees analyzed worldwide each year, this sampling strategy is not practicable. Regardless of wasting an incredible amount of resources, this strategy is simply too expensive. Due to this, the use of increment corers has been established as a standard sampling technique in tree-ring research8. The use of increment corers allows for a minimally invasive extraction of wood cores from stems, starting from the bark and reaching (in optimal cases) the pith of the tree9.

Although coring causes an injury to the stem-a hole with a diameter of ~1 cm-trees are able to close this wound through increased wood formation in the vicinity of the core hole. A disadvantage, apart from the hole itself, is the occurrence of a "compartmentalization zone", an area around the hole where the cells are filled by phenols to prevent the potential spread of fungi starting from the hole10,11. To our knowledge, there is still no evidence that increment coring causes a significant increase of tree decay frequency, at least in undisturbed high-elevation forest stands for Picea abies12 and several hardwood species in a temperate forest13.

Although this sampling standard has been applied for decades all over the world, some problems still remain. One of these is the fact that the cores have to be taken by hand without any mechanical support, which takes a lot of time and is quite exhausting after a while. To ease sampling, several (more or less practicable) strategies have been tested, such as the use of chainsaws equipped with a corer instead of the chain14,15,16,17. The use of chainsaws was preferred to drills because the latter were not powerful enough; however, this idea did not catch on due to the large weight of the chainsaw and the fuel required.

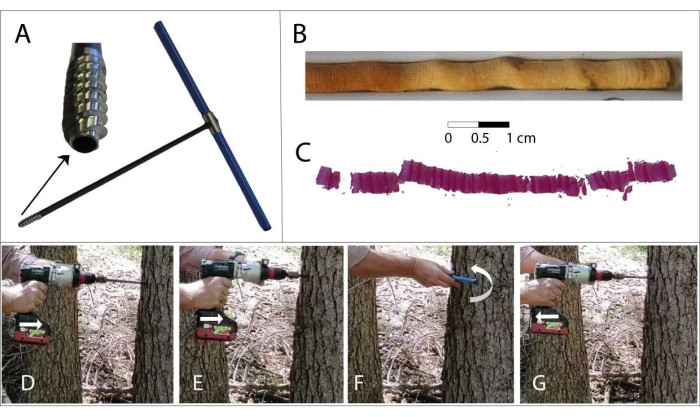

In recent years, wood anatomical techniques have evolved significantly and been integrated into dendroecological studies18,19. However, the ability to analyze wood anatomical parameters over long periods by cutting micro sections from increment cores resulted in unexpected problems. Frequently, the micro sections taken from cores broke into little pieces, which made it impossible to produce coherent cuts (Figure 1). This problem was caused by the manual technique of coring trees and unsharp corers. The mechanical stress exerted on the wood while coring resulted in micro cracks within the core. These micro cracks were never noticed during macroscopic examination of the increment cores, and therefore never presented a problem.

Manual coring is done by placing the handle on the rear end of the corer, pressing the tip with the thread to the stem, and starting to turn the handle until the corer has pierced a little over half the diameter of the stem. While doing this, the tip of the corer is (obviously) fixed in the stem, but the rear end of the corer turned by the handle is always moving sideward or up and down, at least until the drill head is fully screwed into the trunk, giving more guidance and stability to the corer. As a result of the high pressure and the movement of the corer, the increment cores are distorted frequently in the outermost ~5 cm (Figure 1). Even if the friction while turning is reduced to a minimum, another process is exerting stress on the increment core inside the corer. Manual coring does not allow a continuous movement of the cutting edge of the corer inside the stem. One can do a maximum of one full turn, before having to stop to change the grip, and then continue drilling. Each time the rotation restarts, the core is slightly twisted until the friction is overcome and the drill rotates again. These mechanical stresses potentially cause microscopic cracks in the structure of the cores.

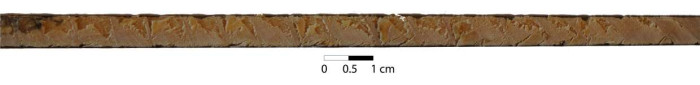

This mechanical stress is even increased when the cutting edge of the corer is not sharp. A visible sign for an unsharp corer is an uneven core surface, showing lots of cracks along its entire extension20 (Figure 2). The frequency of sharpening depends on the density of the trees to be cored and the minerals or sand present in the bark of the tree to be cored. On a general note, one should not assume that new corers are sharp. To date, sharpening a corer is almost never done in the field due to the difficulty of it, since this has to be done by hand and needs a lot of experience11,20.

To summarize, manual coring and unsharp cutting edges both result in micro cracks occurring in cores taken. To date, these problems have not been analyzed systematically, nor have attempts been made to find solutions. This paper presents a protocol to overcome these obstacles by comparing the manual coring technique to the application of a new technique. We propose using a cordless drill equipped with a special adapter for an increment corer. We present to which extent problems are minimized when coring a tree, as well as the effect of continuous, mechanical coring on the preparation of long micro sections. This protocol includes the preparation of long micro sections using a water-soluble tape as a supporting aid and a procedure to sharpen corers in the field.

Protocol

1. Manual coring

- Assemble the increment corer and select the coring position on the stem of a tree depending on the research question (e.g., for geomorphic reconstructions, parallel to the direction of mechanical stress; for age determination, as low down as possible).

NOTE: Always take two cores from each stem, preferably in the opposite direction. - After selecting the coring position, place the corer at a right angle relative to the direction of growth of the stem.

- Place a pusher at the rear end of the corer to stabilize it while drilling.

- Achieve a stable position and lean against the pusher to apply pressure to the cutting edge.

- Turn the handle of the corer with both hands until the threaded part of the drill is fully turned into the stem.

- Release the pressure and remove the pusher.

- Start turning the handle of the corer with both hands until the corer has reached or drilled through the pith. Check this by holding the extractor (which has the same length as the corer) on the handle aside the stem.

- Take the extractor with the open side on top and insert it fully into the corer. Turn the corer backward (one full turn) to break the core from the stem. Pull the extractor out of the corer.

- Remove the core from the extractor and store it in a paper straw.

- Remove the corer from the stem and store it in the handle.

2. Coring with a cordless drill

- Take the cordless drill equipped with a torque booster and add the special adapter for the increment corer developed at WSL.

- Place the increment corer into the adapter on the torque booster and select the position for coring on the stem of a tree depending on the research task (see step 1.1).

- After selecting the coring position, place the corer at a right angle relative to the direction of growth of the stem.

- Achieve a stable position, hold the cordless drill tight, and apply pressure on the cutting edge.

- Start the cordless drill, turning slowly until the threaded part of the drill is fully cored into the stem, then increase the speed until the corer reaches or drills through the pith.

NOTE: The depth can be checked as explained in step 1.7. - Remove the cordless drill from the corer, place the handle on it, and use the extractor to remove the core as explained in step 1.8.

- Store the increment core in a paper straw.

- Remove the handle, place the cordless drill on the corer and remove the corer from the stem.

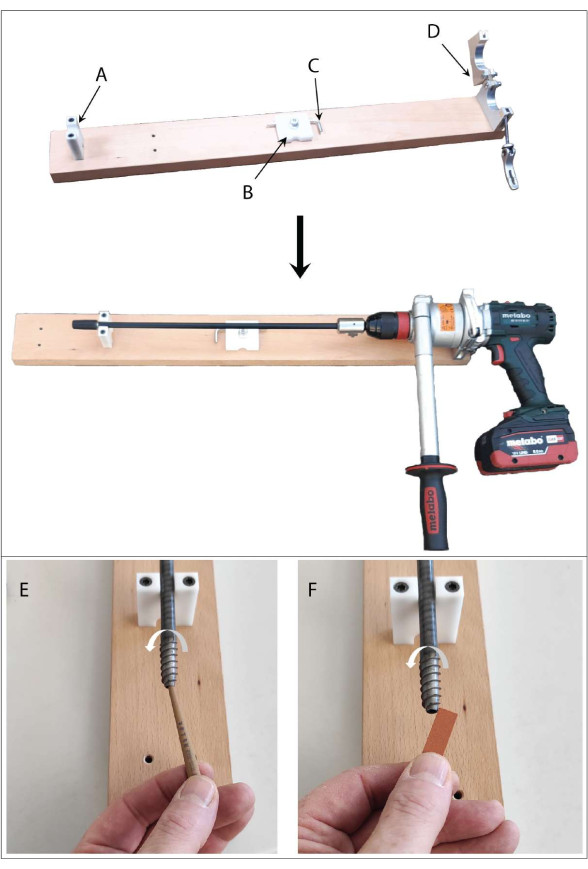

3. Sharpening the cutting edge of increment corers

- Using the WSL sharpening support

- Take the newly designed holder and place it on the ground.

- Place the cordless drill, including the increment corer, at the designated support points and close the mounting bracket to fix the cordless drill.

- Start the cordless drill by fixing the Teflon block on the starter button and let it run. Take the conical grinding stone and grind the inside of the cutting edge with it.

NOTE: The contact angle depends on the inside of the cutting edge. The grinding stone should have full contact with the inner sidewall, reaching from the cutting edge until the inner widening of the corer. - Take the rectangular grindstone and grind the outside of the cutting edge to deburr it.

NOTE: This is necessary to remove the previously formed burr on the edge by grinding it from the inside and to finally sharpen the edge. - Remove the Teflon block from the starter button to stop the drill, open the mounting bracket to release the cordless drill, and take the device out of the holder.

- Checking the sharpness of the cutting edge

- Remove the increment corer from the adapter of the cordless drill.

- Place a sheet of paper on the wooden board of the sharpening support.

- Place the cutting edge of the corer on the paper while holding the corer vertically.

- Turn the corer while holding it vertically without applying pressure to the corer-only the weight of the corer should be pressing on the paper.

- Lift the corer and check whether a round piece of the paper has remained inside the cutting edge of the corer. If so, the corer is sharp. If not, repeat the sharpening procedure (step 3.1). Repeat the entire procedure (steps 3.1 and 3.2) if the outside of a core is not smooth.

5. Cutting micro sections of entire increment cores using a water-soluble tape

- Place a long glass slide next to the microtome and add some water in the middle of the slide along its entire length.

- Place the core in the sample holder of a core microtome.

NOTE: To cut the section as a true cross section, make sure that the direction of the fibers is upright. - Lift the sample holder until the core almost touches the edge of the blade. Pull the blade over the core to cut off the top.

- Place the knife at the beginning of the core again, lift the sample about 10 µm, and repeat the cutting procedure until a plane surface of at least 2 mm width is obtained.

- Add a corn starch solution on the cut surface using a brush21.

- Use a piece of cloth to remove the surplus solution from the top of the core.

- Cut a strip of water-soluble tape to the same length as the core; place one side of the tape to the start of the core, with an overlap of approximately 1 cm, with the beginning of the core facing the blade of the microtome.

- Attach the tape to the surface of the core by stroking the tape on the surface using a finger.

- Lift the sample in the microtome by 15-20 µm, lift the overlapping piece of the tape a little, and place the microtome blade at the edge of the core.

- Cut the section while holding the end of the tape.

- Take the tape with the thin section stuck on it and place it with the cut facing down on the line of water of the glass slide prepared in step 5.1.

- After approximately 10 s, start removing the tape using tweezers, by holding the tape on one side and lifting it up, while taking care that the section remains on the glass slide.

- To produce a permanent slide of this section, follow the standard procedures22.

Results

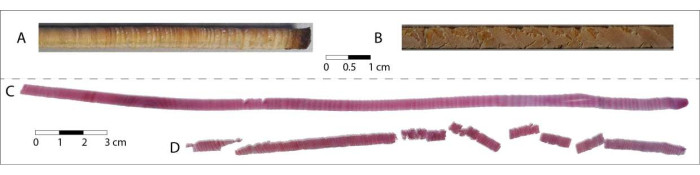

When comparing the manual coring procedure to the use of a cordless drill, the advantages of the latter are obvious. We compared coring spruce trees (Picea abies (L.) H. Karst.) with a stem diameter at a breast height of 60-80 cm. We used 5 mm corers, with a length of 40 cm, for all cores taken, and drilled the full length of the corer into the stem. When taking cores manually, the full procedure of taking a core and removing the corer from the tree again took an average of ~6 min. When repeating this using the cordless drill equipped with a torque booster, the entire procedure took an average of only 1 min. In addition to the fact that coring with the cordless drill is not at all exhausting, none of the cores were deformed, due to pressure exerted on the cutting edge during the first phase of drilling until the thread is completely inside the stem. As soon as the thread is inside the stem, the corer is more or less stabilized, and potential up- and downward movements are minimized (Figure 3).

As soon as the first core was no longer smooth on the outside but showed scratches and cracks, as in Figure 2, sharpening of the cutting edge was required. Because the cordless drill can be fixed, as it is used for coring (i.e., including the adapter and the increment corer; Figure 4), the sharpening procedure is also quite fast. With a little practice, sharpening takes no more than 5 min. As soon as the cut paper sticks inside the corer, sampling can be continued. The resulting cores are smooth without any scratches or cracks. The cores taken with the aid of the cordless drill have a lower probability of showing micro cracks; this is a precondition to cut micro sections of entire increment cores. The application of the water-soluble tape (Figure 5) made the handling of the long and fragile sections easier, since the tape protects the thin section from tearing while taking it off the blade and placing it on the glass slide. This procedure saves time in the lab and improves the quality of the micro sections, because the tape glue stabilizes the cell walls while cutting in addition to the non-Newtonian fluid (corn starch solution; see protocol step 5.5).

Figure 1: Increment corer. (A) Increment corer, as used for manual coring, and a magnified view of the thread and the cutting edge. (B) Distorted increment core due to high pressure exerted to the wood at the beginning of manual coring. (C) Micro section of a part of an increment core fragmented due to micro cracks. Scale bar = 0.5 cm. (D-F) Photos indicating the procedure of coring when using a cordless drill. No high pressure is needed to start coring (D,E), the handle can easily be used to extract the core (F), and the drill is extracted directly thereafter (G). Please click here to view a larger version of this figure.

Figure 2: Increment core showing scratches and cracks on the outside due to the use of an unsharp corer. Scale bar = 0.5 cm. Please click here to view a larger version of this figure.

Figure 3: Increment cores and related micro sections. (A) Straight core taken with a sharp corer and a cordless drill. (B) Distorted core taken manually with an unsharp corer. (C) Continuous section of a Pinus sylvestris core sampled with a sharp corer. (D) Section of a Larix decidua core broken in pieces due to using an unsharp corer. Scale bars = 0.5 cm (A,B); 1 cm (C). Please click here to view a larger version of this figure.

Figure 4: Holder designed for sharpening the cutting edge of increment corers. (A) Teflon block to guide and stabilize the increment corer. (B) Teflon block to fix the starter of the cordless drill. (C) Hexagon wrench to fix A at other positions on the board, depending on the type of corer used. (D) Clamp to fix the cordless drill. (E) Placing the conical grinding stone inside the cutting edge. (F) Placing the straight grinding stone outside to deburr the cutting edge. Please click here to view a larger version of this figure.

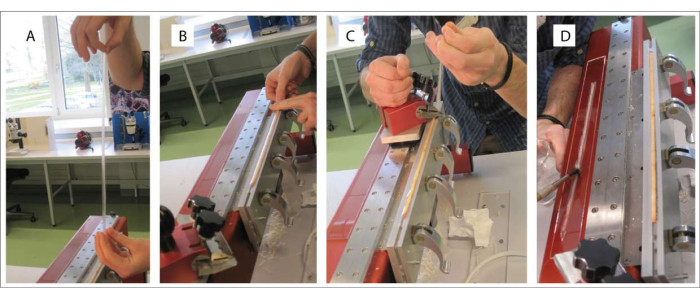

Figure 5: Application of the water-soluble tape. (A) Cut the tape to the length needed to cover the core surface. (B) Place the tape on the prepared surface of the core. (C) Cut the section by holding the edge of the tape in one hand. (D) Place the tape with the section facing down on a glass slide and add water to separate the tape from the section. Please click here to view a larger version of this figure.

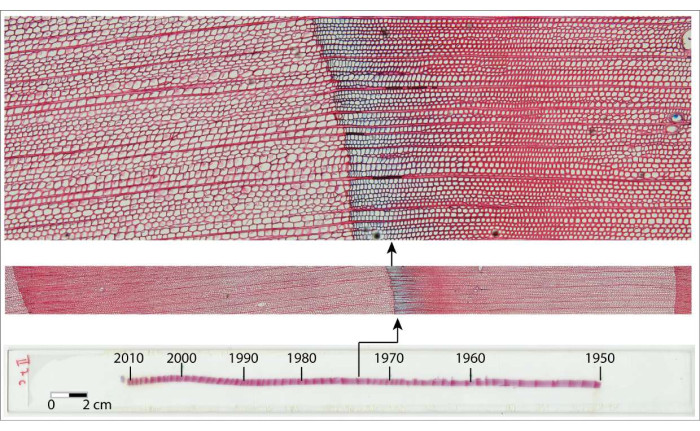

Figure 6: Micro section of a conifer showing a "blue ring". Latewood cell walls not lignified and, for this, blue, in the ring of the year 1974 (magnified above the slide showing the long section). Scale bar = 1 cm. Please click here to view a larger version of this figure.

Discussion

The significant inclusion of wood anatomy in dendroecological studies23,24, as well as an intensified exchange among scientists specialized in tree-ring research and wood anatomists25, has opened a wide field of new and in-depth analyses of past environmental conditions. These new studies have opened up new possibilities and questions, but have also given rise to new problems.

The fast development of this new era of "dendroanatomy" requires a high number of samples, which is definitely supported by the use of a cordless drill as explained before. In addition to the fact that taking cores with the drill is not at all exhausting, it saves a lot of time. Although the results presented in this paper imply sampling possibilities that are six times faster than manual coring, it is a test for single cores. Nevertheless, during regular sampling (one person coring, with one coding and storing the cores), we managed to core 24 spruce trees (two cores of full length each), with stem diameters of approximately 80 cm, within 1.5 h. This is an average of <2 min for one core, including storage, packing, and moving to the next tree.

The fast handling of the entire process is supported by the fact that the newly designed adapter for increment corers can be used without the need to fix the corer inside the adapter with a screw or comparable closures. As a result, changing the drill to the handle of the corer to break and extract the core is fast and easy. The adapter is designed so that one can even pull the corer out while drilling back in case the stem is rotten, or (as is common with some increment corers) if the thread does not grab when turning back and the corer does not move out.

However, it should be noted that when removing the corer from the stem, one needs to tilt the adapter slightly so that it can be successfully pulled without the drill slipping off (protocol step 2.8). The increasing demand for tree-ring studies to create long chronologies based on anatomical proxies19,26 has required the preparation of micro sections from increment cores, cut in pieces before preparation or cut as entire micro sections22. Although the quality of up to 40 cm long micro sections is still not always comparable to short sections (e.g., the variable angle of the cells in their vertical extension frequently hampers cell wall measurements), they can be used to identify and date specific growth reactions as the occurrence of reaction wood or blue rings27 (Figure 6).

Consequently, the quality of the samples is a basic prerequisite for successful preparation and further analyses of anatomical structures. This demand requires more caution regarding the sharpness of the sampling campaign when taking increment cores. As a consequence, preparing micro sections can be very time-consuming and labor-intensive, and sometimes even impossible, if the specimens are not embedded beforehand28.

Sharpening the cutting edge of an increment corer by hand requires a lot of practice and experience, in order to grind the edge evenly all around by hand without any support. The ability of using the new drill mount for sharpening increment cores enables even users inexperienced in sharpening to sharpen the cutting edge of their corers in the field. The fact that this now can be done quickly will increase the quality of samples taken in future.

Although the use of the new equipment shows clear advantages for subsequent processing of the cores, the cordless drill could also be combined with small devices for sharpening, developed and presented almost 40 years ago20. Maeglin20 presented construction details of a modification of "Goodchild's borer sharpener" made of wood and metal29. Nowadays, this device can be modeled and printed in a 3D printer without any problems30. One would only need to create a detailed 3D model of the sharpener to print the single parts and assemble it to use in the field. The possibilities for improvement have not yet been exhausted and we are sure that this publication will inspire many colleagues to further develop the tools presented here. A yet unsolved obstacle is the fact that one needs to remove the drill and add the handle of the corer to extract the core.

The final step of cutting micro sections of entire increment cores22 is still a tricky issue. The application of the water-soluble tape, as described earlier, supports the process by stabilizing the section when cutting and placing it on the glass slide. Nevertheless, this procedure still requires of the user to have a high level of experience.

Disclosures

The authors declare that they have no competing financial interests.

Acknowledgements

None.

Materials

| Name | Company | Catalog Number | Comments |

| BS 18 LTX-3 BL QI | Metabo | Cordless drill | |

| Core-microtome | WSL | Microtome to cut micro sections from increment cores | |

| Drill adapter for increment corer | WSL | Adapter to fix the increment corer on the cordless drill | |

| Increment corer | Haglöff | 40cm increment corer | |

| Power X3 | Metabo | Torque amplifyer | |

| Sharpening support board | WSL | Board to attach the cordless dril to sharpen the cutting edge ofd the corer | |

| Water-soluble tape 5414, transparent 3/4IN | 3M | Transparent tape to support cutting long sections |

References

- Büntgen, U. Scrutinizing tree-ring parameters for Holocene climate reconstructions. Wiley Interdisciplinary Reviews: Climate Change. , 778 (2022).

- Hadad, M. A., González-Reyes, &. #. 1. 9. 3. ;., Roig, F. A., Matskovsky, V., Cherubini, P. Tree-ring-based hydroclimatic reconstruction for the northwest Argentine Patagonia since 1055 CE and its teleconnection to large-scale atmospheric circulation. Global and Planetary Change. 202, 103496 (2021).

- Shen, Y., et al. Effects of climate on the tree ring density and weight of Betula ermanii in a cool temperate forest in central Japan. Trees. , 1-9 (2022).

- Wang, X. Acoustic measurements on trees and logs: a review and analysis. Wood Science and Technology. 47 (5), 965-975 (2013).

- Downes, G. M., et al. Application of the IML Resistograph to the infield assessment of basic density in plantation eucalypts. Australian Forestry. 81 (3), 177-185 (2018).

- Tomczak, K., Tomczak, A., Jelonek, T. Measuring radial variation in basic density of pendulate oak: comparing increment core samples with the Iml power drill. Forests. 13 (4), 589 (2022).

- Piene, H., D'Amours, J., Bray, A. A. Spruce budworm defoliation and growth loss in young balsam fir: estimation of volume growth based on stem analysis and increment cores at breast height. Northern Journal of Applied Forestry. 13 (2), 73-78 (1996).

- Phipps, R. L. Collecting, Preparing, Crossdating,and Measuring Tree Increment Cores. US Department of the Interior, Geological Survey. , (1985).

- Schweingruber, F. H. . Tree Rings and Environment: Dendroecology. , (1996).

- Toole, E. R., Gammage, J. L. Damage from increment borings in bottomland hardwoods. Journal of Forestry. 57 (12), 909-911 (1959).

- Grissino-Mayer, H. D. A manual and tutorial for the proper use of an increment borer. Tree-Ring Research. 59 (2), 63-79 (2003).

- Wunder, J., et al. Does increment coring enhance tree decay? New insights from tomography assessments. Canadian Journal of Forest Research. 43 (8), 711-718 (2013).

- Helcoski, R., et al. No significant increase in tree mortality following coring in a temperate hardwood forest. Tree-Ring Research. 75 (1), 67-72 (2019).

- Hall, A. A., Bloomberg, W. J. A power-driven increment borer. The Forestry Chronicle. 60 (6), 356-357 (1984).

- Scott, J. H., Arno, S. F. Using a power increment borer to determine the age structure of old-growth conifer stands. Western Journal of Applied Forestry. 7 (4), 100-102 (1992).

- Krottenthaler, S., et al. A power-driven increment borer for sampling high-density tropical wood. Dendrochronologia. 36, 40-44 (2015).

- Caetano-Andrade, V. L., et al. Advances in increment coring system for large tropical trees with high wood densities. Dendrochronologia. 68, 125860 (2021).

- Edwards, J., et al. Intra-annual climate anomalies in northwestern North America following the 1783-1784 CE Laki eruption. Journal of Geophysical Research: Atmospheres. 126 (3), 033544 (2021).

- Zhirnova, D. F., et al. A 495-year wood anatomical record of Siberian stone pine (Pinus sibirica Du Tour) as climatic proxy on the timberline. Forests. 13 (2), 247 (2022).

- Maeglin, R. R. . Increment Cores: How to Collect, Handle, and Use Them. 25, (1979).

- Gärtner, H., et al. A technical perspective in modern tree-ring research - how to overcome dendroecological and wood anatomical challenges. Journal of Visualized Experiments. (95), e52337 (2015).

- Gärtner, H., Banzer, L., Schneider, L., Schweingruber, F. H., Bast, A. Preparing micro sections of entire (dry) conifer increment cores for wood anatomical time-series analyses. Dendrochronologia. 34, 19-23 (2015).

- Rodriguez, D. R. O., et al. Exploring wood anatomy, density and chemistry profiles to understand the tree-ring formation in Amazonian tree species. Dendrochronologia. 71, 125915 (2022).

- Gärtner, H., Farahat, E. Cambial activity of Moringaperegrina (Forssk.) Fiori in arid environments. Frontiers in Plant Science. 12, 760002 (2021).

- von Arx, G., et al. Q-NET-a new scholarly network on quantitative wood anatomy. Dendrochronologia. 70, 125890 (2021).

- Seftigen, K., et al. Prospects for dendroanatomy in paleoclimatology-a case study on Picea engelmannii from the Canadian Rockies. Climate of the Past. 18 (5), 1151-1168 (2022).

- Matulewski, P., Buchwal, A., Gärtner, H., Jagodziński, A. M., Čufar, K. Altered growth with blue rings: comparison of radial growth and wood anatomy between trampled and non-trampled Scots pine roots. Dendrochronologia. 72, 125922 (2022).

- Prislan, P., del Castillo, E. M., Skoberne, G., Špenko, N., Gričar, J. Sample preparation protocol for wood and phloem formation analyses. Dendrochronologia. 73, 125959 (2022).

- Heinrichs, J. F. Pocket-sized sharpender for increment borers. Journal of Forestry. 62, 653 (1964).

- Schneider, L., Gärtner, H. Additive manufacturing for lab applications in environmental sciences: pushing the boundaries of rapid prototyping. Dendrochronologia. 76, 126015 (2022).

Reprints and Permissions

Request permission to reuse the text or figures of this JoVE article

Request PermissionThis article has been published

Video Coming Soon

Copyright © 2025 MyJoVE Corporation. All rights reserved