Biofuels: Producing Ethanol from Cellulosic Material

Genel Bakış

Source: Laboratories of Margaret Workman and Kimberly Frye - Depaul University

In this experiment, cellulosic material (such as corn stalks, leaves, grasses, etc.) will be used as a feedstock for the production of ethanol. The cellulosic material is first pretreated (ground and heated), digested with enzymes, and then fermented with yeast. Ethanol production is monitored using an ethanol probe. The experiment can be extended to optimize ethanol production by varying the feedstock used, pretreatment conditions, enzyme variation, yeast variation, etc. An alternative method of monitoring the reaction is to measure the carbon dioxide produced (using a gas sensor) instead of the ethanol. As a low-tech alternative, glucose meters (found in any drug store) can be used to monitor the glucose during the process, if an ethanol probe or carbon dioxide gas sensor is not available.

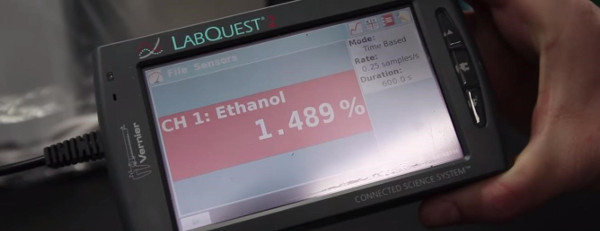

With an increased emphasis on ‘inquiry-based learning”, scientific probes are becoming more popular. Handheld devices like the Vernier Lab Quest used in conjunction with a variety of probes (such as those for conductivity, dissolved oxygen, voltage, and more) allow for less focus on collecting data and/or making graphs and more on analyzing the data and making predictions. Another advantage is that these are small and lightweight and can be taken into the field for measurements.

Prosedür

1. Sample Preparation

- Select cellulosic material to be used as feedstock. This can be corn stalks, grasses, leaves, pet bedding, or paper.

- Using a ball mill grinder (or coffee grinder if ball mill grinder is not available), grind feedstock into a fine powder with no large pieces remaining.

- Measure 1.0 g of feedstock and place in a 50-mL centrifuge tube. Label the tube with the feedstock chosen.

- Label a second 50 mL centrifuge tube as “Control”. Do

Sonuçlar

The % ethanol in the solution will be displayed on the handheld tablet screen using the software related to the brand of the ethanol sensor used (Figure 2).

Representative results of the percent ethanol produced by various feedstocks can be seen in Table 1.