Electrochemical Impedance Spectroscopy

Overview

Source: Kara Ingraham, Jared McCutchen, and Taylor D. Sparks, Department of Materials Science and Engineering, The University of Utah, Salt Lake City, UT

Electrical resistance is the ability of an electrical circuit element to resist the flow of electricity. Resistance is defined by Ohm's Law:

(Equation 1)

(Equation 1)

Where  is the voltage and

is the voltage and  is the current. Ohm's law is useful for determining the resistance of ideal resistors. However, many circuit elements are more complex and can't be described by resistance alone. For example, if an alternating current (AC) is used then the resistivity will often depend on the frequency of the AC signal. Instead of using resistance alone, electrical impedance is a more accurate and generalizable measure of a circuit element's ability to resist the flow of electricity.

is the current. Ohm's law is useful for determining the resistance of ideal resistors. However, many circuit elements are more complex and can't be described by resistance alone. For example, if an alternating current (AC) is used then the resistivity will often depend on the frequency of the AC signal. Instead of using resistance alone, electrical impedance is a more accurate and generalizable measure of a circuit element's ability to resist the flow of electricity.

Most commonly, the goal of electrical impedance measurements is the deconvolution of a sample's total electrical impedance into contributions from different mechanisms such as resistance, capacitance, or induction.

Procedure

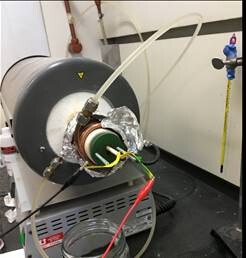

- Obtain a test module and hook it up to the EIS instruments via two electrodes. The test module, pictured in Figure 3, provides data that can be used to model a simple, known circuit. It can be used to confirm that the wires are hooked up to the machine correctly and that all the machinery parts are functioning.

Figure 3: Test module.

Results

Results of EIS are often presented in a Nyquist plot, which shows real impedance versus complex impedance at each frequency tested. The plot of the experiment ran can be seen in Figure 6.

Figure 6: Screenshot of computer after Nyquist plot was obtained.

Application and Summary

Electrochemical Impedance Spectroscopy is a useful tool for determining how a new material or device impedes the flow of electricity. It does this by applying an AC signal through the electrodes connected to the sample. The data is collected and plotted by the computer in the complex plain. With the help of software, the graph can be modeled after specific parts of a circuit. This data can often be very complicated and requires careful analysis. This technique, however complex, is an extremely useful non-destructive mean

Tags

Skip to...

Videos from this collection:

Now Playing

Electrochemical Impedance Spectroscopy

Materials Engineering

23.4K Views

Optical Materialography Part 1: Sample Preparation

Materials Engineering

15.6K Views

Optical Materialography Part 2: Image Analysis

Materials Engineering

11.1K Views

X-ray Photoelectron Spectroscopy

Materials Engineering

21.9K Views

X-ray Diffraction

Materials Engineering

89.7K Views

Focused Ion Beams

Materials Engineering

9.0K Views

Directional Solidification and Phase Stabilization

Materials Engineering

6.7K Views

Differential Scanning Calorimetry

Materials Engineering

38.7K Views

Thermal Diffusivity and the Laser Flash Method

Materials Engineering

13.4K Views

Electroplating of Thin Films

Materials Engineering

20.2K Views

Analysis of Thermal Expansion via Dilatometry

Materials Engineering

16.0K Views

Ceramic-matrix Composite Materials and Their Bending Properties

Materials Engineering

8.4K Views

Nanocrystalline Alloys and Nano-grain Size Stability

Materials Engineering

5.2K Views

Hydrogel Synthesis

Materials Engineering

23.8K Views

Copyright © 2025 MyJoVE Corporation. All rights reserved