需要订阅 JoVE 才能查看此. 登录或开始免费试用。

Method Article

使用Quattro-Parallel 悬臂阵列的主动探针原子力显微镜,用于高通量大规模样品检测

摘要

具有纳米级分辨率的大规模样品检测具有广泛的应用,特别是对于纳米制造的半导体晶圆。原子力显微镜可以成为实现这一目标的绝佳工具,但受到其成像速度的限制。这项工作利用原子力显微镜中的并行有源悬臂阵列来实现高通量和大规模检测。

摘要

原子力显微镜 (AFM) 是一种功能强大且用途广泛的纳米表面研究工具,用于捕获样品的 3D 形貌图像。然而,由于成像通量有限,AFM尚未被广泛用于大规模检测目的。研究人员开发了高速AFM系统,以每秒数十帧的速度记录化学和生物反应中的动态过程视频,但代价是成像面积很小,只有几平方微米。相比之下,检测半导体晶圆等大规模纳米加工结构需要对数百平方厘米的静态样品进行纳米级空间分辨率成像,且生产率很高。传统的原子力显微镜使用带有光束偏转系统的单个无源悬臂探头,在探力显微镜成像过程中一次只能采集一个像素,导致成像吞吐量低。这项工作利用一系列带有嵌入式压阻传感器和热机械致动器的有源悬臂,允许同时并行操作多悬臂操作,以提高成像吞吐量。当与大范围纳米定位器和适当的控制算法相结合时,每个悬臂都可以单独控制以捕获多个AFM图像。通过数据驱动的后处理算法,可以将图像拼接在一起,并通过将它们与所需的几何形状进行比较来执行缺陷检测。本文介绍了使用主动悬臂阵列的定制AFM的原理,然后讨论了检测应用的实际实验注意事项。硅校准光栅、高定向热解石墨和极紫外光刻掩模的选定示例图像使用四个有源悬臂("Quattro")阵列捕获,尖端间隔距离为 125 μm。随着更多的工程集成,这种高通量、大规模成像工具可以为极紫外 (EUV) 掩模、化学机械平坦化 (CMP) 检测、失效分析、显示、薄膜阶跃测量、粗糙度测量模具和激光雕刻的干气密封槽提供 3D 计量数据。

引言

原子力显微镜 (AFM) 可以捕获具有纳米级空间分辨率的 3D 形貌图像。研究人员扩展了AFM的能力,以在机械、电气、磁、光学和热域中创建样品属性图。与此同时,提高成像通量也是使AFM适应新实验需求的研究重点。高通量AFM成像主要有两个应用领域:第一类是小区域的高速成像,以捕获由于生物或化学反应引起的样品动态变化1,2;第二类是用于在检测过程中对静态样品进行高空间分辨率、大规模成像,本文将对此进行详细讨论。随着晶体管尺寸缩小到纳米级,半导体行业迫切需要高通量原子力显微镜来检测具有纳米级空间分辨率的晶圆级纳米制造器件3。

由于晶圆和晶体管特征之间存在巨大的尺度差异,因此在晶圆上表征纳米制造器件可能具有挑战性。用光学显微镜可以自动发现大缺陷4.此外,扫描电子显微镜 (SEM) 广泛用于低至数十纳米的 2D5 检测。对于 3D 信息和更高分辨率,如果可以提高其通量,AFM 是更合适的工具。

在成像通量有限的情况下,一种方法是对选定的晶圆区域进行成像,在这些区域中,纳米加工缺陷更容易发生6。这需要对设计和制造过程有先验知识。或者,将其他模式(例如光学显微镜或SEM与用于概览和缩放的AFM)相结合是可能的7,8。需要一个大范围、高精度的定位系统来正确对齐制造和表征工具之间的坐标系。此外,为了实现这一功能,需要一个自动原子力显微镜系统来对各种选定区域进行成像。

作为替代方案,研究人员研究了提高AFM扫描速度的不同方法。由于实现高通量原子力显微镜是一项系统的精密仪器挑战,研究人员研究了各种方法,包括使用更小的原子力显微镜探针,重新设计高带宽纳米定位器9,10,11,12和驱动电子设备13,优化操作模式,成像控制算法14,15,16,17等。通过这些努力,对于市售的单探针AFM系统,有效的相对针尖和样品速度可以提高到每秒几十毫米左右。

为了进一步提高成像通量,添加多个探头并行操作是一种自然的解决方案。然而,用于悬臂偏转传感的光束偏转(OBD)系统相对笨重,这使得添加多个探头相对具有挑战性。单个悬臂挠度控制也很难实现。

为了克服这一限制,首选嵌入式传感和没有笨重外部组件的驱动原理。正如之前发表的报告18,19所详述的那样,采用压阻、压电和光机械原理的偏转传感可以被认为是嵌入式传感,前两者更成熟,更容易实现。对于嵌入式驱动,可以同时使用具有电加热原理或压电原理的热机械。尽管压电原理可以在更宽的温度范围内工作,但低温环境,它们只能支持敲击模式AFM操作,因为由于电荷泄漏和静电驱动受到滞后和蠕变的影响,无法测量静态偏转。在先前的工作中,使用压阻式传感器和压电传感器的有源悬臂探针阵列已被开发用于大范围成像20,21,但尚未进一步扩大规模以进行大规模成像或商业化。本文选择压阻传感和热机械驱动相结合的嵌入式换能器,实现静态偏转控制能力。

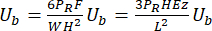

在这项工作中,使用一种新型的"Quattro"22平行有源悬臂阵列作为探头23,使用有源悬臂进行同步成像。为了测量悬臂挠度,惠斯通电桥配置19的压阻式传感器在每个微悬臂的底部进行纳米加工,以测量内应力,该应力与悬臂尖端挠度成线性比例。这种紧凑的嵌入式传感器还可以实现与传统OBD传感器一样的亚纳米分辨率。在方程 119 中显示了长 L、宽 W 和厚度 H、压阻传感器系数 P R 和悬臂 E 电桥电源电压 Ub 的有效弹性模量的悬臂,惠斯通电桥电压输出 U输出响应于施加的力 F 或悬臂挠挠挠 z 的控制方程 1 19。

(1)

(1)

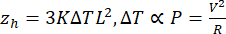

由于动态攻丝/非接触模式操作是非侵入性成像的首选,以避免干扰样品,因此使用由蛇形铝丝制成的热机械致动器来加热由铝/镁合金24、硅和氧化硅材料制成的双晶悬臂。在微观尺度上,热过程的时间常数要小得多,并且可以通过用电信号驱动加热器来激发数十至数百千赫兹的悬臂共振。由加热器温度 ΔT 相对环境控制的悬臂自由端挠度 zh如公式 219所示,悬臂长度 L 具有常数 K,具体取决于双晶材料膨胀热系数以及几何厚度和面积。需要注意的是,ΔT与加热器功率P成正比,P等于施加电压V的平方除以电阻R。

(2)

(2)

此外,除了共振激励外,还可以控制静态偏转。这可能是一种特别有用的功能,可以单独调节每个悬臂的探头-样品相互作用。此外,同一基础芯片上的多个悬臂可以通过嵌入式热机械致动器单独激励,这在传统的压电产生声波的共振激励中是不可能的。

主动悬臂探头结合了压阻传感和热机械驱动,实现了广泛的应用,包括SE显微镜中的并置AF显微镜、不透明液体成像和扫描探头光刻,更多细节见综述25。出于高通量检测目的,使用具有代表性的AFM实现示例创建了主动悬臂阵列,该示例涉及四个平行悬臂,如 图1所示。未来,将使用8个平行主动悬臂和数十个定位器28开发工业规模系统。举例说明比例尺,平面内空间分辨率为 100 nm,对 100 mm x 100 mm 的区域进行成像将产生超过 106 条扫描线和 1012 像素。每个悬臂的扫描速度为 50 mm/s,单个悬臂总共需要超过 555.6 小时(23+ 天)的扫描时间,这太长而无法实际使用。使用带有数十个定位器的主动悬臂阵列技术,所需的成像时间可以减少约两个数量级,达到 5-10 小时(不到半天),而不会影响分辨率,这是工业检测目的的合理时间尺度。

为了捕获大面积、高分辨率图像,纳米定位系统也进行了升级。对于晶圆级大样品的成像,最好扫描探针而不是样品,以减小被移动物体的尺寸。当主动悬臂之间的间隔距离为125 μm时,扫描仪覆盖的区域略大于此范围,因此在后期处理过程中可以将每个悬臂的图像拼接在一起。扫描完成后,粗定位器会自动将探头重新定位到新的相邻区域,以继续成像过程。虽然嵌入式热机械执行器调节每个悬臂的挠度,但所有平行悬臂的平均挠度由另一个比例积分微分 (PID) 控制器调节,以在形貌跟踪过程中协助悬臂。扫描器控制器还确保每个悬臂的弯曲不超过最大阈值,如果形貌变化太大,可能会导致其他探头与表面失去接触。

由于悬臂的静态挠度控制范围约为数十微米,因此可以跟踪同一基础芯片上悬臂的形貌变化水平应受到限制。对于半导体晶圆,样品形貌变化通常在亚微米尺度上,因此它们应该不是什么大问题。然而,随着更多悬臂的增加,样品平面相对于悬臂线的倾斜可能会成为一个问题。在实践中,8个间距接近1 mm的平行悬臂仍允许1°的倾斜角度,而添加更多的悬臂会使倾斜控制更难实现。因此,在单独的探头扫描仪上使用多组八悬臂探头是一项持续的努力,以充分实现并联主动悬臂探头原理的潜力。

数据收集后,需要进行后处理操作以检索所需信息。该过程通常包括去除扫描伪影,拼接相邻图像以形成整体全景图,以及选择性地通过使用合适的算法将结构缺陷与所需的几何形状进行比较来识别结构缺陷26。值得注意的是,对于大范围的图像,积累的数据量可能是巨大的,并且数据驱动的学习算法也正在开发中,以实现更高效的处理27。

本文说明了使用集成到定制 AFM 系统中的并行有源悬臂阵列获取高分辨率 AFM 图像的一般过程。该系统的详细实施可在22、28、29、30 中找到,并且正在商业化,型号在 材料表中列出。所有四个悬臂均在嵌入式热机械执行器激励的敲击模式下运行。提供了校准样品、纳米加工掩模和高度取向热解石墨 (HOPG) 样品的代表性结果(参见 材料表),以说明这种新型 AFM 工具在大面积检测中的有效性。

Access restricted. Please log in or start a trial to view this content.

研究方案

1. 大规模检测样品制备

- 为AFM准备合适尺寸的样品(参见 材料表)。

注:面内直径为 75 mm 至 300 mm 且预期面外高度变化低于 200 μm 的晶圆形样品可以安装在 AFM 样品台上。在这项研究中,在 4 英寸晶圆上使用了极紫外 (EUV) 掩模(参见 材料表)。 - 清洁样品以去除污染物,并将样品保存在洁净室或低尘环境中,例如真空室或氮气吹扫柜。

- 用压缩氮气喷枪吹扫样品,去除大粉尘颗粒,如果样品不与水反应,则用去离子水冲洗。为避免损坏样品,请使用低于 0.1 m3/min 的小流速。

- 或者,应用等离子清洗以去除有机污染物。将样品放入等离子处理机中。关闭腔室并将压力降至 600 mTorr。将样品暴露于等离子体中30秒进行清洁。

注意:步骤 1.3.2 对于去除污染物是可选的。在这项研究中,制造和表征是在洁净室内进行的,因此不需要此步骤。

- 确定合适的成像策略,包括感兴趣区域、扫描范围、空间/像素分辨率和扫描线速度。

- 确定样品是需要对多个较小的选定区域进行整体全景成像还是自动成像。

注意:对于具有所需结构的纳米制造样品,通常更容易确定更容易出现缺陷的关键区域,以便进行检查。对于其他样品,拍摄低空间分辨率图像以快速概览,然后放大较小的感兴趣区域以获得高空间分辨率成像会更容易。 - 根据样本的先验知识估计要素的大小,以确定解析这些要素所需的空间分辨率。

- 使用成像范围和空间分辨率的比率来确定像素分辨率。

- 根据样品的先前经验选择初始扫描线速度,或稍后根据样品材料、探针动力学和所需的空间分辨率使用 AFM 系统软件。

- 确定样品是需要对多个较小的选定区域进行整体全景成像还是自动成像。

2. AFM仪器校准和实验设置

- 选择适当的有源悬臂阵列。

注:探针阵列中每个悬臂的AFM主动悬臂刚度、第一共振频率和未使用的探针尖端锐度是从生产中表征的。数据可以从制造商处检索,并在成像前自动加载到软件中。根据样品材料或应用选择软件推荐的适当悬臂有助于确保成功成像。由于制造的可变性,每个悬臂的性能可能不同,但水平相似。 - 通过打开控制器的主电源来打开 AFM,然后等待系统初始化。打开上位机,打开AFM系统软件。

- 执行主动悬臂探头安装。

- 通过单击 "主动悬臂安装"(Active Cantilever Installation) 将探头扫描仪抬起。等待探头支架从样品台升起并自动停止。

- 将 AFM 悬臂探针阵列安装并固定在探针支架上。

注意: AFM 悬臂阵列连接到 nano-SD 卡形状支架上,可以直接用手处理以进行探头安装。由于传感和驱动原理的根本区别,无需执行任何激光对准。 - 单击 探头自动设置 并加载制造商提供的探头信息(请参阅 材料表)。确保探头和软件中的序列号匹配。

- 进行探头频率扫描以验证每个悬臂的共振以进行成像。单击 "悬臂调整 ",然后单击弹出窗口中的 "扫描 "。如果范围已知,请指定 "开始频率 "和 "结束频率 "。否则,软件将使用默认设置自动更新值。

注意:原则上,此步骤对于新探头是可选的,因为它们在生产后已经过校准。但是,对于以前使用过的探头,建议执行此扫描,以防万一在先前操作期间发生任何性质更改(例如,附着污染物颗粒以改变悬臂共振)。由于热机械驱动,加热功率与驱动电压的平方成正比。对于抽头非接触模式操作,由于 公式2中的平方关系,会产生输入电压正弦波分量的二次谐波。这种二次谐波通常与激励期间的悬臂谐振相匹配,因为直流 (DC) 失调信号不会影响其幅度。因此,直流分量控制平均悬臂挠度,驱动信号的交流电(AC)分量自动设置为悬臂谐振频率的一半进行成像。

- 加载样品并将其固定到位。确保与样品接触的底面与要成像的特征的顶面平行。使用千分尺旋钮微调样品台倾斜度,以确保样品平坦。如果倾斜度太大,微调定位器无法补偿,请添加垫片。

- 使用AFM载物台上的千分尺调整样品的平面内XY位置。使用光学显微镜图像定位感兴趣区域,并将悬臂阵列的相对位置定位到要成像的第一个感兴趣区域上。

- 通过单击 "XYZ 零 点"按钮建立全局坐标。

注意:为了创建全景图像,可以使用光学显微镜视图粗略地执行此步骤。在对纳米制造样品的选定区域进行成像时,可能需要将制造设备的 XYZ 坐标与 AFM 坐标精确对齐。通过执行 AFM 成像并再次单击 XYZ Zero 按钮,可以更精确地执行此步骤。 - 关闭并密封隔音罩。

注意: 隔音罩有助于减少振动在空气中的传播。此外,密封盖还可以减少灰尘颗粒落在样品上的机会,因为大规模成像可能需要很长时间才能完成。在没有振动源的洁净室环境中,该保护罩是可选的。

3. 形貌成像和参数调整

- 选择 "成像参数设置 "选项卡(主动悬臂特征模式、扫描速度、设定值等)并输入所需的成像参数。

- 对于单个全景图像,请输入图像左上角的坐标和扫描尺寸。要自动对多个选定区域进行成像,请对所有要成像的区域重复此过程。在成像区域周围添加额外的填充物,以便进行图像拼接后处理。

注意:在本研究中,EUV掩模的左上角设置了预定义的特征,并且系统配置为使用每个悬臂同时捕获四个130μm×130μm的图像。 - 输入所需的平面内像素分辨率(通常每条扫描线数千像素),并使用软件中默认推荐的线扫描速度进行成像。如果需要,手动调整要成像的每个区域的线扫描速度。

注:在这项研究中,使用每行 26,000 像素的像素分辨率(相当于每像素 5 nm)来获得高分辨率图像。 - 对于非接触模式,请使用软件中从悬臂特性获取的默认驱动幅度、频率和设定值,或手动输入阵列上每个悬臂的设定值。将 PID 控制器设置保留为默认值。

- 对于单个全景图像,请输入图像左上角的坐标和扫描尺寸。要自动对多个选定区域进行成像,请对所有要成像的区域重复此过程。在成像区域周围添加额外的填充物,以便进行图像拼接后处理。

- 将主动悬臂探针阵列与样品啮合。

- 单击 "初始化悬臂"(Initialize Cantilever) 以在成像前预弯曲悬臂。

- 单击 "启动非接触式驱动器 "以激发悬臂共振。

- 单击 "接合"(Engage ),让系统自动使样品和探头接触。完成此步骤后,成像将自动启动。

- 根据扫描的迹线/图像调整每个悬臂的 PID 控制器参数。调整 PID 参数以改善迹线和回溯线之间的匹配,这有助于捕获形貌变化。成像速度也可以相应调整,以提高形貌跟踪性能。

- 通过单击" 保存 "按钮将当前数据保存在屏幕上。在每帧结束时的扫描过程中,数据也将自动保存。

- 通过单击 "停止 "按钮停止成像。系统将停止成像并自动从样品中收回悬臂阵列。悬臂驱动器也将停止,以便安全地卸载探头。

- 小心地取出探头和样品,然后关闭系统。

4. 后处理和图像分析

- 打开供应商提供的AFM图像分析软件。

- 单击" 自动处理 "以应用默认的后处理序列,包括样品倾斜校正、像素级异常值去除和扫描线匹配。

- 通过观察图像手动对图像缺陷进行进一步校正。使用先进的AFM仪器,这种缺陷很少见,但通过这些步骤仍然可以改善图像。

注意:对于大量图像,可以通过相同的操作进行批处理,使用宏或 Python 脚本自动执行该过程。本研究不需要这样做。

- 使用该软件通过单击 "全景图像 "按钮并选择要拼接的多个图像来形成全景图像。

注意:图像拼接是通过直接使用相邻图像的重叠空间自动执行的。或者,图像合并尝试最大化边缘上重叠像素的相关性。这些命令中提供了各种选项,可以对其进行优化以提高整体合并性能。 - 保存数据,以便根据特定样品进行进一步分析。

Access restricted. Please log in or start a trial to view this content.

结果

为了证明使用平行主动悬臂进行形貌成像的AFM大范围成像的有效性, 图2显示了由四个并联操作的悬臂拍摄的校准光栅的拼接图像。硅晶圆校准结构具有 45 μm 长的特征,高度为 14 nm。每个悬臂覆盖 125 μm x 125 μm 的面积,可提供 500 μm x 125 μm 的拼接全景图像。在幅度调制模式下,扫描速度设置为每秒 10 行,每行和通道 1,028 像素,因此完成此大面积扫描只需不到 2 分钟。

...Access restricted. Please log in or start a trial to view this content.

讨论

如代表性结果所示,主动悬臂阵列可用于并行捕获静态样品的多个图像。这种可扩展的设置可以显著提高大面积样品的成像通量,使其适用于检测半导体晶圆上的纳米制造器件。该技术也不仅限于人造结构;只要一组活动悬臂内的形貌变化不是悬臂阵列处理的太大,就可以实现高通量成像。

除了实现高通量、大面积检测外,主动悬臂探针阵列在成像设置方面还具有多项优势。?...

Access restricted. Please log in or start a trial to view this content.

披露声明

作者没有利益冲突。

致谢

作者 Ivo W. Rangelow 和 Thomas Sattel 感谢德国联邦教育和研究部 (BMBF) 和德国联邦经济事务和气候行动部 (BMWK) 通过资助 KMU-innovativ 研究线中的项目 FKZ:13N16580"用于量子计量和纳米制造的金刚石尖端有源探针"来支持所提出的部分方法: 光子学和量子技术,以及KK5007912DF1"用于原子力显微镜中快速和大型计量任务的连接纳米定位器扫描仪",属于中小型工业中央创新计划(ZIM)的资助项目。本文报告的部分工作由欧盟第七框架计划FP7/2007-2013资助,根据第318804号赠款协议"单纳米制造:超越CMOS"资助。作者 Ivo W. Rangelow 和 Eberhard Manske 感谢德国伊尔梅瑙工业大学研究培训小组"基于尖端和激光的 3D 纳米加工"(GRK 2182) 框架内的支持。

Access restricted. Please log in or start a trial to view this content.

材料

| Name | Company | Catalog Number | Comments |

| Active-Cantilever | nano analytik GmbH | AC-10-2012 | AFM Probe |

| E-Beam | EBX-30, INC | 012323-15 | Mask patterning instrument |

| Highly Oriented Pyrolytic Graphite – HOPG | TED PELLA, INC | 626-10 | AFM calibration sample |

| Mask Sample | Nanda Technologies GmbH | Test substrate | EUV Mask Sample substrate |

| NANO-COMPAS-PRO | nano analytik GmbH | 23-2016 | AFM Software |

| nanoMetronom 20 | nano analytik GmbH | 1-343-2020 | AFM Instrument |

参考文献

- Ando, T. High-speed atomic force microscopy and its future prospects. Biophysical Reviews. 10 (2), 285-292 (2018).

- Soltani Bozchalooi, I., Careaga Houck, A., AlGhamdi, J. M., Youcef-Toumi, K. Design and control of multi-actuated atomic force microscope for large-range and high-speed imaging. Ultramicroscopy. 160, 213-224 (2016).

- Sohn, Y., Ryu, S., Yang, Y. Semiconductor technology challenges in high volume manufacturing of semiconductors. Microscopy and Microanalysis. 28, 800-801 (2022).

- Ebayyeh, A. A. R. M. A., Mousavi, A. A review and analysis of automatic optical inspection and quality monitoring methods in electronics industry. IEEE Access. 8, 183192-183271 (2020).

- Nakamae, K. Electron microscopy in semiconductor inspection. Measurement Science and Technology. 32 (5), 052003(2021).

- Nduhura-Munga, J., et al. A literature review on sampling techniques in semiconductor manufacturing. IEEE Transactions on Semiconductor Manufacturing. 26 (2), 188-195 (2013).

- Zhang, T., et al. Correlative AFM and scanning microlens microscopy for time-efficient multiscale imaging. Advanced Science. 9 (12), 2103902(2022).

- Holz, M., et al. Correlative microscopy and nanofabrication with AFM integrated with SEM. Microscopy Today. 27 (6), 24-30 (2019).

- Yang, C., Xia, F., Wang, Y., Truncale, S., Youcef-Toumi, K. Design and control of a multi-actuated nanopositioning stage with stacked structure. 2019 American Control Conference (ACC). , IEEE. Philadeplhia. 3782-3788 (2019).

- Xia, F., Truncale, S., Wang, Y., Youcef-Toumi, K. Design and control of a multi-actuated high-bandwidth and large-range scanner for atomic force microscopy. 2018 Annual American Control Conference (ACC). , IEEE. Milwaukee, WI. 4330-4335 (2018).

- Yong, Y. K., Moheimani, S. O. R., Kenton, B. J., Leang, K. K. Invited review article: high-speed flexure-guided nanopositioning: mechanical design and control issues. The Review of Scientific Instruments. 83 (12), 121101(2012).

- Wang, J. Y., Mullin, N., Hobbs, J. K. High-speed large area atomic force microscopy using a quartz resonator. Nanotechnology. 29 (33), 335502(2018).

- Yang, C., et al. Charge controller with decoupled and self-compensating configurations for linear operation of piezoelectric actuators in a wide bandwidth. IEEE Transactions on Industrial Electronics. 66 (7), 5392-5402 (2019).

- Yang, C., Xia, F., Wang, Y., Youcef-Toumi, K. Comprehensive study of charge-based motion control for piezoelectric nanopositioners: Modeling, instrumentation and controller design. Mechanical Systems and Signal Processing. 166, 108477(2022).

- Xia, F., Yang, C., Wang, Y., Youcef-Toumi, K. Bandwidth based repetitive controller design for a modular multi-actuated AFM scanner. 2019 American Control Conference (ACC). , IEEE. Philadelphia, PA. 3776-3781 (2019).

- Ahmad, A., Schuh, A., Rangelow, I. W. Adaptive AFM scan speed control for high aspect ratio fast structure tracking. The Review of Scientific Instruments. 85 (10), 103706(2014).

- Coskun, M. B., Alemansour, H., Fowler, A. G., Maroufi, M., Moheimani, S. O. R. Q control of an active AFM cantilever with differential sensing configuration. IEEE Transactions on Control Systems Technology. 27 (5), 2271-2278 (2019).

- Xia, F., Mayborne, M. P., Ma, Q., Youcef-Toumi, K. Physical intelligence in the metaverse: mixed reality scale models for twistronics and atomic force microscopy. 2022 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM). , IEEE. Sapporo, Japan. 1722-1729 (2022).

- Xia, F., et al. A modular low-cost atomic force microscope for precision mechatronics education. Mechatronics. 76, 102550(2021).

- Minne, S. C., et al. Centimeter scale atomic force microscope imaging and lithography. Applied Physics Letters. 73 (12), 1742-1744 (1998).

- Minne, S. C., et al. Automated parallel high-speed atomic force microscopy. Applied Physics Letters. 72 (18), 2340-2342 (1998).

- Ahmad, A., et al. Large area fast-AFM scanning with active "Quattro" cantilever arrays. Journal of Vacuum Science & Technology B. 34 (6), (2016).

- Gotszalk, T., Grabiec, P., Rangelow, I. W. Piezoresistive sensors for scanning probe microscopy. Ultramicroscopy. 82 (1), 39-48 (2000).

- Angelov, T., et al. Thermo-mechanical transduction suitable for high-speed scanning probe imaging and lithography. Microelectronic Engineering. 154, 1-7 (2016).

- Rangelow, I. W., et al. Active scanning probes: A versatile toolkit for fast imaging and emerging nanofabrication. Journal of Vacuum Science & Technology B. 35 (6), 101(2017).

- Marinello, F., Bariani, P., De Chiffre, L., Hansen, H. N. Development and analysis of a software tool for stitching three-dimensional surface topography data sets. Measurement Science and Technology. 18 (5), 1404(2007).

- López de la Rosa, F., Sánchez-Reolid, R., Gómez-Sirvent, J. L., Morales, R., Fernández-Caballero, A. A review on machine and deep learning for semiconductor defect classification in scanning electron microscope images. Applied Sciences. 11 (20), 9508(2021).

- Holz, M., et al. High throughput AFM inspection system with parallel active cantilevers. In Photomask Technology 2019. 11148, SPIE. 278-287 (2019).

- Gotszalk, T., Ivanov, T., Rangelow, I. Parallel SPM cantilever arrays for large area surface metrology and lithography. In Metrology, Inspection, and Process Control for Microlithography XXVIII. 9050, SPIE. 274-282 (2014).

- Ahmad, A., et al. 13th Intl. Workshop on Nanomechanical Sensing. Quattro-Cantilever Array: Large Area and High Speed AFM Imaging and Nanolithography. , (2016).

- Shearer, C. J., Slattery, A. D., Stapleton, A. J., Shapter, J. G., Gibson, C. T. Accurate thickness measurement of graphene. Nanotechnology. 27 (12), 125704(2016).

- Shioyama, H. The interactions of two chemical species in the interlayer spacing of graphite. Synthetic Metals. 114 (1), 1-15 (2000).

- Ivanova, K., et al. Scanning proximal probes for parallel imaging and lithography. Journal of Vacuum Science & Technology B. 26 (6), 2367-2373 (2008).

- García, R., San Paulo, A. Attractive and repulsive tip-sample interaction regimes in tapping-mode atomic force microscopy. Physical Review B. 60 (7), 4961-4967 (1999).

- Ruppert, M. G., Fowler, A. G., Maroufi, M., Moheimani, S. O. R. On-chip dynamic mode atomic force microscopy: a silicon-on-insulator MEMS approach. Journal of Microelectromechanical Systems. 26 (1), 215-225 (2017).

Access restricted. Please log in or start a trial to view this content.

转载和许可

请求许可使用此 JoVE 文章的文本或图形

请求许可探索更多文章

This article has been published

Video Coming Soon

版权所属 © 2025 MyJoVE 公司版权所有,本公司不涉及任何医疗业务和医疗服务。