Un abonnement à JoVE est nécessaire pour voir ce contenu. Connectez-vous ou commencez votre essai gratuit.

Method Article

Considérations pratiques pour la conception, l’exécution et l’interprétation d’études portant sur des essais de flexion d’os de rongeurs sur des os entiers

Dans cet article

Résumé

L’analyse mécanique des os de rongeurs est une méthode précieuse pour extraire des informations sur la susceptibilité d’un os à se fracturer. En l’absence d’une bonne compréhension pratique, les résultats peuvent être surinterprétés ou manquer de validité. Ce protocole servira de guide pour s’assurer que les essais mécaniques sont effectués avec précision afin de fournir des données valides et fonctionnelles.

Résumé

La fragilité squelettique conduisant à la fracture est une crise de santé publique américaine qui entraîne 1,5 million de fractures chaque année et 18 milliards de dollars en coûts directs de soins. La capacité de comprendre les mécanismes sous-jacents à la maladie osseuse et la réponse au traitement est non seulement souhaitée, mais essentielle. L’analyse mécanique de l’os est une technique précieuse pour comprendre et quantifier la susceptibilité d’un os à la fracture. Bien que cette méthode semble simple à mettre en œuvre, des conclusions inappropriées et inexactes peuvent être tirées si les hypothèses et les étapes clés ne sont pas prises en compte par l’utilisateur. Cela a été observé dans toutes les disciplines, car les études continuent d’être publiées avec une mauvaise utilisation des méthodes et une interprétation incorrecte des résultats. Ce protocole servira d’introduction aux principes associés aux essais mécaniques ainsi qu’à l’application de ces techniques, depuis les considérations relatives à la taille de l’échantillon jusqu’à l’analyse et l’interprétation des données, en passant par le prélèvement et l’entreposage des tissus. Avec cela à l’appui, il est possible d’obtenir des informations précieuses sur la susceptibilité d’un os à la fracture, ce qui permet de mieux comprendre les résultats de la recherche universitaire et des solutions cliniques.

Introduction

L’analyse mécanique de l’os est la principale méthode pour extraire des informations fonctionnelles liées à la susceptibilité d’un os à la fracture. Dans les études précliniques, plusieurs modalités de test peuvent être utilisées, mais la plus courante est de loin la flexion des os longs. Ces tests sont faciles à réaliser et peuvent être utilisés sur des os dont la taille varie de l’homme à la souris. La souris étant l’un des animaux les plus étudiés dans la recherche préclinique, ce protocole se concentrera sur les tests de flexion effectués sur les fémurs et les tibias des souris.

Avant d’effectuer des tests de flexion, les os doivent être correctement récoltés et stockés. Les méthodes de stockage les plus courantes ont traditionnellement été la congélation des os dans de la gaze imbibée de solution saline, la congélation dans une solution saline seule ou la déshydratation des os dans de l’éthanol 1. Il a été démontré que les os stockés dans l’éthanol ont une rigidité et un module d’élasticité accrus et des paramètres de déformation diminués par rapport à ceux stockés congelés1. Même la réhydratation des os avant le test ne permet pas de retrouver ces propriétés à des niveaux normaux 1. L’entreposage immergé dans une solution saline pourrait endommager l’os, car la pression est exercée lorsque la solution saline se dilate. De plus, une décongélation complète de la solution serait nécessaire pour prélever les os en vue d’une microtomodensitométrie (μCT). Par conséquent, la congélation des os fraîchement récoltés dans de la gaze imbibée de solution saline est devenue la méthode de stockage standard et est recommandée tout au long de ce protocole.

Étant donné que la taille et la forme d’un os affectent sa force apparente et que de nombreux modèles de maladies modifient considérablement la taille et la morphologie des os, les principes d’ingénierie sont utilisés pour normaliser les effets de la taille afin de produire des propriétés qui estiment le comportement du tissu2. Cette approche nécessite une géométrie en coupe transversale de l’emplacement de la défaillance, qui est le plus souvent acquise à l’aide de μCT pour créer des scans des os avant les tests. Le μCT est largement utilisé en raison de sa disponibilité et de sa haute résolution d’image. De plus, les apports de tissus mous ne sont pas inclus, et la scintigraphie ne nécessite pas de fixation chimique ou d’autres modifications de l’os 3,4. Dans toutes les formes de tomodensitométrie, une source de rayons X est focalisée sur un objet tandis qu’un détecteur situé de l’autre côté de l’objet mesure l’énergie des rayons X qui en résulte. Cela produit une ombre radiographique de l’échantillon qui peut être convertie en une image 3,5. L’objet scanné est tourné (ou la source de rayons X et le détecteur sont tournés autour de l’échantillon), générant des images qui peuvent être reconstruites en un ensemble de données tridimensionnelles représentant l’objet5.

La résolution de numérisation, c’est-à-dire la proximité entre deux objets et pouvant être résolus individuellement, est contrôlée en modifiant la taille nominale du voxel ou la taille d’un pixel dans l’image résultante. Il est généralement admis que les objets doivent être au moins deux fois plus grands qu’un seul voxel pour être identifiés3, mais un rapport plus élevé permettra d’améliorer la précision. De plus, les voxels plus grands sont plus sujets aux effets de volume partiel : lorsqu’un seul voxel contient des tissus de densités variables, on lui attribue la moyenne de ces densités, plutôt que la densité spécifique d’un seul tissu, ce qui peut conduire à une surestimation ou à une sous-estimation des surfaces tissulaires et de la densité minérale3. Bien que ces problèmes puissent être atténués en choisissant des tailles de voxel plus petites, l’utilisation d’une résolution plus élevée ne garantit pas l’élimination des effets de volume partiels et peut nécessiter des temps de balayage plus longs3. Lors de la scintigraphie des os ex vivo, une taille de voxel de 6 à 10 μm est généralement recommandée pour évaluer avec précision l’architecture trabéculaire des os de souris. Une taille de voxel plus grande de 10 à 17 μm peut être utilisée pour l’os cortical, bien que la plus petite taille de voxel raisonnable doive être utilisée. Ce protocole utilise une taille de voxel de 10 μm, ce qui est suffisamment petit pour différencier les principales propriétés trabéculaires et minimiser les effets de volume partiels sans temps de balayage prolongé.

Les réglages de l’énergie des rayons X et du filtre d’énergie doivent également être sélectionnés avec soin, car la densité minérale et l’épaisseur élevées du tissu osseux atténuent et modifient considérablement le spectre d’énergie des rayons X transmis. Il est généralement admis que, parce que le spectre des rayons X émis est équivalent au spectre qui sort de l’objet6, l’utilisation de rayons X de faible énergie sur des objets denses tels que les os peut conduire à un artefact connu sous le nom de durcissement du faisceau7. Une tension plus élevée de 50 à 70 kVc est recommandée lors de l’analyse des échantillons d’os afin de réduire l’incidence de ces artefacts5. De plus, l’insertion d’un filtre d’énergie en aluminium ou en cuivre crée un faisceau d’énergie plus concentré, minimisant davantage les artefacts 4,7. Un filtre en aluminium de 0,5 mm sera utilisé tout au long de ce protocole.

Enfin, l’étape de rotation de la numérisation et la longueur de rotation (par exemple, 180°-360°) contrôlent ensemble le nombre d’images capturées, ce qui détermine la quantité de bruit dans la numérisation finale4. La moyenne de plusieurs images à chaque étape peut réduire le bruit, mais peut augmenter le temps de numérisation4. Ce protocole utilise un pas de rotation de 0,7 degré et une moyenne de 2 degrés.

Une dernière remarque à propos de la numérisation : les fantômes d’étalonnage de l’hydroxyapatite doivent être scannés en utilisant les mêmes paramètres de balayage que les os expérimentaux pour permettre la conversion des coefficients d’atténuation en densité minérale en g/cm35. Ce protocole utilise des fantômes de 0,25 g/cm 3 et 0,75 g/cm3 d’hydroxyapatite, bien que différents fantômes soient disponibles. Notez que certains systèmes de balayage utilisent des fantômes internes dans le cadre de l’étalonnage quotidien du système.

Une fois le balayage terminé, les projections angulaires sont reconstruites en images en coupe transversale de l’objet, généralement à l’aide du logiciel d’accompagnement du fabricant. Quel que soit le système utilisé, il est important de s’assurer que l’os entier est capturé dans la reconstruction et que le seuil est défini de manière appropriée pour permettre la reconnaissance de l’os par rapport au non-os. Après la reconstruction, il est essentiel de faire pivoter tous les scans en trois dimensions afin que les os soient orientés de manière cohérente et correctement alignés avec l’axe transversal, toujours à l’aide du logiciel du fabricant.

Après la rotation, les régions d’intérêt (ROI) pour l’analyse peuvent être sélectionnées selon que les propriétés corticales, les propriétés trabéculaires ou la géométrie de la fracture pour la normalisation mécanique sont souhaitées. Dans ce dernier cas, les ROI doivent être sélectionnés après le test en mesurant la distance entre le site de fracture et une extrémité de l’os et en utilisant la taille du voxel pour déterminer l’emplacement de la tranche correspondante dans le fichier de numérisation. La région sélectionnée doit avoir une longueur d’au moins 100 μm, avec le point de fracture au centre approximatif du ROI, pour fournir une estimation adéquate4.

Lorsque les retours sur investissement sont sélectionnés, deux propriétés sont nécessaires pour la normalisation mécanique (pour calculer la contrainte de flexion et la déformation) : la distance maximale entre l’axe de flexion neutre et la surface où la rupture est initiée (supposée être la surface chargée en tension, déterminée par la configuration d’essai) et le moment d’inertie de la zone autour de l’axe neutre (également en fonction de la configuration d’essai). Ce protocole recommande l’utilisation d’un code personnalisé pour déterminer ces valeurs. Pour accéder au code, contactez directement l’auteur correspondant ou visitez le site Web du laboratoire à l’adresse https://bbml.et.iupui.edu/ pour plus d’informations.

Une fois la tomodensitométrie terminée, les essais mécaniques peuvent commencer. Les essais de flexion peuvent être effectués dans des configurations à quatre ou trois points. Les essais de flexion en quatre points sont préférés car ils éliminent la contrainte de cisaillement dans l’os entre les points de charge, ce qui permet une flexion pure dans cette région3. L’os va alors se fracturer sous l’effet de la tension, créant une défaillance plus représentative des véritables propriétés de flexion de l’os3. Cependant, l’os doit être chargé de manière à fournir la même charge aux deux points de chargement (cela peut être facilité par une tête de chargement pivotante). Dans les essais de flexion en trois points, il y a un grand changement de contrainte de cisaillement à l’endroit où le point de charge rencontre l’os, ce qui provoque la rupture de l’os à ce stade en raison du cisaillement et non de la tension3. Les normes ASTM recommandent que les matériaux soumis à la flexion aient un rapport longueur/largeur de 16 :1, ce qui signifie que la longueur de la portée du support doit être 16 fois plus grande que la largeur de l’os pour minimiser les impacts du cisaillement 8,9. Ceci est souvent impossible à réaliser lors de l’essai de petits os de rongeurs, de sorte que la portée de chargement est simplement rendue aussi grande que possible, mais avec un changement de forme de section aussi faible que possible. De plus, lors de la flexion à quatre points, le rapport entre les longueurs de l’envergure inférieure et supérieure doit être de ~3 :18, ce qui peut généralement être réalisé dans le tibia, mais c’est difficile dans le fémur plus court. De plus, les parois corticales plus minces des fémurs les rendent sensibles à la déformation de type anneau qui modifie la forme de la section transversale osseuse pendant le test (cela peut être accentué dans les tests à quatre points car une force plus importante est nécessaire pour induire le même moment de flexion par rapport à la flexion à trois points). Par conséquent, la flexion en trois points sera utilisée pour les fémurs de souris, tandis que la flexion en quatre points sera utilisée pour les tibias tout au long de ce protocole.

Enfin, il est important d’alimenter correctement l’étude pour l’analyse statistique. Une recommandation générale pour les essais mécaniques est d’avoir une taille d’échantillon de 10 à 12 os par groupe expérimental pour être en mesure de détecter les différences, car certaines propriétés mécaniques, en particulier les paramètres post-rendement, peuvent être très variables. Dans certains cas, cela peut signifier commencer avec un échantillon d’animaux de plus grande taille compte tenu de l’attrition qui pourrait se produire au cours de l’étude. L’analyse de la taille de l’échantillon à l’aide des données existantes doit être effectuée avant de tenter une étude.

Il existe de nombreuses limites et hypothèses, mais les tests de flexion peuvent fournir des résultats assez précis, en particulier lorsque les différences relatives entre les groupes sont intéressantes. Ces propriétés, ainsi que l’analyse de l’architecture trabéculaire et de la morphologie corticale, peuvent fournir un meilleur aperçu des états pathologiques et des schémas thérapeutiques. Si l’on prend soin des aspects de l’expérience qui sont sous notre contrôle (par exemple, la récolte, le stockage, la numérisation et les tests), nous pouvons être sûrs que des résultats précis ont été générés.

Protocole

Toutes les procédures décrites dans ce protocole qui impliquaient des animaux ont été approuvées par le Comité institutionnel d’utilisation des animaux (IACUC) de l’École des sciences de l’Université de l’Indiana (IACUC) avant la procédure. Les animaux décrits dans la procédure ont été euthanasiés par inhalation de CO2suivie d’une luxation cervicale comme moyen secondaire d’euthanasie.

1. Récolte, stockage et décongélation des os

- Récolte et stockage

- Placez la souris face ventrale vers le haut. Utilisez un scalpel (ou une lame de rasoir ou des ciseaux) pour faire une incision à la jonction approximative du fémur et du bassin d’un côté.

- Continuez l’incision initiale dorsalement jusqu’à ce que l’articulation de la hanche soit localisée ; Recherchez la tête fémorale qui apparaît comme une petite sphère blanche attachée au bassin.

- Appliquez une pression avec le tranchant d’un scalpel sur le bord proximal de la tête fémorale jusqu’à ce que la tête fémorale sorte de l’alvéole. Retirez les tissus supplémentaires pour libérer le membre postérieur du reste de la carcasse.

- Avec le membre postérieur isolé, séparez le tibia et le fémur en induisant une flexion au niveau de l’articulation du genou. Déplacez le scalpel dans la direction médiale-latérale à la surface antérieure du genou pour couper à travers tout tissu adjacent, y compris les ligaments entre les os.

- Si cela ne sépare pas les os, étendez l’articulation du genou pour permettre l’accès à la surface postérieure. Veillez à ne pas couper l’os ou gratter le cartilage articulaire.

- Une fois le fémur et le tibia séparés, retirez l’arrière-pied du tibia en fléchissant l’articulation et en utilisant un mouvement de sciage médial-latéral sur la face postérieure de l’articulation. Si nécessaire, prolongez l’articulation pour exposer la face antérieure. Veillez à ne pas couper l’os.

- Une fois isolé, nettoyez les os de tous les tissus mous adhérents. Si vous effectuez des tests de flexion en quatre points sur le tibia, retirez également le péroné. Le péroné est relié par des ligaments à l’extrémité proximale mais est fusionné au tibia près de l’extrémité distale de l’os. Utilisez des ciseaux bien aiguisés près du point de connexion pour séparer le péroné.

- Enveloppez séparément les os isolés et nettoyés dans une gaze imbibée de sérum physiologique et conservez-les à -20 °C. Faites-le immédiatement après la récolte.

- Répétez les étapes 1.1.1 à 1.1.8 pour l’autre côté de la carcasse.

REMARQUE : S’il y a une résistance lorsque vous essayez de séparer les os aux étapes 1.1.4 à 1.1.6, il est préférable de répéter les étapes plutôt que d’essayer de séparer les os. Des mouvements violents peuvent entraîner des dommages ou des fractures des os.

- Décongélation

REMARQUE : Le nombre de cycles de gel-dégel d’un os doit être réduit au minimum, car des cycles de gel-dégel excessifs peuvent avoir un impact négatif sur les propriétés mécaniques de l’os. Une décongélation partielle pour la scintigraphie μCT peut être obtenue en laissant l’os à température ambiante pendant 5 à 10 minutes. Ne décongelez complètement l’os que lorsque vous effectuez des tests de flexion comme décrit ci-dessous.- Nuit préférée au dégel

- Déplacez les os de -20 °C à 1-4 °C dans une chambre froide ou un réfrigérateur. Assurez-vous que les os y restent pendant 8 à 12 h pour décongeler complètement avant de procéder à l’analyse.

- Décongélation rapide

- Réglez la température du bain à environ 37 °C. Une fois à cette température, ajoutez les os dans le bain.

- Laissez les os dans le bain pendant environ 1 h.

- Nuit préférée au dégel

2. Balayage μCT

- Enveloppez les os dans un parafilm avant le balayage pour maintenir l’hydratation. Gardez tous les autres os sur la glace en attendant d’être scannés.

- Une fois enveloppé dans du parafilm, placez l’os dans un support pour l’interfacer avec le scanner. Assurez-vous que toutes les structures numérisées sont alignées dans la même orientation, car un alignement cohérent simplifiera la rotation plus tard dans l’analyse.

- Ajustez les paramètres de numérisation en fonction de l’application de la numérisation. Les paramètres de balayage généraux suivants sont recommandés pour les os de souris : résolution/taille du voxel : 10 μm ; Taille des pixels : moyenne, 2000 x 1048 ; filtre : aluminium de 0,5 mm ; pas de rotation : 0,7 ; Moyenne d’images : 2.

REMARQUE : Ces paramètres peuvent différer en fonction du système utilisé pour la numérisation, et le manuel du fabricant et de l’utilisateur doit être consulté si nécessaire. - Une fois que la source de rayons X est allumée, effectuez une correction de champ plat pour minimiser les artefacts. Pour ce faire, assurez-vous d’abord que la chambre est vide et éteignez le champ plat.

- Mesurez l’intensité moyenne du champ et ajustez-la à 60 %. Une fois à 60 %, mettez à jour le champ plat et réactivez-le.

- Assurez-vous que l’intensité moyenne est maintenant (86-88%).

REMARQUE : Ce processus peut varier en fonction du système μCT utilisé. Consultez le manuel d’utilisation avant d’essayer le processus. - Une fois la correction à plat effectuée avec succès, placez le support dans la chambre. Assurez-vous que les échantillons sont centrés et de niveau avant de placer le piédestal dans la chambre.

- Une fois le piédestal fixé, fermez la chambre, assurez-vous que l’os entier sera capturé dans le scan (une vue de reconnaissance peut être nécessaire) et commencez le scan.

- Après la scintigraphie, replacer les os dans une gaze imbibée de sérum physiologique à -20 °C.

3. Reconstruction μCT

- Sélectionnez un retour sur investissement qui capturera l’ensemble de l’os lors de la reconstruction. Pour ce faire, affichez la plus grande section transversale de l’os et dimensionnez le retour sur investissement en fonction de cette section transversale.

- Définissez le seuil du logiciel pour permettre une reconnaissance correcte de l’os par rapport à l’os non osseux. Pour ce faire, utilisez un histogramme dans lequel une contrainte inférieure est définie sur 0 et la contrainte supérieure est définie à la fin des données de l’histogramme de crête.

- Ajustez des paramètres supplémentaires, notamment la réduction des artefacts annulaires et le durcissement du faisceau, à 5 et 20 %, respectivement. Vérifiez que la compensation du désalignement est comprise entre -7 et 7. Ces valeurs peuvent varier en fonction du logiciel. Assurez-vous qu’ils sont vérifiés avec le manuel d’utilisation et les instructions du fabricant avant de commencer la reconstruction.

REMARQUE : Les artefacts peuvent être minimisés pendant la reconstruction à l’aide de corrections pour le durcissement du faisceau, les artefacts annulaires et la compensation des défauts d’alignement. La compensation du désalignement peut servir d’indicateur de la qualité du balayage et, s’il se trouve en dehors d’une plage spécifiée par le fabricant, le balayage doit être répété. Cependant, les paramètres de reconstruction dépendent du logiciel et le manuel de l’utilisateur doit être consulté.

4. Rotation μCT

REMARQUE : Une fois reconstruites, les scintigraphies doivent être pivotées pour établir une orientation cohérente sur tous les os et pour s’assurer que les coupes transversales de l’os résultant sont prises perpendiculairement à l’axe longitudinal avec le moins d’angle de décalage possible. Cela doit être fait avec le logiciel choisi par l’utilisateur.

- Rotation du fémur

- Faites pivoter le fémur de manière à ce que tous les os aient la même orientation longitudinale. Par exemple, orientez tous les os avec l’extrémité proximale de l’os en haut de la numérisation.

- Faites pivoter la structure de manière à ce que l’orientation de la section transversale de toutes les structures soit la même. Par exemple, faites pivoter les os de manière à ce que la face antérieure soit toujours du côté droit des scans.

- Une fois ces réglages effectués, redressez le balayage pour vous assurer que la symétrie est maintenue autour de l’axe central.

- Enregistrez le jeu de données pivoté.

- Rotation du tibia

- Répétez les étapes 4.1.1 à 4.1.4 pour le tibia.

5. Procédure d’essai mécanique

- Préparation

- Avant les essais mécaniques, s’assurer qu’une tomodensitométrie μCT d’une résolution de 6 à 10 μm a été obtenue et reconstruite pour vérifier qu’une analyse de qualité a été acquise pour chaque échantillon afin de calculer la géométrie de la section transversale sur le site de la fracture (sections 2 et 3).

- Une fois les scans obtenus et vérifiés, décongeler tous les os avant de les tester (section 1). Testez tous les os d’une expérience le même jour et randomisez l’ordre des tests pour minimiser le biais de l’utilisateur et la variabilité du système entre les échantillons et les groupes expérimentaux. Assurez-vous que les os restent hydratés tout au long du processus de test.

- Configuration de l’appareil

- Localisez un capteur de pesage avec une sensibilité et une capacité appropriées pour l’échantillon. Tenez compte de la plage de défaillance attendue pour l’échantillon et choisissez un capteur de pesage avec environ 50 % de capacité en plus tout en maximisant la sensibilité (par exemple, un capteur de pesage de 10 lbf avec une capacité de 45 N pour un os de souris dans la plage de défaillance de 0 à 25 N).

- Localisez les dispositifs de chargement et de support.

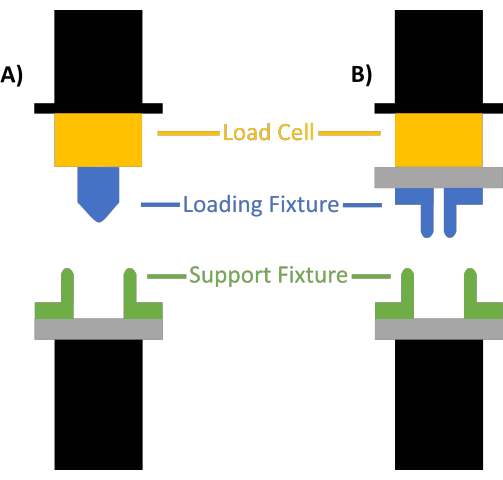

- Installez le capteur de pesage et les fixations comme illustré à la Figure 1, en vissant le capteur de pesage sur le support supérieur ou inférieur du testeur, le dispositif de chargement par le haut sur le capteur de pesage et le dispositif inférieur sur le support inférieur du testeur. Assurez-vous d’un ajustement sûr.

REMARQUE : La fixation de la cellule de charge à la fixation supérieure est généralement recommandée lors de l’exécution d’essais de flexion pour éviter le contact du fluide avec la cellule de charge, mais le bas peut être utilisé si nécessaire. - Une fois le capteur de pesage et les fixations installés, sélectionnez une longueur de portée de support et assurez-vous qu’elle reste constante pour tous les échantillons testés. Pour choisir une distance de portée d’appui, localisez d’abord la structure la plus courte dans le jeu d’échantillons.

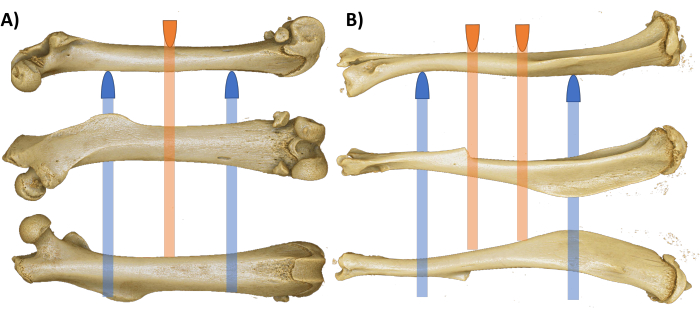

- Orientez l’os entre les fixations comme illustré à la figure 2.

- Pour une flexion en trois points du fémur, suivez la figure 2A. Assurez-vous que la surface antérieure de l’os est contre la travée de support et que la région de la travée se trouve à l’intérieur de la diaphyse de l’échantillon. Évitez d’inclure le troisième trochanter à l’extrémité proximale et le point de transition où l’os s’élargit dans la métaphyse et les condyles à l’extrémité distale.

- Pour le pliage en quatre points, assurez-vous que les travées de support et de charge sont alignées et centrées l’une par rapport à l’autre. Suivez la figure 2B pour charger l’os dans les luminaires.

- Réglez les longueurs des portées de support et de chargement de manière à ce qu’elles suivent un rapport de 3 :18 (par exemple, une portée de support de 9 mm et une portée de chargement de 3 mm).

- Dans le cas d’un tibia, chargez la surface médiale de l’os contre la travée d’appui avec un support à la jonction tibia/péroné. L’autre support sera probablement positionné juste après la crête tibiale. Assurez-vous que la travée de chargement, centrée à l’intérieur de la travée de support, contient une région uniforme de l’os.

- Mesurez la distance de la portée du support si vous effectuez un pliage en trois points et les distances de chargement et de portée du support si vous effectuez un pliage en 4 points et enregistrez ces distances. Assurez-vous que cette valeur est enregistrée à partir du centre des points de charge pour les mesures de la portée de charge et de support.

- Remettez l’os dans une solution saline ou réhydratez-le avec un bolus de solution saline.

REMARQUE : Lors de la sélection de points pour une travée de chargement, il est recommandé d’utiliser des points circulaires (un rayon de 0,75 mm est suffisant car il répartit la charge tout en entrant en contact avec l’os à la tangente du cercle). Bien que la théorie recommande un tranchant de couteau pour représenter une charge ponctuelle, cela écrasera l’os au point d’application de la charge, ce qui entraînera une surestimation de la déformation et une sous-estimation du module. - Assurez-vous que toutes les pièces de l’appareil sont bien serrées et libres de mouvement.

- Configuration du logiciel

- Assurez-vous que le testeur est correctement connecté à l’ordinateur via le boîtier de module, les canaux de la cellule de charge et toute autre exigence conformément au manuel du système.

- Dans le logiciel associé au testeur mécanique, créez un profil d’essai de flexion avec une rampe dont le taux de déplacement est suffisamment lent pour ne pas induire d’effets viscoélastiques (0,025 mm/s est souvent utilisé) pour charger l’os jusqu’à la rupture.

- Une fréquence d’échantillonnage minimale de 25 Hz est également recommandée lors de la création d’un profil de test, bien qu’une fréquence d’échantillonnage plus élevée soit préférable.

- Créez un dossier par groupe d’étude et enregistrez chaque test sous la forme d’un fichier individuel dans ce dossier.

- Chargement et test des échantillons

- Sélectionnez un os correctement décongelé (voir l’étape 1.2). Mesurez et enregistrez toute sa longueur à l’aide d’un pied à coulisse.

- Chargez l’échantillon sur les appareils comme indiqué à la figure 2A si vous testez un fémur en flexion en trois points et à la figure 2B si vous testez un tibia en flexion en quatre points.

- Modifiez le nom du fichier pour qu’il reflète l’échantillon testé.

- Mettez à zéro la charge (et non le déplacement). Allumez le moteur du système ; Assurez-vous qu’il n’est pas en contrôle de charge ou de déplacement.

- En faisant preuve de prudence, appliquez une précharge minimale sur l’os pour sécuriser sa position et aider à empêcher l’os de rouler, mais assurez-vous que cela ne compromet pas l’échantillon. Visez une précharge d’environ 0,25 N. Assurez-vous que l’orientation osseuse souhaitée est maintenue avant de continuer.

- Hydratez l’échantillon en l’aspergeant généreusement de solution saline.

- Commencez le test de flexion en sélectionnant Démarrer ou Exécuter dans le logiciel. CRITIQUE : Surveillez attentivement l’échantillon pendant toute la durée de l’essai et notez les tests où des problèmes sont survenus (p. ex., roulement, glissement).

REMARQUE : Ces problèmes pourraient compromettre les données et il sera utile de consulter des notes sur ces tests pendant l’analyse. - Surveillez l’apparition de l’os qui commence à se fracturer (du côté de la traction). La plupart des tests se poursuivront jusqu’à ce qu’une défaillance se produise. À ce stade, le test se terminera via ses limites programmées. Si une défaillance se produit mais que le testeur continue de se déplacer, arrêtez manuellement le test pour éviter d’endommager le capteur de pesage.

- Une fois le test terminé, mesurez la longueur de l’extrémité distale au point de rupture à l’aide d’un pied à coulisse et enregistrez-la.

- Répétez les étapes 5.4.1 à 5.4.9 pour chaque échantillon.

Figure 1 : Configuration du testeur mécanique. (A) Essais de flexion en trois points et (B) en quatre points. Le capteur de pesage est représenté en jaune, les dispositifs de chargement sont affichés en bleu et les dispositifs de support sont affichés en vert. Veuillez cliquer ici pour voir une version agrandie de cette figure.

Figure 2 : Orientation des os entre les appareils. (A) Orientation correcte d’un fémur dans les dispositifs de charge de flexion à trois points montrant (de haut en bas) des vues des côtés médian, antérieur et postérieur du fémur lorsqu’il est correctement positionné. Les fixations de chargement sont indiquées en orange et les fixations de support sont indiquées en bleu. Les travées inférieures doivent être ajustées pour inclure autant que possible la partie la plus droite de la diaphyse, et le luminaire supérieur doit être centré entre ces travées. (B) Orientation correcte d’un tibia pour une flexion en quatre points montrant (de haut en bas) des vues des côtés antérieur, latéral et médial du tibia. L’os doit être chargé de manière à ce que la surface médiane entre en contact avec le luminaire inférieur et que la surface latérale entre en contact avec le luminaire supérieur. La jonction tibia-péroné doit être placée juste à l’extérieur de la travée de chargement. Les travées doivent être ajustées pour répondre au mieux à un rapport charge/portée de support de 1 :3. Veuillez cliquer ici pour voir une version agrandie de cette figure.

6. Sélection du retour sur investissement

- Une fois les longueurs de rupture enregistrées, chargez les images pivotées dans le logiciel de votre choix. Une fois les images pivotées chargées, localisez et enregistrez les tranches supérieure et inférieure de la structure.

- Calculez la différence entre les tranches supérieure et inférieure. Multipliez cette valeur par la taille du voxel de balayage pour déterminer la longueur totale de l’os en micromètres.

- Pour localiser l’emplacement de la fracture dans la tomodensitométrie, divisez la longueur de la rupture enregistrée (en micromètres) par la taille du voxel pour obtenir le nombre de tranches de μCT de l’extrémité distale de la tomodensitométrie jusqu’au point de rupture.

- Sélectionnez un retour sur investissement, centré sur cet emplacement. Tout d’abord, définissez la longueur totale souhaitée du ROI (au moins 100 μm). Trouvez le nombre de tranches que cette longueur représente en divisant la longueur en micromètres par la taille du voxel pour déterminer le nombre total de tranches dans le ROI.

- Pour obtenir la borne inférieure du ROI, divisez le nombre total de tranches de ROI par 2 et soustrayez cette valeur de l’emplacement de rupture précédemment calculé à l’étape 6.4.

- Ajoutez la longueur totale du ROI en tranches à la valeur calculée précédemment pour obtenir la limite supérieure du ROI.

- Sélectionnez le retour sur investissement approprié, en fonction des limites calculées, et enregistrez-le.

7. Normalisation des données de force et de déplacement

REMARQUE : Le testeur mécanique ne générera que des points avec des coordonnées x et y (déplacement, force). Ces points peuvent être convertis en contrainte et en déformation à l’aide des équations de contrainte et de déformation en flexion d’Euler-Bernoulli, mais celles-ci nécessitent des propriétés géométriques obtenues à partir de balayages μCT. La quantification de ces propriétés peut être effectuée avec le logiciel préféré de l’utilisateur. Nous préférons un code personnalisé, qui donne un contrôle total sur toutes les entrées, calculs et sorties. Comme mentionné précédemment, pour accéder au code, contactez directement l’auteur correspondant ou visitez le site Web du laboratoire à https://bbml.et.iupui.edu/ pour plus d’informations. Les équations de contrainte et de déformation, ainsi que les propriétés géométriques nécessaires qui doivent être obtenues à partir des balayages μCT, pour les calculer sont discutées ci-dessous.

- Équations de normalisation de flexion en trois points

- L’équation utilisée pour calculer la contrainte dans la flexion en trois points est illustrée ci-dessous dans l’équation 1. Dans cette équation, « F » représente la force et « L » représente la longueur de la portée d’appui. Les valeurs de force sont enregistrées par le testeur mécanique pendant l’essai. Assurez-vous que la longueur de la travée de support est enregistrée avant l’essai. « c » et « I » sont des propriétés géométriques qui seront calculées à l’aide de balayages μCT (section 7.3).

(1)

(1) - L’équation pour calculer la déformation est illustrée ci-dessous dans l’équation 2 ; « c » et « L » représentent les mêmes propriétés pour les calculs de contrainte et de déformation. « D » signifie les valeurs de déplacement enregistrées par le testeur mécanique lors des essais.

(2)

(2)

- L’équation utilisée pour calculer la contrainte dans la flexion en trois points est illustrée ci-dessous dans l’équation 1. Dans cette équation, « F » représente la force et « L » représente la longueur de la portée d’appui. Les valeurs de force sont enregistrées par le testeur mécanique pendant l’essai. Assurez-vous que la longueur de la travée de support est enregistrée avant l’essai. « c » et « I » sont des propriétés géométriques qui seront calculées à l’aide de balayages μCT (section 7.3).

- Équations de normalisation de flexion en quatre points

- L’équation de la contrainte dans la flexion en quatre points est illustrée ci-dessous dans l’équation 3. « F » et « I » restent les mêmes variables que celles décrites à l’étape 7.1.1. Calculer « a » à partir des mesures du support et de la portée de charge avant l’essai. Si vous suivez le rapport recommandé de 3 :1 pour la portée de support à la portée de chargement pour une flexion en quatre points, « a » sera un tiers de la longueur de la travée de support.

(3)

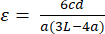

(3) - L’équation de la déformation en flexion en quatre points est illustrée ci-dessous dans l’équation 4. « c » et « a » signifient les mêmes propriétés pour les calculs de contrainte et de déformation. « D » signifie les valeurs de déplacement enregistrées par le testeur mécanique pendant les essais.

(4)

(4)

- L’équation de la contrainte dans la flexion en quatre points est illustrée ci-dessous dans l’équation 3. « F » et « I » restent les mêmes variables que celles décrites à l’étape 7.1.1. Calculer « a » à partir des mesures du support et de la portée de charge avant l’essai. Si vous suivez le rapport recommandé de 3 :1 pour la portée de support à la portée de chargement pour une flexion en quatre points, « a » sera un tiers de la longueur de la travée de support.

- Calcul des propriétés géométriques à partir de scintigraphies μCT

- La variable « c » représente la distance entre l’axe neutre et la surface de l’os qui a été chargé en tension. Par conséquent, déterminez le centroïde de chaque section efficace dans les balayages μCT puisque l’axe neutre passe par le centroïde.

- Si vous suivez l’orientation d’essai d’un fémur en flexion en trois points décrite à l’étape 5.2.6, mesurez « c » par rapport à la face antérieure.

- Si vous suivez l’orientation d’essai d’un tibia décrite à l’étape 5.2.7, mesurez « c » par rapport à la surface médiale de l’os.

- La variable « I » représente le moment d’inertie de l’aire autour de l’axe de flexion (l’axe médial-latéral pour un fémur, l’axe antéro-postérieur pour un tibia). Calculez cette valeur à l’aide de l’équation 5. Dans cette équation, « dA » est l’aire de chaque pixel capturé dans le balayage μCT tandis que y est la distance calculée de chaque pixel par rapport à l’axe neutre.

(5)

(5)

- La variable « c » représente la distance entre l’axe neutre et la surface de l’os qui a été chargé en tension. Par conséquent, déterminez le centroïde de chaque section efficace dans les balayages μCT puisque l’axe neutre passe par le centroïde.

8. Propriétés d’essai mécaniques d’intérêt

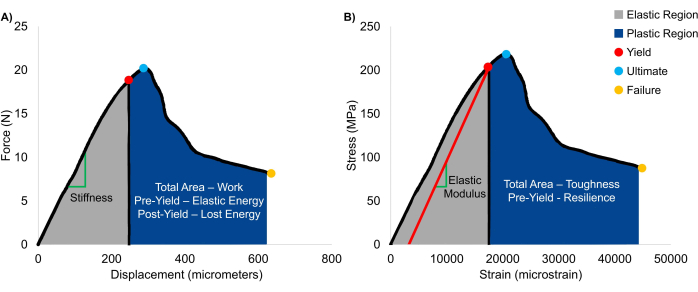

- Avant de calculer des propriétés mécaniques, générez une courbe force-déplacement et une courbe contrainte-déformation (courbes idéales illustrées ci-dessous dans la figure 3, ainsi que les propriétés significatives).

REMARQUE : L’analyse d’échantillons biologiques ne génère pas toujours des courbes qui ressemblent à ces exemples idéalisés, mais elles restent un guide utile. - Examinez ces courbes avant l’analyse pour repérer les erreurs dans les tests, telles qu’un roulement ou un glissement osseux. Ces erreurs provoquent généralement des bosses ou des régions planes dans la partie linéaire initiale de la courbe. Supprimez les données excédentaires, y compris toutes les données qui ont pu être collectées avant que le testeur n’entre en contact avec l’os ou les données après une défaillance, à ce stade.

- Une fois assuré d’un test de qualité par les courbes tracées, commencez l’analyse des propriétés significatives.

- Rigidité et module d’élasticité

- Calculez la rigidité en utilisant uniquement la région élastique de la courbe force-déplacement. La pente de la courbe dans cette région est la rigidité.

- Calculer le module d’élasticité en utilisant uniquement la pente de la partie élastique de la courbe contrainte-déformation.

- Limite d’élasticité

REMARQUE : Il y a deux limites d’élasticité, l’une sur la courbe force-déplacement et l’autre sur la courbe contrainte-déformation. Les valeurs (x,y) de ce point de la courbe force-déplacement sont connues sous le nom de déplacement à la limite d’élasticité et de force d’élasticité, tandis que celles de la courbe contrainte-déformation sont connues sous le nom de déformation à limite d’élasticité et limite d’élasticité. Ces points représentent la fin de la région élastique de la courbe et peuvent être trouvés de la manière indiquée ci-dessous.- Méthode de la courbe contrainte-déformation : Calculez un décalage de ligne par rapport à (0,0) de 0,2 % de déformation (2 000 microdéformations) mais avec la même pente que le module d’élasticité. Tracez cette ligne sur le graphique contrainte-déformation ; La position à laquelle cette droite intercepte la courbe contrainte-déformation est définie comme la limite d’élasticité. Utilisez cette coordonnée de contrainte d’élasticité et de déformation pour trouver les valeurs analogues de force et de déplacement ; Ces valeurs représenteront la force d’élasticité et le déplacement par rapport aux valeurs d’élasticité.

- Méthode sécante : Calculez la rigidité à partir de la courbe force-déplacement et réduisez la rigidité d’un pourcentage choisi (5-10%). Tracez une droite commençant à (0,0) avec la pente de cette rigidité réduite et laissez-la croiser avec la courbe force-déplacement. Le point d’intersection aura les coordonnées (déplacement à la limite d’élasticité, force d’élasticité).

REMARQUE : La méthode sécante peut être utilisée pour trouver la limite d’élasticité sans données de contrainte et de déformation.

- Force ultime et stress ultime

- Calculez la force ultime et la contrainte ultime en trouvant la valeur maximale dans les jeux de données respectifs.

- Propriétés de déplacement et de déformation

- Valeurs de déplacement à élasticité et de déformation à rendement représentant le déplacement ou la déformation jusqu’à la limite d’élasticité. Pour les trouver, localisez le rendement comme décrit à l’étape 8.3.2.

- Les valeurs de déplacement total et de déformation totale représentent le déplacement total ou la déformation totale subie par un échantillon tout au long de l’essai et correspondent au point de défaillance.

- Déplacement post-rendement et déformation post-rendement : Le déplacement post-rendement est couramment rapporté et peut être calculé en soustrayant le déplacement au rendement du déplacement total. Calculer la déformation après le rendement en soustrayant la déformation à la limite d’élasticité de la déformation totale, mais le déclarer avec prudence, car la déformation est d’abord dérivée en supposant que le matériau est linéairement élastique (pré-rendement). Cela rend une mesure post-rendement susceptible d’invalider.

- Propriétés énergétiques

- Calculez l’énergie comme l’aire sous la courbe force-déplacement ou contrainte-déformation.

- L’aire située sous la courbe force-déplacement est connue sous le nom de travail. L’aire calculée sous la partie de la courbe avant la limite d’élasticité, ou région élastique, est connue sous le nom de travail élastique ou d’énergie. La surface calculée sous la courbe au-delà du point d’élasticité, ou de la région plastique, est connue sous le nom de travail post-rendement ou plastique, ou perte d’énergie.

- La surface totale calculée sous la courbe contrainte-déformation est connue sous le nom de ténacité ou module de ténacité, tandis que la surface calculée sous la courbe contrainte-déformation jusqu’à la limite d’élasticité est connue sous le nom de résilience. La ténacité post-rendement, comme la déformation post-rendement, n’est souvent pas rapportée en raison des hypothèses des équations de déformation selon lesquelles cette propriété n’entre pas en ligne de compte.

- Rigidité et module d’élasticité

Figure 3 : Courbes force-déplacement et contrainte-déformation. (A) Courbe force-déplacement idéale ; (B) courbe contrainte-déformation idéale avec la droite dérivée de la méthode de décalage de 0,2 % utilisée pour calculer la limite d’élasticité indiquée en rouge (notez que cette ligne a la même pente que celle de la région élastique de la courbe). Les principales propriétés qui peuvent être obtenues à partir de la courbe force-déplacement comprennent la limite d’élasticité, la force ultime, le déplacement à la limite d’élasticité, le déplacement total et le travail. Les propriétés au niveau tissulaire qui peuvent être obtenues à partir de la courbe contrainte-déformation comprennent la limite d’élasticité, la contrainte ultime, la déformation à la limite, la déformation totale, la résilience et la ténacité. Veuillez cliquer ici pour voir une version agrandie de cette figure.

Résultats

À la fin de la tomodensitométrie, la plupart des examens inadéquats peuvent être détectés lors de la reconstruction. Souvent, les mauvais scans auront une compensation de désalignement élevée qui est un indicateur clair d’une erreur pendant le scan. Cependant, des erreurs peuvent se produire dans d’autres étapes et peuvent également conduire à des données inexactes. Ces erreurs peuvent souvent être repérées lors de l’examen des propriétés architecturales calculées individuellement. Si les valeurs...

Discussion

Tout au long du processus d’analyse et de test, il y a des moments où le dépannage et l’optimisation sont appropriés. Le premier d’entre eux se produit lors de la numérisation des os à l’aide de μCT. Alors que de nombreux systèmes sont livrés avec un support dans lequel un objet peut être tenu et scanné, des supports personnalisés peuvent être fabriqués pour numériser plusieurs os en même temps. L’analyse de plusieurs os peut être un excellent point d’optimisation, mais des précautions doiven...

Déclarations de divulgation

Les auteurs n’ont aucun conflit d’intérêts à déclarer.

Remerciements

Le travail effectué pour développer ce protocole a été soutenu par les National Institutes of Health [AR072609].

matériels

| Name | Company | Catalog Number | Comments |

| CTAn | Bruker | NA | CT Scan Analysis Software |

| DataViewer | Bruker | NA | CT Scan Rotation Software |

| Matrix Laboratory (MATLAB) 2023a | MathWorks | NA | Coding platform used for data analysis |

| NRecon | Bruker | NA | CT Scan Reconstruction software |

| SKYSCAN 1272-100 kV w/ 16 MP CCD detector, incl 3D Suite Software | Micro Photonics Inc | SKY-016814 | Micro-CT system that can non-destructively visualize up to 209 mPs in every virtual slice through an object |

Références

- Vesper, E. O., Hammond, M. A., Allen, M. R., Wallace, J. M. Even with rehydration, preservation in ethanol influences the mechanical properties of bone and how bone responds to experimental manipulation. Bone. 97, 49-53 (2017).

- Jepsen, K. J., Silva, M. J., Vashishth, D., Guo, X. E., van der Meulen, M. C. Establishing biomechanical mechanisms in mouse models: practical guidelines for systematically evaluating phenotypic changes in the diaphyses of long bones. Journal of Bone and Mineral Research. 30 (6), 951-966 (2015).

- Eds Burr, D. B., Allen, M. R. . Basic and Applied Bone Biology. , (2019).

- . . microCT SkyScan 1272 User Manual. , (2018).

- Kim, Y., Brodt, M. D., Tang, S. Y., Silva, M. J. MicroCT for scanning and analysis of mouse bones. Methods in Molecular Biology. 2230, 169-198 (2021).

- Bouxsein, M. L., et al. Guidelines for assessment of bone microstructure in rodents using micro-computed tomography. Journal of Bone and Mineral Research. 25 (7), 1468-1486 (2010).

- . . Micro-CT specimen scanner, Centre for high-throughput phenogenomics. , (2023).

- ASTM International. . Standard test method for flexural properties of unreinforced and reinforced plastics and electrical insulating materials by four-point bending. , (2020).

- ASTM International. . Standard test methods for flexural properties of unreinforced and reinforced plastics and electrical insulating materials. , (2017).

- . Bruker microCT NRecon: An overview. , (2023).

Réimpressions et Autorisations

Demande d’autorisation pour utiliser le texte ou les figures de cet article JoVE

Demande d’autorisationExplorer plus d’articles

This article has been published

Video Coming Soon