Biocarburants : produire de l'éthanol à partir de matière cellulosique

Vue d'ensemble

Source : Laboratoires de Margaret Workman et Kimberly Frye - Depaul University

Cellulosiques (tels que des tiges de maïs, feuilles, herbes, etc.), dans cette expérience, servira de matière première pour la production d’éthanol. Le matériau cellulosique est tout d’abord prétraité (rez-de-chaussée et chauffée), digérés par les enzymes et puis fermentés avec des levures. Production d’éthanol est contrôlée à l’aide d’une sonde de l’éthanol. L’expérience peut être étendue pour optimiser la production d’éthanol en faisant varier la matière première utilisée, conditions de prétraitement, variation de l’enzyme, variation de la levure, etc.. Une autre méthode de contrôle de la réaction est de mesurer le dioxyde de carbone produit (à l’aide d’un détecteur de gaz) au lieu de l’éthanol. Comme une alternative Low-Tech, glucomètres (trouvés dans n’importe quel magasin de drogue) peuvent être utilisés pour surveiller la glycémie au cours du processus, si un détecteur de gaz éthanol sonde ou dioxyde de carbone n’est pas disponible.

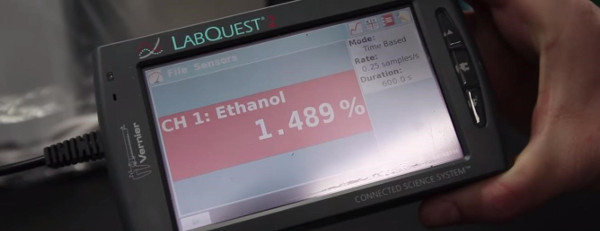

Avec une emphase accrue sur "apprentissage fondé sur la recherche », sondes scientifiques sont de plus en plus populaires. Appareils de poche comme la quête de laboratoire Vernier utilisé en conjonction avec une variété de sondes (tels que ceux de la conductivité, oxygène dissous, tension, etc.) permettant de moins se concentrer sur la collecte de données et/ou de faire des graphiques et plus sur l’analyse des données et faire des prédictions. Un autre avantage est que ceux-ci sont compacts et légers et peuvent être prises dans le champ pour les mesures.

Procédure

1. préparation de l’échantillon

- Sélectionnez cellulosiques pour être utilisé comme matière première. Cela peut être des tiges de maïs, herbes, feuilles, litière pour animaux de compagnie ou du papier.

- À l’aide d’une meuleuse moulin à billes (ou moulin à café si ball mill moulin n’est pas disponible), moudre des matières premières en une fine poudre pas de gros morceaux restant.

- Mesurer à 1,0 g de matière première et le placer dans un tube à centrifuger de 50 mL. Etiqueter le tube avec la m

Résultats

Le % d’éthanol dans la solution apparaît sur l’écran de la tablette de poche utilisant le logiciel lié à la marque de la sonde de l’éthanol utilisée (Figure 2).

Des résultats représentatifs de l’éthanol pourcentage émanant de diverses matières premières peuvent être vu dans le tableau 1.