סגסוגות ננו-קריסטלין ויציבות גודל ננו-גרגר

Overview

מקור: סיינה שהבזמוהמדי ופיימן שהביגי-רודפושטי-רודפושטי, בית הספר להנדסה, אוניברסיטת קונטיקט, סטורז, CT

סגסוגות עם גודל תבואה פחות מ 100 ננומטר ידועים בשם סגסוגות nanocrystaline. בשל תכונותיהם הפיזיות והמכניות המשופרות, יש ביקוש הולך וגובר להעסיק אותם בתעשיות שונות כגון מוליכים למחצה, ביו-סנסורים וחלל.

כדי לשפר את העיבוד והיישום של סגסוגות nanocrystalline, יש צורך לפתח קרוב 100% חומרים בתפזורת צפופה אשר דורש השפעה סינרגטי של טמפרטורה גבוהה ולחץ. על ידי הגדלת הטמפרטורה והלחץ החלים, דגנים קטנים מתחילים לגדול ולאבד את המאפיינים המכובדים שלהם. לכן, חשוב מבחינה טכנולוגית להגיע לפשרה בין מליטה בין חלקיקים עם נקבוביות מינימלית ואובדן גודל תבואה בקנה מידה ננו במהלך איחוד בטמפרטורות גבוהות.

במחקר זה אנו שואפים לחסל חמצן מפתרון מוצק כדי לשפר את יציבות גודל ננו-גרגר בטמפרטורות גבוהות. סגסוגת Fe-14Cr-4Hf ננו-גבישית תהיה מסונתזת בסביבה מוגנת כדי למנוע היווצרות חלקיקי תחמוצת.

Procedure

- תייק את תכולת החמצן הנמוכה בטוהר גבוה בחומרים בתפזורת (מטרות Fe, Cr ו- Hf) בתא הכפפות באמצעות מכונת תיוק מכנית הדדית על מנת למזער את זיהום החמצן באבקות ההתחלתיות.

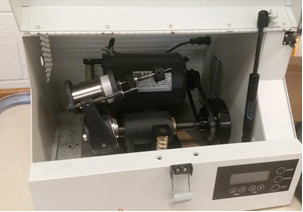

- לטעון את תערובת האבקה עבור סגסוגת ספציפית (Fe14Cr4Hf wt.% במחקר זה) לתוך מחינת אל-חלד יחד עם כדורי כרסום נירוסטה 440C(איור 1). הקטרים של כדורי הטחינה הם 6.4 ו-7.9 מ"מ ויחס אבקת הכדור למשקל הוא 10:1. יש לשמור את הנקריאל האטום תחת אטמוספירה מגנה בתא הכפפות.

- בצע כרסום כדור אנרגיה גבוהה במשך 20 שעות באמצעות SPEX 8000M טחנות כדור אנרגיה גבוהה

Results

איור 3 מציג את נתוני ה-XRD עבור OF-Fe14Cr4Hf שנטחנו במשך שעה אחת ב-900 מעלות צלזיוס. יש חידוד של הפסגות יחד עם שינויי שיא קלים. זה בגלל הרפיה של זן סריג כמו טמפרטורת חישול עולה. כאשר טמפרטורת חישול עולה, כמה פסגות קטנות מתגלות בין ארבע פסגות BCC הגדולות. אלה יצביעו על היווצרות של שלבים משניים.

Application and Summary

הניסוי מדגים כיצד יציבות גודל ננו-גרגר של חומרים nanocrystalline ללא חמצן נומינלי עשוי לשפר את ההשוואה סגסוגות עם כמות משמעותית של חמצן. במחקר זה אבקות OF מסונתזות באטמוספרה מוגנת כדי למזער את האינטראקציה בין חמצן לפתרון מוצק מוביל להגביר את ההפרדה של אלמנטים alloying לגבולות התבואה ולשפר את יציבות ג...

Tags

Skip to...

Videos from this collection:

Now Playing

סגסוגות ננו-קריסטלין ויציבות גודל ננו-גרגר

Materials Engineering

5.1K Views

חומר אופטי חלק 1: הכנת מדגם

Materials Engineering

15.4K Views

חומרוגרפיה אופטית חלק 2: ניתוח תמונה

Materials Engineering

11.0K Views

ספקטרוסקופיית פוטואלקטרון רנטגן

Materials Engineering

21.6K Views

עקיפה של קרני רנטגן

Materials Engineering

89.1K Views

קורות יונים ממוקדות

Materials Engineering

8.9K Views

התגבשות כיוונית וייצוב פאזה

Materials Engineering

6.6K Views

קלורימטריה סריקה דיפרנציאלית

Materials Engineering

37.8K Views

דיפוזיה תרמית ושיטת פלאש לייזר

Materials Engineering

13.2K Views

אלקטרופלינט של סרטים דקים

Materials Engineering

20.1K Views

ניתוח התפשטות תרמית באמצעות דילאטומטריה

Materials Engineering

15.8K Views

ספקטרוסקופיית מכשולים אלקטרוכימית

Materials Engineering

23.2K Views

חומרים מרוכבים מטריקס קרמיקה ומאפייני הכיפוף שלהם

Materials Engineering

8.2K Views

סינתזה הידרוג'ל

Materials Engineering

23.7K Views

Copyright © 2025 MyJoVE Corporation. All rights reserved