A subscription to JoVE is required to view this content. Sign in or start your free trial.

Method Article

Experimental Protocol to Investigate Particle Aerosolization of a Product Under Abrasion and Under Environmental Weathering

In This Article

Summary

In this article, an experimental protocol to investigate particle aerosolization of a product under abrasion and under environmental weathering is presented. Results on the emission of engineered nanomaterials, in the form of aerosols are presented. The specific experimental set-up is described in detail.

Abstract

The present article presents an experimental protocol to investigate particle aerosolization of a product under abrasion and under environmental weathering, which is a fundamental element to the approach of nanosafety-by-design of nanostructured products for their durable development. This approach is basically a preemptive one in which the focus is put on minimizing the emission of engineered nanomaterials' aerosols during the usage phase of the product's life cycle. This can be attained by altering its material properties during its design phase without compromising with any of its added benefits. In this article, an experimental protocol is presented to investigate the nanosafety-by-design of three commercial nanostructured products with respect to their mechanical solicitation and environmental weathering. The means chosen for applying the mechanical solicitation is an abrasion process and for the environmental weathering, it is an accelerated UV exposure in the presence of humidity and heat. The eventual emission of engineered nanomaterials is studied in terms of their number concentration, size distribution, morphology and chemical composition. The purpose of the protocol is to study the emission for test samples and experimental conditions which are corresponding to real life situations. It was found that the application of the mechanical stresses alone emits the engineered nanomaterials' aerosols in which the engineered nanomaterial is always embedded inside the product matrix, thus, a representative product element. In such a case, the emitted aerosols comprise of both nanoparticles as well as microparticles. But if the mechanical stresses are coupled with the environmental weathering, the experimental protocol reveals then the eventual deterioration of the product, after a certain weathering duration, may lead to the emission of the free engineered nanomaterial aerosols too.

Introduction

With a rapid maturity in the nanotechnology, its advancement is driven by rapid commercialization of products containing Engineered Nanomaterials (ENM) with remarkable properties. As described by Potocnick1 in the article 18(5) of Regulation 1169/2011, issued by the European Commission, ENM can be defined as "any intentionally manufactured material, containing particles, in an unbound state or as an aggregate or as an agglomerate and where, for 50% or more of the particles in the number size distribution, one or more external dimensions is in the size range 1 nm to 100 nm". Moreover, the products containing ENM, either in their solid bulk or on their solid surfaces or in their liquid suspensions, can be termed as Nanostructured products. Different types of ENM with different formulations and functionalizations are used in such products according to the nature of application and budget. The products can be in the form of coatings, paints, tiles, house bricks, concrete etc.

As far as the research is concerned, one may also find enormous number of publications on the innovations that have been accomplished through nanotechnology. Despite this enormous research, the appealing traits of ENM are under probe for potential health or environmental dangers due to their tendency to get released or emitted in air in the form of aerosols during the use or processing of the nanostructures products (for example Oberdorster et al.2, Le Bihan et al.3 and Houdy et al.4). Kulkarni et al.5 defines an aerosol as the suspension of solid or liquid particles in the gaseous medium. Hsu and Chein6 have demonstrated that during the use or processing of a nanostructured product, a nanostructured product is subjected to various mechanical stresses and environmental weathering which facilitate such an emission.

According to Maynard7, upon exposure, these aerosols of ENM may interact with human organism through inhalation or dermal contacts and get deposited inside the body which consequently may cause various detrimental effects, including the carcinogenic ones. Thus, a thorough understanding of the ENM emission phenomenon is of paramount importance given the unprecedented use of nanostructured products, as mentioned by Shatkin et al.8. This may not only help in avoiding unanticipated health related complications arising from their exposure but also in encouraging public confidence in nanotechnologies.

Nevertheless, the exposure related problem has now started getting attention by the research community and has been recently highlighted by various research units throughout the world (for example, Hsu and Chein6, Göhler et al.9, Allen et al.10, Allen et al.11, Al-Kattan et al.12, Kaegi et al.13, Hirth et al.14, Shandilya et al.15, 31, 33, Wohlleben et al.16, Bouillardet al.17, Ounoughene et al.18). Considering the large scale deployment of nanostructured products in the commercial markets, the most effective approach to tackle the problem would be a preemptive one. In such an approach, a product is designed in such a way that it is "nanosafe-by-design" or "Design for safer Nanotechnology" (Morose19) i.e., low emissive. In other words, it maximizes their benefits in problem solving during its use while emitting a minimum amount of aerosols in the environment.

To test the nanosafety-by-design during the usage phase of a nanostructured product, the authors present an appropriate experimental methodology to do so in the present article. This methodology consists of two types of solicitations: (i) mechanical and (ii) environmental which aim at simulating the real life stresses to which the nanostructured product, a masonry brick, is subjected to during its usage phase.

(i) A linear abrasion apparatus which simulates the mechanical solicitation. Its original and commercial form, as shown in Figure 1A, is referenced in numerous internationally recognized test standards like ASTM D406020, ASTM D603721 and ASTM D104422. According to Golanski et al.23, due to its robust and user-friendly design, its original form is already being used widely in industries for analyzing the performance of products like paint, coating, metal, paper, textile, etc. The stress being applied through this apparatus corresponds to the typical one applied in a domestic setting, for example, walking with shoes and displacement of different objects in a household (Vorbau et al.24 and Hassan et al.25). In Figure 1A, a horizontally displacing bar moves the standard abradant in a to and fro motion over the sample surface. The abrasion wear occurs at the contact surface due to the friction at the contact. The magnitude of the abrasion wear can be varied by varying the normal load (FN) which acts at the top of the abradant. By changing the type of the abradant and normal load value, one may vary the abrasiveness and hence the mechanical stress. Morgeneyer et al.26 have pointed out that the stress tensor to be measured during abrasion is composed of normal and tangential components. The normal stress is the direct result of the normal load, i.e., of FN whereas the tangential stress is the result of the tangentially acting friction process, measured as force (FT) and it acts parallel or anti-parallel to the direction in which abrasion takes place. In the original form of this abrasion apparatus, one cannot determine FT. Therefore, the role of the mechanical stresses during the aerosolization of ENM cannot completely be determined. To eradicate this limitation, as described in details by Morgeneyer et al.26, we have (a) modified it by replacing the already installed horizontal steel bar by a replica in aluminum 2024 alloy and (b) mounted a strain gauge on the top surface of this replicated aluminum alloy bar. This is shown in Figure 1B. This strain gauge has 1.5 mm of active measuring grid length and 5.7 mm of measuring grid carrier length. It is made of a constantan foil having 3.8 µm of thickness and 1.95 ± 1.5% of gauge factor. A proper measurement of the mechanical stresses are ensured through a dynamic strain gauge amplifier which is connected in series to the strain gauge, thus allowing a reliable measurement of the strain produced in the gauge. The data transmitted via amplifier is acquired using data acquisition software.

Figure 1. Abrasion Apparatus and Strain Gauge. The commercial standard form of the Taber abrasion apparatus (A) with abrasion speed, duration and stroke length controls. The originally mounted steel bar was replaced by an aluminum bar and was further equipped with a strain gauge (B) to measure the tangential force (FT). Please click here to view a larger version of this figure.

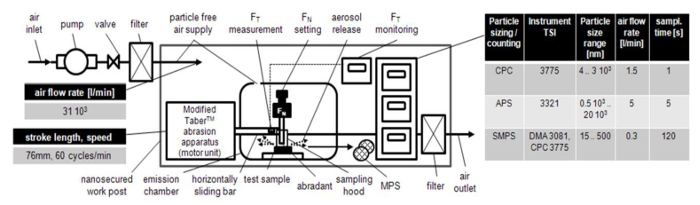

In the Figure 2, the complete experimental set-up is shown where this modified Taber abrasion apparatus is placed under the conformity of a nanosecured work post. A particle free air is constantly circulating inside this work post at a flow rate of 31,000 l/min. It has a particle filter efficiency of 99.99% and has already been successfully employed by Morgeneyer et al.27 in various nanoparticles' dustiness tests.

Figure 2. Experimental Set-up (Shandilya et al.31). A nanosecured work facility to carry out the abrasion tests and real time characterization (both qualitative and quantitavive) of the generated aerosol particles. A small fraction of the particle free air passes through a slot inside the emission chamber to eliminate its background particles number concentration. Please click here to view a larger version of this figure.

The motor of the abrasion apparatus is kept outside and its linearly sliding part is kept inside a self-designed emission test chamber, with dimensions, 0.5 m × 0.3 m × 0.6 m, (details in Le Bihan et al.28). It helps in preventing the abrasion apparatus' motor emissions from interfering in the test results. The sampling of the generated aerosol particles is done inside the proximity of a radial symmetric hood (volume of 713 cm3). By employing such a hood, the aerosol particles losses due to their deposition on the surfaces can be minimized. The other advantage includes increase in the aerosol particles number concentration due to a relatively lower volume of the hood with respect to the emission test chamber. Thanks to this set up, a real time characterization and analysis of the particle aerosols getting generated during the abrasion wear can be done experimentally in terms of their number concentrations, size distributions, elemental compositions and shapes. According to Kulkarni et al.5, the number concentration of ENM aerosols particles can be defined as "the number of ENM present in unit cubic centimeter of air". Similarly, the size distribution of ENM aerosols is "the relationship expressing the quantity of an ENM property (usually number and mass concentrations) associated with particles in a given size range".

A particle Counter (measurable size range: 4 nm to 3 µm) measures the aerosol particles number concentration (PNC). The particle sizers (measurable size range: 15 nm - 20 µm) measure the particle size distribution (PSD). An aerosol particles sampler (described in details by R'mili et al.30) is used for the particle collection through filtration technique on a porous copper mesh grid which can be used later in Transmission Electron Microscope (TEM) for various qualitative analyses of the released particles.

(ii) The environmental solicitation can be simulated through accelerated artificial weathering in a weathering chamber, shown in Figure 3. As shown by Shandilya et al.31, the weathering conditions can be kept in conformity with the international standards or be customized depending upon the type of simulation. The UV exposure is provided via xenon arc lamp (300 − 400 nm) installed with an optical radiation filter. The action of rain is simulated by spraying deionized and purified water onto them. A reservoir is placed beneath the test samples to collect the runoff water. The collected water or leachate can be used later to perform the ENM leaching analysis.

Figure 3. Weathering Chamber. The commercial form of the Suntest XLS+ weathering chamber contains a stainless steel hood inside which the nanocoated samples are placed. The water reservoir is placed beneath the hood which is the source of the water to be sprayed inside the hood. Please click here to view a larger version of this figure.

Protocol

NOTE: The technique presented in the Protocol here is not only limited to the presented test samples but can be used for other samples as well.

1. Artificial Weathering [CEREGE Platform, Aix en Provence]

- Take a 250 ml sample of the deionized and purified water to be sprayed in a beaker. Immerse the tip of the water conductivity meter into the water. Note the water conductivity. Repeat the process and note the water conductivity each time.

NOTE: According to the ISO 1647432, it should never be higher than 5 µS/cm. - After measuring the conductivity, connect the water source to the reservoir of the weathering chamber present underneath the stainless steel hood (shown in Figure 3).

- Connect the overflow spout on the back of the chamber to a drain opening through a hose pipe.

- Place the nanocoating samples to weather into the stainless steel hood and close the door. To enable a statistical evaluation of the results, use a minimum of three identical nanocoating and reference samples.

- On the digital console, present on the front of the weathering chamber, select a 2 hr cycle composed of 120 min of UV light, 102 min dry and 18 min water spray.

- Enter the number of cycles equal to 2658 which corresponds to 7 months.

- Choose the irradiance level of the xenon arc lamp equal to 60 ± 5 W/m2.

- Set the ambient temperature at 38 °C.

- Start the weathering test by pressing the LAUNCH button on the console.

2. Abrasion and ENM Aerosols Characterization [INERIS S-NANO Platform, Verneuil]

NOTE: Before using, pre-verify the particle aerosol characterizing instruments on a calibration bench of INERIS S-NANO Platform which comprises of separate and already installed reference counter parts. By following a specific protocol, ensure that the instruments are working properly.

- Assemble all the units and instruments shown in the experimental set-up and make the necessary connections as shown in Figure 2 (details on the units and setting up of instruments are provided in Shandilya et al.33).

- Switch on the circulation of the particle free air inside the nanosecured workpost by pressing the FLUX ON button.

- Make this particle free air to pass through the emission test chamber by opening the chamber and keeping it open inside the nanosecured work post.

- To set up the experiment, connect the particle counter directly to the emission test chamber to measure the instantaneous number concentration of the particles inside the chamber. Observe the concentration value directly on the display counter.

- While the particle free air is passing through the chamber, continue to monitor this instantaneous number concentration value until it drops to zero. In this way, ensure that the chamber is free of any background particle.

- In the meantime, chamfer the edges of the standard cylindrically shaped abradant by gently turning its one end in a to and fro motion inside the slot of a tool provided with the abrasion apparatus.

- Using a digital balance with a measurement precision of at least 0.001 g, weigh the abradant and sample to be abraded.

- Once done, fix the chamfered abradant to the vertical shaft of the abrasion apparatus through a chuck present at its bottom.

- Place the nanostructured product to be abraded gently beneath the fixed abradant and firmly fix its position on the mounting system.

- Open the aerosol sampler and, by using a tweezer, place a copper mesh grid inside the slot with its brighter side upwards. Put a circular ring over the grid to fix it.

- Close the sampler and connect it to a pump via a filter on one end (i.e., towards darker side of the grid) and to the particle source on the other end (i.e., towards brighter side of the grid). Mount the required normal load on the vertical shaft using the dead weights.

- Through the particle counter, check if the background particles concentration inside the open chamber has dropped to zero. If not, wait for it. If yes, close the door of the emission test chamber.

- Via the digital consoles on the instruments, manually set the flow rates of the particle counter and the sizers as follows: CPC- 1.5 l/min; SMPS- 0.3 l/min; APS- 5 l/min

- Set the total sampling duration at 20 min for all these three instruments. Set the abrasion duration and speed equal to 10 min and 60 cycles per minute respectively in the abrasion apparatus.

- Connect the strain gauge to the dynamic strain gauge amplifier. Connect the dynamic strain gauge amplifier to the computer which shall be used for the data acquisition using software installed in it.

- Open the software.

- Click NEW DAQ PROJECT to open a new data acquisition file.

- Stop the option for live data acquisition by clicking LIVE UPDATE

- Click 0 EXECUTE to set the reference signal value equal to zero.

- Switch back on the live data acquisition by clicking LIVE UPDATE.

- Click VISUALIZATION to choose the real time graphical mode of data representation.

- Click NEW to open the templates.

- Choose the option SCOPE PANEL, for example.

- Start the data acquisition in the particle counters and sizers at once.

- After a delay of approx. 5 min, start the abrasion.

- Click START in the data acquisition software window to acquire the strain gauge signals corresponding to the ongoing abrasion.

- After 2 min, switch on the pump connected to the MPS.

- Keep the pump running for 2 - 4 min depending upon the quantity of the emission of the aerosol particles. NOTE: The number of aerosol particles sampled using MPS should be optimal in number i.e., neither too scarce nor too surplus which might prevent a thorough microscopic analysis.

- Once the abrasion stops, switch off the data acquisition by clicking STOP.

- Save the acquired data by clicking SAVE DATA NOW.

- After the counter and sizers stop acquiring data, open the emission test chamber and weigh again the abradant and abraded nanostructured product.

- Continue the entire process for every abrasion test.

- Once the abrasion tests, once again verify the three particle aerosol characterizing instruments are on the calibration bench of INERIS S-NANO Platform.

3. TEM Analysis of the Liquid Suspensions- Drop Deposition Technique [INERIS Calibration Platform, Verneuil]

- Prepare a 1% volume diluted aqueous solution of the liquid suspension (i.e., the 'paint') by adding 1 part of the coating suspension in 99 parts of the filtered and de-ionized water.

- Open the cover of the glow discharge machine

- Set the following operating conditions: 0.1 mbar, 45 mA, 3 min duration.

- In order to make a TEM copper mesh grid hydrophilic by its plasma treatment, put it on the metal stand. Close the cover and start the motor. After 3 min, it stops automatically.

- Take out the hydrophilic turned mesh grid using a tweezer. Place it gently with its brighter side up. Deposit a drop of the diluted solution (8 µl approx.) onto the hydrophilic mesh grid using a syringe.

- Dry the mesh grid in a closed chamber so that the water content gets evaporated and the constituent particles rest deposited on the grid. Make sure that the mesh grid doesn't get charged with the stray particles which can be easily identified as circular or strand shapes which are characteristic of oil or soot particles.

- Once ready, put the grid in the TEM probe and carry out the microscopic analysis. [electron accelerating voltage 120 kV, cf] 31.

- If the grid appears too laden with particles to analyze, lower the dilution percentage and volume of the deposited drop. The maximum volume an operator is able to deposit is approximately equal to 12 µl.

Results

Test Samples

The protocols presented in the article were applied to three different commercial nanostructured products. A focus is put here on the details of the experimental approach:

(a) alumino-silicate brick reinforced with TiO2 nanoparticles, (11 cm x 5 cm x 2 cm). It finds its frequent application in constructing façades, house walls, wall tiles, pavements etc. Its material properties along with a scanning electron microscope ima...

Discussion

In the present article, an experimental investigation of the nanosafety-by-design of commercial nanostructured products is presented. The nanosafety-by-design of any product can be studied in terms of its PNC and PSD when it is subjected to mechanical stresses and environmental weathering. The products chosen for the study are alumino-silicate brick reinforced with TiO2 nanoparticles, glaze with CeO2 nanoparticles and photocatalytic nanocoatings with TiO2 nanoparticles. These products are...

Disclosures

The authors have nothing to disclose.

Acknowledgements

This work was carried out in the framework of the Labex SERENADE (ANR-11-LABX-0064) and the A*MIDEX Project (ANR-11-IDEX-0001-02), funded by the French Government program, Investissements d'Avenir, and managed by the French National Research Agency (ANR). We thank the French Ministry of Environment (DRC 33 and Program 190) and ANSES (Nanodata Project 2012/2/154, APR ANSES 2012) for financing the work. We are equally grateful to Olivier Aguerre-Chariol, Patrice Delalain, Morgane Dalle, Laurent Meunier, Pauline Molina, and Farid Ait-Ben-Ahmad for their cooperation and advice during the experiments.

Materials

| Name | Company | Catalog Number | Comments |

| Photocal Masonry | Nanofrance Technologies | Test sample | |

| Masonry brick (ref. 901796) | Castorama | Support for test sample | |

| Optical microscope (model Imager.M1m) | Carl Zeiss MicroImaging GmbH | For microcopic analysis | |

| Energy-dispersion spectroscope (model X-max) | Oxford Instruments | For elemental composition analysis | |

| Transmission Electron Microscope (model CM12) | Philips | For microcopic analysis | |

| Weathering chamber (model Suntest XLS+) | Atlas | For accelerated artificial weathering | |

| Xenon arc lamp (model NXE 1700) | Ametek SAS | UV rays source | |

| Inductively Coupled Plasma Mass spectrometer (model 7500cx) | Agilent Technologies | For leachate water samples analysis | |

| Taber linear abraser (model 5750) | Taber Inc. | For abrasion | |

| Taber H38 abradant | Taber Inc. | For abrasion | |

| Condensation Particle Counter 3775 | TSI | For counting number concentration of aerosol particles | |

| Aerodynamic Particle Sizer 3321 | TSI | For measuring the size of aerosol particles | |

| Differential Mobility Analyzer 3081 | TSI | For measuring the size of aerosol particles | |

| Mini Particle Sampler | Ecomesure | For sampling the aerosol particles | |

| Gilian LFS-113 Low Flow Personal Air Sampling Pump | Sensidyne | For sampling the aerosol particles |

References

- Potocnick, J. . European Commission Recommendation on the definition of nanomaterial (2011/696/EU). , (2011).

- Oberdorster, G., Oberdorster, E., Oberdorster, J. Nanotoxicology: an emerging discipline evolving from studies of ultrafine particles. Environ Health Persp. 113 (7), 823-839 (2005).

- Le Bihan, O., Shandilya, N., Gheerardyn, L., Guillon, O., Dore, E., Morgeneyer, M. Investigation of the Release of Particles from a Nanocoated Product. Adv Nanoparticles. 2 (1), 39-44 (2013).

- Houdy, P., Lahmani, M., Marano, F. . Nanoethics and Nanotoxicology. , (2011).

- Kulkarni, P., Baron, P. A., Willeke, K. . Aerosol Measurement: Principle, Techniques and Applications. , (2011).

- Hsu, L. Y., Chein, H. M. Evaluation of nanoparticle emission for TiO2 nanopowder coating materials. J Nanopart Res. 9 (1), 157-163 (2007).

- Maynard, A. D. Safe handling of nanotechnology. Nature. 444 (1), 267-269 (2006).

- Shatkin, J. A., et al. Nano risk analysis: advancing the science for nanomaterials risk management. Risk Anal. 30 (11), 1680-1687 (2011).

- Göhler, D., Nogowski, A., Fiala, P., Stintz, M. Nanoparticle release from nanocomposites due to mechanical treatment at two stages of the life-cycle. Phys Conf Ser. 429, 012045 (2013).

- Allen, N. S., et al. Ageing and stabilisation of filled polymers: an overview. Polym Degrad Stabil. 61 (2), 183-199 (2004).

- Allen, N. S., et al. Degradation and stabilisation of polymers and coatings: nano versus pigmentary titania particles. Polym Degrad Stabil. 85 (3), 927-946 (2004).

- Al-Kattan, A., et al. Release of TiO2 from paints containing pigment-TiO2 or nano-TiO2 by weathering. J Environ Monitor. 15 (12), 2186-2193 (2013).

- Kaegi, R., et al. Synthetic TiO2 nanoparticle emission from exterior facades into the aquatic environment. Environ Pollut. 156 (2), 233-239 (2008).

- Hirth, S., Cena, L., Cox, G., Tomovic, Z., Peters, T., Wohlleben, W. Scenarios and methods that induce protruding or released CNTs after degradation of nanocomposite materials. J Nanopart Res. 15 (2), 1504-1518 (2013).

- Shandilya, N., Le Bihan, O., Morgeneyer, M. A review on the study of the generation of (nano-) particles aerosols during the mechanical solicitation of materials. J Nanomater. 2014, 289108 (2014).

- Wohlleben, W., et al. On the lifecycle of nanocomposites: comparing released fragments and their in vivo hazards from three release mechanisms and four nanocomposites. Small. 7 (16), 2384-2395 (2011).

- Bouillard, J. X., et al. Nanosafety by design: risks from nanocomposite/nano waste combustion. J Nanopart Res. 15 (1), 1519-1529 (2013).

- Ounoughene, G., et al. Behavior and fate of Halloysite Nanotubes (HNTs) when incinerating PA6/HNTs nanocomposite. Environ Sci Technol. 49 (9), 5450-5457 (2015).

- Morose, G. The 5 principles of "Design for Safer Nanotechnology". J Clean Prod. 18 (3), 285-289 (2010).

- ASTM International. . ASTM D4060: Standard test method for the abrasion of organic coatings by the Taber abradant. , (2007).

- ASTM International. . ASTM D6037: Standard test methods for dry abrasion mar resistance of high gloss coatings. , (1996).

- ASTM International. . ASTM D1044: Standard test method for resistance of transparent plastics to surface abrasion. , (2008).

- Golanski, L., Guiot, A., Pras, M., Malarde, M., Tardif, F. Release-ability of nano fillers from different nanomaterials (toward the acceptability of nanoproduct). J Nanopart Res. 14 (1), 962-970 (2012).

- Vorbau, M., Hillemann, L., Stintz, M. Method for the characterization of the abrasion induced nanoparticle release into air from surface coatings. J Aerosol Sci. 40 (3), 209-217 (2009).

- Hassan, M. M., Dylla, H., Mohammad, L. N., Rupnow, T. Evaluation of the durability of titanium dioxide photocatalyst coating for concrete pavement. Constr Build Mater. 24 (8), 1456-1461 (2010).

- Morgeneyer, M., Shandilya, N., Chen, Y. M., Le Bihan, O. Use of a modified Taber abrasion apparatus for investigating the complete stress state during abrasion and in-process wear particle aerosol generation. Chem Eng Res Des. 93 (1), 251-256 (2015).

- Morgeneyer, M., Le Bihan, O., Ustache, A., Aguerre Chariol, O. Experimental study of the aerosolization of fine alumina particles from bulk by a vortex shaker. Powder Technol. 246 (1), 583-589 (2013).

- Le Bihan, O., Morgeneyer, M., Shandilya, N., Aguerre Chariol, O., Bressot, C., Vogel, U., Savolainen, K., Wu, Q., Van Tongeren, M., Brouwer, D., Berges, M. Chapter 7. Handbook of Nanosafety: Measurement, Exposure and Toxicology. , (2014).

- Göhler, D., Stintz, M., Hillemann, L., Vorbau, M. Characterization of nanoparticle release from surface coatings by the simulation of a sanding process. Ann Occup Hyg. 54 (6), 615-624 (2010).

- R'mili, B., Le Bihan, O., Dutouquet, C., Aguerre Charriol, O., Frejafon, E. Sampling by TEM grid filtration. Aerosol Sci Tech. 47 (7), 767-775 (2013).

- Shandilya, N., Le Bihan, O., Bressot, C., Morgeneyer, M. Emission of Titanium Dioxide Nanoparticles from Building Materials to the Environment by Wear and Weather. Environ Sci Technol. 49 (4), 2163-2170 (2015).

- AFNOR. . ISO 16474-1: Paints and varnishes − Methods of exposure to laboratory light sources − Part 1: General guidance. , (2012).

- Shandilya, N., Le Bihan, O., Bressot, C., Morgeneyer, M. Evaluation of the particle aerosolization from n-TiO2 photocatalytic nanocoatings under abrasion. J Nanomater. 2014, 185080 (2014).

- Shandilya, N., Le Bihan, O., Morgeneyer, M. Effect of the Normal Load on the release of aerosol wear particles during abrasion. Tribol Lett. 55 (2), 227-234 (2014).

- White, L. R. Capillary rise in powders. J Colloid Interf Sci. 90 (2), 536-538 (1982).

- Dufresne, E. R., et al. Flow and fracture in drying nanoparticle suspensions. Phys Rev Lett. 91, 224501 (2003).

- Hare, C. H. The degradation of coatings by ultraviolet light and electromagnetic radiation. JPCL. , (1992).

- Tirumkudulu, M. S., Russel, W. B. Cracking in drying latex films. Langmuir. 21 (11), 4938-4948 (2005).

- Shandilya, N., Morgeneyer, M., Le Bihan, O. First development to model aerosol emission from solid surfaces subjected to mechanical stresses: I. Development and results. J Aerosol Sci. 89, 43-57 (2015).

- Shandilya, N., Morgeneyer, M., Le Bihan, O. First development to model aerosol emission from solid surfaces subjected to mechanical stresses: II. Experiment-Theory comparison, simulation and sensibility analysis. J Aerosol Sci. 89, 1-17 (2015).

- Bressot, C., et al. Environmental release of engineered nanomaterials from commercial tiles under standardized abrasion conditions. J Hazardous Materials. , (2016).

Reprints and Permissions

Request permission to reuse the text or figures of this JoVE article

Request PermissionThis article has been published

Video Coming Soon

Copyright © 2025 MyJoVE Corporation. All rights reserved