Method Article

PARbars: Cheap, Easy to Build Ceptometers for Continuous Measurement of Light Interception in Plant Canopies

In This Article

Summary

Here, we present detailed instructions on how to build and calibrate research quality ceptometers (light sensors that integrate light intensity across many sensors arrayed linearly along a horizontal bar).

Abstract

Ceptometry is a technique used to measure the transmittance of photosynthetically active radiation through a plant canopy using multiple light sensors connected in parallel on a long bar. Ceptometry is often used to infer properties of canopy structure and light interception, notably leaf area index (LAI) and effective plant area index (PAIeff). Due to the high cost of commercially available ceptometers, the number of measurements that can be taken is often limited in space and time. This limits the usefulness of ceptometry for studying genetic variability in light interception, and precludes thorough analysis of, and correction for, biases that can skew measurements depending on the time of day. We developed continuously logging ceptometers (called PARbars) that can be produced for USD $75 each and yield high quality data comparable to commercially available alternatives. Here we provide detailed instruction on how to build and calibrate PARbars, how to deploy them in the field and how to estimate PAI from collected transmittance data. We provide representative results from wheat canopies and discuss further considerations that should be made when using PARbars.

Introduction

Ceptometers (linear arrays of light sensors) are used to measure the proportion of photosynthetically active radiation (PAR) intercepted by plant canopies. Ceptometers are used widely for agricultural crop research due to the relatively straightforward nature of measurements and simplicity of data interpretation. The basic principle of ceptometry is that the transmittance of light to the base of a plant canopy (τ) is dependent on the projected area of light absorbing materials above. Measurements of PAR above and below the canopy can, therefore, be used to estimate canopy traits such as leaf area index (LAI) and effective plant area index (PAIeff) (which includes stems, culms and reproductive structures in addition to leaves)1,2,3. Reliability of PAIeff estimates inferred from τ is improved by modeling the effects of the beam fraction of incoming PAR (fb), the leaf absorptance (a) and the effective canopy extinction coefficient (K); K, in turn, depends on both the solar zenith angle (θ) and the leaf angle distribution (χ)1,4,5,6. It is a common practice to correct for these effects. However, there are other biases that have not received due consideration in the past due to methodological and cost limitations.

We recently identified significant time-dependent bias in instantaneous ceptometry measurements of row crops, such as wheat and barley7. This bias is caused by an interaction between row planting orientation and solar zenith angle. To overcome this bias, continuously logging ceptometers can be mounted in the field to monitor diurnal cycles of canopy light interception and then daily averages of τ and PAIeff can be calculated. However, continuous measurements are often infeasible due to the prohibitively high cost of commercially available ceptometers – often several thousand US dollars for a single instrument – and the requirement for measurements of many field plots. The latter is particularly evident in the -omics era where many hundreds of genotypes are required for genomic analyses, such as genome wide association studies (GWAS) and genomic selection (GS) (for review see Huang & Han, 20148). We recognized that there was a need for cost-effective ceptometers that could be produced in large numbers and be used for continuous measurements across many genotypes.

As a solution, we designed easy-to-build, high-accuracy ceptometers (PARbars) at a cost of USD $75 per unit and requiring approximately one hour of labor to construct. PARbars are built using 50 photodiodes that are sensitive only in the PAR waveband (wavelengths 390 – 700 nm), with very little sensitivity outside this range, obviating the use of costly filters. The photodiodes are connected in parallel across a 1 m length to produce an integrated differential voltage signal that can be recorded with a datalogger. The circuitry is encased in epoxy for waterproofing and the sensors operate over a large temperature range (-40 to +80 °C), allowing the PARbars to be deployed in the field for extended periods of time. With the exception of the photodiodes and a low-temperature-coefficient resistor, all parts required to build a PARbar can be purchased from a hardware store. A full list of required parts and tools is provided in the Table of Materials. Here we present detailed instructions on how to build and use PARbars for the estimation of PAIeff and present representative results from wheat canopies.

Protocol

1. Build and calibrate the PARbars

- Gather all parts and tools required for the assembly in a clean workspace.

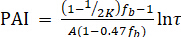

- Drill a 4 mm diameter hole 20 mm from each end of a white acrylic diffuser bar (1,200 mm length x 30 mm width x 4.5 mm thickness). Drill and tap threaded holes 20 mm from each end of a section of aluminum U-bar to secure diffuser. Drill and tap threaded holes to suit mounting hardware (e.g., a tripod mounting plate).

- Obtain a 1.25 m length of bare copper wire (1.25 mm diameter). If the wire came on a roll, then straighten it by securing one end into a vice or clamp and the other end into the grips of a hand drill, and then turning on the drill at a low speed (100-200 rpm). Repeat with a second 1.25 m length of bare copper wire.

- Mark the intended locations of the photodiodes along the edge of the diffuser using a fine-tip permanent marker, beginning with the first photodiode position at 13.5 cm from one end of the diffuser and the other positions located every 2 cm between the first diode and the far end of the diffuser.

- Mark the position of the first copper wire on the diffuser by centering one photodiode on the diffuser bar with its electrical connection tabs pointing towards the sides of the bar, placing the wire underneath one of the tabs, and marking the wire's location.

- Repeat the preceding step to mark the wire's position at the center and the opposite end of the bar.

- Use cyanoacrylate glue to glue the first straightened copper wire to the diffuser, using the locations marked in the preceding step to align the wire.

- Use cyanoacrylate glue to glue 50 photodiodes face-down along the diffuser at 20 mm intervals (as marked in the preceding step), ensuring that they are in the center of the diffuser and that all are arranged all in the same orientation such that the large tab sits on the copper wire, and the small tab sits opposite.

- Place the second copper wire such that it sits underneath each of the smaller tabs of the photodiodes, and then glue the wire to the diffuser with cyanoacrylate glue.

- Wet both tabs of one photodiode, as well as the adjacent and underlying wires, with flux using a solder flux pen. Solder each tab of the diode to the underlying copper wires using a fine tipped soldering iron at a temperature of approximately 350-400 oC. Test the solder connections by shining a light onto the photodiode and checking for a voltage signal across the wires using a multimeter. Repeat this step for all 50 photodiodes.

NOTE: Step 1.7 is optional (if the resistor is not soldered into the PARbar, it can instead later be connected in parallel with the PARbar signal inputs on the datalogger). - Solder a 1.5 Ω low temperature coefficient precision resistor in parallel across the copper wires.

- Solder the male end of a waterproof DC connector to the ends of the copper wires (the same ends to which the resistor was soldered, if you followed optional step 1.7) and then seal the connections using glue lined heat shrink tubing.

- Create a continuous silicone barrier around the circuity on the diffuser to form a fluid-tight well, by applying a bead of silicone sealant to the surface of the diffuser, near the edge. Inspect the bead closely to ensure that no air gaps remain between the silicone and the diffuser bar, as gaps will permit epoxy to leak out. Once the sealant has cured, fill the well with epoxy resin.

- When the epoxy resin has hardened (overnight), remove the silicone sealant using a razor blade. Bolt the diffuser to the pre-threaded aluminum U-bar using M4 bolts.

- Use masking tape to secure the diffuser to the aluminum along its whole length, and then fill the void inside the ceptometer with polyurethane foam filler. Once the foam filler has set (overnight), remove the masking tape.

- Solder the female end of the DC connector to a length of two-conductor cable and seal the connections with glue lined heat shrink.

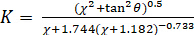

- To calibrate the PARbar against a quantum sensor,

- Connect both sensors to a datalogger or voltmeter capable of measuring a differential voltage output (connect a 1.5 Ω low temperature-coefficient precision resistor in parallel with the PARbar if a resistor was not integrated into the design in step 1.7),

- Set them outside in full sun on a level plane (level with a spirit level or spirit bubble), record the outputs of both sensors across a period during which solar radiation varies widely, such as a full diurnal cycle, and determine the calibration factor for the PARbar as the slope of a linear regression of PAR reported from the quantum sensor (as the dependent variable) vs. raw voltage output (as the independent variable).

2. Install in the field

- To infer effective plant area index (PAIeff), install one PARbar above the canopy (ensuring that it is not shaded by any light-absorbing elements within the canopy) and another below all light-absorbing elements whose absorptance you wish to measure (typically, below the lowest leaves), with both PARbars aligned at a 45° angle to planting rows. Ensure the upper PARbar is positioned so as not to shade the lower PARbar. Level the PARbars using a spirit level or bubble level.

- Connect the PARbars to a datalogger or voltmeter using cables made in step 1.11. If a 1.5 Ω low temperature-coefficient precision resistor was not integrated into the PARbar circuit during construction (step 1.7), then connect such a resistor in parallel with each PARbar at this stage.

- Convert differential voltage output to PAR using the calibration factor determined for each PARbar in step 1.13.

3. Calculate the effective plant area index (PAIeff)

- Calculate PAIeff for each pair of above- and below-canopy PAR measurements using the following equations6:

(1) ,

,

where A = 0.283 + 0.0785a – 0.159a2 (in which a is leaf absorptance), τ is the ratio of below- to above-canopy PAR, and K and fb are modeled by Equation 24 and Equation 39, respectively:

(2) ,

,

where χ is a dimensionless parameter describing leaf angle distribution, θ is the solar zenith angle, and

(3) ,

,

where r is PAR above the canopy (PARabove) as a fraction of its maximum possible value (PARabove,max = 2550∙cosθ); i.e. r = PARabove/PARabove,max. Consult the literature for values of a and c appropriate to your study species (we assumed a = 0.9 and c = 0.9610 for the wheat canopies used for trial measurements presented here).

NOTE: A sample R script is provided as a supplementary file to assist users in developing code for automated processing of large datasets.

Results

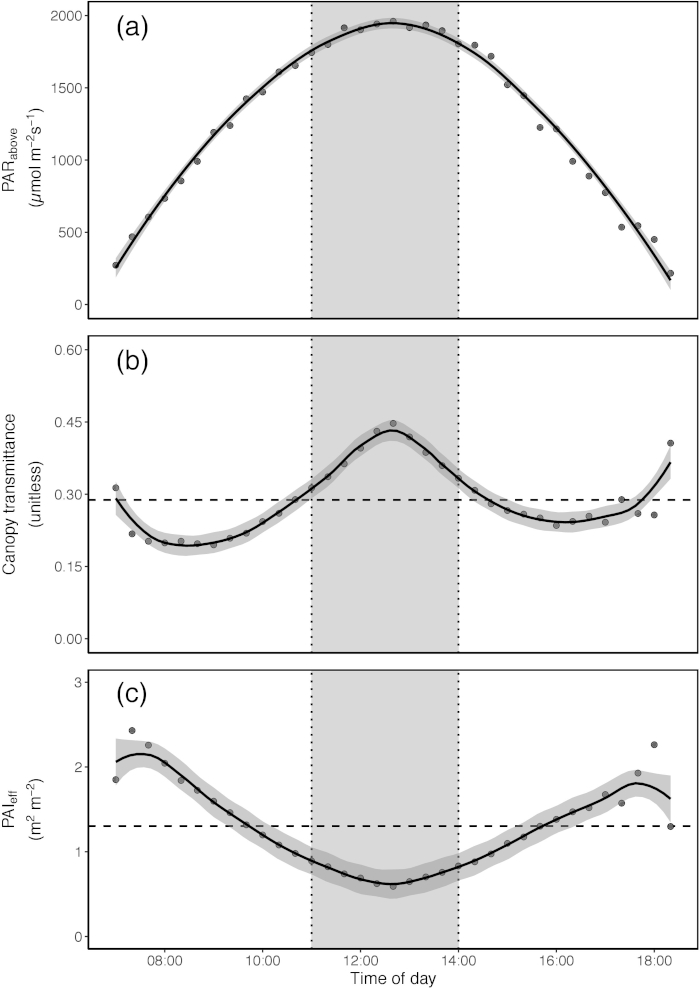

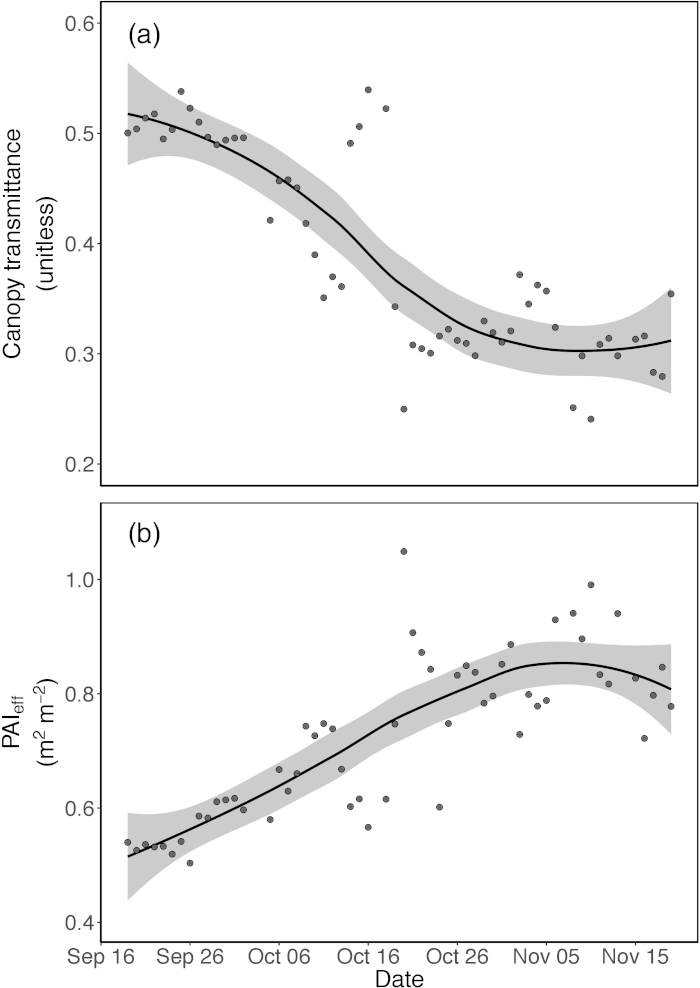

A schematic for the PARbar build is shown in Figure 1. A representative calibration curve for a PARbar is shown in Figure 2. The differential voltage output of a PARbar is linearly proportional to the PAR output from a quantum sensor, with R2 = 0.9998. PARbars were deployed in wheat canopies and logged every 20 s across the development of the plants. A typical diurnal time course of the canopy light environment collected using a PARbar on a clear sunny day is shown in Figure 3 (raw transmittance data and corrected PAIeff are shown for comparison). Figures 3b and 3c demonstrate the bias that could be introduced by taking instantaneous ceptometry measurements at various times of day (as per Salter et al. 20187). The wheat plots used for the collection of this data had a row planting orientation due north-south with the transmission of light to the lower canopy peaking at 12:30 (Figure 3b). If an instantaneous measurement were to be taken at this point, PAIeff would be underestimated, whereas if it were taken in the morning or afternoon it may be overestimated. The weatherproof PARbars can also be deployed in the field for long time periods; Figure 4 demonstrates how PARbars could be used to monitor how canopy light environment changes as plants develop.

Figure 1. Schematics for the PARbar build. (a) Location and arrangement of the waterproof connector and the internal shunt resistor; (b) arrangement and spacing of the photodiodes; (c) drilling locations on the acrylic diffuser bar; (d) drilling locations on the aluminum U-bar; and (e) electronic circuit diagram of a PARbar. Please click here to view a larger version of this figure.

Figure 2. Representative PARbar calibration curve. The relationship between the differential voltage output of a PARbar (mV) and the photosynthetic photon flux density or PAR (μmol m-2 s-1) from a quantum sensor. Each point represents a single pair of measurements from the PARbar and quantum sensor, recorded once every 20 seconds over a period of 4 hours for one day. Please click here to view a larger version of this figure.

Figure 3. Representative daily timecourse of PARbar output. Data collected on a clear day using PARbars in wheat canopies at anthesis in Canberra, Australia (-35°12'00.1008", 149°05'17.0988"). (a) PAR measured above the canopy (μmol m-2 s-1), (b) uncorrected transmittance (the ratio of PARabove/PARbelow) (unitless), and (c) the effective plant area index (PAIeff, m2 m-2), calculated from Equation 1. Data points shown in (b) and (c) are means (n = 30), solid lines are LOESS local regressions fitted in R (a = 0.5), shaded areas are standard errors of the fit and the dashed horizontal lines represent the daily means. The shaded area between the dotted lines is the time window (1100 – 1400h) recommended for instantaneous ceptometer measurements in wheat by CIMMYT11. Please click here to view a larger version of this figure.

Figure 4. Representative data collected across a growing season. PARbar data collected from early tillering to anthesis in wheat canopies in Canberra, Australia (-35°12'00.1008", 149°05'17.0988"). (a) Uncorrected transmittance data (unitless), and (b) effective plant area index (PAIeff, m2 m-2) calculated from Equation 1. Data points shown represent daily means for the period 1,000 – 1,400h (n = 30). Solid lines are LOESS local regressions fitted in R (a = 0.75), shaded areas are standard errors of the fit. Raw data was not included in further analysis if PARabove was < 1,500 µmol m-2 s-1 and if PARbelow/PARabove was > 1. Please click here to view a larger version of this figure.

Discussion

Successful implementation of the protocol outlined here for building ceptometers (PARbars) depends most sensitively on two steps: 1.5 (gluing photodiodes in place) and 1.6 (soldering photodiodes to the copper wire). Step 1.5 is prone to error by aligning the photodiodes incorrectly with respect to their intrinsic polarity. For the photodiodes that we used, and which we recommend as essential specific items, the polarity is identified by virtue of the two electrical connector tabs on the diode having clearly different sizes. Thus, before applying cyanoacrylate glue and soldering the photodiodes in place, it is strongly advised to double-check that all diodes are placed with the large connector tabs facing in one direction and the small tabs facing in the other direction. Step 1.6 is prone to failure due to poor soldering technique and formation of a cold soldered junction. This can be avoided by applying thin solder flux using a flux pen immediately before soldering and ensuring that both the wire and the photodiode tab are heated with the solder tip (at approximately 350-400 oC) before soldering itself is applied to the junction. Problems with electrical connections in a PARbar typically manifest in the form of a calibration slope distinctly different from those of other PARbars. Such problems can be caught early by testing each electrical connection during construction (as described in Step 1.6), and again after all connections have been soldered, but before they have been encased in epoxy (Step 1.9). A third potential source of error arises from the failure to use a low temperature-coefficient precision resistor, whose resistance is insensitive to temperature; using an ordinary resistor will cause the error as the resistance, and hence the voltage output per unit of light absorbed by the diodes, changes with ambient temperature. The final major source of error is not unique to PARbars, but applies to all ceptometry measurements: namely, the inference of effective plant area index or leaf area index from light capture depends on features of canopy structure (notably mean leaf absorptance and leaf angle distribution; a and c in Eqns 1 and 2) that may vary during plant development and between genotypes.

There are two main areas in which the protocol described here could be modified or adapted. First, the PARbars that we present here were designed specifically for use in row crops, such as wheat and barley, but the design could easily be modified for other applications. For example, a shunt resistor with larger resistance could be used to enhance gain (mV output per unit PAR) at lower PAR ranges. For versatility, a low-temperature coefficient precision potentiometer (variable resistor) could be used to modify the PARbar's sensitivity range as needed or to make small adjustments to gain so that each of many PARbars have identical calibration slopes. Second, the photodiodes could also be used individually as quantum sensors, allowing the user to capture spatial as well as temporal variation within individual canopies for a much lower cost than possible using commercially available quantum sensors. This could be particularly valuable given the growing interest in dynamic photosynthesis under fluctuating light conditions12. Third, although we used a conventional (and expensive) datalogger for the data presented in this study, there is scope for dataloggers to instead be built using off-the-shelf componentry, enabling the creation of a combined ceptometry and datalogger system on a limited budget. The popularity of so-called maker platforms, such as Arduino and Raspberry Pi, offer great promise in this area; we suggest the open-source Arduino-based Cave Pearl project13 as a starter for further development. Cave Pearl dataloggers were designed for environmental monitoring of cave ecosystems, so ruggedness and low power demand were key considerations in their design. Similar considerations are relevant for implementation to plant phenotyping work. Cave Pearl datalogger components are inexpensive (less than USD $50 per unit) and small, which could enable them to be directly incorporated into PARbars.

Application of the PARbars described here faces three main limitations. First, the inference of plant area index or leaf area index from measured light capture is hampered by strong time-dependent biases, particularly in row crops7. This can be overcome by making repeated or continuous measurements over a day. Second, inexpensive photodiodes do not have a spectral output that is exactly proportional to photon flux (the variable of greatest interest in photosynthesis research). This can cause bias when light quality changes greatly through a canopy, although previous estimates of the resulting error indicate that it is on the order of a few percent7. Third, PARbars cannot distinguish between the direct beam and diffuse components of incoming PAR above the canopy. As diffuse radiation penetrates deeper into the canopy than direct sunlight14, transmittance will be increased and PAIeff will be underestimated as the diffuse fraction of total irradiance increases. When all radiation is diffuse, PAIeff is directly proportional to the logarithm of 1/τ rather than the relationship shown in Equation 115. Cruse et al. (2015)16 noted that currently available commercial instruments that can measure direct and diffuse PAR are expensive and require regular maintenance, so they designed a simple and inexpensive apparatus to address this issue. Their system consists of a quantum sensor that is routinely shaded by a motorized, moving shadowband and allows for continuous measurement of total, direct and diffuse PAR. The sensor used in the Cruse et al.16 system could be replaced with the same photodiode used in PARbars to further reduce cost and may be easily incorporated into the existing PARbar setup. These measurements could be integrated into the data processing pipeline and would further enhance the reliability of estimates of PAIeff.

The major advantage of PARbars relative to existing commercial ceptometers is their low cost, which makes it feasible to produce them in large numbers. Recently, there has been a growing interest in novel high-throughput plant phenotyping technologies for the estimation of canopy traits (for review see Yang et al., 201717). Whilst these methods are promising in that they produce huge amounts of data they are typically very indirect and require validation against conventional techniques. PARbars could serve as a cost-effective, ground-based validation tool for these new techniques.

The low production cost of PARbars also make them a viable option for continuous measurements in the field. This could be useful for several reasons. For example, continuous measurements can be used to characterize row-orientation biases to develop time-specific correction functions for instantaneous measurements (for more information see Salter et al. 20187). Continuous ceptometry can also capture short fluctuations in canopy light capture over time (sunflecks and shadeflecks) caused by clouds passing overhead, movement of the canopy, etc. Photosynthesis is known to be highly sensitive to small changes in environmental conditions and ‘dynamic’ changes in photosynthesis are now thought to be important in driving crop yield (for review see Murchie et al., 201812). PARbars installed in the field with a suitably short logging interval could be used to capture these short fluctuations and provide better understanding of the dynamic nature of plant canopies.

Disclosures

The authors confirm that they have no conflicts of interest and nothing to disclose.

Acknowledgements

The authors would like to thank Dr. Richard Richards and Dr. Shek Hossain at CSIRO, Agriculture, and Food for access to and management of the field plots used for this research. This research was supported by the International Wheat Yield Partnership, through a grant provided by the Grains Research and Development Corporation (US00082). TNB was supported by the Australian Research Council (DP150103863 and LP130100183) and the National Science Foundation (Award #1557906). This work was supported by the USDA National Institute of Food and Agriculture, Hatch projects 1016439 and 1001480.

Materials

| Name | Company | Catalog Number | Comments |

| 1.5 Ω low temperature coefficient precision resistor | TE Connectivity Ltd., Schaffhausen, Switzerland. | UPW25 series | Could be made using multiple larger resistors in parallel but they need to have low temperature coefficient (i.e. ± 3 ppm/°C). URL for commercial source: https://bit.ly/2DFuPpm |

| Acrylic diffuser | Plastix Australia Pty. Ltd., Arncliffe, NSW, Australia. | 445 - Opal White | 1200 mm length x 30 mm width x 4.5 mm thick. URL for commercial source: https://bit.ly/2Bq0fyc |

| Aluminum U-bar | Capral Ltd., Bundamba, QLD, Australia. | EK9160 | 1220 mm length x 35 mm width x 25 mm depth. URL for commercial source: https://bit.ly/2PPfJou |

| Bare solid core copper wire | Non-specific part | ||

| Bolts | Non-specific part | ||

| Clamps | Non-specific part | ||

| Clear epoxy potting resin | Solid Solutions, East Bentleigh, VIC, Australia. | 651 - Universal Epoxy Potting Resin | Clear epoxy resin for electrical applications. URL for commercial source: https://bit.ly/2qY0pHa |

| Cyanoacrylate glue | Non-specific part | ||

| Datalogger | Campbell Scientific, Logan, Utah, USA. | CR5000 | Other dataloggers that record differential voltages could be used. URL for commercial source: https://bit.ly/2U7Io5H |

| Drill or drill press | Non-specific part | ||

| Glue lined heat shrink | Non-specific part | ||

| Heat gun | Non-specific part | ||

| LED torch | Non-specific part | ||

| Masking tape | Non-specific part | ||

| Photodiodes (50) | Everlight Americas Inc., Carrollton, Texas, USA. | EAALSDSY6444A | It is important that this specific component is used due to spectral response. URL for commercial source: https://bit.ly/2FzVnuH |

| Polyurethane foam filler | Non-specific part | ||

| Quantum sensor | LI-COR, Lincoln, Nebraska, USA. | LI-190R | For calibration of PARbars only. URL for commercial source: https://bit.ly/2HEfKbh |

| Screwdrivers | Non-specific part | ||

| Silicone sealant | Non-specific part | ||

| Solder | Non-specific part | ||

| Solder flux pen | Non-specific part | ||

| Soldering iron | Non-specific part | ||

| Spirit/bubble level | Non-specific part | ||

| Tap and die set | Non-specific part | ||

| Two-core cable | Non-specific part | ||

| Voltmeter | Non-specific part | ||

| Waterproof connectors | Core Electronics, Adamstown, NSW, Australia. | ADA743 | 2 core waterproof connector. DC power connectors work well. URL for commercial source: https://bit.ly/2Brcrik |

References

- Armbrust, D. V. Rapid measurement of crop canopy cover. Agronomy Journal. 82 (6), 1170-1171 (1990).

- Breda, N. J. J. Ground-based measurements of leaf area index: a review of methods, instruments and current controversies. Journal of Experimental Botany. 54 (392), 2403-2417 (2003).

- Francone, C., Pagani, V., Foi, M., Cappelli, G., Confalonieri, R. Comparison of leaf area index estimates by ceptometer and PocketLAI smart app in canopies with different structures. Field Crops Research. 155, 38-41 (2014).

- Campbell, G. S. Extinction coefficients for radiation in plant canopies calculated using an ellipsoidal inclination angle distribution. Agricultural and Forest Meteorology. 36 (4), 317-321 (1986).

- Cohen, S., Rao, R. S., Cohen, Y. Canopy transmittance inversion using a line quantum probe for a row crop. Agricultural and Forest Meteorology. 86 (3-4), 225-234 (1997).

- . . AccuPAR PAR/LAI Ceptometer Model LP-80 Operator's Manual. , (2017).

- Salter, W. T., Gilbert, M. E., Buckley, T. N. Time-dependent bias in instantaneous ceptometry caused by row orientation. The Plant Phenome Journal. , (2018).

- Huang, X. H., Han, B., Merchant, S. S. . Annual Review of Plant Biology. 65, 531-551 (2014).

- . . Application Note: Beam fraction calculation in the LP80. , (2009).

- Campbell, G. S., Van Evert, F. K. . Light interception by plant canopies - efficiency and architecture. , (1994).

- Pask, A., Pietragalla, J., Mullan, D., Reynolds, M. . Physiological breeding II: a field guide to wheat phenotyping. , (2012).

- Murchie, E. H., et al. Measuring the dynamic photosynthome. Annals of Botany. 122 (2), 207-220 (2018).

- Beddows, P. A., Mallon, E. K. Cave Pearl Data Logger: a flexible Arduino-based logging platform for long-term monitoring in harsh environments. Sensors. 18 (2), 26 (2018).

- Li, T., et al. Enhancement of crop photosynthesis by diffuse light: quantifying the contributing factors. Annals of Botany. 114 (1), 145-156 (2014).

- Lang, A. R. G., Yueqin, X. Estimation of leaf-area index from transmission of direct sunlight in discontinuous canopies. Agricultural and Forest Meteorology. 37 (3), 229-243 (1986).

- Cruse, M. J., Kucharik, C. J., Norman, J. M. Using a simple apparatus to measure direct and diffuse photosynthetically active radiation at remote locations. Plos One. 10 (2), 19 (2015).

- Yang, G. J., et al. Unmanned aerial vehicle remote sensing for field-based crop phenotyping: current status and perspectives. Frontiers in Plant Science. 8, 26 (2017).

Reprints and Permissions

Request permission to reuse the text or figures of this JoVE article

Request PermissionThis article has been published

Video Coming Soon

Copyright © 2025 MyJoVE Corporation. All rights reserved