Aerodynamic Performance of a Model Aircraft: The DC-6B

Overview

Source: Jose Roberto Moreto and Xiaofeng Liu, Department of Aerospace Engineering, San Diego State University, San Diego, CA

The low-speed wind tunnel is a valuable tool to study aircraft aerodynamic characteristics and evaluate aircraft performance and stability. Using a scale model of a DC-6B aircraft that has a removable tail and a 6-component external aerodynamic force balance, we can measure the lift coefficient (CL), drag coefficient (CD), pitching moment coefficient (CM), and yaw moment coefficient (CN) of the model airplane with and without its tail and evaluate the effect of the tail on aerodynamic efficiency, longitudinal stability and directional stability.

In this demonstration, airplane aerodynamic characteristics and flight performance and stability are analyzed using the aerodynamic force balance measurement method. This method is widely used in aerospace industries and research labs for aircraft and rocket development. Here, a model DC-6B airplane is analyzed at different flow conditions and configurations, and its behavior is analyzed when it is subjected to sudden changes.

Procedure

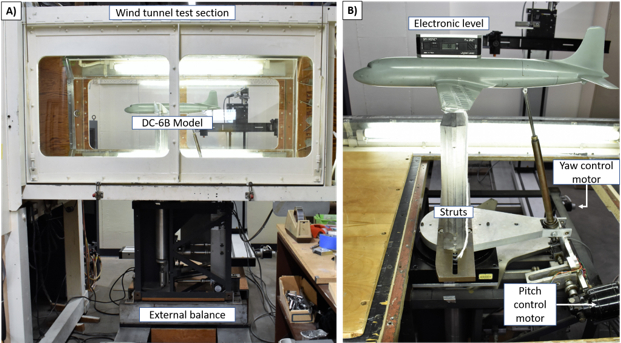

The DC-6B model set-up on the aerodynamic force balance is displayed below.

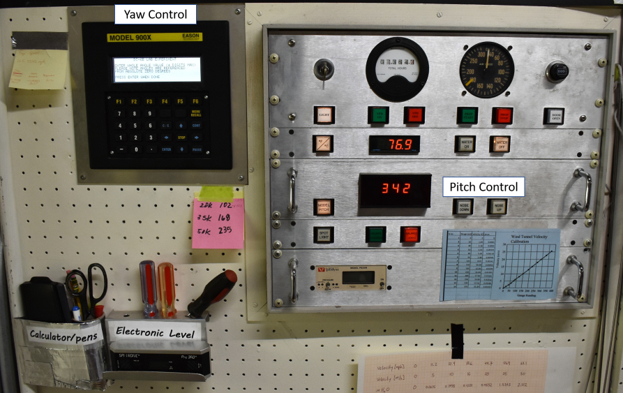

Figure 1. Mounted DC-6B model. A) DC-6B model inside low-speed wind tunnel test section with an external aerodynamic balance. B) DC-6B Model mounted on the balance by three articulated points. There is also a yaw angle control motor, pitch control motor and an electronic level to calibrate the pitch angle.

.css-f1q1l5{display:-webkit-box;display:-webkit-flex;display:-ms-flexbox;display:flex;-webkit-align-items:flex-end;-webkit-box-align:flex-end;-ms-flex-align:flex-end;align-items:flex-end;background-image:linear-gradient(180deg, rgba(255, 255, 255, 0) 0%, rgba(255, 255, 255, 0.8) 40%, rgba(255, 255, 255, 1) 100%);width:100%;height:100%;position:absolute;bottom:0px;left:0px;font-size:var(--chakra-fontSizes-lg);color:#676B82;}

Results

In this demonstration, the performance and stability characteristics of a DC-6B model in two configurations were measured. In one configuration, a conventional airplane tail was attached to the model (tail-on), and in the second configuration, the tail was removed and replaced with a cone (tail-off). For each configuration, the variation of lift coefficient and drag coefficient with angle of attack was determined (Figure 3). The variation in pitch moment coefficient and yaw moment coeffic

Application and Summary

Testing a small-scale model using an aerodynamic balance in a wind tunnel enables the determination of major aerodynamic characteristics of an aircraft. A 6-component balance measures three force components, lift, drag, and lateral forces, and three moment components, pitch, yaw, and roll moments.

When the dynamic similarity between the full-scale object and the model is achieved, for example the Reynolds number is the same for the case of incompressible steady flow, then the aerodynamic coeff

Skip to...

Videos from this collection:

Now Playing

Aerodynamic Performance of a Model Aircraft: The DC-6B

Aeronautical Engineering

8.3K Views

Propeller Characterization: Variations in Pitch, Diameter, and Blade Number on Performance

Aeronautical Engineering

26.5K Views

Airfoil Behavior: Pressure Distribution over a Clark Y-14 Wing

Aeronautical Engineering

21.2K Views

Clark Y-14 Wing Performance: Deployment of High-lift Devices (Flaps and Slats)

Aeronautical Engineering

13.4K Views

Turbulence Sphere Method: Evaluating Wind Tunnel Flow Quality

Aeronautical Engineering

8.7K Views

Cross Cylindrical Flow: Measuring Pressure Distribution and Estimating Drag Coefficients

Aeronautical Engineering

16.2K Views

Nozzle Analysis: Variations in Mach Number and Pressure Along a Converging and a Converging-diverging Nozzle

Aeronautical Engineering

38.0K Views

Schlieren Imaging: A Technique to Visualize Supersonic Flow Features

Aeronautical Engineering

11.7K Views

Flow Visualization in a Water Tunnel: Observing the Leading-edge Vortex Over a Delta Wing

Aeronautical Engineering

8.2K Views

Surface Dye Flow Visualization: A Qualitative Method to Observe Streakline Patterns in Supersonic Flow

Aeronautical Engineering

4.9K Views

Pitot-static Tube: A Device to Measure Air Flow Speed

Aeronautical Engineering

49.2K Views

Constant Temperature Anemometry: A Tool to Study Turbulent Boundary Layer Flow

Aeronautical Engineering

7.3K Views

Pressure Transducer: Calibration Using a Pitot-static Tube

Aeronautical Engineering

8.5K Views

Real-time Flight Control: Embedded Sensor Calibration and Data Acquisition

Aeronautical Engineering

10.3K Views

Multicopter Aerodynamics: Characterizing Thrust on a Hexacopter

Aeronautical Engineering

9.2K Views

Copyright © 2025 MyJoVE Corporation. All rights reserved