Ceramic-matrix Composite Materials and Their Bending Properties

Overview

Source: Sina Shahbazmohamadi and Peiman Shahbeigi-Roodposhti-Roodposhti, School of Engineering, University of Connecticut, Storrs, CT

Bones are composites, made of a ceramic matrix and polymer fiber reinforcements. The ceramic contributes compressive strength, and the polymer provides tensile and flexural strength. By combining ceramic and polymer materials in different amounts, the body can create unique materials tailored for a specific application. As biomedical engineers, having the ability to replace and replicate bone due to disease or traumatic injury is a vital facet of medical science.

In this experiment we will create three different ceramic-matrix composites with plaster of Paris (which is a calcium sulfate compound), and allow them to undergo three-point bending test in order to determine which preparation is the strongest. The three composites are as follows: one comprised only of plaster of Paris, one with chopped glass shards mixed in a plaster matrix and lastly a plaster matrix with a fiberglass network embedded within it.

Procedure

1. Making one plain plaster sample

- Obtain a blue rubber mold from the instructor. Each mold can make 3 bar-shaped samples, the size of the each bar is roughly about 26 mm in the width, 43 mm in the length, and 10 mm in the thickness.

- Weigh 40 grams of dry plaster powder into a paper cup. Slowly add 20 ml of deionized water, and stir the slurry with a wooden stick, until a smooth consistency is achieved. Proceed immediately to step 3! The plaster starts to harden in ~5 minutes.

Results

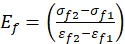

The overall objective of the series of aforementioned tests is to compare the different physical characteristics between various composite bone substitutes. Flexural strength and strain needs to be calculated using Equations 4 and 5, respectively. The stress and strain for each sample will be plotted in MATLAB. From this, the maximum flexural strength and the corresponding flexural strain can be found for each data set. The stress (σf1, Log in or to access full content. Learn more about your institution’s access to JoVE content here

Application and Summary

This experiment was designed to study flexural strength on three different kind of composite material. We fabricated three specimens with different reinforcement materials. The matrix was plaster of Paris (a calcium sulfate compound), and we used chopped glass fibers and fiberglass tape as reinforcements. We performed 3-point bending test on the fabricated specimens, and analyzed the achieved data, comparing the properties of composites made with long, oriented fibers vs. short random fibers.

Log in or to access full content. Learn more about your institution’s access to JoVE content here

Skip to...

Videos from this collection:

Now Playing

Ceramic-matrix Composite Materials and Their Bending Properties

Materials Engineering

8.0K Views

Optical Materialography Part 1: Sample Preparation

Materials Engineering

15.3K Views

Optical Materialography Part 2: Image Analysis

Materials Engineering

10.9K Views

X-ray Photoelectron Spectroscopy

Materials Engineering

21.5K Views

X-ray Diffraction

Materials Engineering

88.2K Views

Focused Ion Beams

Materials Engineering

8.8K Views

Directional Solidification and Phase Stabilization

Materials Engineering

6.5K Views

Differential Scanning Calorimetry

Materials Engineering

37.1K Views

Thermal Diffusivity and the Laser Flash Method

Materials Engineering

13.2K Views

Electroplating of Thin Films

Materials Engineering

19.6K Views

Analysis of Thermal Expansion via Dilatometry

Materials Engineering

15.6K Views

Electrochemical Impedance Spectroscopy

Materials Engineering

23.0K Views

Nanocrystalline Alloys and Nano-grain Size Stability

Materials Engineering

5.1K Views

Hydrogel Synthesis

Materials Engineering

23.5K Views

Copyright © 2025 MyJoVE Corporation. All rights reserved

(6)

(6)