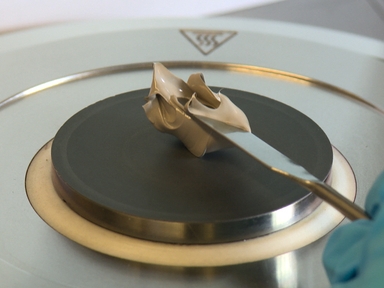

Convergent Polishing: A Simple, Rapid, Full Aperture Polishing Process of High Quality Optical Flats & Spheres

December 1st, 2014

•A novel optical polishing process, called “Convergent Polishing”, which enables faster, lower cost polishing, is described. Unlike conventional polishing processes, Convergent Polishing allows a glass workpiece to be polished in a single iteration and with high surface quality to its final surface figure without requiring changes to polishing parameters.

Tags

Related Videos

Fabrication of Silica Ultra High Quality Factor Microresonators

Process of Making Three-dimensional Microstructures using Vaporization of a Sacrificial Component

Construction of a High Resolution Microscope with Conventional and Holographic Optical Trapping Capabilities

The Generation of Higher-order Laguerre-Gauss Optical Beams for High-precision Interferometry

Fabrication Process of Silicone-based Dielectric Elastomer Actuators

Adsorption Device Based on a Langatate Crystal Microbalance for High Temperature High Pressure Gas Adsorption in Zeolite H-ZSM-5

Challenges in Rheological Characterization of Highly Concentrated Suspensions — A Case Study for Screen-printing Silver Pastes

Method for Recording Broadband High Resolution Emission Spectra of Laboratory Lightning Arcs

Atomic Layer Deposition of Vanadium Dioxide and a Temperature-dependent Optical Model

Predicting Catalyst Extrudate Breakage Based on the Modulus of Rupture

ABOUT JoVE

Copyright © 2024 MyJoVE Corporation. All rights reserved