Aby wyświetlić tę treść, wymagana jest subskrypcja JoVE. Zaloguj się lub rozpocznij bezpłatny okres próbny.

Method Article

Curtain Flow Column: Optimization of Efficiency and Sensitivity

W tym Artykule

Podsumowanie

Here, we present a protocol for the operation and optimization of Active Flow Technology (AFT) column in Curtain flow (CF) mode for enhanced separation performance.

Streszczenie

Active Flow Technology (AFT) is a form of column technology that increases the separation performance of a HPLC column through the use of a specially purpose built multiport end-fitting(s). Curtain Flow (CF) columns belong to the AFT suite of columns, specifically the CF column is designed so that the sample is injected into the radial central region of the bed and a curtain flow of mobile phase surrounding the injection of solute prevents the radial dispersion of the sample to the wall. The column functions as an 'infinite diameter' column. The purpose of the design is to overcome the radial heterogeneity of the column bed, and at the same time maximize the sample load into the radial central region of the column bed, which serves to increase detection sensitivity. The protocol described herein outlines the system and CF column set up and the tuning process for an optimized infinite diameter 'virtual' column.

Wprowadzenie

In recent years column technology for High Performance Liquid Chromatography (HPLC) has advanced greatly; peak capacities have increased considerably thanks largely to the use of smaller particle sizes and the more efficient core shell particles. Since separations are generally more efficient, a flow-on effect has been an increase in sensitivity since peaks are now sharper and hence taller1-8.

Nevertheless, radial bed heterogeneity is still a limiting factor in the performance of all columns, but this is not a new story since chromatographers have known this for many years. Column beds are heterogeneous in both the radial direction9-12, and along the column axis10,12-15. The wall-effect especially is an important contributor to the loss of separation performance7,16-18. Shalliker and Ritchie7 recently reviewed aspects of column bed heterogeneity and hence this need not be discussed here further. Although suffice to say, that the variation in column bed packing density and the wall effects lead to a distortion of the solute plug, such that bands elute through the column in plugs that resemble partially filled soup bowls rather than thin flat solid discs7 that are usually depicted in basic teaching texts. When experiments were undertaken such that the solute migration through the bed could be visualized the plug profiles inside the column were partly hollow and the tailing section of the band is largely the wall component of the sample plug. The end result is that it takes many more plates to separate these 'partially hollow' plugs than would be required if the discs were solid and flat12,14,17. To overcome the band broadening issues associated with wall effects and the variation in radial packing density, a new form of column technology known as Active Flow Technology (AFT) was designed7,19. The purpose of this design was to remove wall effects through the physical separation of solvent eluting along the wall region, from that of mobile phase eluting in the radial central region of the column19. There are two main types of AFT columns; Parallel Segmented Flow (PSF) columns and Curtain Flow (CF) columns 7. Since this protocol is aimed at the use and optimization of CF columns, PSF columns will not be further discussed.

Curtain Flow (CF)

Curtain Flow (CF) column formats utilize AFT end-fittings at both the inlet and the outlet of the column. AFT end-fittings consist of an annular frit located inside a multiport fitting. The frit is made up of three parts: a porous radial central portion that is aligned with the central port of the end fitting, a porous outer portion that is aligned with the peripheral port(s) of the end fitting, and an impermeable ring that separates the two porous portions preventing any cross-flow between the radial central and outer regions of the frit19. Figure 1 illustrates the design of the AFT frit and Figure 2 illustrates the CF column format. In this mode of operation (CF) the sample is injected into the radial central port of the inlet fitting, whilst additional mobile phase is introduced through the peripheral port of the inlet to 'curtain' the migration of solutes through the radial central region of the column. Hence the sample enters the bed in the radial central region of the column with the outer region of the column having mobile phase only passed through it. Studies have shown that a volumetric flow rate ratio of around 40:60 (central:peripheral port) for the inlet end-fitting of a 4.6 mm internal diameter (i.d.) column is optimal6,7,16. The AFT outlet of the CF column allows the adjustment of the central and peripheral flow to their relative portion and can be varied to almost any desired ratio through pressure management. The optimization of a CF column can significantly improve various functional aspects of the column technology, such as separation efficiency or detection sensitivity. In this manner a 'wall-less', 'infinite-diameter' or 'virtual' column is established6,10,18,20. The purpose of CF columns is to actively manage the migration of sample through the column to prevent the sample from reaching the wall region. Thus, the solute concentration upon exit to the detector is maximized, increasing sensitivity of around 2.5 times greater than the conventional column format when using Ultraviolet (UV) detection16, and even greater when using mass spectral detection6.

CF columns are ideally suited for low concentration samples, since detection sensitivity is increased. Further, they are ideal when coupled to flow rate limited detectors, such as the mass spectrometer (MS)6. An AFT column in a 4.6 mm i.d. format, for example can be tuned to deliver the same volume of solvent to a detector as a standard 2.1 mm i.d. format column when operated at the same linear velocities, by adjusting exiting central flow to 21%. Likewise the AFT column could also be tuned to deliver the same volume load to a detector as a 3.0 mm i.d. column, by adjusting exiting central flow to 43%. In fact any 'virtual' column format could be produced to suit the analytical requirement6,18,22. Using these specially designed end-fittings at the inlet and the outlet ensures that a true wall-less column is established.

There are two ways to set up the solvent delivery system to the central and peripheral ports of the inlet: split-flow system6 and two pump system6,7. Figure 3 illustrates each of these CF system set ups.

Split-flow system

In a split-flow system (Figure 3A) the pump flow leading to the injector is split pre-injector using a zero-dead volume T-piece, where one flow stream of mobile phase is connected to the injector, which is then connected to the central port of the inlet end-fitting of the column. The second flow stream of mobile phase by-passes the injector and is connected to the peripheral port on the inlet of the column. During the splitting of flow, the flow stream percentage is adjusted to 40:60 (center:peripheral) before the lines are connected to the column, i.e., from injector to center and pump to peripheral.

Two pump system

The CF column requires two flow streams at the inlet end-fitting of the column. Depending on the type of autosampler/injector of the HPLC instrument, split-flow set up may not be possible, and so CF can then be achieved through 2 pumps (Figure 3B21). Each pump is allocated and connected to either the central or peripheral port and the flow rate is set to represent 40% of flow for central port and 60% for peripheral port. For example, if the total flow rate is 1.0 ml min-1, the central pump flow rate is set to 0.4 ml min-1 and the peripheral pump is set to 0.6 ml min-1.

The choice of which mode of operation is largely dependent on the HPLC instrumentation and chromatographic mode of operation. For example in some autosamplers a change in pressure between sample load position and sample inject position may occur disrupting the split-flow ratio and thus in this case a dual pump set up would be recommended for optimal CF performance. Regardless of the solvent delivery system set up chosen for the inlet of the CF column, the CF outlet optimization remains the same. The outlet central port of the CF column is attached to the Ultraviolet-Visible (UV-Vis) detector with the smallest volume possible of tubing to minimize the effects of post-column dead volume. Since, CF columns emulate narrow-bore columns, dead volume between the column outlet and the detector is detrimental to the separation performance of the CF column. It is critical to ensure the smallest amount of volume of tubing between the central port and the UV-Vis detector to minimize the effects of dead volume such as band broadening, loss in efficiency and sensitivity. Hence, the use of narrow bore tubing (0.1 mm i.d.) is advised to readily allow pressure adjustments without adding inappropriate dead volume. Tubing is also attached to the peripheral port and directed to waste. Upon the outlet of the CF column, the segmentation ratio can be adjusted to any ratio that fits the purpose of the analyst. When a 4.6 mm i.d. CF is used, for example, it is often convenient to set the ratio as either 43:57 or 21:79 (center:peripheral) to emulate a 'virtual' 3.0 mm i.d. column or 2.1 mm i.d. column, respectfully. That way the separation performance is readily bench-marked. The segmentation ratio is measured by weighing the amount of flow exiting from the detector that is connected to the central port and flow exiting the peripheral port over a period time. The percentage flow through each port can then be determined and the ratios can be adjusted by altering the length of tubing attached or using tubing that has a different internal diameter (i.d.).

This video protocol details the operation and optimization procedures of a CF column for enhanced chromatographic performance.

Protokół

Caution: Please refer to material safety data sheets (MSDS) for all materials and reagents before use (i.e., MSDS for methanol). Ensure the use of all appropriate safety practices when handling solvents and High Performance Liquid Chromatography (HPLC) eluent. Ensure appropriate use of engineering controls of HPLC, analytical balance and detector instrumentation, and ensure the use of personal protective equipment (safety glasses, gloves, lab coat, full length pants, and closed-toe shoes).

Note: This protocol contains instructions on how to use a CF column on a HPLC system coupled with a UV-Vis detector. The protocol has been written assuming the reader has basic knowledge and experience in chromatography.

1. Setup of HPLC Instrument

Note: This section can be altered to suit the analysts' needs, i.e., choice of solvents, detector wavelength and flow rate that are appropriate to the sample of interest.

- Prepare the HPLC instrument with 100% ultrapure water (e.g., Milli-Q water) for line A and 100% methanol for line B as the mobile phase and purge the pumps as per manufacturer requirement.

- Set the UV-Vis detector to 254 nm.

- Choose either a pre-injection flow split mode of set-up, or a dual pump flow set-up. For the split-flow mode proceed to Step 2, for the dual pump mode proceed to Step 3.

2. Split-flow System Setup

- Disconnect the pump line from the injector valve of the auto-sampler.

- Attach a T-piece to the pump line.

- Attach a 15 cm piece of 0.13 mm i.d. tubing to each port of the T-piece.

- Connect one tube from the T-piece to injector valve of auto-sampler.

- Set the pump to 1.0 ml min-1.

- Before connecting pump lines to the inlet of the CF column, tune the segmentation ratio of the flow to 40%:60% (center line:peripheral line) as follows in step 2.7.

- Tuning of CF inlet ratio on split-flow system

- Measure the mass of two empty collection vessels using an analytical balance and label one collection vessel central and the other one peripheral (one for the line from the auto-sampler to center port and one for the line from the T-piece to peripheral port).

- For 1.0 min, collect the exiting mobile phase from the line coming from the injector (at the point that will be connected to the column) into the collection vessel, whose mass was measured in 2.7.1.

- Re-weigh the collection vessel on the analytical scale and determine the mass of mobile phase collected.

- Repeat steps 2.7.2 to 2.7.3 for the eluent exiting the line from the T-piece that is to be connected to the peripheral port.

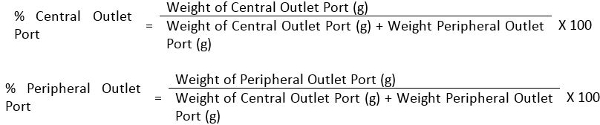

- Determine the percentage of flow (ml min-1) from each line of flow according to the following equations:

- Adjust the flow ratio to 40%:60% (± 2%) (line from injector to central port:line from T-piece to peripheral port). If the line from the injector to the central port flow percentage is above 40%, increase the pressure drop by decreasing the internal diameter of the tubing, or increasing its length. If the line from injector to central port flow percentage is below 40%, increase internal diameter of the tubing or decrease the length of the tube.

- Once the flow ratios are tuned turn the pump flow off.

- Connect the line from the injector to the central port of the column inlet and the line from the T-piece to the peripheral port of the column inlet.

- Slowly ramp the flow rate to 1.0 ml min-1 at 100% line B.

- Equilibrate the column (4.6 mm i.d. x 100 mm length) by allowing 100% Methanol (line B) mobile phase to flow through the column at 1.0 ml min-1 for 10 min. This time is scaled according to the dimensions of other columns the user may employ.

- For the tuning of the CF outlet go to Step 4. 'Tuning of CF outlet flow'.

3. Dual Pump System Setup

- Connect the HPLC system pump to the injector and then connect the line from the injector to the central inlet port of the column.

- Connect the additional pump directly to the inlet peripheral port of the column. Note that this second pump by-passes the injector.

- Ramp the flow rate of the system pump attached to the central port to 0.4 ml min-1 (representative of 40% of the total flowrate of 1.0 ml min-1) at 100% Methanol (line B).

- At the same time as Step 3.3, ramp the flow rate of the peripheral pump to 0.6 ml min-1 (representative of 60% of the total flowrate of 1.0 ml min-1) at 100% Methanol (line B).

- Equilibrate the column (4.6 mm i.d. x 100 mm length) by allowing 100 % Methanol (line B) mobile phase to flow through the column at 1.0 ml min-1 for 10 min. This time is scaled according to the dimensions of other columns the user may employ.

- For the tuning of the CF outlet go to Step 4. 'Tuning of CF outlet flow'.

4. Tuning of CF Outlet Flow

- Connect the central outlet port to the UV-Vis detector using a 15 cm piece of 0.13 mm i.d. tubing.

- Connect a 15 cm piece of 0.13 mm i.d. tubing to the peripheral outlet port of the CF column.

- Weigh the mass of two empty collection vessels on the analytical balance and label one vessel central and the other peripheral.

- For 1.0 min, collect the exiting mobile phase from the UV-Vis detector (central flow) into the collection vessel label central, whose mass was measured in 4.2.

- Re-weigh the collection vessel containing the collected eluent on the analytical scale and determine the mass of mobile phase collected.

- Repeat steps 4.4 to 4.5 for the eluent exiting the line from the peripheral outlet port.

- Determine the percentage of flow from each line of flow according to the following equations:

- Adjust the flow ratio to 21%:79% (± 2%) (central outlet flow from UV-Vis:peripheral outlet flow from line ). If the central flow percentage from the UV-Vis is above 21%, increase the pressure drop by decreasing the internal diameter of the tubing attached to the exit of the UV-Vis detector, or increasing its length. If the central flow percentage from the UV-Vis is below 21%, increase internal diameter of the tubing attached to the exit of the UV-Vis detector, or decrease the length of the tube. Each time the length of tubing has been changed, repeat steps 4.3 to 4.7.

Note: The CF column in 'virtual' 2.1 mm i.d. mode is ready for analysis.

Wyniki

AFT columns were developed using a specialized frit design (Figure 1) in the multiport column end-fittings to overcome the column bed heterogeneity and improve separation performance. An inter-laboratory study on the separation performance of CF chromatography columns (Figure 2) was carried out with a dual pump system set up (Figure 3B) as described in section 3 of this protocol23. A three component test mixture was analyzed un...

Dyskusje

This study involved the inter-laboratory analysis of CF chromatography columns to test the analytical performance in terms of efficiency and sensitivity. The CF column was set up with a dual pumping system as described in section '3. Dual pump system set up' to achieve a flow ratio of 40:60 (center:peripheral) on the inlet of the CF column. The 40:60 (center:peripheral) flow ratio was achieved by setting the flow rate of each pump to the value that represents 40% and 60% of the total flow rate, respectively. The ...

Ujawnienia

This work was supported by UWS and ThermoFisher Scientific.

Podziękowania

One of the authors (DK) acknowledges the receipt of an Australian Postgraduate Award.

Materiały

| Name | Company | Catalog Number | Comments |

| HPLC instrument | |||

| Additional Pump | Required if 2 pump CF system set up is to be used. | ||

| Curtain Flow HPLC column | Thermo Fisher Scientific | Not Defined | Soon to be commercialized |

| Methanol | Any brand | HPLC Grade | |

| PEEK tubing | Any brand | Various lengths and i.d. | |

| PEEK tube cutter | Any brand | ||

| Analytical Scale Balance | Any brand | ||

| Stop watch | Any brand | ||

| Eluent collection vessels | Any brand | 1-2 ml sample vials can be used as eluent collection vessels | |

| T-piece | Any brand |

Odniesienia

- Camenzuli, M., et al. The use of parallel segmented outlet flow columns for enhanced mass spectral sensitivity at high chromatographic flow rates. Rapid Commun. Mass Sp. 26 (8), 943-949 (2012).

- Camenzuli, M., Ritchie, H. J., Ladine, J. R., Shalliker, R. A. Enhanced separation performance using a new column technology: Parallel segmented outlet flow. J. Chromatogr. A. 1232, 47-51 (2012).

- Camenzuli, M., Ritchie, H. J., Shalliker, R. A. Gradient elution chromatography with segmented parallel flow column technology: A study on 4.6mm analytical scale columns. J. Chromatogr. A. 1270, 204-211 (2012).

- Camenzuli, M., Ritchie, H. J., Shalliker, R. A. Improving HPLC separation performance using parallel segmented flow chromatography. Microchem. J. 111, 3-7 (2013).

- Camenzuli, M., et al. Parallel segmented outlet flow high performance liquid chromatography with multiplexed detection. Anal. Chim. Acta. 803, 154-159 (2013).

- Kocic, D., et al. High through-put and highly sensitive liquid chromatography-tandem mass spectrometry separations of essential amino acids using active flow technology chromatography columns. J. Chromatogr. A. 1305, 102-108 (2013).

- Shalliker, R. A., Ritchie, H. Segmented flow and curtain flow chromatography: Overcoming the wall effect and heterogeneous bed structures. J. Chromatogr. A. 1335, 122-135 (2014).

- Shellie, R., Haddad, P. Comprehensive two-dimensional liquid chromatography. Anal. Bioanal. Chem. 386 (3), 405-415 (2006).

- Abia, J. A., Mriziq, K. S., Guiochon, G. A. Radial heterogeneity of some analytical columns used in high-performance liquid chromatography. J. Chromatogr. A. 1216 (15), 3185-3191 (2009).

- Knox, J. H., Laird, G. R., Raven, P. A. Interaction of radial and axial dispersion in liquid chromatography in relation to the "infinite diameter effect". J. Chromatogr. A. 122, 129-145 (1976).

- Miyabe, K., Guiochon, G. Estimation of the column radial heterogeneity from an analysis of the characteristics of tailing peaks in linear chromatography. J. Chromatogr. A. 830 (1), 29-39 (1999).

- Shalliker, R. A., Scott Broyles, B., Guiochon, G. Axial and radial diffusion coefficients in a liquid chromatography column and bed heterogeneity. J. Chromatogr. A. 994 (1-2), 1-12 (2003).

- Gritti, F., Guiochon, G. Effects of the thermal heterogeneity of the column on chromatographic results. J. Chromatogr. A. 1131 (1-2), 151-165 (2006).

- Shalliker, R. A., Wong, V., Broyles, B. S., Guiochon, G. Visualization of bed compression in an axial compression liquid chromatography column. J. Chromatogr. A. 977 (2), 213-223 (2002).

- Tallarek, U., Albert, K., Bayer, E., Guiochon, G. Measurement of transverse and axial apparent dispersion coefficients in packed beds. AICHE J. 42 (11), 3041-3054 (1996).

- Camenzuli, M., Ritchie, H. J., Ladine, J. R., Shalliker, R. A. Active flow management in preparative chromatographic separations: A preliminary investigation into enhanced separation using a curtain flow inlet fitting and segmented flow outlet. J. Sep. Sci. 35 (3), 410-415 (2012).

- Shalliker, R. A., Broyles, B. S., Guiochon, G. Physical evidence of two wall effects in liquid chromatography. J. Chromatogr. A. 888 (1-2), 1-12 (2000).

- Shalliker, R. A., Camenzuli, M., Pereira, L., Ritchie, H. J. Parallel segmented flow chromatography columns: Conventional analytical scale column formats presenting as a 'virtual' narrow bore column. J. Chromatogr. A. 1262, 64-69 (2012).

- Camenzuli, M., Ritchie, H. J., Ladine, J. R., Shalliker, R. A. The design of a new concept chromatography column. Analyst. 136 (24), 5127-5130 (2011).

- Foley, D., et al. Precision and Reliability: an Intercontinental Study of Curtain Flow Chromatography. Thermo Scientific. , (2013).

- Pravadali-Cekic, S. Multidimensional Approaches for the Analysis of Complex Samples using HPLC. University of Western Sydney. , (2014).

- Soliven, A., et al. Improving the performance of narrow-bore HPLC columns using active flow technology. Microchem. J. 116, 230-234 (2014).

- Foley, D., et al. Curtain flow chromatography ('the infinite diameter column') with automated injection and high sample through-put: The results of an inter-laboratory study. Microchem. J. 110, 127-132 (2013).

Przedruki i uprawnienia

Zapytaj o uprawnienia na użycie tekstu lub obrazów z tego artykułu JoVE

Zapytaj o uprawnieniaThis article has been published

Video Coming Soon

Copyright © 2025 MyJoVE Corporation. Wszelkie prawa zastrzeżone