Aby wyświetlić tę treść, wymagana jest subskrypcja JoVE. Zaloguj się lub rozpocznij bezpłatny okres próbny.

Method Article

Modeling and Experimental Analysis of the Single-Shaft Coaxial Motor-Pump Assembly in Electrohydrostatic Actuators

W tym Artykule

Podsumowanie

We built a simulation model to evaluate pump flow characteristics and performance of the single-shaft coaxial motor-pump assembly in electrohydrostatic actuators and investigate the overall efficiency in a wide set of working conditions of the motor-pump assembly experimentally.

Streszczenie

An electrohydrostatic actuator (EHA) can be the most promising alternative compared with the traditional hydraulic servo actuators for its high power density, ease of maintenance, and reliability. As the core power unit that determines the performance and service life of the EHA, the motor-pump assembly should simultaneously possess a wide speed/pressure range and a high dynamic response.

This paper presents a method to test the performance of the motor-pump assembly through simulation and experimentation. The flow output characteristics were defined through simulation and analysis of the assembly at the beginning of the experiment, leading to the conclusion of whether the pump could meet the requirements of the EHA. A series of performance tests were conducted on the motor-pump assembly via a pump test bench in the speed range of 1,450-9,000 rpm and the pressure range of 1-30 MPa.

We tested the overall efficiency of the motor-pump assembly under various working conditions after confirming the consistency between the test results of the flow output characteristics with the simulation results. The results showed that the assembly has higher overall efficiency when working at 4,500-7,000 rpm under the pressure of 10-25 MPa and at 2,000-2,500 rpm under 5-15 MPa. Overall, this method can be utilized for determining in advance whether the motor-pump assembly meets the requirements of EHA. Moreover, this paper proposes a rapid test method of the motor-pump assembly in various working conditions, which could assist in predicting EHA performance.

Wprowadzenie

Known as a typically integrated actuator with high power density, the EHA has broad prospects in areas such as aerospace, aviation, construction machinery, and robotics1,2. The EHA mainly consists of a servo motor, pump, cylinder, pressurized reservoir, valve block, mode control valves, module control valves, and sensors, constituting a highly integrated, pump-controlled, closed hydraulic system. The schematic diagram and physical model are shown in Figure 13,4,5,6,7. The motor-pump assembly is the core power and the control component, and it determines the static and dynamic performance of the EHA7.

The conventional motor-pump assembly consists of a separate motor and pump, whose shafts are connected by a shaft coupling8. This structure has significant negative effects on the performance and life of the EHA. First, both the motor and pump will bear a relatively large vibration due to the assembling accuracy, especially at high speed5. Vibration will not only affect the output characteristics of the pump but also accelerate the wear of the friction interfaces in the pump, leading to the failure of the motor-pump assembly9. Second, sealings must be set at the shaft ends of the pump, which cannot fundamentally prevent leakage. Meanwhile, the mechanical efficiency of the motor-pump assembly decreases with increasing friction resistance10. Third, the frequent reversing of the motor-pump assembly will accelerate the wear of the coupling and increase the possibility of fatigue fracture, reducing the system reliability of the EHA11,12.

Thus, a single-shaft coaxial motor-pump assembly within a shared housing was developed to avoid these shortcomings. The structure is shown in Figure 2. A no-coupling design is adopted in this component, which could simultaneously increase the dynamic performance and the lubricating status of the motor and pump. This single-shaft coaxial design ensures the alignment of the two rotors and improves dynamic balance under high-speed conditions. Moreover, shared housing fundamentally eliminates shaft end leakage.

Testing the output characteristics of the EHA motor-pump assembly is of great significance for the optimization and improvement of the EHA performance. However, there are relatively few studies on performance testing of the motor-pump assembly, especially for EHAs. Therefore, we conducted a testing method of combining simulation and experiments. This method is suitable for testing motor-pump assemblies with a wide range of operating conditions, especially EHA pumps.

There are two main challenges: the first is to build an accurate simulation model to analyze the output flow characteristics of the motor-pump and provide assistance for the optimal design of the motor-pump assembly. We have established a simulation model of the motor-pump assembly through hierarchical modeling and realized the simulation analysis of the output flow by changing different parameters. The second is the cavitation of the test element caused by high speed, which is the most important aspect that distinguishes it from ordinary pumps. Therefore, we focused more on the design of the oil supply system when designing the test system to realize the test under various working conditions.

In this protocol, a one-dimensional simulation model was established to simulate the pump flow characteristics initially, judging whether the pump flow characteristics meet the requirements of EHA. Then, the flow characteristics and the overall efficiency were experimentally tested on a dedicated test bench, obtaining the overall efficiency map that cannot be accurately simulated by simulation. Lastly, the pump flow characteristics were compared with the experimental results to verify the accuracy of the simulation results. Meanwhile, the overall efficiency map was obtained to evaluate the performance of the single-shaft coaxial motor-pump assembly.

Protokół

1. Simulation of pump flow characteristics

- Build the simulation model of the motor-pump assembly. Open the AMESim simulation platform and enter the SKETCH mode.

- Build the simulation model for a single piston according to the kinematic mathematic model and the distribution curve (Figure 3). Encapsulate the single-piston model as a super component (Figure 4).

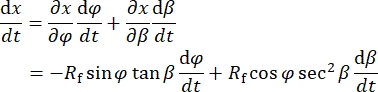

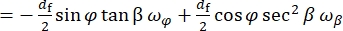

NOTE: The main kinematic mathematic model of the piston (Eq (1)) yields:

(1)

(1)

In this equation, x is the absolute displacement of the piston, β is the swash plate incline angle, φ is the phase angle of the piston, Rf is the distribution radius of the cylinder block, df is the distribution diameter of the cylinder block. - Build the pump model considering the leakage and friction of the valve plate (Figure 4). To build the valve plate module, mainly focus on the viscous friction and throttling effect of the piston/cylinder block interface and slipper/swash plate interface.

- Build the motor model via an ideal torque module (Figure 4). Use an ideal torque module to simulate the motor, ignoring the iron loss, copper loss, and stirring loss of the motor.

- Build the simulation model for a single piston according to the kinematic mathematic model and the distribution curve (Figure 3). Encapsulate the single-piston model as a super component (Figure 4).

- Set the main parameters of the motor-pump assembly model.

- Set the parameters of the motor-pump assembly according to Table 1. Enter the PARAMETER mode and set the main parameters by double-clicking the specific component in the simulation model. Set the rotating speed and test pressure according to Table 2.

- Set the prerun parameters of the model : Start time: 0 s, Final time: 1 s, Print interval: 1 ms.

- Prerun the simulation to achieve the steady state.

- Run the simulation and check whether the system will reach the steady state at the end of the simulation. If the system reaches the steady state, check the use old final values option in the Run Parameters window. If not, reset the Final time in step 1.2.1 to 2 s or even longer and repeat step 1.2.2 until the system reaches the steady state.

- Set the run parameters of the model: Start time: 0 s, Final time: 0.2s, Print interval: 0.002 ms.

- Run the simulation and save the simulation data.

NOTE: Repeat steps 1.2.1-1.2.4 for a specific working condition; save the data after the simulation. - Export the simulation data and plot the flow characteristic contour of the motor-pump assembly in OriginPro. Calculate the value of the pump flow as the average of the pump flow recorded within 0.2 s.

- Determination of output flow characteristics

- Plot the output flow curve of the motor-pump assembly at the maximum speed under different pressure conditions.

- Compute the required output flow rate of the pump according to the specific EHA maximum speed, and plot the required output flow rate curve at different pressure conditions.

- Ensure that the required flow rate curve of the EHA is enveloped by the output flow rate curve of the motor-pump assembly.

2. Establishment of the experimental platform

- Establish the test bench.

- Prepare hydraulic components of the test bench according to Table 3. Ensure that the key parameters of each component meet the requirements listed in Table 3.

- Design and manufacture the hydraulic valve blocks and build a hydraulic system according to the hydraulic schematic diagram (Figure 5). Ensure that the relative positions of components are the same as the schematic diagram shown, and the pressure sensors and temperature sensors are positioned as close to the test point as possible.

NOTE: This series of experiments was conducted on a dedicated high-speed and high-pressure pump load simulation test bench, as shown in Figure 6. - Design and manufacture the tooling and test valve blocks. Ensure that design tooling is according to the specific interface of the tested pump and the test bench.

- Installation of the mechanical interfaces (Figure 7)

- Connect the end face of the motor-pump assembly with the test valve block. Use at least 4 screws to ensure a good sealing performance.

- Fix the motor-pump assembly and the test valve block on the workbench of the test bench (Figure 8). Connect the motor-pump assembly and the test valve block to the dedicated tooling with four screws and the tooling to the workbench with 2 screws.

NOTE: Make sure that the two screws are sufficiently strong so that no vibration appears while conducting the test. - Install two groups of pressure and temperature sensors of port A and port B on the test valve block. Connect these sensors directly to the leakage port for leakage monitoring.

NOTE: It is necessary to design and manufacture different tooling for different tested motor pump assemblies to complete the experiment.

- Connection of the hydraulic interfaces (Figure 7)

- Connect the two high-pressure oil ports of the pump source with port A or B of the test valve block.

- Connect the pressurized oil port with the leakage oil port of the pump.

- Air-exhausting of the motor-pump assembly

- Make sure the relief valve of the oil supply system is in the unloading state. Run the oil supply motor for 3 minutes to exhaust the air of the testing system and warm it.

NOTE: The specific running time is determined according to the specific conditions of the test bench. The main purpose of this step is to ensure that the oil is fully flowing into each component of the testing circuit and the surface temperature of the tested pump is close to the oil temperature.

- Make sure the relief valve of the oil supply system is in the unloading state. Run the oil supply motor for 3 minutes to exhaust the air of the testing system and warm it.

- To check for leaks in the motor-pump assembly, shut off the relief valve of the oil supply system. Adjust the oil supply pressure to 2 MPa for more than 1 min.

NOTE: This will help find out if there is any obvious leakage in the testing system, such as the leakage caused by the failure of the O-ring.- Look for leakage in the motor-pump assembly. If it leaks, first, shut down the hydraulic system and replace the seal, and then repeat steps 2.3 and 2.4. If there is no leakage, open the relief valve of the oil supply system.

- Connection of the electrical interfaces (Figure 9)

- Connect the power supply interface and the rotary signal interface to the motor-pump assembly driver.

- Connect the driver to the controller via RS 442, working in full-duplex mode.

- Connect the driver to 270 VDC power.

- No-load inspection of the motor-pump assembly

- Run the oil supply pump and keep the relief valves of the oil supply and loading systems in the unloading state. Power on the driver and controller and check whether the motor-pump assembly can receive the control command normally.

NOTE: The inlet port of the motor-pump assembly can be pressurized via an oil supply pump, preventing the component from cavitation. - Set an instruction of 2,000 rpm forward to the motor-pump assembly. Observe the working state of the motor-pump assembly and check whether there is leakage at the valve block (see step 2.5).

- Set an instruction of 2,000 rpm reverse to the motor-pump assembly. Observe the working state of the motor-pump assembly and check whether there is leakage at the valve block (see step 2.5).

- Run the oil supply pump and keep the relief valves of the oil supply and loading systems in the unloading state. Power on the driver and controller and check whether the motor-pump assembly can receive the control command normally.

3. Pump flow and overall efficiency test of the motor-pump assembly

- Setting of the oil supply system

- Run the oil supply pump and switch the relief valves of the oil supply system and loading system to the loading state.

- Adjust the oil supply relief valve to the minimum oil supply pressure psmin of 0.6 MPa. Follow steps 3.1.2.1-3.1.2.3 to select psmin.

NOTE: psmin is the pressure in the inlet port of the motor-pump assembly to avoid cavitation.- Adjust the oil supply pressure to 1 MPa or more, which is decided by the tested motor-pump assembly.

- Adjust the rotational speed of the tested motor-pump assembly to 9,000 rpm, making sure that the pump flow is equal to the theoretical pump flow. Otherwise, increase the oil supply pressure to avoid cavitation.

- Reduce the oil supply pressure slowly and record the change of the pump flow. Plot the relative pump flow versus oil supply pressure, and find the inflection point of the pump flow-the oil supply pressure of this point is the minimum oil supply pressure psmin.

- Adjust the load relief valve to psmin.

- Turn on the temperature control system and adjust the oil temperature to 30 °C.

- Turn on the thermal imager to detect the surface temperature of the motor-pump assembly.

- Send control instructions to the motor-pump assembly to make it run continuously at a specific speed (Table 2).

- Adjust the load relief valve and gradually increase the load pressure to a specific value (Table 2). Hold for 4 s at each critical measured pressure.

NOTE: Pay close attention to the motor temperature during the experiment. Ensure the temperature of the motor-pump assembly surface is lower than 100 °C. - After the pressure reaches the specific value of the speed, adjust the load relief valve back to 1 MPa.

- Repeat steps 3.3 and 3.4 until the characteristics of all critical pressure measuring points are tested according to Table 2.

- Export the experimental flow data and plot the pump flow characteristic map of the motor-pump assembly.

- Calculate the overall efficiency ηo of the motor-pump assembly in different working conditions and plot the overall efficiency map.

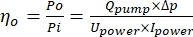

NOTE: The overall efficiency of the motor-pump assembly is given by Eq (2):

. (2)

. (2)

Where Po is the output power of the motor-pump assembly, Pi is the input power of the driver, Qpump is the pump flow; Δp is the pump pressure difference; Upower is the power supply output voltage; Ipower is the power supply output current.

Wyniki

The simulation result of the discharge flow (Figure 10A) indicated that the discharge flow decreased slightly with the increase in load pressure when the speed was constant. Furthermore, the output flow rate increased linearly with increasing speed when the pressure is constant, judging from the same belt width. To directly evaluate the performance of the motor-pump assembly under different working conditions, we plotted its volumetric efficiency diagram (Figure 11A

Dyskusje

When conducting these experimental steps, it is important to make sure that the pressure measuring points are close enough to the oil port of the pump, which would greatly influence the experimental results. In addition, pay attention to the pressure of the inlet port of the motor-pump assembly to ensure that no cavitation exists, especially at high-speed working conditions.

This method enables a dynamic adjustment of oil supply pressure, realizing an accurate simulation of different working c...

Ujawnienia

The authors declare that they have no conflicts of interest.

Podziękowania

This work was supported by Chinese Civil Aircraft Project [No. MJ-2017-S49] and China Postdoctoral Science Foundation [No.2021M700331].

Materiały

| Name | Company | Catalog Number | Comments |

| AmeSim simulation platform | Siemens | Amesim 16 | |

| DAQ card | Advantech | PCI1710 | |

| Flowmeter | KRACHT | VC0.04E1RS, 0.02-4 L/min | |

| Flowmeter | KRACHT | VC0.4E1RS, 0.2-40 L/min | |

| Industrial Computer | Advantech | 610H | |

| Oil supply motor | Siemens | 1TL0001-1BB23-3JA5 | |

| Oil supply pump | Kangbaishi | P222RF01DT | |

| OriginPro | OriginLab Corporation | OriginPro 2021 (64-bit) 9.8.0.200 | |

| Pressure sensor | Feejoy | PI131G(0-5 MPA)F4MCAH5C | |

| Proportional relief valve | Huade hydraulic | DBE10-30B/50YV | |

| Proportional relief valve | Huade hydraulic | DBE10-30B/315YV | |

| Spindle motor | HAOZHI | DGZX-18020 / 22A2-KFHWVJLS | Max speed: 18,000 rpm; Power: 22 kW |

| Temperature sensor | Feejoy | TI-A42M1A180/30+F1 |

Odniesienia

- Yu, B., Wu, S., Jiao, Z., Shang, Y. Multi-objective optimization design of an electrohydrostatic actuator based on a particle swarm optimization algorithm and an analytic hierarchy process. Energies. 11 (9), 2426 (2018).

- Chao, Q., et al. Load-sensing pump design to reduce heat generation of electro-hydrostatic actuator systems. Energies. 11 (9), 2266 (2018).

- Zhao, J., et al. Experimental research on tribological characteristics of TiAlN coated valve plate in electro-hydrostatic actuator pumps. Tribology International. 155, 106782 (2021).

- Zhao, J., et al. Review of cylinder block/valve plate interface in axial piston pumps: Theoretical models, experimental investigations, and optimal design. Chinese Journal of Aeronautics. 34 (1), 111-134 (2021).

- Chao, Q., Zhang, J., Xu, B., Huang, H., Pan, M. A review of high-speed electro-hydrostatic actuator pumps in aerospace applications: challenges and solutions. Journal of Mechanical Design. 141 (5), 050801 (2019).

- Fu, Y., et al. Design and performance analysis of position-based impedance control for an electrohydrostatic actuation system. Chinese Journal of Aeronautics. 31 (3), 584-596 (2018).

- Alle, N., Hiremath, S. S., Makaram, S., Subramaniam, K., Talukdar, A. Review on electro hydrostatic actuator for flight control. International Journal of Fluid Power. 17 (2), 125-145 (2016).

- Chakraborty, I., Mavris, D. N., Emeneth, M., Schneegans, A. A methodology for vehicle and mission level comparison of More Electric Aircraft subsystem solutions: Application to the flight control actuation system. Proceedings of the Institution of Mechanical Engineers, Part G: Journal of Aerospace Engineering. 229 (6), 1088-1102 (2014).

- Zhang, T., He, D. A reliability-based robust design method for the sealing of slipper-swash plate friction pair in hydraulic piston pump. IEEE Transactions on Reliability. 67 (2), 459-469 (2018).

- Guo, S., Chen, J., Lu, Y., Wang, Y., Dong, H. Hydraulic piston pump in civil aircraft: current status, future directions and critical technologies. Chinese Journal of Aeronautics. 33 (1), 16-30 (2020).

- Habibi, S., Goldenberg, A. Design of a new high-performance electrohydraulic actuator. IEEE/ASME Transactions on Mechatronics. 5 (2), 158-164 (1999).

- Xu, B., Hu, M., Zhang, J., Mao, Z. Distribution characteristics and impact on pump's efficiency of hydro-mechanical losses of axial piston pump over wide operating ranges. Journal of Central South University. 24 (3), 609-624 (2017).

Przedruki i uprawnienia

Zapytaj o uprawnienia na użycie tekstu lub obrazów z tego artykułu JoVE

Zapytaj o uprawnieniaThis article has been published

Video Coming Soon

Copyright © 2025 MyJoVE Corporation. Wszelkie prawa zastrzeżone