A subscription to JoVE is required to view this content. Sign in or start your free trial.

Method Article

Characterization of Surface Modifications by White Light Interferometry: Applications in Ion Sputtering, Laser Ablation, and Tribology Experiments

In This Article

Summary

White light microscope interferometry is an optical, noncontact and quick method for measuring the topography of surfaces. It is shown how the method can be applied toward mechanical wear analysis, where wear scars on tribological test samples are analyzed; and in materials science to determine ion beam sputtering or laser ablation volumes and depths.

Abstract

In materials science and engineering it is often necessary to obtain quantitative measurements of surface topography with micrometer lateral resolution. From the measured surface, 3D topographic maps can be subsequently analyzed using a variety of software packages to extract the information that is needed.

In this article we describe how white light interferometry, and optical profilometry (OP) in general, combined with generic surface analysis software, can be used for materials science and engineering tasks. In this article, a number of applications of white light interferometry for investigation of surface modifications in mass spectrometry, and wear phenomena in tribology and lubrication are demonstrated. We characterize the products of the interaction of semiconductors and metals with energetic ions (sputtering), and laser irradiation (ablation), as well as ex situ measurements of wear of tribological test specimens.

Specifically, we will discuss:

- Aspects of traditional ion sputtering-based mass spectrometry such as sputtering rates/yields measurements on Si and Cu and subsequent time-to-depth conversion.

- Results of quantitative characterization of the interaction of femtosecond laser irradiation with a semiconductor surface. These results are important for applications such as ablation mass spectrometry, where the quantities of evaporated material can be studied and controlled via pulse duration and energy per pulse. Thus, by determining the crater geometry one can define depth and lateral resolution versus experimental setup conditions.

- Measurements of surface roughness parameters in two dimensions, and quantitative measurements of the surface wear that occur as a result of friction and wear tests.

Some inherent drawbacks, possible artifacts, and uncertainty assessments of the white light interferometry approach will be discussed and explained.

Introduction

The surface of solid materials determines to a large extent properties of interest for those materials: electronically, structurally, and chemically. In many areas of research, the addition of material (for instance, thin film deposition by pulsed laser/magnetron sputtering deposition, physical/chemical vapor deposition), removal of material (reactive ion etching, ion sputtering, laser ablation, etc.), or some other processes, need to be characterized. Additionally, surface modification through interaction with energetic light pulses or charged particles has numerous applications and is of fundamental interest. Tribology, the study of friction and wear, is another area of interest. On a benchtop scale, a multitude of tribological test geometries exist. Non-conformal contact geometries may be used, and a ball or cylinder may be slid or rotated against a flat surface, another ball, or cylinder, for a length of time, and the amount of material that is removed is measured. Because the wear scar is three-dimensional and irregular in nature, optical profilometry may be the only technique suitable for obtaining accurate wear volume measurements. Common analysis tasks include also surface roughness parameters, step height, loss of material volume, trench depth, and so on; all of them can be obtained additionally to simple 2D and 3D topography visualization.

Optical profilometry refers to any optical method that is used to reconstruct the profile of surfaces. Profilometric methods include white light interferometric, laser, or confocal methods. Some optical profilometers obtain information through approaches based on conventional diffraction-limited microscope objectives. For example, a scanning laser may be integrated with a microscope to obtain topographic and true color information of surfaces. A second method uses a technique which exploits the extremely small depth of focus of conventional objectives to assemble a series of in-focus "image slices" of the surface to obtain a 3D topographic map.

In this work we show how a white light interferometric microscope/profilometer enables the measurement of the amount of material lost during mechanical wear processes, or during material etching processes such as ion sputtering craters or laser ablation. Most attention is paid to methodology of this method to illustrate its large installed capacity that makes it widely available and attractive for numerous applications. Most types of WLI employ the Mirau technique, which uses a mirror internal to the microscope objective to cause interference between a reference light signal and the light reflected from the sample surface. The choice of Mirau interferometry is dictated by simple convenience, because the entire Mirau interferometer can be fit inside the microscope objective lens and coupled to a regular optical microscope (Figure 1). A series of two-dimensional interferograms are acquired with a video camera, and software assembles a 3D topographic map. The white light source supplies broad spectrum illumination which helps to overcome the "fringe order" ambiguity inherent to a monochromatic source. A monochromatic source of light may be used to obtain more accurate measurement of shallow topographic features. The lateral resolution is fundamentally limited to λ/2 (numerical aperture, NA=1), but in most instances is larger, being determined by the NA of the objective, which is in turn connected to magnification/field-of-view size. Table 1 in Ref. 1 has a direct comparison of all mentioned parameters. Depth resolution approaches ≈1 nm, being a function of the interferometric nature of the technique. Further information on Mirau WLI can be found in Refs. 2, 3. An introduction on white light interferometric approach can be found in Ref. 4.

Other methods for analysis of surfaces are atomic force microscopy (AFM), scanning electron microscopy (SEM), and stylus profilometry. The WLI technique compares favorably to these methods and has its own advantages and drawbacks that are due to the optical nature of the method.

The AFM is capable of obtaining 3D images and thus corresponding cross sections, but AFM has a limited scanning ability in the lateral (<100 μm) and depth (<10 μm) axes. In contrast to those, the main advantage of WLI is the flexible field-of-view (FOV) of up to a few millimeters with simultaneous real 3D imaging capability. In addition, as we will demonstrate it has wide vertical scanning range capacity, allowing one to solve a variety of problems of surface modification simply. Researchers who have worked with AFM are aware of the problem with plane positioning of a sample when measuring prolonged features of low vertical gradients. Generally, one may think of WLI/OP as an "express" technique over AFM. Of course, there are a number of areas for which only AFM is suitable: when lateral features to be resolved have characteristic dimensions smaller than the lateral resolution of WLI, or instances where data from WLI is ambiguous due to unknown or complex optical properties of a sample in a way that affects the accuracy of measurements (to be discussed later), etc.

The SEM is a powerful way to look at surfaces, being very flexible in terms of the FOV size with large depth of focus, larger than any conventional optical microscope can offer. At the same time, 3D imaging by SEM is cumbersome, particularly as it requires taking of stereo-pair images that then are converted to 3D images by the anaglyphic method, or through observing with optical viewers, or used for direct calculation of depths between different points of interest on a sample.5 By contrast, WLI/OP profilometry offers easy-to-use 3D reconstruction with simultaneously flexible FOV. WLI scans through the full height range needed for the particular sample (from nanometers to hundreds of microns). WLI is unaffected by the electrical conductivity of the sample material, which may be a problem with SEM. WLI clearly does not require a vacuum. On the other hand there are a number of applications for which SEM provides superior information: lateral features to be resolved of characteristic dimensions below the lateral resolution of WLI, or cases where different parts of a sample can be topographically distinguished only when secondary electron emission coefficients differ.

One more technique for surface inspection, which is widely used in secondary ion mass spectrometry6 and in the field of microelectromechanical systems characterization7 is stylus profilometry. This technique is popular because of its simplicity and robustness. It is based on direct mechanical contact scanning of a stylus tip over the sample surface. This is a coarse contact tool, which is able to scan along a single line at a time. It makes 3D surface raster-scan imaging extremely time consuming. Another drawback of the stylus technique is the difficulty of measuring surface features of high aspect ratio and of size comparable with its characteristic tip size (submicron to several microns typically) that implies a tip radius and a tip apex angle. An advantage of stylus profilometry is its insensitivity to varying optical properties of a sample, which can affect the accuracy of WLI/OP measurements (to be discussed later).

The surface maps in the present article were obtained using a conventional Mirau-type WLI (Figure 1). Many companies such as Zygo, KLA-Tencor, nanoScience, Zemetrics, Nanovea, FRT, Keyence, Bruker, and Taylor Hobson produce commercial table-top OP instruments. The acquired maps were reconstructed and processed using commercial software of the type that is commonly used for WLI, scanning electron, or probe microscopy. The software has the ability to perform mathematical manipulations of the surface, cross section profile analysis, void and material volume calculations, and plane correction. Other software packages may automate some of these features.

Access restricted. Please log in or start a trial to view this content.

Protocol

1. Hardware Alignment for General WLI Scan

To obtain quantitative information through WLI, the following steps may serve as a guideline. It is assumed that the operator has basic knowledge of interferometer operation. The guidelines are common regardless of the specific instrument. For some investigations, the specimen will be flat. For others, the specimen may be curved.

- Place the sample on the stage with the feature (ion sputtered crater, ion beam/ablated spot, or wear scar) facing straight up. Use a low-magnification objective and focus the instrument on it. For best resolution obtain an image in which the object of interest largely fills the screen, see Figure 2 for an example of a ball.

- Adjust the vertical position of the specimen so that interference fringes appear near the feature of interest. For a flat surface it is desirable that the specimen is tilted such that the plane is perpendicular to the optical axis, i.e. the fringe spacing will be large. For a curved surface (e.g. a ball), the specimen should be oriented such that fringes are centrally located around the feature, such as in Figure 3.

- Obtain a scan according to the instrument instructions. It may be necessary to adjust the illumination or scan height in order to obtain the best topographic map. Fill in any bad or missing data using the interpolate function, and then save the topographic map.

2. Volume Analysis Using Generic Software

In tribology, testing machines often employ non-conformal contact testing geometries such as a ball or a cylinder that is slid or rotated against a flat or another cylinder. Typically, material is lost at the point of sliding contact, although sometimes material may transfer from one surface to another, and this "transfer layer" will be measured as a surplus of material on one of the contacting specimens. Because the wear scar is three-dimensional and irregular in nature, optical profilometry may be the only technique suitable for obtaining accurate wear volume measurements - approximations are not valid. The goal is to measure the very small amounts of material which may be lost (or gained) in the contacting region at the completion of a test.

The basic principle of measurement is to define a mathematical plane at the level of the undisturbed surface: surface analysis software assumes that there is a "solid surface" (zero level), whatever above this level is "empty." The analysis function that measures the integrated removed volume below the plane of the "solid surface" will be referred to as "void volume." The function that measures the integrated volume above the plane of the "solid surface" (e.g. an accumulation of debris) will be called the "material volume."

Real undisturbed surfaces are seldom perfectly smooth and flat. For greatest accuracy in measuring small features it is good practice to define an area of interest (AOI); the area outside of which is excluded from analysis. The AOI is used to restrict the measurement area because irregularities in the surface contribute additional volume to the calculations that is not truly from the disturbed area.

3. Flat Surface - Mechanical Wear Analysis

- Volume analysis of a flat surface with a trench scar or depression, whether generated by mechanical wear, ion beam sputtering, or laser ablation, is easy to perform. Obtain an image such as Figure 4 left which shows a mechanical scar on a polished steel surface. Select an AOI that excludes the depression and then use whatever tilt and/or curvature removal function is available to level the undisturbed surface to maximum flatness. Then use the software to set the average surface height to Z=0. Figure 4 right is a pseudocolor view of a scar on a flat surface after these steps. In this view the excluded "void volume" is tinted red. In this color scheme, the dark brown denotes low areas, while orange denotes high areas.

- Delete the AOI. If the software has an automated volume measuring function, place a region of measurement over the scar. In this software, the measuring function will tally the "void and material volume" shown with blue tint in Figure 5. Total wear is "material volume" above the plane subtracted from "void volume." This is the volume change of the disturbed surface. (For software that does not have this function, but does have a histogram, or to clearly visualize which areas are raised above the surface or are below the surface, skip step 3.2 and go to step 3.3.)

The following three steps describe an alternate method of measuring wear volume.

- Invert the AOI from step 3.1 to enable the scar region to be analyzed (the scar is included now).

- Generate a histogram of the data. The histogram is a graph of vertical height on the abscissa vs. the frequency of occurrence on the ordinate. Place one cursor at the Z=0 position (Figure 6 left). This may not be at the peak of the histogram. In this figure the cursors have been set up to selectively analyze only the missing material below the plane. The software integrates the total volume between the two cursors. The red tinted area shows what is omitted. The orange untinted areas in Figure 6 right are below the surface. The histogram function should generate a "void volume" number with the cursors positioned as shown to measure the material lost from the surface.

- Using the same histogram, place the other cursor this time at the Z=0 height position (Figure 7 left), and the other at the opposite end. The orange untinted areas in Figure 7 right are above the surface. The histogram function should generate a "material volume" number, i.e. surplus material raised above the flat surface. Total wear is "material volume" subtracted from "void volume," the same as in step 3.2. The histogram method should give the same wear volume as in step 3.2, but it provides additional details about the distribution of raised and lowered material, and shows a map of the distribution of this area.

In the example above there is no net material lost from the wear scar, instead there is material gain. This is unusual, but sometimes occurs when material transfers from one test counterface to another.

The same "flat surface characterization" approaches are beneficial for obtaining volumes removed in experiments with ion sputtering and laser ablation, considered in examples that follow.

4. Flat Surface - Craters and Ion Beam Profiles Measurements to Estimate Sputtering Yield, and to Perform Time-to-depth Calibration

As an alternative to the known and widely employed method for estimating sputtering yields using mass-loss method, based on direct weighing or quartz microcrystal balance,8, 9 we find that the WLI method is useful for direct visualization of the sputtered ion beam spots/craters obtained by static sputtering/raster scanning of an ion beam. Figure 8 compares longitudinal cross sections of a spot (green solid and blue dotted lines) of a normally incident static 5 keV and 150 eV Ar+ ion beams against their craters (olive open circles and cyan open diamonds) obtained by 100×100 pixels digital raster scanning of the same ion beam over the surface of a Cu(110) single crystal. The curve corresponding to the static beam overlaps one edge of the crater to demonstrate how raster scan of the ion beam generates the crater during sputter depth profiling.

5. Flat Surface - Characterization of Ultrafast Laser Ablation

Ultrafast laser ablation is recognized as a method for removing material from a solid while minimizing the heat affected zone.10 This process enables high rate micromachining with high aspect ratios and minimal damage (cracking, oxidation) to the remaining material, and opens up the possibility of efficient ablation of transparent materials.11 More recently, interest has developed in using ultrafast ablation as an analytical tool.12-15 The high nonlinearity of the ablation process also provides a means of reducing the ablated spot size significantly below the irradiated spot size (as typically defined by 1/e2) and even below the diffraction limit, as has been demonstrated.16 Depth resolution, while not competitive with the best ion beam methods, may be <20 nm. Removal rates can easily be increased nonlinearly by increasing the laser fluence, so that very rapid profiling through microns of material is possible. Ideally, characterizing material removal by ultrafast ablation requires a technique that is fast and quantitative and well calibrated, all characteristics fulfilled by WLI.

Figure 9 shows pseudocolor images of two neighboring craters formed by repetitive ablation of GaAs with an ultrafast (60 fs, 800 nm) laser beam focused to a spot size of ≈8 μm and having fluences corresponding to 0.4 and 1.0 J/cm2.

6. Curved Surfaces - Mechanical Wear Analysis

Volume analysis of a curved regular surface (ball or cylinder) is similar to that of a flat, but requires curvature removal. The following protocol shows an analysis of a circular wear scar on a steel ball. To find the volume lost from a ball it is necessary to do mathematical processing to transform a ball with a flat area into a flat plane with an indentation, then measure the volume of the indentation as was done in Section 3 on flat surfaces. A wear scar on a ball will be measured, first using the simpler automatic technique, then with the histogram technique.

- Figure 10 left shows an isometric view of a wear scar on a ball. Select an AOI that excludes the wear scar, and select the software curve fitting tool that will transform the surface so that it is a worn depression in the middle of an undisturbed flat area. Because curvature removal may be an iterative technique it may be necessary to run the fit several times so that the undisturbed area is flat to nm level accuracy. Any visible non-uniformity outside of the wear scar indicates a problem and the calculation will not be correct. Set the average height outside the scar to Z=0. Figure 10 right shows a pseudocolor view of the scar after curvature removal and setting Z=0 with an AOI properly masking the worn area.

- Use the measuring tool, if available, to analyze the wear, as shown in Figure 11. Total wear volume is "material volume" subtracted from the "void volume."

The following steps describe an alternate method of measuring wear volume.

- In the same manner as step 3.3, invert the AOI so that the wear scar is included. Generate a histogram of the data. Place one cursor at the Z=0 position (Figure 12 left). The orange untinted areas in Figure 12 right are below the surface. The histogram function should generate a "void volume" number.

- Using the same histogram, place the other cursor this time at the Z=0 height position (Figure 13 left), and the other at the opposite end. The orange untinted areas in Figure 13 right are above the surface. The histogram function should generate a "material volume" number. Total wear volume is "material volume" above the plane subtracted from "void volume," the same as in step 3.2. The histogram method should calculate the same wear volume as in step 6.2, but it provides additional details about the distribution of raised and lowered material, and shows a map of the distribution of this area.

Access restricted. Please log in or start a trial to view this content.

Results

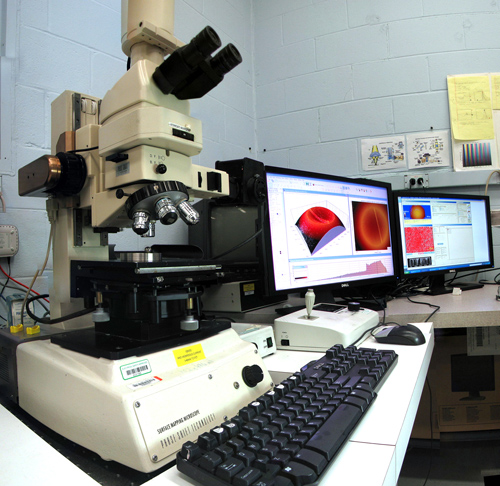

Figure 1. Photograph of a simple profilometer used in the present study: a multiple objective turret is seen in the picture. Two objectives are standard (10x and 50x), and two are Mirau objectives (10x and 50x). This microscope has an intermediate magnification feature that enables step-wise magnification multipliers of 0.62, 1.00, 1.25, or 2.00 to be selected.

Access restricted. Please log in or start a trial to view this content.

Discussion

Example 1

WLI is not widely used for surface characterization in tribological work, but it is in fact a powerful method for quantitative measurement of wear volumes for many contact geometries. WLI produces a full 3D representation of the surface that can be analyzed using any of several visualization software packages. These packages enable various types of measurements to be performed. For greater lateral resolution, images can be "stitched" together to produce wide-area information (several mm...

Access restricted. Please log in or start a trial to view this content.

Disclosures

No conflicts of interest declared.

Acknowledgements

The irradiated GaAs sample was provided by Yang Cui of the University of Illinois at Chicago. This work was supported under Contract No. DE-AC02-06CH11357 between UChicago Argonne, LLC and the U.S. Department of Energy and by NASA through grants NNH08AH761 and NNH08ZDA001N, and the Office of Vehicle Technologies of the U.S. Department of Energy under contract DE-AC02-06CH11357. The electron microscopy was accomplished at the Electron Microscopy Center for Materials Research at Argonne National Laboratory, a U.S. Department of Energy Office of Science laboratory, operated under Contract DE-AC02-06CH11357 by UChicago Argonne, LLC.

Access restricted. Please log in or start a trial to view this content.

Materials

| Name | Company | Catalog Number | Comments |

| Single crystal substrates of Si, GaAs and Cu | for sputtering and ablation | ||

| Pure metal alloys | for tribology examples |

References

- Gao, F., Leach, R. K., Petzing, J., Coupland, J. M. Surface measurement errors using commercial scanning white light interferometers. Meas. Sci. Technol. 19, 015303(2008).

- Cheng, Y. -Y., Wyant, J. C. Multiple-wavelength phase-shifting interferometry. Appl. Opt. 24, 804-807 (1985).

- Kino, G. S., Chim, S. S. C. Mirau correlation microscope. Appl. Opt. 29, 3775-3783 (1990).

- Wyant, J. C. White light interferometry. Proc. SPIE. 4737, 98-107 (2002).

- Sakseev, D. A., Ershenko, E. M., Baryshev, S. V., Bobyl, A. V., Agafonov, D. V. Deep microrelief measurement and stereo photography in scanning electron microscopy. Tech. Phys. 56, 127-131 (2011).

- Morris, R. J. H., Dowsett, M. G. Ion yields and erosion rates for Si1-xGex (0≤x≤1) ultralow energy O2+ secondary ion mass spectrometry in the energy range of 0.25-1 keV. J. Appl. Phys. 105, 114316(2009).

- O'Mahony, C., Hill, M., Brunet, M., Duane, R., Mathewson, A. Characterization of micromechanical structures using white-light interferometry. Meas. Sci. Technol. 14, 1807-1814 (2003).

- Andersen, H. H., Bay, H. L. Sputtering yield measurements. Topics in Applied Physics. Behrisch, R. 47: Sputtering by Particle Bombardment, Springer-Verlag. Berlin, Heidelberg. 145-218 (1981).

- Wu, S. -M., de Kruijs, R. van, Zoethout, E., Bijkerk, F. Sputtering yields of Ru, Mo, and Si under low energy Ar+ bombardment. J. Appl. Phys. 106, 054902(2009).

- Liu, X., Du, D., Mourou, G. Laser ablation and micromachining with ultrashort laser pulses. IEEE J. Quantum Electron. 33, 1706-1716 (1997).

- Gattass, R. R., Mazur, E. Femtosecond laser micromachining in transparent materials. Nature Photonics. 2, 219-225 (2008).

- Russo, R. E., Mao, X., Gonzalez, J. J., Mao, S. S. Femtosecond laser ablation. ICP-MS. J. Anal. At. Spectrom. 17, 1072-1075 (2002).

- Brady, J. J., Judge, E. J., Levis, R. J. Analysis of amphiphilic lipids and hydrophobic proteins using nonresonant femtosecond laser vaporization with electrospray post-ionization. J. Am. Soc. Mass Spectrom. 22, 762-772 (2011).

- Berry, J. I., Sun, S., Dou, Y., Wucher, A., Winograd, N. Laser desorption and imaging of proteins from ice via UV femtosecond laser pulses. Anal. Chem. 75, 5146-5151 (2003).

- Coello, Y., Jones, A. D., Gunaratne, T. C., Dantus, M. Atmospheric pressure femtosecond laser imaging mass spectrometry. Anal. Chem. 82, 2753-2758 (2010).

- Korte, F., Serbin, J., Koch, J., Egbert, A., Fallnich, C., Ostendorf, A., Chichkov, B. N. Towards nanostructuring with femtosecond laser pulses. Appl. Phys. A. 77, 229-235 (2003).

- Fu, Y., Bryan, N. K. A., Shing, O. N., Wyan, H. N. P. Influence analysis of dwell time on focused ion beam micromachining in silicon. Sensors and Actuators A. 79, 230-234 (2000).

- Jiang, F., Li, J., Yan, L., Sun, J., Zhang, S. Optimizing end-milling parameters for surface roughness under different cooling/lubrication conditions. Int. J. Adv. Manuf. Technol. 51, 841-851 (2010).

- Reiter, A. E., Mitterer, C., Figueiredo, M. R., Franz, R. Abrasive and adhesive wear behavior of arc-evaporated Al1-xCrxN hard coatings. Tribol. Lett. 37, 605-611 (2010).

- Devillez, A., Lesko, S., Mozer, W. Cutting tool crater wear measurement with white light interferometry. Wear. 256, 56-65 (2004).

- Shekhawat, V. K., Laurent, M. P., Muehleman, C., Wimmer, M. A. Surface topography of viable articular cartilage measured with scanning white light interferometry. Osteoarthritis and Cartilage. 17, 1197-1203 (2009).

- Hershberger, J., Öztürk, O., Ajayi, O. O., Woodford, J. B., Erdemir, A., Erck, R. A., Fenske, G. R. Evaluation of DLC coatings for spark-ignited, direct-injected fuel systems. Surf. Coat. Technol. 179, 237-244 (2004).

- Ajayi, O. O., Erck, R. A., Lorenzo-Martin, C., Fenske, G. R. Frictional anisotropy under boundary lubrication: Effect of surface texture. Wear. 267, 1214-1219 (2009).

- Wittmaack, K. Analytical description of the sputtering yields of silicon bombarded with normally incident ions. Phys. Rev. B. 68, 235211-23 (2003).

- Zeuner, M., Neumann, H., Scholze, F., Flamm, D., Tartz, M., Bigl, F. Characterization of a modular broad beam ion source. Plasma Sources Sci. Technol. 7, 252-267 (1998).

- Barna, A., Menyhard, M., Kotis, L., Kovacs, G. J., Radnoczi, G., Zalar, A., Panjan, P. Unexpectedly high sputtering yield of carbon at grazing angle of incidence ion bombardment. J. Appl. Phys. 98, 024901(2005).

- Weck, A., Crawford, T. H. R., Wilkinson, D. S., Haugen, H. K., Preston, J. S. Laser drilling of high aspect ratio holes in copper with femtosecond, picosecond and nanosecond pulses. Appl. Phys. A. 90, 537-543 (2008).

- Roosendaal, H. E. Sputtering yields of single crystalline targets. Topics in Applied Physics. ed, I. .,B. ehrisch,R. ., 47: Sputtering by Particle Bombardment, Springer-Verlag. Berlin, Heidelberg. 219-256 (1981).

- Seah, M. P. An accurate semi-empirical equation for sputtering yields II: For neon, argon and xenon ions. Nucl. Instrum. Methods Phys. Res. B. 229, 348-358 (2005).

- Seah, M. P., Clifford, C. A., Green, F. M., Gilmore, I. S. An accurate semi-empirical equation for sputtering yields I: For argon ions. Surf. Interface Anal. 37, 444-458 (2005).

- James Ziegler - SRIM & TRIM [Internet]. , Available from: http://www.srim.org/ (2011).

- Moller, W., Eckstein, W. Tridyn - A TRIM simulation code including dynamic composition changes. Nucl. Instrum. Methods Phys. Res. B. 2, 814-818 (1984).

- Insepov, Z., Norem, J., Veitzer, S. Atomistic self-sputtering mechanisms of rf breakdown in high-gradient linacs. Nucl. Instrum. Methods Phys. Res. B. 268, 642-650 (2010).

- Puech, L., Dubarry, C., Ravel, G., de Vito, E. Modeling of iron oxide deposition by reactive ion beam sputtering. J. Appl. Phys. 107, 054908(2010).

- Ho, S., Tamakoshi, T., Ikeda, M., Mikami, Y., Suzuki, K. Net sputtering rate due to hot ions in a Ne-Xe discharge gas bombarding an MgO layer. J. Appl. Phys. 109, 084908(2011).

- Nakles, M. R. Experimental and Modeling Studies of Low-Energy Ion Sputtering for Ion Thrusters [dissertation]. , Virginia Polytechnic Institute and State University. 1-129 (1988).

- Hada, M., Ninomiya, S., Seki, T., Aoki, T., Matsuo, J. Using ellipsometry for the evaluation of surface damage and sputtering yield in organic films with irradiation of argon cluster ion beams. Surf. Interface Anal. 43, 84-87 (2011).

- Kozole, J., Wucher, A., Winograd, N. Energy deposition during molecular depth profiling experiments with cluster ion beams. Anal. Chem. 80, 5293-5301 (2008).

- Linde, D. vonder, Sokolowski-Tinten, K. The physical mechanisms of short-pulse laser ablation. Appl. Surf. Sci. 154-155, 1-10 (2000).

- Margetic, V., Bolshov, M., Stockhaus, A., Niemax, K., Hergenroder, R. Depth profiling of multi-layer samples using femtosecond laser ablation. J. Anal. At. Spectrom. 16, 616-621 (2001).

- Cui, Y., Moore, J. F., Milasinovic, S., Liu, Y., Gordon, R. J., Hanley, L. Depth profiling and imaging capabilities of an ultrashort pulse laser ablation time of flight mass spectrometer. Rev. Sci. Instrum. 83, 093702(2012).

- Borowiec, A., MacKenzie, M., Weatherly, G. C., Haugen, H. K. Femtosecond laser pulse ablation of GaAs and InP: Studies utilizing scanning and transmission electron microscopy. Appl. Phys. A. 77, 411-417 (2003).

- Harasaki, A., Schmit, J., Wyant, J. C. Offset of coherent envelope position due to phase change on reflection. Appl. Opt. 40, 2102-2106 (2001).

- Luttge, A., Arvidson, R. S. Reactions at surfaces: A new approach integrating interferometry and kinetic simulations. J. Am. Ceram. Soc. 93, 3519-3530 (2010).

- Conroy, M., Mansfield, D. Scanning interferometry: Measuring microscale devices. Nature Photonics. 2, 661-663 (2008).

- Harasaki, A., Wyant, J. C. Fringe modulation skewing effect in white-light vertical scanning interferometry. Appl. Opt. 39, 2101-2106 (2000).

- Roy, M., Schmit, J., Hariharan, P. White-light interference microscopy: Minimization of spurious diffraction effects by geometric phase-shifting. Opt. Express. 17, 4495-4499 (2009).

Access restricted. Please log in or start a trial to view this content.

Reprints and Permissions

Request permission to reuse the text or figures of this JoVE article

Request PermissionThis article has been published

Video Coming Soon

Copyright © 2025 MyJoVE Corporation. All rights reserved