A subscription to JoVE is required to view this content. Sign in or start your free trial.

Method Article

Robotic-based Experimental Procedure for Colorimetric Gas Sensing Development

In This Article

Summary

Here, we present a protocol to develop colorimetric gas sensors using a robotic-based Design-Build-Test-Learn (DBTL) approach. This protocol integrates high-throughput automation, machine learning, and multi-objective optimization to efficiently discover and optimize sensor formulations for detecting gases like CO2, enabling rapid, cost-effective, and precise sensor development.

Abstract

This paper presents a robot-based experimental program aimed at developing an efficient and fast colorimetric gas sensor. The program employs an automated Design-Build-Test-learning (DBTL) approach, which optimizes the search process iteratively while optimizing multiple recipes for different concentration intervals of the gas. In each iteration, the algorithm generates a batch of recipe suggestions based on various acquisition functions, and with the increase in the number of iterations, the values of weighted objective function for each concentration interval significantly improve.

The DBTL method begins with parameter initialization, setting up the hardware and software environment. Baseline tests establish performance standards. Subsequently, the DBTL method designs the following round of optimization based on the proportion of recipes in each round and tests performance iteratively. Performance evaluation compares baseline data to assess the effectiveness of the DBTL method. If the performance improvement does not meet expectations, the method will be performed iteratively; if the objectives are achieved, the experiment concludes. The entire process maximizes system performance through the DBTL iterative optimization process.

Compared to the traditional manual developing process, the DBTL method adopted by this experimental process uses multi-objective optimization and various machine learning algorithms. After defining the upper and lower limits of component volume, the DBTL method dynamically optimizes iterative experiments to obtain the optimal ratio with the best performance. This method greatly improves efficiency, reduces costs, and performs more efficiently within the multi-formulation variable space when finding the optimal recipe.

Introduction

The practical applications of gas sensors are very extensive and have been used in various fields such as environmental monitoring, aerospace, and waste gas treatment1,2,3. The working principle of gas sensors typically relies on multiple mechanisms, such as electrochemistry, gas chromatography, and optical. Among many detection mechanisms, one based on color change has evolved into an acid-base mechanism that stands out uniquely. Due to its low cost and simple application, it is widely used in the design of many portable and disposable gas sensors, such as CO2 sensors1,4,5. This type of sensor uses the color change of certain chemicals to detect gas concentrations. When the gas concentration changes, it causes the sensor material to experience chemical reactions such as ionic complexation or indicator color changes, leading to the change in color of the gas-sensitive dye6. By detecting and analyzing the changes in color, the gas concentration can be measured indirectly. Meanwhile, despite the advantages of low cost and portability, this type of sensor still has some shortcomings, such as a long development cycle and low efficiency7,8,9. At the same time, traditional methods of sensor design struggle to meet multiple sensing characteristics simultaneously, such as achieving the required response time, reversibility, and detection limit. Under the traditional research and development paradigm, these difficulties severely hinder the production and widespread application of colorimetric gas sensors.

In response to the above-mentioned challenges in on-demand research and development, the colorimetric sensor technology developed through this experimental process can address some of the shortcomings of traditional gas sensing. By employing an iterative Design-Build-Test-learning (DBTL) approach10,11, the efficiency of sensor development can be significantly improved, thereby reducing the research and development time and effectively meeting the needs of the research and development1,12. In a typical DBTL development setup, the development of new materials is taken as an iterative feedback loop. The loop contains four key steps: 1. Design of the optimization parameters, targets, and sample the parameter space for a trial experiment; 2. Build the samples of the selected parameters; 3. Test the target value for the built samples; 4. Machine Learning analysis of the target feedback to guide the selection of next batch parameters. In this iterative process, the high-throughput experiment platform that allows for fast building and testing of samples, and the machine learning algorithms are the key components. The automated high-throughput testing platform can simultaneously test up to 384 sensing units, collecting a large amount of high-quality response data. By utilizing machine learning algorithms13,14,15,16,17, such as multi-objective Bayesian optimization, multiple sensing metrics of the sensing units (e.g., sensitivity, response time, and reversibility) can be simultaneously and automatically optimized, thereby improving the overall performance of various sensing characteristics. The sensing unit recipes generated by the optimization algorithm can achieve quantitative CO2 concentration detection without individual calibration, and the root mean square error (RMSE) metric can also meet the required indicators.

Our program is an experimental procedure developed based on colorimetric gas sensing (see Figure 1 for the flowchart). With the development of self-driven labs, the automated DBTL approach has shown excellent prospects due to its high efficiency, speed, and repeatability5,12. The traditional manual development process involves the adjustment of one variable at a timeThe traditional manual development process involves adjusting one variable at a time, followed by modifying another variable to optimize the target parameter and achieve the desired outcome. The primary drawbacks of this process include low efficiency in manual experiments, susceptibility to human error, difficulty in managing multi-dimensional variables in complex high-dimensional scenarios, and a tendency to get stuck in local optima. Compared to the manual development process, the DBTL method adopted in this experimental program uses robotics combined with advanced active learning algorithms such as multi-objective Bayesian optimization. Bayesian optimization is a probabilistic approach for optimizing expensive-to-evaluate objective functions15,18. It builds a surrogate model, often a Gaussian process, to approximate the objective function and uses an acquisition function to decide the next point to sample. The acquisition function balances exploration (searching less-sampled regions) and exploitation (refining known high-performing regions) to efficiently find the global maximum or minimum. This method is particularly useful in high-dimensional, non-convex search spaces where traditional optimization techniques struggle. After roughly defining the upper and lower limits of component content, it dynamically optimizes experiments to obtain the optimal ratio with the best performance iteratively. This method greatly improves efficiency and reduces costs and performs more efficiently within the multi-variable space for developing the optimal recipe5,12.

The overall goal of this article is to establish an experimental procedure based on the automated DBTL method through various computer technologies such as machine learning, multi-object Bayesian optimization, and experimental testing platforms, including the automated liquid handling platform and high-throughput gas testing platform. This will enable the design and research of colorimetric gas sensors. The customized "Opentrons OT-2" liquid handling robot platform is used to complete experiments according to program settings, automatically carrying out steps such as recipe synthesis, mixing, and dipping. The homemade high-throughput gas testing platform is used for gas testing and colorimetric sensor reading in a high-throughput manner, precisely controlling the concentrations of target gases and recording the color changes of the sensing units in real time. Compared with other experimental systems designed based on DBTL, this system has a relatively low hardware cost. Simultaneously, we have partially addressed the aspects of the task that involve human error through a semi-automated approach. providing the maximum marginal benefit while retaining the advantages of DBTL design.

Access restricted. Please log in or start a trial to view this content.

Protocol

1. Preliminary experiment (feasibility test)

NOTE: Based on Zhang's paper8, the relevant variables of chemical colorimetric sensors for the target gas, such as carbon dioxide, can be selected. Before performing the on-demand optimization of the colorimetric sensor formulations, a preliminary experiment using the following procedures can be conducted to establish the variable space.

- Determine the concentration range of the target gas and establish a gas test configuration.

NOTE: The concentration of the target gas within the gas test configuration increases linearly or exponentially. - Before and after the flowing of each concentration of the target gas, purge the testing system with nitrogen. Keep the ratio of the flowing time for nitrogen to the target gas at 1:1.

NOTE: If the concentration of the target gas is <1 ppm, the flowing time is ~10 min; if the target gas concentration is ≥1 ppm, the flowing time is ~5 min. - Prepare the source solutions of variables with solution-appropriate concentrations based on factors such as saturation and viscosity.

NOTE: It is generally advisable to maintain the highest possible concentration of the source solutions. - Set the total volume of the solution of the colorimetric sensor formulation to 400 µL; then, set the volume range for each source solution of the variables according to the literature.

NOTE: The volume ranges for the source solutions of dyes are generally between 0 µL and 200 µL, while the volume ranges for other source solutions are generally between 0 µL and 100 µL. The source solution sampling interval is ~25 µL. - Generate a batch of 96 formulations through random sampling functions to verify the feasibility of detecting the target gas using chemical colorimetry.

- Load the colorimetric sensor formulation file, source solution, tips, 96-well plate, and PTFE membrane into the liquid handler,and sequentially generate independent identity information numbers (Figure 2).

- Set the liquid handler to simulation mode to mimic the operation of synthesizing colorimetric sensor formulations, such as liquid aspirating, dispensing, shaking, and dripping (Figure 3).

- If there are no errors in the simulation state, set the liquid handler to the experiment and start automating the synthesis of colorimetric sensors.

NOTE: The code for automating the process is developed based on the "Opentrons" open-source software package. The synthesis of colorimetric sensors is expected to take 3-6 h. - Place the colorimetric sensors in an oven at 40 °C and heat for 50 min.

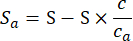

- Place the dried colorimetric sensors in the gas chamber and check the uniformity of the lighting in the testing environment and the airtightness of the testing chamber. Once confirmed to be without issues, use the Mass Flow Controllers (MFC) to automatically control the flow rates of the analyte gas (with concentration ca) and nitrogen (concentration cn), executing the gas testing configuration. Suppose the overall gas flow rate is S in volume/min, and the target analyte concentration is c. the flow rates for the analyte gas MFC and nitrogen MFC in volume/min are

(1)

(1)

(2)

(2) - During the flowing process, positiona camera above the gas chamber to take a photo every 5 s to record the color changes of the colorimetric sensors (Figure 4).

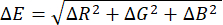

NOTE: The flowing test is expected to be completed in approximately 2 h. - Note that the computer loads the captured images in chronological order, extracts the RGB color values from each colorimetric sensor in each image, and then calculates the differences relative to the baseline color measured prior to exposure to the target gas, thereby plotting a color variation figure of the colorimetric sensors over the flowing time. The formula for calculating the color difference ΔE is shown as Eq (1):

(3)

(3) - Observe whether there are colorimetric sensors exhibiting significant color changes in the target gas and whether the color change values increase in conjunction with an increase in the target gas concentration. If so, the feasibility of using chemical colorimetric sensors to detect the target gas is verified.

- Based on the pre-experimental results, adjust the upper and lower limits of source solutions of the variables and remove source solutions that have an insubstantial effect.

2. Utilize a robotic experimental platform to conduct the Design-Build-Test-Learn (DBTL) iterative optimization process

- Design: Set up multi-objective functions and generate colorimetric sensor formulations.

- Set up a multi-objective function to calculate the weighted evaluation score for multiple figures of merit of the colorimetric sensors (Figure 5).

NOTE: The detail of the weighted evaluation score can be found in the reference1. - If the DBTL optimization is in the initial round, then randomly generate 96 initial colorimetric sensor formulations and create a campaign ID for this optimization task.

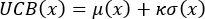

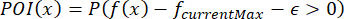

- If the DBTL is in the second or later rounds, design the next batch of 96 colorimetric sensor formulations using different acquisition functions (such as Upper Confidence Bound, Probability of Improvement, and Expected Improvement). Additionally, fine-tune the hyperparameters of the acquisition function in each round. Generally, κ as the hyperparameter for UCB, with a value not exceeding 5 and

serves as the hyperparameter for EI and POI, which gradually decreases to near 0 as the optimization iterations increase. The following three equations (4), (5), and (6) respectively illustrate the acquisition functions for UCB, EI, and POI:

serves as the hyperparameter for EI and POI, which gradually decreases to near 0 as the optimization iterations increase. The following three equations (4), (5), and (6) respectively illustrate the acquisition functions for UCB, EI, and POI:

(4)

(4)

(5)

(5)

(6)

(6)

Where μ(x) is the mean; σ(x) is the variance; κ, are parameters that balance exploration and exploitation, controlled by the iteration round and decay rate; f(x) is the weighted evaluation score; fcurrentMax is the current highest weighted evaluation score.

are parameters that balance exploration and exploitation, controlled by the iteration round and decay rate; f(x) is the weighted evaluation score; fcurrentMax is the current highest weighted evaluation score. - After generating colorimetric sensor formulations in each non-initial round, observe whether these colorimetric sensor formulations exhibit high expectations or high uncertainty. If not, repeat the operation of step 2.1.3. If so, perform the build step.

- Set up a multi-objective function to calculate the weighted evaluation score for multiple figures of merit of the colorimetric sensors (Figure 5).

- Build: Automatically synthesize colorimetric sensors. See details in steps 1.7-1.10.

- Test: Let the automated testing of colorimetric sensors proceed. See details in steps 1.11-1.13.

- Learn: Fit Surrogate model

- Use the colorimetric sensor formulation variables and their weighted evaluation scores as the input and output of the surrogate model, respectively.

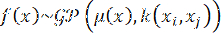

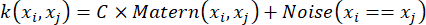

- Use a Gaussian process regression with the mean function for k(xi, xj) and the covariance function (kernel) k(xi, xj) to fit the surrogate model.

NOTE: Figure 6 shows the surrogate model for one- and two-dimensional variables. In the developed Gaussian process fitting algorithm, an anisotropic Matérn kernel combined with a white noise kernel (see following two equations, Eq (7) and Eq (8)) is chosen to ensure the generality of the kernel function.

(7)

(7)

(8)

(8)

- Optimization termination criteria: Note that the DBTL optimization stops when the number of iterations reaches a preset value, or when there is no significant improvement in the weighted scores of the generated colorimetric sensors.

3. Construction and characterization of the optimal colorimetric sensor array

- For the six concentration intervals of the target gas, carry out n DBTL optimization campaigns to discover six globally optimal or quasi-optimal colorimetric sensor formulations. Within each concentration interval, the optimized colorimetric sensor formulation exhibits the highest weighted evaluation score in the target gas testing.

- Utilize the liquid handler to construct approximately the colorimetric sensor arrays composed of the six optimized colorimetric sensor formulations. Steps 1.7-1.10 detail the specific operation using the liquid handler.

- Shelf-life testing:

- Construct 14 colorimetric sensor arrays and divide them into two groups. Store one group in an open condition at 25 °C and the other in a vacuum.

- Maintain consistent testing conditions and perform daily response tests over a 7 day period to evaluate the impact of the two storage conditions on the performance of the colorimetric sensor array, thereby inferring the shelf life under both storage strategies.

4. Calibration of the colorimetric sensor array

- For colorimetric sensor array construction, see details in steps 3.1-3.2.

- Data sampling:

- Select 5-10 concentration values at equal intervals for each concentration range of the target gas, with a total of no less than 20 different concentrations.

- Expose the colorimetric sensor array to the target gas according to the concentration value in ascending or descending order and record the response values of the colorimetric sensor array.

NOTE: Five to 10 CO2/N2 cycles were needed for each CO2 concentration.

- Sensing data recording: After exposing to the target gas at various concentrations for 5 or 10 min, extract R, G, and B channel values of n colorimetric sensors from the colorimetric sensor array as features to input into the calibration model. The feature vector contains 3 × n dimensions.

- Dataset division: Based on the number of concentrations of the target gas, divide the response data at different concentrations into the training set, validation set, and test set in a 7:1.5:1.5 ratio.

- Model training: First, use the Python packages, such as scikit-learn and torch, to construct four machine learning regression models for calibration: Ridge, Random Forest, Xgboost, and Deep Neural Network. Then, set the root mean square error as the loss function. Finally, load the dataset and start training the calibration model.

- Model selection: Validate the performance of the four machine learning regression models using the validation set and select the model with the smallest root mean square error as the final calibration model.

- Model testing: Use the test set to perform a performance test on the final calibration model, evaluating the performance of the colorimetric sensor array and the calibration model for quantitative analysis of the target gas.

Access restricted. Please log in or start a trial to view this content.

Results

A typical example of this experimental setup is the "Wide-Range High-Sensitivity Colorimetric CO2 Sensor Array"12. First, the experiment generates a chart based on the change in ΔE over time at a fixed CO2 concentration after Bayesian multi-objective optimization (Figure 7A). Based on its poor response time, ΔE, and reversibility, unnecessary 1 (slow response time), unnecessary 2 (non-responsive), and unnecessary 3 (baseline dri...

Access restricted. Please log in or start a trial to view this content.

Discussion

This article proposes an experimental design that can develop colorimetric gas sensors more quickly and accurately. This experimental process can be used to develop colorimetric sensors for various gases, such as humidity, CO2, and ammonia1,4,5. Through the method of this platform, it can meet the needs of users with various preferences, such as high sensitivity, low detection limit, required response time, considerin...

Access restricted. Please log in or start a trial to view this content.

Disclosures

The authors have no conflicts of interest to declare.

Acknowledgements

This work is supported by the Natural Science Foundation of Zhejiang Province (LQ24F040006) and startup fund of Shenzhen University of Advanced Technology.

Access restricted. Please log in or start a trial to view this content.

Materials

| Name | Company | Catalog Number | Comments |

| 96-Well Deep Well Plate | NEST | NEST 2 mL 96-Well Deep Well Plate, V Bottom | |

| 96-Well PCR Plate | NEST | NEST 0.1 mL 96-Well PCR Plate | |

| cresol red | sigma aldrich | 1.05225 | Dyes for colorimetric reagents |

| Ethyl cellulose | sigma aldrich | 200689 | Dyes for colorimetric reagents |

| Ethyl cellulose | Aladdin | E110670-100g | Additive |

| Industrial Camera | HKVision | MV-CS060-10UM/C-PRO | used for recording color changes |

| Liquid handler | Opentrons | OT2 | liquid handler |

| Mass Flow Controller | ASERT | AST10-DLCMX-500C-042-A2B2-48VY | used in controlling analytes gas mixtures |

| m-cresol purple | sigma aldrich | 1.05228 | Dyes for colorimetric reagents |

| Opentrons OT-2 Tips | Opentrons | OT-2 Tips, 300µL | |

| Opentrons OT-2 Tips | Opentrons | OT-2 Tips, 20µL | |

| phenol red | sigma aldrich | 1.07241 | Dyes for colorimetric reagents |

| polyethylene glycol | sigma aldrich | P1458 | Dyes for colorimetric reagents |

| PTFE film | Interstate Specialty Products | PM15M | PTFE mambrane |

| Tetrabutylammonium hydroxide | sigma aldrich | 86854 | Base for colorimetric reagents |

| thymol blue | sigma aldrich | 1.08176 | Dyes for colorimetric reagents |

References

- Chen, Y., et al. Robot-accelerated development of a colorimetric CO2 sensing array with wide ranges and high sensitivity via multi-target Bayesian optimizations. Sensors and Actuators B: Chemical. 390, 133942(2023).

- Cho, S. H., Suh, J. M., Eom, T. H., Kim, T., Jang, H. W. Colorimetric sensors for toxic and hazardous gas detection: A review. Electron Mater Lett. 17 (1), 1-17 (2021).

- Li, Z., Askim, J. R., Suslick, K. S. The optoelectronic nose: Colorimetric and fluorometric sensor arrays. Chem Rev. 119 (1), 231-292 (2019).

- Ai, Z., et al. On-demand optimization of colorimetric gas sensors using a knowledge-aware algorithm-driven robotic experimental platform. ACS Sens. 9 (2), 745-752 (2024).

- Ai, Z., et al. Customizable colorimetric sensor array via a high-throughput robot for mitigation of humidity interference in gas sensing. ACS Sens. 9 (8), 4143-4153 (2024).

- Evyapan, M., Dunbar, A. D. F. Improving the selectivity of a free base tetraphenylporphyrin based gas sensor for NO2 and carboxylic acid vapors. Sensors and Actuators, B: Chemical. 206, 74-83 (2015).

- Liu, B., Zhuang, J., Wei, G. Recent advances in the design of colorimetric sensors for environmental monitoring. Environ Sci: Nano. 7 (8), 2195-2213 (2020).

- Zhang, Y., Lim, L. -T. Colorimetric array indicator for NH3 and CO2 detection. Sensors and Actuators B: Chemical. 255, 3216-3226 (2018).

- Xu, W., et al. Non-destructive determination of beef freshness based on colorimetric sensor array and multivariate analysis. Sensors and Actuators B: Chemical. 369, 132282(2022).

- Abolhasani, M., Kumacheva, E. The rise of self-driving labs in chemical and materials sciences. Nat Synth. 2 (6), 483-492 (2023).

- Hickman, R. J., Bannigan, P., Bao, Z., Aspuru-Guzik, A., Allen, C. Self-driving laboratories: A paradigm shift in nanomedicine development. Matter. 6 (4), 1071-1081 (2023).

- Chen, Y., et al. Robot-assisted optimized array design for accurate multi-component gas quantification. Chem Eng J. 496, 154225(2024).

- Antonova, R., Rai, A., Li, T., Kragic, D. Bayesian optimization in variational latent spaces with dynamic compression. , (2019).

- Balandat, M., et al. BoTorch: A framework for efficient Monte-Carlo Bayesian optimization. , http://arxiv.org/abs/1910.06403 (2020).

- Frazier, P. I. A tutorial on Bayesian optimization. , (2018).

- Zhang, L., et al. Navigating the complexity of hybrid materials without structural dependency: PerovGNN as a map. Acta Materialia. 281, 120437(2024).

- Uplift modeling based on Graph Neural Network combined with causal knowledge. Wang, H., et al. Proceedings - 2024 IEEE Conference on Artificial Intelligence, CAI 2024, , 1487-1492 (2024).

- Häse, F., Roch, L. M., Kreisbeck, C., Aspuru-Guzik, A. Phoenics: A Bayesian optimizer for chemistry. ACS Cent Sci. 4 (9), 1134-1145 (2018).

- Wadekar, D., et al. Augmenting astrophysical scaling relations with machine learning: Application to reducing the Sunyaev-Zeldovich flux-mass scatter. Proc Natl Acad Sci U S A. 120 (12), e2202074120(2023).

- Han, N., Tian, Y., Wu, X., Chen, Y. Improving humidity selectivity in formaldehyde gas sensing by a two-sensor array made of Ga-doped ZnO. Sensors and Actuators, B: Chemical. 138 (1), 228-235 (2009).

- Bae, G., et al. Impact of a diverse combination of metal oxide gas sensors on machine learning-based gas recognition in mixed gases. ACS Omega. 6 (36), 23155-23162 (2021).

- Mahboubifar, M., Hemmateenejad, B., Jassbi, A. R. Evaluation of adulteration in distillate samples of Rosa damascena Mill using colorimetric sensor arrays, chemometric tools and dispersive liquid-liquid microextraction-GC-MS. Phytochem Anal. 32 (6), 1027-1038 (2021).

- Cao, Y., Yu, H., Abbott, N. L., Zavala, V. M. Machine learning algorithms for liquid crystal-based sensors. ACS Sens. 3 (11), 2237-2245 (2018).

- Mahata, B., Acharyya, S., Banerji, P., Guha, P. K. Assessment of fish adulteration using SnO2 nanopetal-based gas sensor and machine learning. Food Chem. 438, 138039(2024).

- Zhang, N., et al. Switchable operating modes enable low power consumption and improved gas sensing efficiency in MoS2/BP heterojunction. Sensors and Actuators B: Chemical. 396, 134620(2023).

- Amarbayasgalan, T., Pham, V. H., Theera-Umpon, N., Piao, Y., Ryu, K. H. An efficient prediction method for coronary heart disease risk based on two deep neural networks trained on well-ordered training datasets. IEEE Access. 9, 135210-135223 (2021).

- Xu, Q., Jiang, J. Recent development in machine learning of polymer membranes for liquid separation. Mol Syst Des Eng. 7 (8), 856-872 (2022).

- Kimani, S. W., et al. Discovery of a novel DCAF1 ligand using a drug-target interaction prediction model: Generalizing machine learning to new drug targets. J Chem Inf Model. 63 (13), 4070-4078 (2023).

- Xiao, J., Hobson, J., Ghosh, A., Haranczyk, M., Wang, D. Y. Flame retardant properties of metal hydroxide-based polymer composites: A machine learning approach. Composites Communications. 40, 101593(2023).

Access restricted. Please log in or start a trial to view this content.

Reprints and Permissions

Request permission to reuse the text or figures of this JoVE article

Request PermissionExplore More Articles

This article has been published

Video Coming Soon

Copyright © 2025 MyJoVE Corporation. All rights reserved