A subscription to JoVE is required to view this content. Sign in or start your free trial.

Method Article

Lab-Scale Model to Evaluate Odor and Gas Concentrations Emitted by Deep Bedded Pack Manure

In This Article

Summary

A protocol has been developed to measure gases, odors, and nutrient composition in lab-scaled bedded manure packs, which can be used to study ways to improve air quality in commercial cattle facilities using deep-bedded manure packs.

Abstract

A lab-scaled simulated bedded pack model was developed to study air quality and nutrient composition of deep-bedded packs used in cattle mono-slope facilities. This protocol has been used to effectively evaluate many different bedding materials, environmental variables (temperature, humidity), and potential mitigation treatments that can improve air quality in commercial deep-bedded mono-slope facilities. The model is dynamic and allows researchers to easily collect many chemical and physical measurements from the bedded pack. Weekly measurements, collected over the course of six to seven weeks, allows sufficient time to see changes in air quality measurements over time as the bedded pack matures. The data collected from the simulated bedded packs is within the range of concentrations previously measured in commercial deep-bedded mono-slope facilities. Past studies have demonstrated that 8 - 10 experimental units per treatment are sufficient to detect statistical differences among the simulated bedded packs. The bedded packs are easy to maintain, requiring less than 10 minutes of labor per bedded packs per week to add urine, feces, and bedding. Sample collection using the gas sampling system requires 20 - 30 minutes per bedded pack, depending on the measurements that are being collected. The use of lab-scaled bedded packs allows the researcher to control variables such as temperature, humidity, and bedding source that are difficult or impossible to control in a research or commercial facility. While not a perfect simulation of "real-world" conditions, the simulated bedded packs serve as a good model for researchers to use to examine treatment differences among bedded packs. Several lab-scale studies can be conducted to eliminate possible treatments before trying them in a research or commercial-sized facility.

Introduction

Beef cattle confinement facilities are a popular housing option in the Midwest and Upper Great Plains. Confinement facilities are more common in this region than the Southern Plains because the region receives more annual precipitation, which creates more feedlot runoff that must be contained. Many producers chose to build mono-slope barns for beef cattle. The primary reasons cited by producers for selecting a mono-slope facility was the ability to schedule labor and manure removal, and improved performance compared to open lot feedlots1. A majority of cattle producers (72.2%) using mono-slope barns maintain a bedded pack for one turn of cattle or longer, using a deep-bedding management system for bedding and waste1. The most common bedding material used is corn stover, although producers report using soybean stubble, wheat straw, corn cobs, and sawdust1. Because of the regional demand for corn stover bedding, many producers were interested in alternative bedding materials that could be used in mono-slope facilities. In addition to economics and animal comfort, producers questioned how the bedding material would impact the environment of the facility, including the production of odorous gases, nutrient composition of the resulting manure/bedding, and presence of pathogens.

Few studies have been conducted to measure air quality resulting from different bedding materials used in livestock housing, with most focusing only on ammonia. Most of the previous evaluations of air quality include on-farm data collection with one or two experimental units per treatments being analyzed at once2,3,4,5. Having limited numbers of experimental units requires the study to be repeated multiple times, thus adding additional variables such as weather conditions, age or stage of production of animals, and perhaps bedding materials produced in different growing seasons.

With no known lab-scaled model to study factors affecting air quality and nutrient composition of the manure/bedding mixture resulting from beef deep-bedded mono-slope facilities, researchers first attempted to utilize commercial cattle facilities using a deep-bedded system6,7,8. Static flux chambers were used to measure NH3 concentrations on the surface of mono-slope deep bedded cattle facilities over an 18 month period6. Two pens in each of two barns were measured. Chopped corn stalks were the preferred bedding material, but wheat straw and soybean stalks were also used for bedding during brief periods of this project. Bedding use ranged from 1.95 - 3.37 kg per animal per day and pen density ranged from 3.22 - 6.13 m2 per animal. Subsequent studies measured ammonia and hydrogen sulfide emissions from the barn7, and particulate matter concentrations outside the barn8. These studies were conducted over a 2 year period using two to four barn locations. The challenge with on-farm data collection is the lack of control that the research has over the system. Producers change cattle diets, move animals from pen to pen, use bedding materials from different sources, and clean and re-bed pens as their production and labor force allows, thus confounding many variables. On-farm research also involves travel expenses and large quantities of experimental treatments (such as bedding material). The objective of this project was to develop a lab-scale model that could be used to study factors affecting air quality and nutrient management in cattle deep-bedded mono-slope facilities.

Protocol

The study is designed to be conducted over 42 days with weekly data collection. All animal procedures were reviewed and approved by the US Meat Animal Research Center Institutional Animal Care and Use Committee.

1. Constructing Simulated Bedded Packs

- Begin with plastic cylinder containers that are 0.42 m high with a 0.38 m diameter.

NOTE: In this study, one particular 10-gallon commercial trash container was used (see Table of Materials), but other similar-sized plastic containers would be suitable. - Drill six 1-cm holes equally spaced around the circumference of the plastic container into each plastic container approximately 5 cm the top of the plastic container. Remove any plastic remnants from the container.

- Tare the plastic container and record the mass on the side of the plastic container. Weigh 320 g of selected bedding material into weigh pan using a balance and add bedding material to the plastic container.

NOTE: Any bedding material deemed suitable for use in livestock facilities can be used9,10,11,12,13,14,15. For modeling deep bedded cattle facilities in the Upper Great Plains, corn stover is considered the most common bedding material1 but soybean stover, wheat straw, and wood chips have also been used1. If using this system to model deep-bedded swine or dairy facilities, wheat straw, barley straw, oat straw, hay, wood shavings, wood chips, sawdust, newspaper, corn cobs, soybean stubble, rice hulls, or sand may be more suitable16,17,18. - Weigh 320 g of fresh cattle feces on a plastic plate using balance and add to the plastic container.

NOTE: Urine and feces are collected and maintained as previously described11. - Measure 320 mL of fresh cattle urine in 1000-mL graduated cylinder. Empty contents into the plastic container. Using a stirring rod (5.08-cm circumference), mix the bedding material mixture slightly for 30 s.

NOTE: In this case, a hollow steel rod with a plastic cover on the end was used. Alternatively, any type of rod could be used. - Clean the end of the stirring rod between each bedded pack using an antiseptic disposal wipe to prevent cross-contamination of microbes.

NOTE: A bucket of warm soapy water can also be used to clean the stirring rod. A plastic sandwich bag can also be secured with a rubber band to the end of the rod and replaced after each bedded pack to prevent cross contamination. - Weigh and record the final mass of the bedding mixture. Place the plastic container in the environmental chamber19 set to an ambient temperature of 18 - 20 °C with a dew point of 12 °C.

2. Maintaining the Simulated Bedded Packs

- Forty-eight hours before adding feces and urine, remove frozen feces and urine from freezer and allow to thaw at room temperature (20 - 25 ˚C).

- Less than an hour before adding urine to bedded pack, measure the pH of the urine.

- Put on appropriate personal protective equipment (gloves, safety glasses) necessary for handling 6 M NaOH.

- Pour 25 mL of 6 M sodium hydroxide (NaOH) into the graduated cylinder. Stir the mixture, then test the pH using a pH probe. Repeat until the urine reaches pH 7.4, physiological pH20.

- Once the pH of the urine is adjusted, replace cap on the urine container when not in use to prevent volatilization of nitrogen from urine.

- Weigh and record the mass of the bedded pack. If fresh bedding is to be added on this day, weigh 320 g of selected bedding material into aluminum pan using balance and add bedding material to the respective bedded packs. If no bedding is to be added on this day, continue to Step 2.7.

- Weigh 320 g of thawed cattle feces on a plastic plate using balance and add to the bedded pack.

NOTE: On Day 21, use fresh feces instead of thawed feces. - Measure 320 mL of thawed cattle urine in 1000-mL graduated cylinder. Empty contents onto the bedded pack.

NOTE: On Day 21, use fresh urine instead of thawed urine. - Using a stirring rod, stir the bedding pack mixture slightly for 30 seconds. Clean the plastic end of the stirring rod between each bedded pack to prevent cross-contamination of microbes. Weigh and record the final mass of the bedding mixture.

- Return the plastic container in the environmental chamber.

- Repeat steps 2.1 - 2.10 on Monday, Wednesday, and Friday of each week, with bedding material being added (Step 2.6) and air samples collected each Wednesday.

3. Collecting Samples from the Simulated Bedded Packs

NOTE: Samples are collected from the simulated bedded packs once weekly, prior to adding feces, urine, and fresh bedding.

- Preparing to collect air samples from headspace of each simulated bedded pack.

- Turn on all air sampling equipment and allow to warm up according to manufacturer's directions, approximately 1 hour.

NOTE: See Table of Materials for ammonia (NH3), hydrogen sulfide (H2S), methane (CH4), nitrous oxide (N2O) and carbon dioxide (CO2) gas analyzers used in this study. - Measure the distance from the top of the simulated bedded pack to the top of the plastic container holding the simulated bedded pack using a ruler.

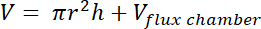

- Calculate the volume of the headspace area using the following formula:

where r = radius of the plastic container,

h = distance from the top of the bedded pack to the top of the plastic container, and

Vflux chamber = volume of the flux chamber located on top of the plastic container.

NOTE: The flux chambers used in this study had an internal volume of 0.007m3 with a surface area of 0.064 m21,22. - Push a metal stake approximately 5 cm into surface of the bedded pack at the approximate center of the pack. Thread 0.64-cm inert tubing through one of the 1-cm holes at the top of each simulated bedded pack container and secure on a 12.5-cm metal stake 1.3 cm above the surface of the bedding pack. Place stainless steel hemispherical static flux chambers21,22 with rubber skirts on top of each simulated bedded pack (Figure 1).

NOTE: Rubber skirts are 61-cm squares made of soft, elastic rubber with 22.9-cm diameter holes cut in the center. The hole fits over the flux chamber and the skirts form a seal on the top of the plastic container when placed on the container. - Attach 0.64-cm inert tubing to the flux chambers using inert compression fittings.

NOTE: The inert tubing is attached to the gas sampling manifold which feeds into the air sampling equipment. The gas sampling system is controlled by a 24-volt Programmable Logic Relay (see Table of Materials) which signals multi-positional 3-way solenoids to open and close one of eight air inlet lines on the gas sampling manifold. One line is opened at a time to allow for individual air sampling from each bedded pack. - Begin flushing ambient air from the room through the tubing at a rate of 5 L min-1 for 30 minutes.

NOTE: See Table of Materials for pump used to flush the air through the sample lines.

- Turn on all air sampling equipment and allow to warm up according to manufacturer's directions, approximately 1 hour.

- Measure concentration of ammonia, carbon dioxide, methane, and hydrogen sulfide in headspace of simulated bedded packs.

- After adequately flushing the simulated bedded packs, open stopcock on sample line to draw ambient air from the room into inert sample lines connected to gas sampling manifold.

- Activate the programmable logic relay to begin pulling air into the air sampling equipment. Record measurements from ambient air for 20 minutes to determine concentration of measured gases in ambient air. This will be used as a background air concentration. When finished collecting ambient air concentration, close the stopcock on the sample line.

- Activate the programmable logic relay to begin sampling air from the inert sample lines attached to each flux chamber. Record measurements from each sample line for 20 minutes to determine concentrations of measured gases in the headspace of each bedded pack.

- Results can be reported as the average concentration of the gas (NH3, CO2, N2O, CH4, H2S) in the air samples (mg kg-1 or ppm), or the flux density (emission rate) of the gas can be calculated on a mass per unit area per unit time basis using the following equation:

where J = the flux in µg m-2 min-1,

A = the area of the source (m2) inside the chamber,

Q = the sweep air flow rate m3 min-1, and

Cair = the VOC concentration leaving the chamber (µg m-3)23.

- Measure concentration of odorous volatile organic compounds in the headspace of simulated bedded packs.

- Put on latex or nitrile disposable gloves.

- After adequately flushing the simulated bedded packs, remove brass storage caps from preconditioned stainless steel sorbent tubes.

NOTE: The sorbent tubes used in this study were 89 mm × 6.4 mm OD filled with Tenax TA sorbent (see Table of Materials). Brass caps have polythtrafluorethylene (PTFE) ferrules. - Attach the scored end of the sorbent tube to the inlet port on the flux chamber using flexible rubber tubing, and the other end of the sorbent tube to a vacuum pump.

NOTE: The vacuum pump used in this study (see Table of Materials) pulled air through the sorbent tubes at a flow rate of 75 mL min-1. - Allow the pump to pull air into the sorbent tube for 5 min for a sample volume of 0.375 L, then turn off pump and disconnect sorbent tube. Replace the brass storage caps on the ends of the sorbent tubes.

- Repeat Steps 3.3.1 - 3.3.4 to collect one sorbent tube for each bedded pack.

- Store sorbent tubes until analysis by thermal desorption-gas chromatograph-mass-spectrometry (TD-GC-MS). Tubes may be stored at room temperature (20 - 25 ˚C) for <24 h. If storing >24 h, store in refrigerator.

- Immediately before sample analysis on the TD-GC-MS system, remove brass storage caps from sorbent tubes and replace with PTFE analytical caps23.

- Analyze sorbent tubes for volatile organic compounds24 (acetic acid, butyric acid, propionic acid, isobutyric acid, isovaleric acid, valeric acid, hexanoic acid, heptanoic acid, phenol, p-cresol, indole, skatole, dimethyl disulfide, and dimethyl trisulfide) using TD-GC-MS23,24,25.

- Results can be reported as concentration of the VOC in the air samples (µg m-3), or the flux density (emission rate) of the VOC can be calculated on a mass per unit area per unit time basis using the following equation:

where J = the flux in µg m-2 min-1,

A = the area of the source (m2) inside the chamber,

Q = the sweep air flow rate m3 min-1, and

Cair= the VOC concentration leaving the chamber (µg m-3)23.

- Collect physical and chemical measurements of the simulated bedded packs.

NOTE: Temperature, pH, and evaporative water loss are measured each time additional materials were added to the simulated bedded packs. Nutrient composition is determined at Day 0 and Day 42. Free air space is determined at Day 42 only.- Determine the temperature of the bedded pack by inserting a temperature probe into the center of the bedded pack, approximately 7.6 cm below the surface of the simulated bedded pack. Allow the temperature to stabilize and record.

- Determine estimated evaporative water loss

- Place the plastic container on the balance.

- Measure and record the mass of the simulated bedded pack before and after each addition of feces/urine/bedding to the simulated bedded pack.

- Calculate the estimated evaporative water loss by subtracting the current day's beginning mass from the previous day's ending mass. The difference is the estimated mass of water that evaporated from the bedded pack between the days and can be used to compare relative differences between bedded pack, although it does not reflect absolute loss.

- Determine pH of simulated bedded pack

- Collect a representative 5 - 10 g sample from each simulated bedded pack from the center of the pack at a depth of approximately 7.6 cm below the surface of the bedded pack. Put the sample in a plastic 50-mL conical tube, cap, and label.

- Calibrate the pH meter with buffers pH 4 and 7 according to manufacturer's directions.

- Determine the mass of each conical.

- Dilute each sample 1:2 on a mass basis with distilled, deionized water. Shake the conical to mix the water and bedding material. Insert the pH probe into the conical, measure, and record the pH of the sample.

- On Days 0 and 42 only, determine nutrient content of the simulated bedded pack.

- Collect a 50 g representative sample from each simulated bedded pack from the center of the pack at a depth of approximately 7.6 cm below the surface of the bedded pack. Place in a paper soil sample bag.

- Transport to a laboratory for nutrient analysis within 24 hours. Store in refrigerator until samples can be transported to a laboratory for nutrient analysis.

NOTE: Any macro or micro nutrient can be analyzed. We analyze for total nitrogen26, phosphorus and sulfur analysis27 at a commercial laboratory.

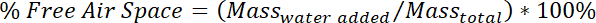

- On Day 42 only, determine free air space in simulated bedded pack.

- Place the plastic container on a balance and record the mass. Slowly fill with water until the surface of the water is even with the surface of the simulated bedded pack. Allow water to settle until no more bubbles are coming from the simulated bedded pack, then record the mass of the plastic container

- Determine the percentage of free air space using the following calculation:

- After completing all desired data collection steps (Steps 3.1 - 3.4), add feces, urine, and bedding to the simulated bedded packs following Steps 2.1 - 2.10.

Results

To date, seven research studies have been published9,10,11,12,13,14,15 using this procedure, with modifications and adjustments made to improve the model and reflect objectives of the specific experiments. This procedure has been used to evaluate the effect o...

Discussion

The frequent addition of urine and feces to the bedded packs is a critical step. We experimented with adding urine and feces just once weekly, but found that the bedded pack developed a crust, which trapped gases inside the pack and was not representative of commercial facilities. The use of fresh feces at the beginning of the study ensures that the bedded packs is inoculated with common bacterial populations found in cattle facilities. It is also important, when adding the urine, to remember to adjust the pH to physiolo...

Disclosures

This research was funded by federally appropriated funds to the USDA Agricultural Research Service, Research Project Number 3040-41630-001-00D.

Mention of trade names or commercial products in this article is solely for the purpose of providing specific information and does not imply recommendation or endorsement by the USDA.

USDA is an equal opportunity provider and employer.

Acknowledgements

The author wishes to acknowledge Alan Kruger, Todd Boman, Shannon Ostdiek, Elaine Berry, and Ferouz Ayadi who assisted with data collection using the simulated bedded packs. The author also recognizes Tami Brown-Brandl and Dale Janssen for their assistance maintaining the environmental chambers.

Materials

| Name | Company | Catalog Number | Comments |

| 10 gallon plastic cylinder containers | Rubbermaid | Model 2610 | Other similar-sized plastic containers are suitable |

| Mass balance | Any | Capable of measuring 0.1 gram | |

| Electric drill with 1 cm bit | Any | ||

| Methane analyzer | Thermo Fisher Scientific | Model 55i Methane/Non-methane Analyzer | |

| Hydrogen sulfide analyzer | Thermo Fisher Scientific | Model 450i | |

| Ammonia analyzer | Thermo Fisher Scientific | Model 17i | |

| Carbon dioxide analyzer | California Analytical | Model 1412 | |

| Nitrous oxide analyzer | California Analytical | Model 1412 | |

| Programmable Logic Relay | TECO | Model SG2-020VR-D | |

| Stainless steel flux chambers | Any | Constructed using the parts list and directions cited at Woodbury et al., 2006 | |

| Rubber skits | Any | Constructed from flexible rubber material. Cut into squares (61 cm x 61 cm) with 22.9 cm diameter hole in center. | |

| pH meter | Spectrum Technologies | IQ150 | |

| thermometer | Spectrum Technologies | IQ150 | |

| Ruler or tape measure | Any | Capable of measuring in cm | |

| Sorbent tubes | Markes International | Tenax TA | |

| Pocket pumps | SKC Inc. | Series 210 | |

| Inert sampling line | Teflon | 0.64 cm diameter | |

| Pump | Thomas | 107 series | Used to flush air through sample lines |

References

- Doran, B., Euken, R., Spiehs, M. Hoops and mono-slopes: What we have learned about management and performance. Feedlot Forum 2010. , 8-16 (2010).

- Andersson, M. Performance of bedding materials in affecting ammonia emissions from pig manure. J. Agric. Engng. Res. 65, 213-222 (1996).

- Jeppsson, K. H. Volatilization of ammonia in deep-litter systems with different bedding materials for young cattle. J. Agric. Engng. Res. 73, 49-57 (1999).

- Powell, J. M., Misselbrook, T. H., Casler, M. D. Season and bedding impacts on ammonia emissions from tie-stall dairy barns. J. Environ. Qual. 37, 7-15 (2008).

- Gilhespy, S. L., Webb, J., Chadwick, D. R., Misselbrook, T. H., Kay, R., Camp, V., Retter, A. L., Bason, A. Will additional straw bedding in buildings housing cattle and pigs reduce ammonia emissions. Biosystems Engng. , 180-189 (2009).

- Spiehs, M. J., Woodbury, B. L., Doran, B. E., Eigenberg, R. A., Kohl, K. D., Varel, V. H., Berry, E. D., Wells, J. E. Environmental conditions in beef deep-bedded mono-slope facilities: A descriptive study. Trans ASABE. 54, 663-673 (2011).

- Cortus, E. L., Spiehs, M. J., Doran, B. E., Al Mamun, M. R. H., Ayadi, F. Y., Cortus, S. D., Kohl, K. D., Pohl, S., Stowell, R., Nicolai, R. . Ammonia and hydrogen sulfide concentration and emission patterns for mono-slope beef cattle facilities in the Northern Great Plains. , (2014).

- Spiehs, M. J., Cortus, E. L., Holt, G. A., Kohl, K. D., Doran, B. E., Ayadi, F. Y., Cortus, S. D., Al Mamun, M. R., Pohl, S., Nicolai, R., Stowell, R., Parker, D. Particulate matter concentration for mono-slope beef cattle facilities in the Northern Great Plains. Trans. ASABE. 57, 1831-1837 (2014).

- Ayadi, F. Y., Cortus, E. L., Spiehs, M. J., Miller, D. N., Djira, G. D. Ammonia and greenhouse gas concentrations at surfaces of simulated beef cattle bedded manure packs. Trans. ASABE. 58, 783-795 (2015).

- Ayadi, F. Y., Spiehs, M. J., Cortus, E. L., Miller, D. N., Djira, G. D. Physical, chemical, and biological properties of simulated beef cattle bedded manure packs. Trans. ASABE. 58, 797-811 (2015).

- Spiehs, M. J., Brown-Brandl, T. M., Parker, D. B., Miller, D. N., Berry, E. D., Wells, J. E. Effect of bedding materials on concentration of odorous compounds and Escherichia coli in beef cattle bedded manure packs. J. Environ. Qual. 42, 65-75 (2013).

- Spiehs, M. J., Brown-Brandl, T. M., Parker, D. B., Miller, D. N., Jaderborg, J. P., Diconstanzo, A., Berry, E. D., Wells, J. E. Use of wood-based materials in beef bedded manure packs: 1. Effect on ammonia, total reduced sulfide, and greenhouse gas concentrations. J. Environ. Qual. 43, 1187-1194 (2014).

- Spiehs, M. J., Brown-Brandl, T. M., Berry, E. D., Wells, J. E., Parker, D. B., Miller, D. N., Jaderborg, J. P., Diconstanzo, A. Use of wood-based materials in beef bedded manure packs: 2. Effect on odorous volatile organic compounds, odor activity value, Escherichia coli, and nutrient concentration. J. Environ. Qual. 43, 1195-1206 (2014).

- Spiehs, M. J., Brown-Brandl, T. M., Parker, D. B., Miller, D. N., Berry, E. D., Wells, J. E. Ammonia, total reduced sulfides, and greenhouse gases of pine chip and corn stover bedding packs. J. Environ. Qual. 45, 630-637 (2016).

- Spiehs, M. J., Berry, E. D., Wells, J. E., Parker, D. B., Brown-Brandl, T. M. Odorous volatile organic compounds, Escherichia coli, and nutrient concentrations when kiln-dried pine chips and corn stover bedding are used in beef bedded manure packs. J. Environ. Qual. 46, 722-732 (2017).

- Herbert, S., Hashemi, M., Chickering-Sears, C., Weis, S. . Bedding options for livestock and equine. , (2008).

- Effects of bedding on pig performance. Iowa State Research Farm Progress Reports Available from: https://lib.dr.iastate.edu/farms_reports/134/ (2012)

- Brown-Brandl, T. M., Nienaber, J. A., Eigenberg, R. A. Temperature and humidity control in indirect calorimeter chambers. Trans. ASABE. 54, 685-692 (2011).

- Abney, C. S., Vasconcelos, J. T., McMeniman, J. P., Keyser, S. A., Wilson, K. R., Vogel, G. J., Galyean, M. L. Effects of ractophamine hydrochlodride on performance, rate and variation in feed intake, and acid-base balance in feedlot cattle. J. Anim. Sci. 85, 3090-3098 (2007).

- Miller, D. N., Woodbury, B. L. A solid-phase microextraction chamber method for analysis of manure volatiles. J. Environ. Qual. 35, 2383-2394 (2006).

- Woodbury, B. L., Miller, D. N., Eigenberg, R. A., Nienaber, J. A. An inexpensive laboratory and field chamber for manure volatile gas flux analysis. Trans. ASABE. 49, 767-772 (2006).

- Koziel, J. A., Spinhirne, J. P., Lloyd, J. D., Parker, D. B., Wright, D. W., Kuhrt, F. W. Evaluation of sample recovery of malodorous livestock gases from air sampling bags, solid-phase microextraction fibers, Tenax TA sorbent tubes, and sampling canisters. J. Air Waste Manag. Assn. 55, 1147-1157 (2005).

- Parker, D. B., Gilley, J., Woodbury, B., Kim, K., Galvin, G., Bartelt-Hunt, S. L., Li, X., Snow, D. D. Odorous VOC emission following land application of swine manure slurry. Atmos. Environ. 66, 91-100 (2013).

- Parker, D. B., Koziel, J. A., Cai, L., Jacobson, L. D., Akdeniz, N. Odor and odorous chemical emissions from animal buildings: Part 6. Odor activity value. Trans. ASABE. 55, 2357-2368 (2012).

- Watson, M., Wolf, A., Wolf, N., Peters, J. Total nitrogen. Recommended methods of manure analysis. , 18-24 (2003).

- Wolf, A., Watson, M., Wolf, N., Peters, J. Digestion and dissolution methods for P, K, Ca, Mg, and trace elements. Recommended methods of manure analysis. , 30-38 (2003).

- Euken, R. A survey of manure characteristics from bedded confinement buildings for feedlot beef productions: Progress report. Animal Industry Report. , (2009).

- Li, L., Li, Q. -. F., Wang, K., Bogan, B. W., Ni, J. -. Q., Cortus, E. L., Heber, A. J. The National Air Emission Monitoring Study's southeast layer site: Part I. Site characteristics and monitoring methodology. Trans. ASABE. 56, 1157-1171 (2013).

Reprints and Permissions

Request permission to reuse the text or figures of this JoVE article

Request PermissionThis article has been published

Video Coming Soon

Copyright © 2025 MyJoVE Corporation. All rights reserved