Fractional Distillation

Overview

Source: Laboratory of Dr. Nicholas Leadbeater — University of Connecticut

Distillation is perhaps the most common laboratory technique employed by chemists for the purification of organic liquids. Compounds in a mixture with different boiling points separate into individual components when the mixture is carefully distilled. The two main types of distillation are "simple distillation" and "fractional distillation", and both are widely used in organic chemistry laboratories.

Simple distillation is used when the liquid is (a) relatively pure (containing no more than 10% liquid contaminants), (b) has a non-volatile component, such as a solid contaminant, or (c) is mixed with another liquid with a boiling point that differs by at least 25 °C. Fractional distillation is used when separating mixtures of liquids whose boiling points are more similar (separated by less than 25 °C).

This video will detail the fractional distillation of a mixture of two common organic solvents, cyclohexane and toluene.

Principles

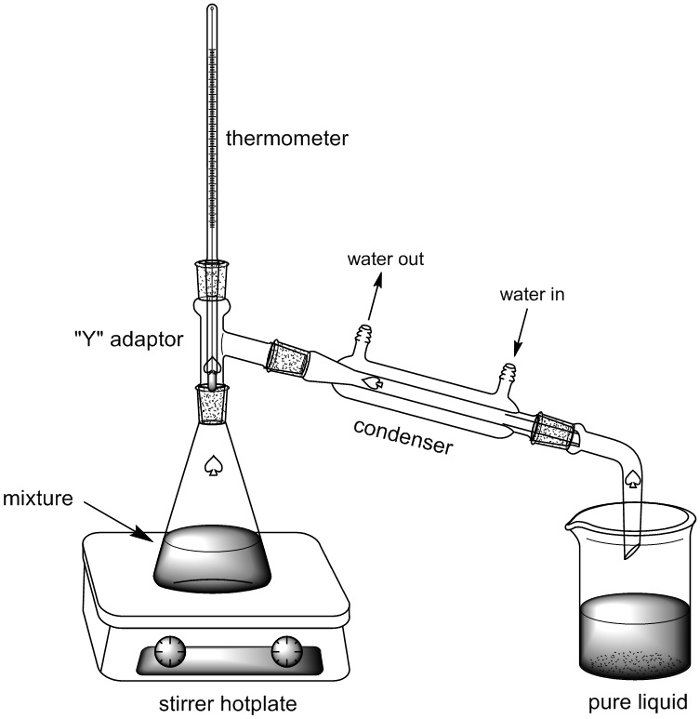

To separate two or more liquids by simple distillation, they are first heated in a flask. The more volatile liquid (the liquid with the lower boiling point) will typically evaporate first, and the vapor will pass into a condensing column, where it can revert into a liquid (condense) on the cool glass walls and then drip into a collection vessel (Figure 1).

Figure 1. Apparatus for simple distillation.

In fractional distillation, a mixture of liquids is boiled and the resulting vapors travel up a glass tube called a "fractionating column" and separate. The fractionating column is placed between the flask containing the mixture and the "Y" adaptor, and is usually filled with glass or plastic beads, which improves the separation between the liquids being distilled. Fractional distillation leads to a better separation than simple distillation because the glass beads in the fractionating column provide 'theoretical plates' on which the vapors can condense, reevaporate, and then recondense, essentially distilling the mixture over and over. One theoretical plate is equivalent to one vaporization-condensation cycle, which is equivalent to one simple distillation. The more volatile liquids will gradually move towards the top of the fractionating column, while lower boiling liquids will stay towards the bottom, giving a better separation between the liquids. The vapor eventually reaches the condenser, where it is cooled and then drips into the collection vessel.

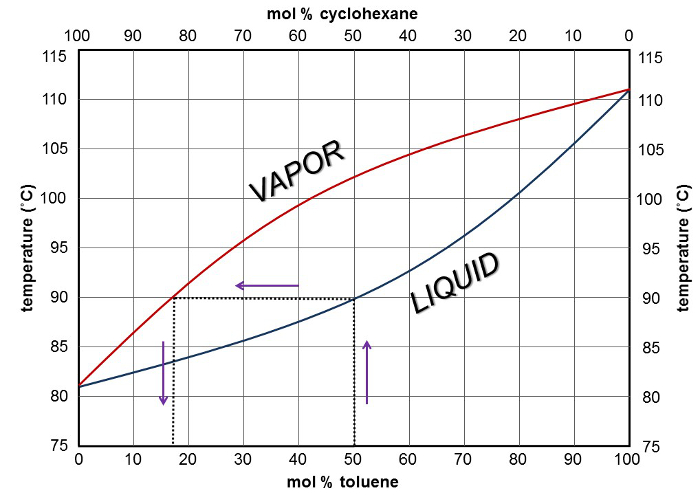

A boiling point composition curve (Figure 2) can be used to predict the number of theoretical plates needed to achieve a desired separation. Data for the curve is obtained by taking mixtures of varying composition, heating them to the boiling point, recording the temperature, and analyzing the composition of the vapor above each mixture. The lower curve represents the liquid composition and the upper curve represents the vapor composition. In the case of this experiment, the starting mixture was 50% cyclohexane and 50% toluene. By starting at the X-axis at the 50:50 point, drawing a line straight up to the liquid curve, then a straight horizontal line over to the vapor curve and then back down to the X-axis, it can be seen that during the simple distillation of a 50% cyclohexane : 50% toluene mixture, the first drop of distillate would be comprised of approximately 80% cyclohexane and 20% toluene.

Figure 2. Boiling point-composition curve for cyclohexane and toluene showing one simple distillation.

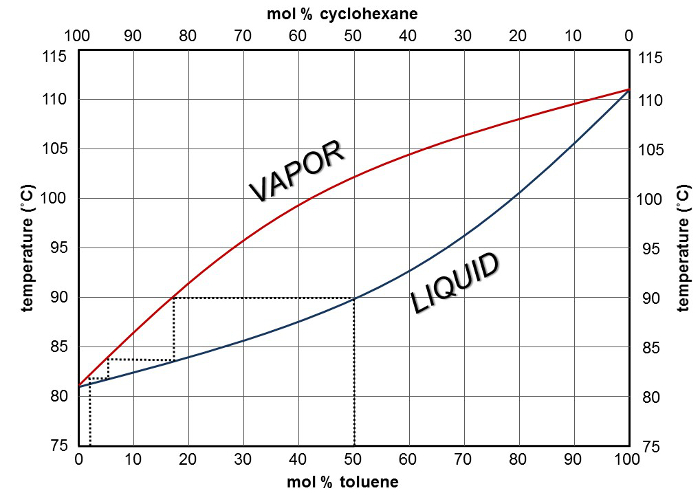

Fractional distillation is basically a number of simple distillations performed in sequence, the number being determined by the number of theoretical plates. It is possible to use the boiling point composition curve to determine the number of theoretical plates required to obtain a certain degree of separation (Figure 3). Starting with a mixture that is 50% cyclohexane and 50% toluene, a fractionating column with an efficiency equal to two theoretical plates would result in distillate that is 95% pure cyclohexane. A third theoretical plate would result in distillate that is about 99% pure cyclohexane. However, in practice, the situation is not as simple. As the distillation proceeds and the mixture in the distilling flask becomes increasingly enriched in toluene — essentially, resulting in a new starting mixture that is further to the right on the liquid composition curve. In order to obtain pure cyclohexane, more theoretical plates are needed, but the efficiency of the fractionating column is fixed, and so a point is reached at which it can no longer provide the required degree of separation, resulting in distillate that contains more contaminating traces of toluene.

Figure 3. Boiling point-composition curve for cyclohexane and toluene showing three theoretical plates.

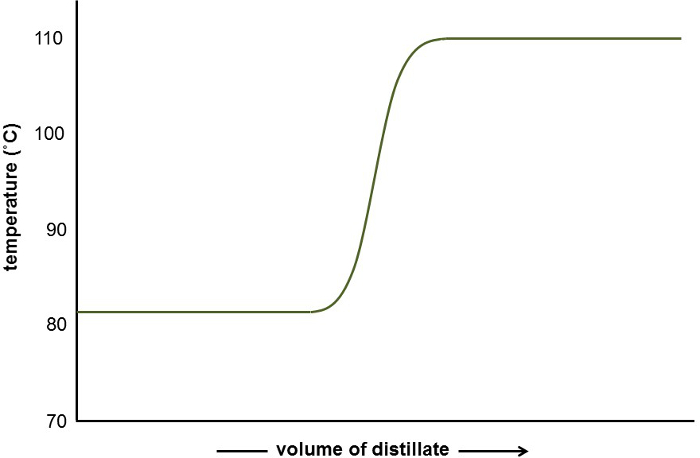

A distillation curve, which plots temperature vs. volume of distillate, is shown in Figure 4. Distillation initially occurs at about 82 °C, the boiling point of cyclohexane. The relatively stable temperature shows that nearly pure material is distilling during this time. The temperature then rises and reaches another plateau around 110 °C, the boiling point of toluene. Between the two plateaus the temperature rises gradually, not instantly. Recall that as the distillation proceeds and the cyclohexane is removed, more theoretical plates are required to obtain the desired purity. At some point the fractionating column is at its maximum number of plates and can no longer effectively separate the mixture, meaning that there will be distillate containing both the cyclohexane and toluene components. Once all the cyclohexane has been distilled, however, pure toluene begins distilling as evidenced by the second temperature plateau. To obtain the optimal distillation, the distillation rate must be constant and relatively slow.

Figure 4. Fractional distillation curve for cyclohexane and toluene.

Procedure

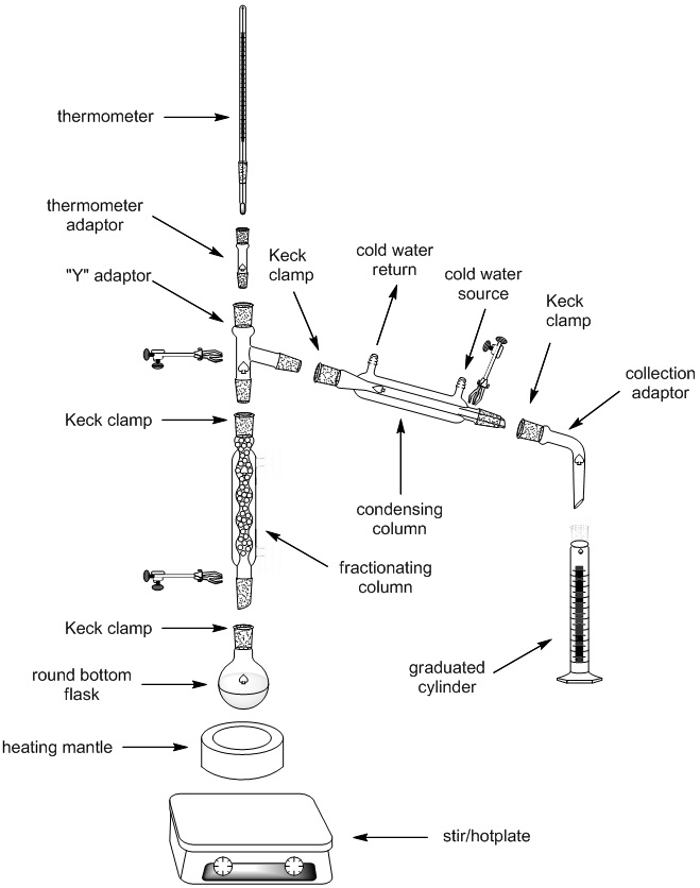

1. Set-up of Fractional Distillation Apparatus

| Fractional Distillation Apparatus | Quantity |

| Retort stands (ring stands) | 2 |

| Screw jack | 1 |

| Clamps | 4 |

| Keck clamps | 4 |

| Magnetic stir bar | 1 |

| Fractionating column | 1 |

| “Y” adaptor | 1 |

| Thermometer & Thermometer Adaptor | 1 |

| 100-mL round bottom flask | 1 |

| Condenser with water inlet and outlet tubes | 1 |

| Collection adaptor | 1 |

| 25-mL graduated cylinders | 3 |

| Heating mantle | 1 |

| Stir plate | 1 |

Table 1. Fractional distillation apparatus components.

Note: all glassware, with the exception of the graduated cylinders, should have ground-glass joints

- Gather all of the equipment needed to assemble the fractional distillation apparatus (Table 1) and place them in a fume hood.

- Place the heating mantle and stir plate at the foot of the retort stand, sitting on top of a screw jack.

- Using the screw jack, elevate the heating mantle to a height of 20 cm.

- Attach a clamp on the retort stand. Secure the round-bottom flask to the retort stand using the clamp so that the flask sits snuggly in the heating mantle.

- Remove the screw jack and the heating mantle, putting them aside for later.

- Add a magnetic stir bar to the round-bottom flask.

- Add a fractionating column to the top of the round-bottom flask, securing it to the retort stand with a clamp.

- Add a "Y" adaptor to the top of the fractionating column, securing it to the retort stand with a clamp and to the fractionating column with a Keck clip.

- Add a condensing column to the downward sloping arm of the "Y" adaptor, securing it with a Keck clip. For additional stability, the condenser can be secured with a clamp to a second retort stand.

- Connect tubing from the water source to the lower connection on the condenser and attach the water return tube to the higher connection on the condenser. Ensure the tubing is securely fitted to the condenser (consider using copper wire to hold the tubing in place).

- Connect a collection adaptor to the open end of the condenser and secure the connection with a Keck clip.

- Have three 25 mL graduated cylinders available for collection of the distillate.

Figure 5. Apparatus for fractional distillation.

2. Preparation for the Distillation

- Remove the round bottom flask from the assembly by lowering it to the base of the retort stand.

- Place a stemmed funnel into the top of the round-bottom flask, and add the liquid to be distilled. Do not fill the flask more than half full.

- After filling the flask, remove the funnel.

- Raise the flask once again and place the flask back in its original position on the retort stand.

- Using the thermometer adaptor, place the thermometer into the remaining open port on the "Y" adaptor. The thermometer should be added last, as it is most susceptible to breakage.

- Position the bulb of the thermometer so that it is just below the side arm of the "Y" adaptor. This ensures an accurate reading of the vapor temperature.

- Replace the heating mantle and screw jack to their original position, snuggly enveloping the round-bottom flask.

- Place a graduated cylinder underneath the condenser adaptor, ready to collect the distillate.

3. Performing the Distillation

- Increase the temperature of the heating mantle gradually until the liquid in the round-bottom flask begins boiling.

- As soon as boiling commences, hold the temperature for 2 min.

- Note the ring of condensate rising slowly up the fractionating column. The rise should be gradual, which ensures proper separation of the mixture components across the theoretical plates. If the ring of condensate stops rising, increase the temperature slightly. It should take at least 5 min for the ring to reach the top of the column.

- Once the first drops of liquid start to fall down the condenser, the temperature should remain nearly constant. Record the temperature as each 2 mL of distillate collects in the graduated cylinder.

- Adjust the heat accordingly to allow for 1—2 drops/s from the condenser into the graduated cylinder.

- Each time the graduated cylinder reaches 4 mL, quickly replace it with an empty one.

- Pour the distillate into a clean, labeled vial for safekeeping.

- If the distillation is occurring very slowly, wrap the column with aluminum foil or glass wool to protect it from cold drafts.

- When the temperature begins to drop significantly, nearly all the cyclohexane has been distilled. Increase the temperature until the toluene starts to boil and distill. Again, record the temperature as each 2 mL of distillate collects.

- Before the entire content of the flask evaporates, stop heating the flask. It is important to ensure that the flask does not become dry, which might cause it to crack.

- Remove the heating mantle by lowering the screw jack to the base of the retort stand

- Analyze the contents of the vials of distillate to confirm the purity using a chosen technique, such as 1H NMR spectroscopy.

Results

Fractional Distillation of a Cyclohexane-Toluene Mixture

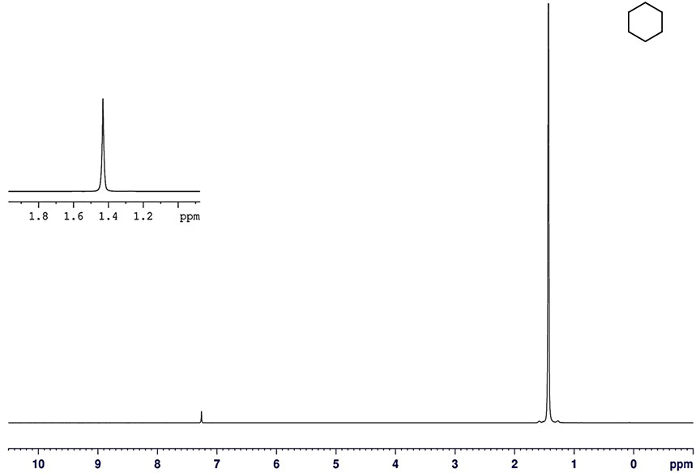

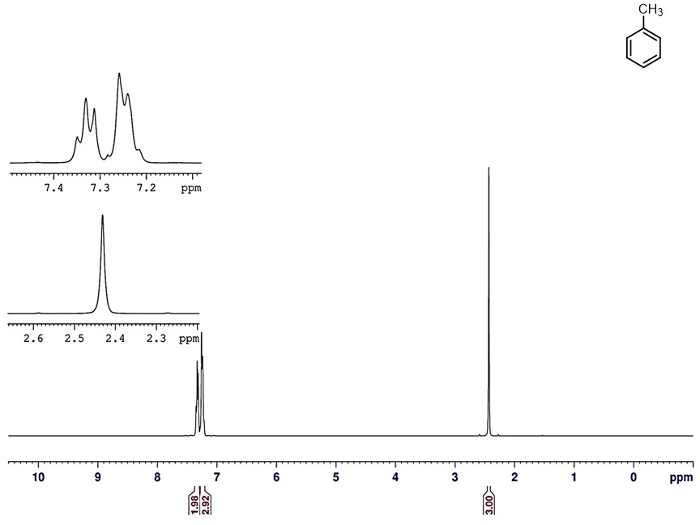

The purity of the distillate can be assessed by a number of techniques. One of the best is NMR spectroscopy. The 1H-NMR spectrum of the initial mixture prior to distillation is shown in Figure 6. Signals for both toluene and cyclohexane are clearly visible. 1HNMR spectra of the pure cyclohexane and pure toluene distillates are shown in Figures 7 and 8, respectively. No contaminants from the other component are seen in each case, showing the effectiveness of the distillation.

Figure 6.1H-NMR of a mixture of cyclohexane and toluene prior to distillation.

Figure 7.1H-NMR of the pure cyclohexane distillate.

Figure 8.1H-NMR of the pure toluene distillate.

Application and Summary

Distillation accounts for about 95 % of all current industrial separation processes. The main difference between distillations performed on the laboratory-scale and those performed industrially is that the former are usually run in a batch-wise manner, whereas the latter are often run continuously. In continuous distillation, the starting mixture, vapors, and distillate are kept at a constant composition by carefully replenishing the staring material and removing fractions from both vapor and liquid in the system. The most widely used industrial application of continuous, fractional distillation is in petroleum refineries and natural gas processing facilities. At temperatures below 36 °C, natural gas separates from petroleum. Other substances, including petroleum ether and naphtha, separate before the petroleum reaches the 69–74 °C range, at which point gasoline separates.

Distillation also finds application in the food industry. It is used to produce a wide variety of alcoholic beverages, e.g., whiskey, rum, and brandy. When fruit and plant materials ferment, a dilute solution of ethanol is produced. Distilling the fermented material purifies and concentrates the ethanol. A variety of other components, such as fragrant esters and other types of alcohol, are also collected during the distillation process, which accounts for the unique flavor of the finished spirit.

Skip to...

Videos from this collection:

Now Playing

Fractional Distillation

Organic Chemistry

334.1K Views

Introduction to Catalysis

Organic Chemistry

34.4K Views

Assembly of a Reflux System for Heated Chemical Reactions

Organic Chemistry

167.2K Views

Conducting Reactions Below Room Temperature

Organic Chemistry

70.5K Views

Schlenk Lines Transfer of Solvents

Organic Chemistry

41.6K Views

Degassing Liquids with Freeze-Pump-Thaw Cycling

Organic Chemistry

56.1K Views

Preparing Anhydrous Reagents and Equipment

Organic Chemistry

79.3K Views

Purifying Compounds by Recrystallization

Organic Chemistry

707.9K Views

Separation of Mixtures via Precipitation

Organic Chemistry

157.6K Views

Solid-Liquid Extraction

Organic Chemistry

237.7K Views

Rotary Evaporation to Remove Solvent

Organic Chemistry

212.8K Views

Growing Crystals for X-ray Diffraction Analysis

Organic Chemistry

32.4K Views

Performing 1D Thin Layer Chromatography

Organic Chemistry

289.3K Views

Column Chromatography

Organic Chemistry

359.8K Views

Nuclear Magnetic Resonance (NMR) Spectroscopy

Organic Chemistry

247.5K Views

Copyright © 2025 MyJoVE Corporation. All rights reserved