Method Article

Sample Preparation and Experimental Design for In Situ Multi-Beam Transmission Electron Microscopy Irradiation Experiments

In This Article

Summary

Sample preparation techniques are outlined with specific considerations for in situ ion irradiation TEM experiments. Ion species, energy, and fluence are discussed with methods for how to select and compute them. Finally, procedures for conducting an experiment are described and accompanied by the representative results.

Abstract

There is a need to understand materials exposed to overlapping extreme environments such as high temperature, radiation, or mechanical stress. When these stressors are combined there may be synergistic effects that enable unique microstructural evolution mechanisms to activate. Understanding of these mechanisms is necessary for the input and refinement of predictive models and critical for engineering of next generation materials. The basic physics and underlying mechanisms require advanced tools to be investigated. The in situ ion irradiation transmission electron microscope (I³TEM) is designed to explore these principles.

To quantitatively probe the complex dynamic interactions in materials, careful preparation of samples and consideration of experimental design is required. Particular handling or preparation of samples can easily introduce damage or features that obfuscate the measurements. There is no one correct way to prepare a sample; however, many mistakes can be made. The most common errors and things to consider are highlighted within. The I³TEM has many adjustable variables and a large potential experimental space, therefore it is best to design experiments with a specific scientific question or questions in mind.

Experiments have been performed on large number of sample geometries, material classes, and with many irradiation conditions. The following are a subset of examples that demonstrate unique in situ capabilities utilizing the I3TEM. Au nanoparticles prepared by drop casting have been used to investigate the effects of single ion strikes. Au thin films have been used in studies on the effects of multibeam irradiation on microstructure evolution. Zr films have been exposed to irradiation and mechanical tension to examine creep. Ag nanopillars were subjected to simultaneous high temperature, mechanical compression, and ion irradiation to study irradiation induced creep as well. These results impact fields including: structural materials, nuclear energy, energy storage, catalysis, and microelectronics in space environments.

Introduction

The transmission electron microscope (TEM) is widely utilized for its ability to observe specimens at the nanoscale. Early in the development of electron microscopes, microscopists identified in situ TEM as a powerful tool that could be used to directly observe the role of crystal defects, kinetic measurements of reaction rates, and the fundamental mechanisms in dynamic processes1. By carefully controlling the environment and directly observing material evolution, insight into fundamental mechanisms can be gained. This knowledge informs predictive modeling for materials response2,3, which is critically important in applications where traditional materials reliability testing is prohibitively difficult; applications where materials are extremely remote, in incredibly hostile environments, in service for exceedingly long times, or a combination of these factors. Radiation environments are one such example where there are significant challenges to conducting experimental studies due to the hazards of radiation areas, handling of radioactive material, and long timelines required for effects.

Space and nuclear reactor settings are both examples of these extreme radiation environments. Materials for nuclear energy can be exposed to high energy neutrons, as well as a spectrum of high energy charged particles. Likewise, in space applications materials can be exposed to a variety of charged particles. Understanding and developing predictive modeling of the resulting material evolution from exposure to these complex and extreme environments requires insight into the fundamental mechanisms occurring at the nanoscale. In situ TEM is one tool for investigating these dynamic nanoscale mechanisms in real time4,5.

In situ ion irradiation experiments in the TEM began in 1961 with the serendipitous emission of O- ions from a contaminated tungsten electron gun filament6. Researchers at Harwell were the first to link a heavy ion accelerator to a TEM for direct observation of ion irradiation effects7. More recently several facilities have assembled microscopes with multiple attached ion accelerators to enable in situ multibeam ion irradiation experiments including at the Japan Atomic Energy Research Institute8, National Institute for Materials Science9, Argonne National Laboratory10, University of Huddersfield11, JANNUS Orsay12, Wuhan University13, Sandia National Laboratories14, and others15 including multiple facilities under development. Multibeam ion irradiation can be used to study the synergistic effects that occur due to simultaneous gas generation and displacement cascade damage in materials exposed to complex radiation environments. Elevated or cryogenic temperature TEM stages are often utilized with multibeam irradiation to more closely mimic specific environments, as temperature plays a significant role in defect evolution. Additionally, mechanical testing stages can be utilized to quantify the role of synergistic effects on mechanical property changes as a function of irradiation dose.

Ion irradiation has been used as an accelerated aging technique to simulate the atomic displacement cascade damage that occurs during neutron irradiation in a reactor environment, as the technique can provide many orders of magnitude faster damage rate while avoiding prolonged activation of the target material16. The I3TEM facility at Sandia National Laboratories harnesses two types of accelerators to make possible a wide range of ion species and energies. The high energy ion beam is produced by a 6 MV Tandem accelerator and low energy ions are produced by a 10 kV Colutron accelerator. Au ions up to 100 MeV have been produced in the Tandem, while the Colutron has successfully run gaseous species including H, Deuterium (D), He, N, and Xe14,17. A mixed D2 and He gas plasma can be utilized to perform triple ion irradiation with the heavy ion beam coming from the Tandem, and a mixed D2 + He beam coming from the Colutron.

Controlled production of ions allows for precise dosing of material to reach a target damage and implantation concentration. When simulating neutron irradiation with ion beam irradiation, the damage dose, in displacements per atom (dpa) can be computed. This value represents the average number of displacements of an atom from its original lattice site position, and is not the same as the total defect concentration. Calculating the total defect concentration requires more advanced simulation tools with the capability to account for recombination effects. The dpa can be calculated using ion irradiation damage models such as the Monte Carlo simulation software Stopping Range of Ions in Matter (SRIM)18. SRIM can output vacancy distribution, stopping powers, and ion ranges in a target based on the target composition, ion species, and ion energy. This provides information necessary for quantifying ion implantation, radiation damage, sputtering, ion transmission, as well as medical and biological applications.

When considering this tool for investigating the effects of irradiation it is important to design the experiment to take full advantage of the strengths of the technique. The utilization of in situ TEM irradiation creates an ideal scenario to quantify the dynamic evolution of defects created in radiation environments. While this technique provides insight into defect evolution including loop faulting/defaulting reactions and defect-grain boundary (GB) accommodation mechanisms, significant experimental limitations exist in comparing the defect quantification to bulk scale irradiations due to well-known thin-film effects including loss of point defect and defect clusters to the sample surface19,20.

This article provides novel considerations and procedures on preparation and mounting of samples for in situ multibeam TEM experiments. Also described are experimental design considerations including modeling and geometric considerations specific to the I³TEM facility as well as protocol for beam alignment and beam characterization. A demonstration of the use of SRIM to calculate the energy required for a given depth of ion implantation, and the ion distribution and damage profile is provided. While the modeling methods21,22 and some sample preparation methods have been reported previously, the application of this information to experimental design is emphasized here. Representative results from in situ TEM experiments are presented and typical data analysis is also described.

Protocol

CAUTION: Please consult all relevant material safety data sheets (MSDS) before use. Also, complete relevant training and utilize appropriate precautions for hazards which may include but are not limited to chemicals used, high voltage, vacuum, cryogens, pressurized gasses, nanoparticles, lasers, and ionizing radiation. Ensure authorization and training for use of all equipment. Please use all appropriate safety practices dictated in the operating procedures (radiation monitoring device, personal protective equipment, etc.).

NOTE: All parameters given in this protocol are valid for the instruments and models indicated here.

1. In situ ion irradiation TEM experimental design

NOTE: There are many variables that can be changed resulting in a large potential experimental space. Designing systematic experiments such that they will answer specific scientific questions will result in the most success. First, choose appropriate ion species and energies that will model the system to be emulated.

- Ion species selection

NOTE: Ion interaction with materials is complex and the details are beyond the scope of this document. There exist several publications detailing ion interaction in solids23, or more specifically with metals24, and semiconductors25. Space radiation environments consist of a spectrum of ion energies and masses, which can be effectively modeled with light and heavy ions. Nuclear systems can be emulated using a combination of heavy ion irradiation and gas implantation. Heavy ion irradiation simulates the displacement cascade damage induced by neutrons and high energy fission or radioactive decay products. He is often generated in nuclear materials by either transmutation reactions or radioactive decay.- Choose an element to implant, based upon chemistry, damage type, and matching neutron spectrum. To minimize chemistry effects due to ion implantation, self-ion irradiation is often utilized, where the ion selected is the same as the material to be examined. Alternatively, doping studies can select specific ions for implantation. Damage type is determined by the kinetic energy of the ions with higher energies producing larger damage. For a fixed energy, light ions can be chosen to produce Frenkel pairs, heavy ions for damage cascades, and heaviest ions for ion tracks26.

- To simulate neutron damage, choose an ion that matches primary knock-on atom (PKA) displacements with the neutron spectrum of interest27.

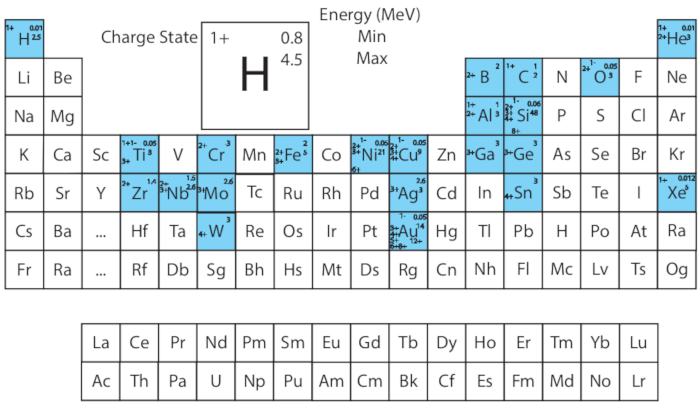

NOTE: Not all elements form stable negative ions suitable for use in Tandem accelerators. See Figure 1 for a list of all ions successfully run in the I³TEM facility. For background on accelerator operations and a list of 6 MV Tandem compatible elements with stable negative ions please refer to Middleton’s cookbook28.

- To simulate neutron damage, choose an ion that matches primary knock-on atom (PKA) displacements with the neutron spectrum of interest27.

- Choose an element to implant, based upon chemistry, damage type, and matching neutron spectrum. To minimize chemistry effects due to ion implantation, self-ion irradiation is often utilized, where the ion selected is the same as the material to be examined. Alternatively, doping studies can select specific ions for implantation. Damage type is determined by the kinetic energy of the ions with higher energies producing larger damage. For a fixed energy, light ions can be chosen to produce Frenkel pairs, heavy ions for damage cascades, and heaviest ions for ion tracks26.

Figure 1: Ions run to date (highlighted in blue), charge states, and energy ranges in I³TEM. Please click here to view a larger version of this figure.

- Ion energy selection using the stopping and range tables in SRIM

NOTE: The Stopping and Range tables provide a quick method for determining the depth of penetration of ions into a material. The stopping power, dE/dx, describes the energy (dE) an ion loses per unit distance (dx) traveled in a solid. The stopping power consists of two components: 1) nuclear stopping, the energy lost to elastic collisions with target atoms, and 2) electronic stopping, the energy lost due to interactions with the target atom electrons. The following procedure describes the implementation of a typical SRIM table.- In SRIM software select Stopping / Range Tables.

- Select the ion to be implanted and the target material. Multiple target elements may be selected for a compound target.

NOTE: A calculated density is provided but is usually very inaccurate and a value should be entered manually. - Select Calculate Table to see a table of ion energies vs projected range, lateral and longitudinal straggling in the material.

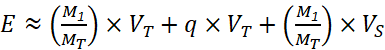

NOTE: For implantation experiments, the peak stopping range should be within the foil thickness. - Energies above 6 MV are possible with multiple charge states. Where the ion energy, E, is approximately determined by:

Equation (1)

Equation (1)

Where M1 is the mass of the selected ion, MT is the total mass of the compound in the source (MT = M1 for single element sources), q is charge state, VT is terminal voltage and VS is source potential.

NOTE: Charge states also influence beam current, which will affect fluence achievable and the time of exposure for experiments (see Equations 2, 3).

- Ion fluence and flux selection using SRIM

NOTE: Verify the penetration depth profile for the energy used in 1.2 by using SRIM. Decide on a target ion concentration (dose, fluence) or damage level based on relevant literature. Damage level is often reported in dpa and does not reflect the final number of defects, but is the average number of displacements without accounting for defect annihilation at free surfaces or recombination. Other environmental conditions such as temperature or mechanical load may be applied simultaneously. These may affect the damage and microstructural evolution mechanisms and should be considered. The following is a description of how to use SRIM to calculate damage or fluence. There are alternate methods to calculate damage22, but the method described is widely used and considered simpler and quicker. It is highly recommended that these guidelines are followed for the relevant radiation conditions, and most importantly that the simulation parameters are recorded and reported so that they can be reproduced.- In SRIM software, select the ion to be implanted and the target material. Multiple target elements may be selected for a compound target. A calculated density is provided but is usually very inaccurate and a value should be entered manually.

- Select TRIM calculation type: “Ion Distribution and Quick Calculation of Damage” and “Quick K-P” damage model.

NOTE: The vacancy.txt method provides a quick approximation of the damage profile that is sufficient for planning most I3TEM experiments. Stoller et al.21 detail how to use SRIM to implement the quick Kinchin-Pease equation to determine the dpa per ion per area in metal systems. There are competing arguments for the usage of “quick K-P” vs. “Full Cascade” options21,22, especially in ionic compounds containing elements with different threshold displacement energies. The authors recommend researching each of these methods to determine the most appropriate calculation method for reporting the final dpa in publications, depending on the specific sample type and experimental design. - Set layer thickness the same as the TEM sample thickness (10‒150 nm).

NOTE: The software will automatically divide the depth into 100 bins of equal size, so choosing a larger thickness will cause less accurate binning. - Set the ion incidence angle to match experimental conditions (typically 60° from normal).

NOTE: The ion beam is nearly normal to the electron beam in the TEM and typically the specimen is tilted towards the ion beam by 30°. See sections 3 and 4 for experimental configuration schematics. - Choose a threshold displacement energy from a reputable literature source, such as ASTM E52129. Set the lattice and surface energy to zero.

NOTE: Publications on both modeling30 and experimental work31 present threshold displacement energies on various materials. Zero lattice and surface energy are appropriate for most conditions, but for special cases, a value may need to be supplied21. - Run the simulation.

- Check the VACANCY.txt file for damage events as a function of depth, both VACANACIES by IONS and VACANCIES by RECOILS for each depth. This file can be imported into a spreadsheet.

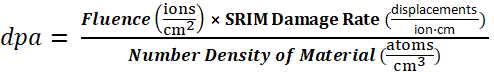

NOTE: Using the vacancy.txt file may not be the most accurate method for calculating damage dose and should be considered a quick approximation21. - Convert the units from (displacements/ion-Å) to (displacements/ion·cm). Then use the measured ion fluence to determine the dpa or determine the necessary ion fluence for a desired dpa (Equation 2, see section 3.1.5 and 3.2.5 for how to measure fluence). If damage rate (dpa/s) is desired, substitute flux (ions/cm2-s) for fluence.

Equation (2)

Equation (2) - Calculate the time of exposure necessary for a target fluence.

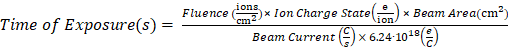

NOTE: Below are the relationships between these values where e is the electron charge and C is Coulombs (Equation 3). Some experiments range over several decades of fluence and thus a commensurate range of times with a given flux. For high fluence experiments, maximum flux is desired to minimize experiment time24. Due to the limiting speed of the gate valves and the Faraday cup actuator, low fluence requires a lower flux such that the exposure time can be achieved with sufficient precision: on the scale of seconds. High beam current can result in local heating of the sample which may change the diffusion properties and the observed microstructural evolution. In experiments utilizing high beam current, the sample should be cooled to room temperature and the temperature monitored with thermocouples during the irradiation.

(Equation 3)

(Equation 3)

- TEM stage selection

NOTE: Simple ion irradiation experiments can be performed on a single tilt holder. Depending on the material system and properties of interest, however, a variety of holders may be appropriate. It is possible to combine a variety of extreme environment components simultaneously with ion irradiation including conditions such as temperature, gas or liquid environment, and mechanical stress.- Consider the use of cryogenic or heating holders. Temperature plays an important role in the diffusion of atoms. Implantation temperature can influence the type and intensity of damage. Cryo-holders or heating holders can be selected to maintain a desired temperature. Maintain room temperature with the use of a heating holder running chilled water.

NOTE: For high temperature experiments samples should be mounted to a Mo grid or other thermally stable grids. - Consider the use of double tilt or tomographic holders. Crystal orientation can be important to understand and is needed to obtain two beam condition conducive to quantifying dislocation loops or black spot densities. Double tilt or tomographic holders may be used for these cases. This would also be useful for examining radiation induced phase changes.

- Consider the use of environmental holders to expose the material to gas or liquid in situ. Specimen preparation for this type of experiment varies, can be very difficult, and is beyond the scope of this document32.

- Consider the use of stages specialized for mechanical testing including tension, compression, bend, fatigue, and creep.

NOTE: Specific sample preparation is required for these types of experiments and is beyond the scope of this document33,34,35,36. Now that the ion species, ion energy, and target fluence have been determined, and specific holders for additional environmental complexity have been considered, the next step in designing ion irradiation experiments is preparing specimens for TEM. Careful preparation of the specimen is required to satisfy the geometric constraints for in situ ion irradiation TEM experiments. Several sample preparation methods are described below.

- Consider the use of cryogenic or heating holders. Temperature plays an important role in the diffusion of atoms. Implantation temperature can influence the type and intensity of damage. Cryo-holders or heating holders can be selected to maintain a desired temperature. Maintain room temperature with the use of a heating holder running chilled water.

2. Preparation of thin sample and mounting on TEM grid

NOTE: There are many ways to prepare a sample for TEM. The most appropriate method depends on starting sample geometry, material, and features of interest. For an extensive list and descriptions of preparation methods please refer to the sample preparation handbook for TEM37. Below are described three common methods. For magnetic materials a bonding method should be applied so the films or particles do not come off when subjected to the magnetic field in the TEM. Insulating substrates (i.e., oxides) should be avoided to minimize electrostatic expulsion due to ion beam induced charge.

- Drop casting of nanoparticles

NOTE: This is the most straightforward method for TEM sample preparation for nanoparticles with diameter less than 200 nm. Several different support materials can be used including lacey carbon, polymer, and silicon nitride membranes. These materials may interact differently with the nanoparticles due to ligand interactions. Select whichever substrate results in well dispersed nanoparticles.- Disperse nano-particles into a solvent such as alcohol, deionized water, or other combination until well mixed. Sonication may be used to break up additional agglomerates. The fluid concentration can be used to control the nanoparticle density on the grid.

- Use a Pipette to deposit dispersed particles onto the top side of a supported TEM grid.

NOTE: Make sure the support side of the grid is facing upwards, so the nanoparticles stick on the top side of the grid. It is possible to take advantage of the capillary effect which drags the nanoparticles as the droplet dries. An off-center drop will result in a lower density of nanoparticles in the central irradiation area.

- Thin film float-off

NOTE: This method requires a thin (<100 nm) film deposited on a dissolvable substrate such as salt or photoresist. A small portion of the sample is cleaved and placed into a solvent. As the substrate dissolves in the solvent, the thin film separates from the substrate and floats to the surface of the solution where it can be scooped onto a TEM grid.- Prepare 50 mL of solvent solution in a Petri dish.

NOTE: The solvent depends on the substrate for the thin film. NaCl substrates are common with water being the solvent. Alcohol can be added to the solution to change the surface tension. Too much alcohol will often cause the sample to sink, and too little alcohol will increase the surface tension making it difficult to transfer the film to the grid. - Cleave or cut the substrate into approximately 1.5 mm × 1.5 mm sections.

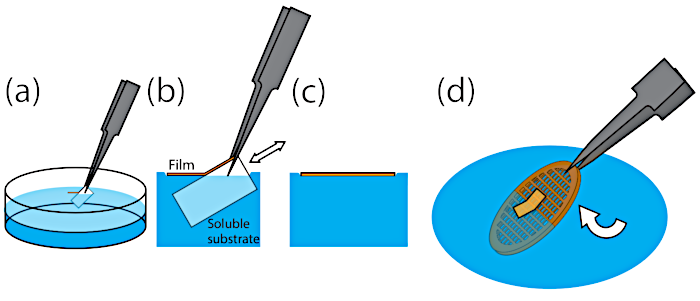

NOTE: The edges of the film are usually lower quality and should be avoided when possible. - Using tweezers, insert the substrate, with film facing up, into the solution at an incident angle of about 30° (Figure 2a). Repeatedly retract and insert slowly until the film floats free (Figure 2b,c). The substrate can be set aside.

- Insert the TEM grid into the solution and bring below the film. Slowly lift the grid under the film until film is centered over grid. Quickly lift the grid out of the solution and the film will attach (Figure 2d).

NOTE: If film is not well centered reinsert the grid and film into the solution to re-float the film and center as necessary. Be aware that the film can fold back on itself.

- Prepare 50 mL of solvent solution in a Petri dish.

Figure 2: Thin film float-off. Schematic showing (a) the insertion of a section of thin film, deposited on soluble substrate, into a solvent solution, (b) a cross sectional view of floating off the thin film by dissolving the adhesion layer of substrate, (c) a cross sectional view of thin film free floating on solution by surface tension, and (d) using TEM grid to lift the film from the solution. Please click here to view a larger version of this figure.

- Focused ion beam milling

NOTE: Most bulk materials can be prepared by focused ion beam (FIB) milling and information detailing this process can be found in the handbook for TEM sample preparation37. FIB milling is a time consuming and involved process compared to the methods mentioned previously but is very short and easy compared to traditional hand polishing methods of preparing TEM specimens from bulk samples. It also has the advantage of high degree of control over the site which allows for selection of area of interest to investigate, such as boundaries or defects. The foils produced by FIB have residual ion irradiation damage induced by the ion beam milling process that will convolute quantification of the damage induced by the in situ irradiation38.- Prepare the lift out. A variety of lift out strategies can be used to produce site-specific TEM foils in different geometries. For detailed methods please refer to publications for preparing samples in geometries such as: cross sectional39, plan view40, crack tips41, nano-pillars42, atom probe needles43, etc.

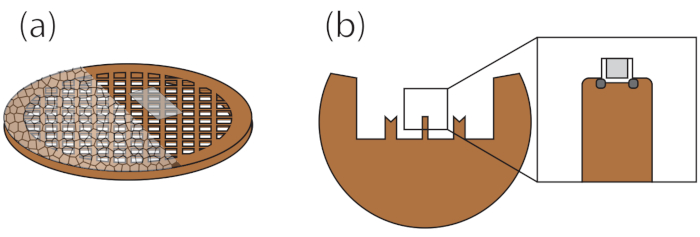

- Mount the foil. Ex situ lift outs can be placed on top of TEM grid similarly to thin films (Figure 3a). For specimens welded to a grid, the foil should be welded on the tip of a post on the face of the grid to avoid shadowing effects (Figure 3b). Avoid mounting in the V posts (Figure 3b: left and right).

- Perform a final polish to the lamella. Standard FIB thinning will result in ion beam damage to the specimen. This damage can be minimized by flush polishing at a very small glancing angle and by gentle milling with a low accelerating voltage. Alternatives to traditional final thinning via Ga+ ion beam include flash electropolishing44,45 and ion milling with Ar+46.

- Electro polishing

NOTE: This is often the most preferred method for preparing single phase metallic specimens for in situ ion beam irradiation experiments from bulk material. It avoids the damage caused by FIB milling and traditional polishing techniques. However, the electrolyte solution, electric potential, and time for polishing are material specific and these parameters may be difficult to determine.

Figure 3: Schematic showing TEM grids with specimens mounted on upper face to prevent shadowing. Grid with lacey carbon or thin film (a), half-moon grid with FIB lift-out welded to tip (b). Please click here to view a larger version of this figure.

3. Ion beam conditions and alignment

- Tandem accelerator

NOTE: The Tandem accelerator is best suited for high energy ions 800 keV – 100 MeV. Sources of negative ions by cesium sputtering (SNICS) are frequently used to produce energetic metal ion beams and its operation is outside the scope of this document28. Adjustments and considerations for in situ TEM experiments are described below.- Align the ion beam inside the TEM with steering magnets, bending magnets, and lenses so that irradiation events can be observed in situ. Perform final ion beam alignments by using a camera to view ion beam induced luminescence (IBIL) on a quartz-tipped TEM sample holder.

- Align the ion beam to be coincident with the cathodoluminescence produced by the electron beam with electron beam objective lens power matching that used in the experiment.

- Insert the Faraday cup upstream from the TEM to capture the ion beam, and take a reading to measure the beam current. Beam current measurements are necessary to calculate the fluence (Equation 3).

- For additional accuracy in the beam current measurement, insert a TEM holder equipped with a Faraday stage to measure the ion beam current in the specimen area of the TEM.

- If current needs to be monitored in real time, use the beam profile monitor (BPM). Power on the BPM then monitor the oscilloscope read out to perform current measurements. The BPM works by regularly chopping the beam which results in temporal distortion of the beam and is a qualitative measure of the beam current.

NOTE: The ion beam current can drift so checking its stability throughout the experiment is advised.

- Measure the beam area using a burn spot. Burn spots can be used to confirm alignments in 3.1.1.

- Mount a piece of clear adhesive tape onto a single-tilt TEM specimen holder flat plate tip and expose to the electron beam and ion beam. Remove the tape and place onto a white background.

- To determine the area, photograph the burn spot with a ruler and import into an image processing software such as ImageJ47. Together with beam current, the beam area measurement can be used to determine the ion flux (Equation 2).

- Insert a calibration sample to visualize beam damage, which should appear as black spot contrast in kinematic bright field imaging conditions. Typically, Au or CuAu are chosen due to their readily apparent black spot formation and ease of sample preparation48.

- Align the ion beam inside the TEM with steering magnets, bending magnets, and lenses so that irradiation events can be observed in situ. Perform final ion beam alignments by using a camera to view ion beam induced luminescence (IBIL) on a quartz-tipped TEM sample holder.

- Colutron accelerator

NOTE: The Colutron accelerator utilizes a gas-fed hot filament ion source49. It is possible to accelerate multiple gas species simultaneously, however, the mass to charge ratio of the two ion species must be equal in order for the bending magnet, steerers, and lenses to act identically; for example, 4He2+ and 2D1+.- Perform SRIM calculations as described in section 1.2 to obtain the desired gas implantation energy.

NOTE: The necessary bending magnet strength depends on the mass of the ion, its charge state, and the accelerating voltage. If the gas species has multiple isotopes, selecting the one which is most abundant will result in highest beam current. Also note that if the Tandem is active, this bending magnet will also act on its beam; additional corrections for the tandem will have to come after the Colutron beam is aligned. - Steer the ion beam such that it is coincident with the electron beam, as described in step 3.1.1.

- Measure the beam current as described in step 3.1.2.

- Estimate beam area using a burn spot, as described in step 3.1.3.

NOTE: This step can be performed simultaneously with the measurement of the ion beam from the Tandem accelerator. However, if the beam current from the Colutron accelerator is too high compared to the beam from the Tandem (> 3 orders of magnitude) it will cover up the signal and the measurements should be made separately. - Perform final adjustments to steer the beam onto the TEM specimen as described in step 3.1.4.

- Perform SRIM calculations as described in section 1.2 to obtain the desired gas implantation energy.

4. TEM loading and imaging conditions

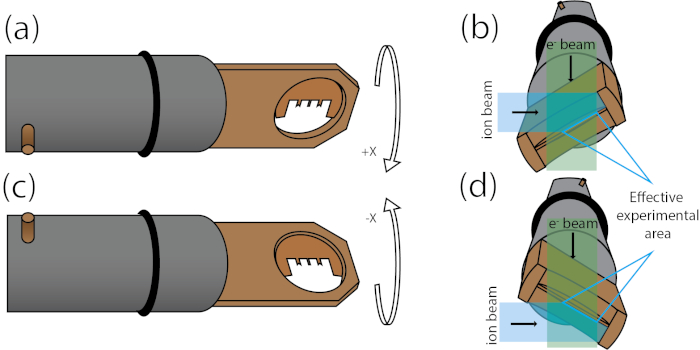

Figure 4: TEM loading and imaging conditions. Overhead view of TEM holder with electron beam direction into the page with holder tilted 30° in positive X (a) and negative X (c). Cross sectional view down the axis of the holder with electron beam (green) and ion beam (blue) highlighted with holder tilted 30° in positive X (b) and negative X (d) for bottom side illumination of the ion beam. Highlighted area where both the electron beam and ion beam are not shadowed. Please click here to view a larger version of this figure.

- Specimen loading and geometric concerns

- Load grid onto the holder such that the specimen side of the grid is facing up and the grid is oriented to prevent shadowing effects when titled towards the ion beam (Figure 4a,c).

NOTE: Figure 4b,d depicts a schematic of the ion beams path and electron beam path in the irradiation configuration where the effective experimental area is highlighted. - Check for shadowing effects using an optical microscope. Tilt the holder 30° in the positive X direction as shown in Figure 4a,b. The overhead view will be parallel to that of the electron beam. Tilt the holder 60° in the negative X direction where the overhead view will be parallel to that of the ion beam. If the area of interest of the specimen is not visible in both orientation, there is a shadowing issue and the specimen must be moved.

NOTE: For some holders the bottom of the stage has fewer shadowing issues and thus tilting to negative 30° such that the ion beam strikes the bottom side of the sample may be optimal (Figure 4d). - Mount the specimen onto a TEM holder following the manufacturers guidelines for the specific holder. Load the holder into the TEM to begin the pump cycle. Wait for vacuum to stabilize and insert the holder.

NOTE: When loading and unloading holders in the TEM, the valve to the beamline should be closed to prevent any loading induced vacuum crashes in the TEM from affecting the beamline. - In the TEM control software, load the most recent alignment file for the accelerating voltage being used. Manually refine the alignments for the condenser lens and aperture, gun tilt and shift, and the objective lens.

- Find a region of interest on the specimen and adjust imaging conditions as described by Jenkins and Kirk50 for the type of analysis to be performed. Use brightfield kinematic conditions to image damage events.

NOTE: For high Z number materials such as tungsten, an additional condenser lens may be engaged for additional brightness.

NOTE: Low Z materials can be displaced by high energy electrons resulting in knock-on damage from the electron beam that may convolute the damage caused by the ions51. Using a low dose electron beam and limiting exposure to the specimen as well as using low dwell time scanning TEM will help to mitigate this. - Tilt the holder the maximum safe distance (30° for most holders) up to 81° towards the ion beam.

- Apply any additional stressors such as heating, cooling, environmental, mechanical, etc. using the manufacturer recommended procedures specific to the chosen TEM holder.

NOTE: For high magnification work, allow time for stage to stabilize so drift is not significant. Applied stressors may cause the specimen to deform as well. - Open the TEM ion beam valve and remove the Faraday cup to expose the experimental specimen to ion irradiation. Pause exposure by inserting the Faraday cup and closing valves to the beam line. The Faraday cup should be inserted before closing the TEM valve to prevent damage to the valve.

NOTE: The gun pressure in the TEM should be monitored such that it does not exceed the manufacturer-specified threshold for safe operation levels. It may be necessary to halt exposure to allow vacuum to recover if sample or stage is producing significant outgassing during ion beam exposure. - Record images or videos to document the evolution of the microstructure.

- Load grid onto the holder such that the specimen side of the grid is facing up and the grid is oriented to prevent shadowing effects when titled towards the ion beam (Figure 4a,c).

- Additional imaging modes

- To map relative orientations of grains, use automated crystal orientation mapping (ACOM), a technique which allows for the identification of the crystallographic orientation of all crystallites with sizes as low as 10 nm. Software systems automate the collection of diffraction patterns with a precessed beam which are indexed resulting in an orientation map52.

- For ultrafast events, use the high-speed deflector. It is a magnetic lens that deflects projected electrons into different quadrants of the camera at fast rates effectively increasing frame time by an order of magnitude. It can be used to capture events that occur in the microsecond time scale in a single frame53.

- Perform electron tomography by capturing a tilt series of the specimen and subsequently perform reconstruction with software. This reveals the three-dimensional structure of the specimen and can be used to analyze volumetric distributions54.

- Make electron holography measurements by capturing a through-focus series. This measurement can be used to distinguish voids, bubbles, and nanoparticles55.

- Use weak beam dark field to view dislocations and damage caused by the ion beam. Two-beam condition for a single crystal is used to measure dislocation character and density50.

Results

In situ ion irradiation TEM experiments have been conducted on several material systems and with several different methods of specimen preparation 14,32,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70, 71,72,73,74,75. Below are a few selected systems that demonstrate this variety. Sample preparation methods include nanoparticle drop-casting, thin-film float off, cross-sectional FIB liftout on half-moon grid, push-to-pull foils, and nanopillars.

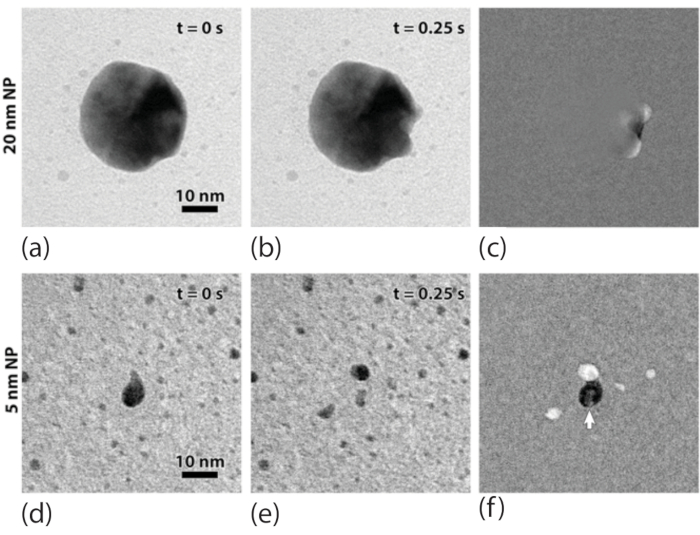

Highlighted here is an experiment on the effects of single ion strikes on Au nanoparticles (NPs)60. The number density of particles in the irradiation window was controlled by taking advantage of the capillary forces that pull NPs along as a droplet dries. By dropping off center, the droplet pulls NPs towards the edge of the disc as it dries. The active mechanisms for damage can be highlighted by taking the difference before and after an event (Figure 5). The measurements reveal several mechanisms for damage induced by single self-ion irradiation including creation of surface craters, sputtering, filament formation, and particle fragmentation where the types of damage depend on ion energy. Filament formation is seen at lower ion energies, whereas cratering, sputtering, and particle fragmentation are observed at high ion energies. These different energy regimes can be used to investigate the effects of the electronic and nuclear stopping powers.

Figure 5: Effects of single 46 keV ions in NPs of decreasing size. Note that the magnification is similar for all micrographs. Each pair of micrographs is separated by 1 frame, about 0.25 s here. (a–c) A single ion strike in a 60 nm NP created a surface crater, marked by the white arrow. Panel (c) shows the difference image highlights the change between (a) and (b); features present only in (a) are dark and newly formed features present only in (b) appear light. (d–f) A single ion creating a crater in a 20 nm NP. Panel (f) shows the difference image of (d) and (e). This figure has been modified with permission from Cambridge University Press60. Please click here to view a larger version of this figure.

Nanocrystalline thin films of Au were prepared for in situ multibeam TEM experiments. The samples were deposited by pulsed laser deposition onto NaCl substrates then floated off in deionized water onto Mo TEM grids. The samples were annealed in a vacuum furnace at 300 °C for 12 h to relax the as-deposited metastable nanocrystalline structure resulting in polycrystalline gold with ultrafine grain size.

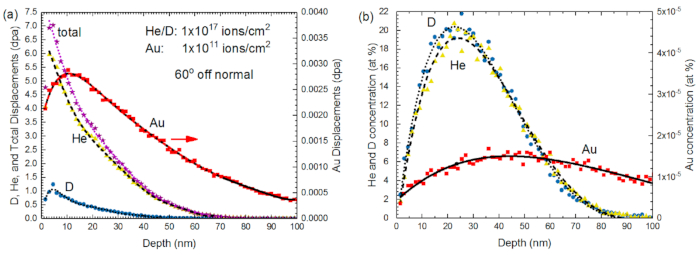

In this study, 2.8 MeV Au4+ ions are used to simulate neutron irradiation. The energy is chosen based on SRIM modeling to result in peak damage within the film thickness (Figure 6a). Simultaneous 10 keV He+ simulates the production of α-particles from neutron-radiation induced nuclear reactions. The He ion energy is chosen such that the ions are implanted within the foil thickness rather than passing through (Figure 6b).

Figure 6: SRIM modeling. SRIM calculated (a) displacement and (b) concentration profiles as a function of depth for Au irradiated with various ion species. The total dpa profile (D + He + Au) is indicated by purple stars in (a). Lines of fit are a guides to the eye. This figure has been modified with permission from MDPI17. Please click here to view a larger version of this figure.

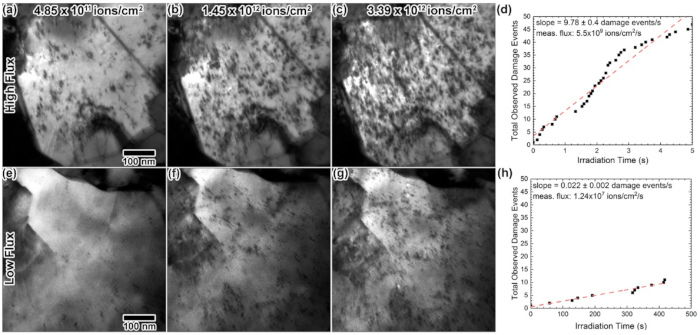

The material was then irradiated by Au ions and damage was observed with respect to fluence. The microstructure developed defects induced by the high energy ions (Figure 7). With increasing time of exposure and thus fluence, the damage increased linearly. At high doses the concentration of damage sites is too high to reliably quantify.

Figure 7: TEM images showing damage spots. TEM images from in situ 2.8 MeV Au4+ irradiation into a Au foil using dose rates of 9.69 × 1010 (a–c) and 9.38 × 108 ions/cm2·s (e–g), at fluences of 4.85 × 108, 1.45 × 1012 and 3.39 × 1012 ions/cm2. (d,h) show linear increases in number of damage spots with time. All TEM images were taken at the same magnification. This figure has been modified with permission from MDPI17. Please click here to view a larger version of this figure.

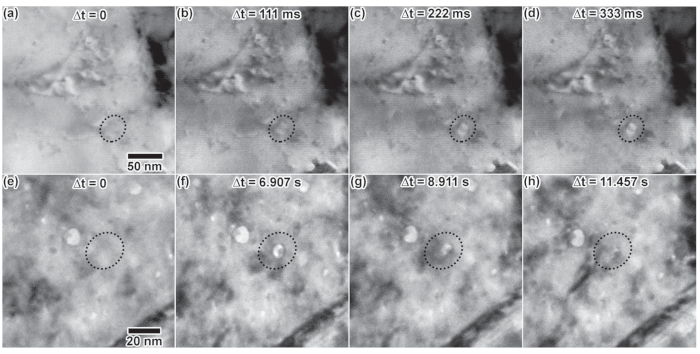

To explore the effects of multiple beams interacting with the material at the same time, double and triple ion beam irradiation is then performed on Au (Figure 8). Cavity nucleation, growth, and evolution are measured.

Figure 8: In situ TEM images showing cavity growth. In situ TEM images showing cavity growth as a function of time due to (a–d) double ion irradiation with 5 keV D + 1.7 MeV Au and cavity formation and collapse as a function of time due to (e–h) triple ion irradiation with 10 keV He, 5 keV D and 2.8 MeV Au. Dashed circles highlight the cavity of interest in each image. This figure has been modified with permission from MDPI17. Please click here to view a larger version of this figure.

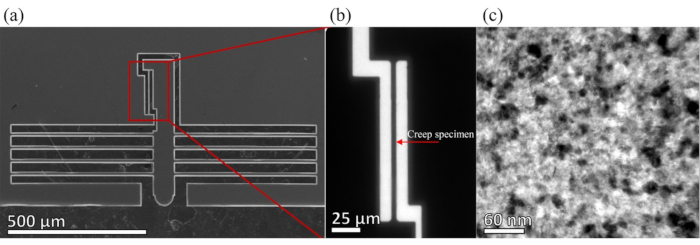

To explore irradiation induced creep in Zr, a microelectromechanical system (MEMS) device was fabricated by sputter depositing Zr thin films on silicon-on insulator wafers followed by photolithographic patterning and subsequent deep reactive ion etching. Figure 9 shows the free standing Zr specimen and the Si push-to-pull test frame which enables in situ tensile testing. 1.4 MeV Zr ions were used to irradiate the specimen under load to determine irradiation creep response in Zr. By conducting the experiment in a TEM, dynamic mechanisms at the nanoscale can be observed. Measurements reveal a texture change as well as a lengthening of the specimen. Volumetric swelling was not expected due to the thin foil specimen geometry, room temperature conditions, and low levels of irradiation damage. This is confirmed by the lack of observed bubble and cavity formation.

Figure 9: In situ mechanical testing. (a) SEM image of the push-to-pull device with Zr tensile sample location highlighted. (b) Low-magnification TEM image of the device from (a). (c) Higher-magnification bright-field TEM image of the nanocrystalline Zr microstructure in the test region. This figure has been modified with permission from Springer Nature75. Please click here to view a larger version of this figure.

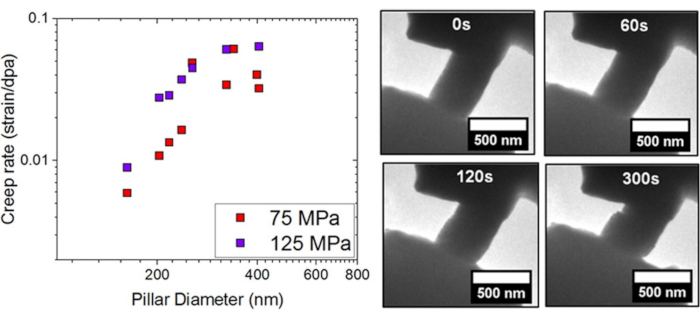

Additional mechanical stressor states can be applied simultaneously during in situ ion irradiation TEM experiments. Figure 10 shows work on high temperature irradiation induced creep of Ag nanopillars67. This utilizes a picoindentor to apply a controlled stress to a TEM specimen. Pillars were prepared from 1 μm thick Ag film grown on Si by FIB milling. The pillars were irradiated with 3 MeV Ag³+ ions. The specimens were heated with a 1064 nm laser beam coincident with both the ion beam and electron beam. The results of this study show that combined irradiation and temperature result in orders of magnitude faster creep rate than room temperature irradiation and high temperature thermal creep.

Figure 10: Radiation-induced creep. Radiation-induced creep rate versus pillar diameter at 75 and 125 MPa loading stresses (left), selected frames from video recording of in situ TEM radiation induced creep in Ag nanopillar irradiated by 3 MeV Ag ions (right). This figure has been modified with permission from Elsevier67. Please click here to view a larger version of this figure.

Considerations for the preparation of nanopillars for shallow ion irradiation has been described in depth by Hosemann et al.76. One of the key factors to consider is the shape of the nanopillar. At this small scale any deviation from ideal geometry can have a large impact on the mechanical performance. A rectangular prism tip is much better than a cylindrical tip due to tapering of the tip in annular milled geometry.

These representative results demonstrate a range of material systems, preparation methods, and complex environments that are possible with in situ ion irradiation TEM. In each case careful sample preparation and planning of experimental parameters are critical to extract meaningful data. Further detail on these considerations is discussed below.

Discussion

The procedures described in this document are specific to the I3TEM facility at Sandia National Laboratories, however the general approach can be applied to other in situ ion irradiation TEM facilities. There is a facilities group called the Workshop On TEM With In situ Irradiation (WOTWISI), that holds biannual meetings to discuss ion accelerator electron microscopes. There are several facilities in Japan including at the Japan Atomic Energy Research Institute (JAERI)8, and the National Institute for Materials Science (NIMS)9. Another facility capable of in situ ion irradiation is the Microscope and Ion Accelerator for Materials Investigations (MIAMI) facility at the University of Huddersfield77. CSNSM-JANNUS Orsay facility78 equipped with a FEI Tecnai G2 20 TEM working at 200 kV and coupled with the IRMA ion implanter. IVEM-Tandem Facility at Argonne National Lab is a Nuclear Science User Facility10. These facilities integrate ion accelerators differently which results in unique angles of intersection of the ion beam and electron beam. Some of the Japanese facilities introduce the ion beam at 30-45° from the electron beam, ANL and MAIMI similarly at 30° JANNUS at an angle of 68°, and I³TEM and Wuhan university have ion beams normal to the electron beam.

Depending on the material and starting form of the sample a variety of techniques can be used to prepare a specimen for TEM. The specimen needs to be sufficiently thin (less than about 100 nm) to be imaged in a TEM. Several methods for specimen preparation can be found in the handbook of TEM sample prep methodologies37. Of greatest ease are nanoparticles which can readily be drop cast. Thin films deposited on soluble substrate are also quite easy to prepare (Figure 2). Bulk metallic material can be prepared by polishing thin followed by punching through with jet polish where the area around the hole is thin enough for TEM viewing. The focused ion beam (FIB) lift out method is a well-known method for preparing a variety of materials for TEM and has been described in depth previously39,79,80. One primary advantage of the technique is the ability to selectively examine sites such as grain and phase boundaries. Another advantage is the variety of possible sample geometries including: foils, nano tension, nanopillars, and atom probe needles for additional stress environments or correlative studies. The drawback for FIB prepared samples for in situ ion irradiation experiments is that damage induced by the FIB process convolutes damage accumulated during the experiment making it difficult to determine quantitative observations. Biological or polymer samples can be prepared via cryo-FIB or cryo-microtomy, however these processes are not detailed here.

When planning ion beam implantation or irradiation experiments it is necessary to consider a number of important parameters for the ions. Penetration depth, flux/fluence, and radiation damage are variables that are often controlled when investigating effects of radiation. These parameters are modeled using a variety of simulation techniques. Stopping Range of Ions in Materials, SRIM, is a Monte Carlo simulation written to calculate ion deposition profiles in materials exposed to energetic beams of ions21,81. An alternative to SRIM is the Robinson model82 which uses a variety of functions to model the various physics of high energy ion interaction in materials. Another alternative is a model developed for single event effects in aerospace applications which can be adapted for use in ion beam experiments83. SRIM uses the Kinchin-Pease84 equation to model the displacement of atoms by radiation. The software is easy to use, and a range of ions, target elements, and ion energies can be quickly calculated with a variety of useful outputs. However, the software is limited in choice of models to use and since it is a Monte Carlo program takes a large number of iterations, and proportionally longer time to run the larger the simulation. The Robinson model utilizes a modified version of the Kinchin-Pease equation84 that has a higher agreement with experimental results, however, it is more difficult to use. Because of its widespread adoption and ease of use, methods for using SRIM were applied here and have generally become the industrial standard.

One of the primary limitations when considering multibeam in situ TEM is the sample geometry. Because of the nature of TEM as a projection imaging technique and the linear ion beam, shadowing of the electron beam or ion beams can affect the experiment. Shadows from the electron beam and ion beam can be formed from the sample stage, mounts, and even other parts of the sample. To avoid shadowing of the sample by the stage, most stages have a tilt limitation between 25° and 40°. More consideration must also be taken to account for geometries where the sample may shadow itself or be shadowed by the TEM grid. For this reason, when mounting the specimen, take care to mount such that there is the lowest possibility of shadowing. For FIB mounting samples on post grids this means attaching to the end of the post at the furthest out and highest point.

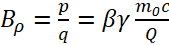

For experiments involving simultaneous irradiation by multiple ion species, there are limitations. Because the different ion species are being produced by different accelerators or sources the second beam must be bent by the magnet into the path of the first. This bending angle for the described instrumentation is about 20°. There must be a high ratio of beam rigidity for the bending to result in colinear beams. Beam rigidity (Bρ) is defined by total momentum divided by total charge, it can be calculated by:

Equation (4)

Equation (4)

Where p is momentum, q is charge, β is particle bending velocity proportionality (β = ν/c), m0 is the rest mass of the ion, c is the speed of light, and γ is the relativistic Lorentz factor:

Equation (5)

Equation (5)

This means that for multibeam experiments, it is best to use high energy heavy ions and low energy light ions such as Au and He respectively. If multiple beams are being produced by the same accelerator, they must have the same mass/energy ratio, for example 4He+ and 2D2+. Imaging conditions can also affect the ion beams. The objective lens magnetic field in high magnification imaging modes can be strong enough to bend the path of ions. Keep in mind the type of analysis that is desired when aligning the ion beams.

Contrast in TEM can arise from differences in thickness, phase, crystal order, and chemistry. Depending on the feature to be examined, there are several different types of contrast and imaging conditions that should be considered. Understanding the mechanisms behind diffraction contrast and phase contrast is useful. Understanding how to manipulate the electron microscope to achieve two-beam dynamical, bright-field kinematical, and weak-beam dark-field imaging conditions will also be useful. These are described in detail in Jenkins and Kirk, 200050.

To analyze dislocations, multiple diffraction patterns at different angles must be indexed to determine the reciprocal space lattice vector (g). Two beam imaging conditions can then be used to determine the Burgers vector of the dislocations (b). In weak beam dark-field, the dislocations can be imaged with higher resolution and contrast. This method is applied when there is a high density of dislocations or many partials. To calculate volumetric dislocation density, the thickness of the foil must be measured precisely in the area of interest. This can be done using a technique such as electron energy loss spectroscopy or convergent beam electron diffraction. For low angle grain boundaries, the dislocations in the boundary can be distinguished as a network under two beam dynamical conditions. For high angle grain boundaries, one grain is imaged in two beam dynamical conditions and the other in kinematical conditions. Twin boundaries can be characterized similarly. Fresnel imaging conditions are used to visualize gas filled bubbles and voids. Small cavities are more visible when the image is slightly out of focus and in kinematical diffraction conditions. Underfocused conditions are used to determine real diameter. Bubbles can also induce strain fields for which values can be estimated in the case of small bubbles. Automated Crystal Orientation Mapping (ACOM) is used to map several grains and their orientation similar to Electron Back Scatter Diffraction (EBSD) in the scanning electron microscope (SEM). It is best if crystals are through thickness to avoid interference from overlapping diffraction patterns.

It is possible to conduct experiments with other external stressors such as temperature and mechanical stress. The sample preparation and experimental considerations are much the same as for the multibeam experiments. Care needs to be taken in ensuring that the heating method and temperature range is appropriate for the material. Geometry must also be considered to avoid shadowing effects. The special holders for heating or mechanical testing will have specific geometric constraints and their specifications must be consulted14. Combinations of these stressors are also possible. In situ mechanical testing requires additional sample preparation to the appropriate geometry. There are specialized stages for experiments to test mechanical performance in various loading conditions such as: tension, compression, bend, fatigue, and creep. In situ heating can be performed both while irradiating and after irradiation for anneal studies. MEMS based, or conductive heating stages can be used to control temperatures up to 1000 °C. Higher temperatures can be achieved using an in situ laser to heat samples to a few thousand degrees Celsius33. Samples can be subjected to different environments with in situ holders. This includes various gases, liquids, and even corrosive environments.

In summary, in situ multibeam TEM experiments have the capability to emulate extreme environments and observe the microstructure and material evolution in real time at the nanoscale. The insight into the fundamental mechanisms governing dynamic processes gained from these experiments can help inform predictive models that pave the way for design of next generation materials. It is important to prepare samples as described to insure the best chance for a successful experiment.

Disclosures

The authors have nothing to disclose.

Acknowledgements

The authors would like to acknowledge Daniel Bufford, Samuel Briggs, Claire Chisolm, Anthony Monterrosa, Brittany Muntifering, Patrick Price, Daniel Buller, Barney Doyle, Jennifer Schuler, and Mackenzie Steckbeck for their technical and scientific input. Christopher M. Barr and Khalid Hattar were fully supported by Department of Energy Office of Science Basic Energy Science program. This work was performed, in part, at the Center for Integrated Nanotechnologies, an Office of Science User Facility operated for the U.S. Department of Energy (DOE) Office of Science. Sandia National Laboratories is a multimission laboratory managed and operated by National Technology & Engineering Solutions of Sandia, LLC, a wholly owned subsidiary of Honeywell International, Inc., for the U.S. DOE’s National Nuclear Security Administration under contract DE-NA-0003525. The views expressed in the article do not necessarily represent the views of the U.S. DOE or the United States Government.

Materials

| Name | Company | Catalog Number | Comments |

| Colutron Accelerator | Colutron Research Corporation | G-1 | 10 kV ion accelerator |

| Cu Omniprobe Lift-Out Grid with 4 posts | Ted Pella | DM71302 | Cu Omniprobe Lift-Out Grid with 4 posts |

| Double Tilt Cryo TEM Stage | Gatan | DT636 | Cryogenically cooled double tilt TEM holder |

| Double Tilt Heating TEM Stage | Gatan | DT652 | Resistive heater equipped double tilt TEM holder |

| I3TEM | JEOL | JEM-2100 | Modified transmission electron microscope for in-situ ion irradiation |

| Isopropanol | Fisher Scientific | A459-4 | 70 % v/v isopropanol |

| Mo Omniprobe Lift-Out Grid with 4 posts | Ted Pella | DM810113 | Mo Omniprobe Lift-Out Grid with 4 posts |

| Petri Dish | Fisher Scientific | Corning 316060 | 60 mm diamter 15 mm height petri dish |

| Picoindenter TEM Stage | Bruker Hysitron | PI95 | Picoindenter TEM Stage |

| Scios 2 | Thermofisher Scientfic | SCIOS2 | Dual beam focused ion beam scaning electron microscope |

| Tandem Accelerator | High Voltage Engineering Corporation | 6 MV Van de Graaff-Pelletron ion accelerator | |

| Tomography TEM holder | Hummingbird | TEM holder for tomography measurements | |

| Tweezers | PELCO | 5373-NM | Reverse action self closing fine tip tweezer |

References

- Butler, E. In situ experiments in the transmission electron microscope. Reports on Progress in Physics. 42, 833(1979).

- Odette, G. R., Wirth, B. D., Bacon, D. J., Ghoniem, N. M. Multiscale-Multiphysics Modeling of Radiation-Damaged Materials: Embrittlement of Pressure-Vessel Steels. MRS Bulletin. 26, 176-181 (2001).

- Wirth, B. D. How does radiation damage materials. Science. 318, 923-924 (2007).

- Butler, E. P., Hale, K. F. Dynamic experiments in the electron microscope. , North-Holland Pub. Co. (1981).

- Jungjohann, K., Carter, C. B. Transmission Electron Microscopy. Carter, C. B., Williams, D. B. , Springer International Publishing. Ch. 2 (2016).

- Pashley, D., Presland, A. Ion damage to metal films inside an electron microscope. Philosophical Magazine. 6, 1003-1012 (1961).

- Whitmell, D., Kennedy, W., Mazey, D., Nelson, R. A heavy-ion accelerator-electron microscope link for the direct observation of ion irradiation effects. Radiation Effects and Defects in Solids. 22, 163-168 (1974).

- Hojou, K., et al. In situ EELS and TEM observation of silicon carbide irradiated with helium ions at low temperature and successively annealed. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms. 116, 382-388 (1996).

- Furuya, K., Song, M., Saito, T. In-situ, analytical, high-voltage and high-resolution transmission electron microscopy of Xe ion implantation into Al. Microscopy. 48, 511-518 (1999).

- Allen, C. W., Ryan, E. A. In situ ion beam research in Argonne's intermediate voltage electron microscope. MRS Online Proceedings Library Archive. 439, (1996).

- Greaves, G., et al. New Microscope and Ion Accelerators for Materials Investigations (MIAMI-2) system at the University of Huddersfield. Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment. 931, 37-43 (2019).

- Gentils, A., Cabet, C. Investigating radiation damage in nuclear energy materials using JANNuS multiple ion beams. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms. 447, 107-112 (2019).

- Guo, L., et al. Establishment of in situ TEM-implanter/accelerator interface facility at Wuhan University. Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment. 586, 143-147 (2008).

- Hattar, K., Bufford, D. C., Buller, D. L. Concurrent in situ ion irradiation transmission electron microscope. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms. 338, 56-65 (2014).

- Hinks, J. A review of transmission electron microscopes with in situ ion irradiation. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms. 267, 3652-3662 (2009).

- Was, G., et al. Emulation of reactor irradiation damage using ion beams. Scripta Materialia. 88, 33-36 (2014).

- Taylor, C. A., et al. In situ TEM Multi-Beam Ion Irradiation as a Technique for Elucidating Synergistic Radiation Effects. Materials. 10, 1148(2017).

- Ziegler, J. F., Ziegler, M. D., Biersack, J. P. SRIM-The stopping and range of ions in matter. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms. 268, 1818-1823 (2010).

- Li, M., Kirk, M., Baldo, P., Xu, D., Wirth, B. Study of defect evolution by TEM with in situ ion irradiation and coordinated modeling. Philosophical Magazine. 92, 2048-2078 (2012).

- Ulmer, C. J., Motta, A. T. Characterization of faulted dislocation loops and cavities in ion irradiated alloy 800H. Journal of Nuclear Materials. 498, 458-467 (2018).

- Stoller, R. E., et al. On the use of SRIM for computing radiation damage exposure. Nuclear Instruments and Methods in Physics Research B. 310, 75-80 (2013).

- Weber, W. J., Zhang, Y. Predicting damage production in monoatomic and multi-elemental targets using stopping and range of ions in matter code: Challenges and recommendations. Current Opinion in Solid State and Materials Science. 23, 100757(2019).

- Wesch, W., Wendler, E. Ion Beam Modification of Solids. 61, Springer. (2016).

- Was, G. S. Fundamentals of radiation materials science: metals and alloys. , Springer. (2016).

- Crowder, B. Ion implantation in semiconductors and other materials. , Springer Science & Business Media. (2013).

- Merkle, K., Averback, R. S., Benedek, R. Energy Dependence of Defect Production in Displacement Cascades in Silver. Physical Review Letters. 38, 424(1977).

- Averback, R. S., Benedek, R., Merkle, K. Correlations between ion and neutron irradiations: Defect production and stage I recovery. Journal of Nuclear Materials. 75, 162-166 (1978).

- Middleton, R. A negative ion cookbook. , University of Pennsylvania. unpublished (1989).

- ASTM International. ASTM E521, Standard Practice for Netron Radiation Damage Simulation by Charged-Particle Irradiation. 12.02, ASTM International. (2009).

- Smith, R. Atomic and ion collisions in solids and at surfaces: theory, simulation and applications. , Cambridge University Press. (2005).

- Averback, R. S., Diaz De La Rubia, T. Displacement damage in irradiated metals and semiconductors. Solid state physics. 51, New York. 281(1997).

- Taylor, C. A., et al. Investigating Helium Bubble Nucleation and Growth through Simultaneous In-Situ Cryogenic, Ion Implantation, and Environmental Transmission Electron Microscopy. Materials. 12, 2618(2019).

- Grosso, R., et al. In situ Transmission Electron Microscopy for Ultrahigh Temperature Mechanical Testing of ZrO2. Nano Letters. , (2020).

- Barr, C. M., et al. Application of In-situ TEM Nanoscale Quantitative Mechanical Testing to Elastomers. Microscopy and Microanalysis. 25, 1524-1525 (2019).

- Wang, B., Haque, M. A., Tomar, V., Hattar, K. Self-ion irradiation effects on mechanical properties of nanocrystalline zirconium films. MRS Communications. 7, 595-600 (2017).

- Sun, C., et al. Microstructure, chemistry and mechanical properties of Ni-based superalloy Rene N4 under irradiation at room temperature. Acta Materialia. 95, 357-365 (2015).

- Ayache, J., Beaunier, L., Boumendil, J., Ehret, G., Laub, D. Sample preparation handbook for transmission electron microscopy: techniques. 2, Springer Science & Business Media. (2010).

- Aitkaliyeva, A., Madden, J. W., Miller, B. D., Cole, J. I., Gan, J. Comparison of preparation techniques for nuclear materials for transmission electron microscopy (TEM). Journal of Nuclear Materials. 459, 241-246 (2015).

- Heaney, P. J., Vicenzi, E. P., Giannuzzi, L. A., Livi, K. J. Focused ion beam milling: A method of site-specific sample extraction for microanalysis of Earth and planetary materials. American Mineralogist. 86, 1094-1099 (2001).

- Li, C., Habler, G., Baldwin, L. C., Abart, R. An improved FIB sample preparation technique for site-specific plan-view specimens: A new cutting geometry. Ultramicroscopy. 184, 310-317 (2018).

- Huang, Y., Lozano-Perez, S., Langford, R., Titchmarsh, J., Jenkins, M. Preparation of transmission electron microscopy cross-section specimens of crack tips using focused ion beam milling. Journal of microscopy. 207, 129-136 (2002).

- Kuzmin, O. V., Pei, Y. T., De Hosson, J. T. Nanopillar fabrication with focused ion beam cutting. Microscopy and Microanalysis. 20, 1581-1584 (2014).

- Miller, M. K., Russell, K. F. Atom probe specimen preparation with a dual beam SEM/FIB miller. Ultramicroscopy. 107, 761-766 (2007).

- Horváth, B., Schäublin, R., Dai, Y. Flash electropolishing of TEM lamellas of irradiated tungsten. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms. 449, 29-34 (2019).

- Yang, T. N. The Effect of Principal Elements on Defect Evolution in Single-Phase Solid Solution Ni Alloys. , (2018).

- Huang, Z. Combining Ar ion milling with FIB lift-out techniques to prepare high quality site-specific TEM samples. Journal of Microscopy. 215, 219-223 (2004).

- Abràmoff, M. D., Magalhães, P. J., Ram, S. J. Image processing with ImageJ. Biophotonics international. 11, 36-42 (2004).

- English, C., Jenkins, M., Kirk, M. Characterisation of displacement cascade in Cu3Au produced by fusion-neutron Irradiation. Journal of Nuclear Materials. 104, 1337-1341 (1981).

- Wåhlin, L. The colutron, a zero deflection isotope separator. Nuclear Instruments and Methods. 27, 55-60 (1964).

- Jenkins, M. L., Kirk, M. A. Characterisation of Radiation Damage by Transmission Electron Microscopy. 1st edn. , CRC Press. (2000).

- Williams, D. B., Carter, C. B. Transmission electron microscopy. , Springer. 3-17 (1996).

- Rauch, E., et al. Automatic crystal orientation and phase mapping in TEM by precession diffraction. Microscopy and Analysis-UK. 128, 5-8 (2008).

- Reed, B., et al. Initiation of Grain Growth Observed Using Electrostatic-Subframing. Microscopy and Microanalysis. 25, 1518-1519 (2019).

- Hoppe, S. M., et al. Penetrating Radiation Systems and Applications XIII. , International Society for Optics and Photonics. 85090 (2012).

- Midgley, P. A., Dunin-Borkowski, R. E. Electron tomography and holography in materials science. Nature Materials. 8, 271(2009).

- Aguiar, J. A., et al. In-situ Ion Irradiation and Recrystallization in Highly Structured Materials. Microscopy and Microanalysis. 25, 1572-1573 (2019).

- Briot, N. J., Kosmidou, M., Dingreville, R., Hattar, K., Balk, T. J. In situ TEM investigation of self-ion irradiation of nanoporous gold. Journal of materials science. 54, 7271-7287 (2019).

- Bufford, D., Abdeljawad, F., Foiles, S., Hattar, K. Unraveling irradiation induced grain growth with in situ transmission electron microscopy and coordinated modeling. Applied Physics Letters. 107, 191901(2015).

- Bufford, D., Dingreville, R., Hattar, K. In situ Observation of Single Ion Damage in Electronic Materials. Microscopy and Microanalysis. 21, 1013-1014 (2015).

- Bufford, D. C., Hattar, K. Physical response of gold nanoparticles to single self-ion bombardment. Journal of Materials Research. 29, 2387-2397 (2014).

- Bufford, D. C., Snow, C. S., Hattar, K. Cavity Formation in Molybdenum Studied In situ in TEM. Fusion Science and Technology. 71, 268-274 (2017).

- Chen, Y., et al. In situ study of heavy ion irradiation response of immiscible Cu/Fe multilayers. Journal of Nuclear Materials. 475, 274-279 (2016).

- Cowen, B. J., El-Genk, M. S., Hattar, K., Briggs, S. A. A study of irradiation effects in TiO2 using molecular dynamics simulation and complementary in situ transmission electron microscopy. Journal of Applied Physics. 124, 095901(2018).

- Dillon, S. J., et al. Irradiation-induced creep in metallic nanolaminates characterized by In situ TEM pillar nanocompression. Journal of Nuclear Materials. 490, 59-65 (2017).

- El-Atwani, O., et al. In-situ TEM/heavy ion irradiation on ultrafine-and nanocrystalline-grained tungsten: Effect of 3 MeV Si, Cu and W ions. Materials Characterization. 99, 68-76 (2015).

- Jawaharram, G. S., Barr, C., Price, P., Hattar, K., Dillon, S. J. In situ TEM Measurements of Ion Irradiation Induced Creep. Microscopy and Microanalysis. 25, 1566-1567 (2019).

- Jawaharram, G. S., et al. High temperature irradiation induced creep in Ag nanopillars measured via in situ transmission electron microscopy. Scripta Materialia. 148, 1-4 (2018).

- Li, N., Hattar, K., Misra, A. In situ Probing of the Evolution of Irradiation-induced Defects in Copper. Microscopy and Microanalysis. 21, 443-444 (2015).

- Muntifering, B., Dunn, A., Dingreville, R., Qu, J., Hattar, K. In-Situ TEM He+ Implantation and Thermal Aging of Nanocrystalline Fe. Microscopy and Microanalysis. 21, 113-114 (2015).

- Muntifering, B., et al. In situ transmission electron microscopy He+ implantation and thermal aging of nanocrystalline iron. Journal of Nuclear Materials. 482, 139-146 (2016).

- Muntifering, B., Juan, P. A., Dingreville, R., Qu, J., Hattar, K. In-Situ TEM Self-Ion Irradiation and Thermal Aging of Optimized Zirlo. Microscopy and Microanalysis. 22, 1472-1473 (2016).

- Taylor, C., Muntifering, B., Snow, C., Hattar, K., Senor, D. Using in-situ TEM Triple Ion Beam Irradiations to Study the Effects of Deuterium, Helium, and Radiation Damage on TPBAR Components. Microscopy and Microanalysis. 23, 2216-2217 (2017).

- Taylor, C. A., et al. Investigation of Helium Behavior in Multilayered Hydride Structures Through In-situ TEM Ion Implantation. Microscopy and Microanalysis. 25, 1570-1571 (2019).

- Wang, X., et al. Defect evolution in Ni and NiCoCr by in situ 2.8 MeV Au irradiation. Journal of Nuclear Materials. , (2019).

- Bufford, D. C., Barr, C. M., Wang, B., Hattar, K., Haque, A. Application of In situ TEM to Investigate Irradiation Creep in Nanocrystalline Zirconium. JOM. , (2019).

- Hosemann, P., Kiener, D., Wang, Y., Maloy, S. A. Issues to consider using nano indentation on shallow ion beam irradiated materials. Journal of Nuclear Materials. 425, 136-139 (2012).

- Hinks, J., Van Den Berg, J., Donnelly, S. MIAMI: Microscope and ion accelerator for materials investigations. Journal of Vacuum Science & Technology A: Vacuum, Surfaces, and Films. 29, 021003(2011).

- Serruys, Y., et al. Multiple ion beam irradiation and implantation: JANNUS project. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms. 240, 124-127 (2005).

- Giannuzzi, L. A., Stevie, F. A. A review of focused ion beam milling techniques for TEM specimen preparation. Micron. 30, 197-204 (1999).

- Langford, R., Petford-Long, A. Preparation of transmission electron microscopy cross-section specimens using focused ion beam milling. Journal of Vacuum Science & Technology A: Vacuum, Surfaces, and Films. 19, 2186-2193 (2001).

- Ziegler, J. F., Biersack, J. P. Nuclear Energy Agency of the OECD (NEA). , (2008).

- Robinson, M. T., Torrens, I. M. Computer simulation of atomic-displacement cascades in solids in the binary-collision approximation. Physical Review B. 9, 5008(1974).

- Hands, A., et al. New data and modelling for single event effects in the stratospheric radiation environment. IEEE Transactions on Nuclear Science. 64, 587-595 (2016).

- Kinchin, G., Pease, R. The displacement of atoms in solids by radiation. Reports on progress in physics. 18, 1(1955).

Reprints and Permissions

Request permission to reuse the text or figures of this JoVE article

Request PermissionExplore More Articles

This article has been published

Video Coming Soon

Copyright © 2025 MyJoVE Corporation. All rights reserved