A subscription to JoVE is required to view this content. Sign in or start your free trial.

Method Article

Mass Production of Entomopathogenic Fungi, Metarhizium robertsii and Metarhizium pinghaense, for Commercial Application Against Insect Pests

In This Article

Summary

Entomopathogenic fungi have gained importance as the biological control agents of agricultural insect pests. In this study, the mass production of a sufficient number of resilient infective propagules of South African isolates of both Metarhizium robertsii and M. pinghaense for commercial application against insect pests was successfully conducted using agricultural grain products.

Abstract

Entomopathogenic fungi of the Metarhizium anisopliae species complex have gained importance as the biological control agents of agricultural insect pests. The increase in pest resistance to chemical insecticides, the growing concerns regarding the negative effects of insecticides on human health, and the environmental pollution from pesticides have led to a global drive to find novel sustainable strategies for crop protection and pest control. Previously, attempts to mass culture such entomopathogenic fungi (EPF) species as Beauveria bassiana have been conducted. However, only limited attempts have been conducted to mass culture Metarhizium robertsii and M. pinghaense for use against insect pests. This study aimed to mass-produce a sufficient number of resilient infective propagules of South African isolates of M. robertsii and M. pinghaense for commercial application. Three agricultural grain products, flaked oats, flaked barley, and rice, were used as the EPF solid fermentation substrates. Two inoculation methods, conidial suspensions and the liquid fungal culture of blastospores were used to inoculate the solid substrates. Inoculation using conidial suspensions was observed to be relatively less effective, as increased levels of contamination were observed on the solid substrates relative to when using the blastospore inoculation method. Flaked oats were found not to be a suitable growth substrate for both M. robertsii and M. pinghaense, as no dry conidia were harvested from the substrate. Flaked barley was found to favor the production of M. robertsii conidia over that of M. pinghaense, and an average of 1.83 g ± 1.47 g of dry M. robertsii conidia and zero grams of M. pinghaense conidia was harvested from the substrate. Rice grains were found to favor the conidial mass production of both M. pinghaense and M. robertsii isolates, with an average of 8.2 g ± 4.38 g and 6 g ± 2 g harvested from the substrate, respectively.

Introduction

Entomopathogenic fungi (EPF) have gained importance as crop protection agents in the biological control of important agricultural insect pests1,2. The entomopathogens, which occur naturally in soil, cause epizootics in the populations of various pest species3. The species of EPF are host-specific and pose relatively few risks in terms of attacking nontarget species, and they are nontoxic to the environment4. EPF have a unique mechanism for invading their host, as well as for propagating and persisting in their immediate environment1. They attack the host mainly through asexual spores that attach to and penetrate the host cuticle to invade and proliferate in the host hemocoel. The host eventually dies due to depletion of the hemolymph nutrients or as a result of the toxemia caused by the toxic metabolites released by the fungus. Following death, under ideal environmental conditions, the fungus emerges on the outer surface (overt mycosis) of the host cadaver5,6.

Growing concerns regarding the negative effects of chemical residues on human health, environmental pollution, and the development of pest resistance have led to the global drive to reduce inputs of chemical-based insecticides and to find alternative, novel, and sustainable strategies for crop protection and pest control6,7,8. This has provided opportunities to develop microbial-based insecticides for use in Integrated Pest Management (IPM) programs, which are more ecologically favorable strategies than conventional chemical control3,8.

To develop a successful microbial control agent for an agricultural pest, a suitable organism must first be isolated, characterized, identified and its pathogenicity for the target pest confirmed. However, an easy, cost-effective method for large-scale production of the microbial agent is required to produce a viable product for use in biological control programmes9,10,11,12,13. Mass production of substantial quantities of good-quality entomopathogens depends on the microbial strain, the environment, the target pest, the formulation, the market, the application strategy, and the desired end product14,15,16. EPF can be mass-produced using liquid substrate fermentation to produce blastospores or the solid substrate fermentation process to produce aerial conidia6,17,18. However, the mass production and formulation process of entomopathogens directly influences the virulence, the cost, the shelf life, and the field efficacy of the final product. For successful use in IPM, the production process of the entomopathogens must be easy to run, require minimal labor, produce a high-yield concentration of virulent, viable, and persistent propagules, and be low in cost4,13,14,16.

Understanding the nutritional requirements of entomopathogens is important for mass cultivation with all culturing methods4,12. The nutritional components of the production medium have a significant impact on the attributes of the resulting propagules, including biocontrol efficacy, yield, desiccation tolerance, and persistence8,19,20,21. The optimization of production procedures is designed to address such factors22. For EPF, the main requirements for good growth, sporulation, and mass production of fungal conidia are adequate moisture, optimum growth temperature, pH, gas exchange of CO2 and O2, and nutrition, including good phosphorous, carbohydrate, carbon, and nitrogen sources18.

Jaronski and Jackson18 describe the solid substrate fermentation method as the most efficient and the closest approximation method to the natural process for EPF production relative to the liquid substrate fermentation method because, under natural conditions, the fungal conidium is borne on solid erect structures, like the surface of insect cadavers. Agricultural products and by-products containing starch are mostly used for the mass production of hypocrealean fungi, as the fungi readily decompose starch through secretion of highly concentrated hydrolytic enzymes from their hyphal tips, to penetrate the solid substance, and to access the nutrients present in the substance11,17,18,23. The grain products also provide the requirements for healthy biomass production because, when they are hydrated and sterilized, the substrates can absorb further nutrients from any liquid medium16,18,24.

Previously, several studies attempted to mass culture EPF species like Beauveria bassiana (Bals.) Vuil., Cordyceps fumosorosea (Wize) Kelper B. Shrestha & Spatafora, Verticillium lecanii (Zimm.) Viegas and some of the Metarhizium anisopliae (Metschn.) Sorokin species complex isolates on various substrates16,23,24. Such mass-produced and commercially developed isolates include Green Muscle® (strain IMI 330189), developed from M. anisopliae var Metarhizium acridum (Driver & Milner) J.F. Bisch, Rehner & Humber, Metarhizium 69 (Meta 69 strain ICIPE69), and Real Metarhizium 69 (L9281), developed from M. anisopliae, and Broadband® (strain PPRI 5339) and Eco-Bb®, developed from B. bassiana25,26. However, limited attempts have been made to mass culture Metarhizium robertsii J.F. Bisch., S.A. Rehner & Humber and Metarhizium pinghaense Chen & Guo. These two isolates were selected in a previous study as the most effective for the control of the mealybug, Pseudococcus viburni Signoret (Hemiptera: Pseudococcidae)27. Therefore, the current study aimed to formulate and mass-produce a sufficient number of resilient infective propagules of the local isolates of M. robertsii and M. pinghaense for commercial application against insect pests. The solid substrate fermentation method was used to mass-produce the fungal conidia for both EPF isolates. Two EPF inoculation methods, using conidial suspensions and the liquid fungal culture of blastospores, were used to inoculate the solid substrates.

Protocol

1. Source of fungal strains

- Use South African isolated fungal strains of both M. pinghaense 5 HEID (GenBank Accession number: MT367414/MT895630) and M. robertsii 6EIKEN (MT378171/MT380849), collected from apple orchards in the Western Cape province, South Africa.

- Grow cultures of each EPF isolate on 60 g of Sabouraud dextrose agar medium, supplemented with 1 g of yeast extract (SDAY) and 10 µL of Streptomycin.

NOTE: Incubate EPF cultures at a controlled temperature of ± 25 °C in the dark.

2. Metarhizium pinghaense and M. robertsii conidial suspension inoculation

- Preparation of the solid substrates

- Use two agricultural products, namely flaked oats and flaked barley, as growth mediums for the two EPF isolates and autoclave bags (305 mm × 660 mm) as fermentation bags.

- Use a small polyvinylchloride waste pipe (1000 mm × 50 mm) to create a neck for the fermentation bag at the open end of the autoclave bag and use autoclave tape to secure the pipe to the bag.

- Close the pipe with a sterile cotton wool plug to allow sufficient gas exchange during fermentation.

- Weigh dry grains (200 g) of both the flaked oats and flaked barley and place them in the fermentation bags, and to each bag, add 100 mL of distilled water and thoroughly mix the contents of the bags.

- Leave the wet grains to rest for 15-30 min to absorb moisture before autoclaving and sterilization. Prepare six bags for each grain type, and to prevent contamination, place the bags in other autoclave bags, and autoclave the substrates at 121 °C for 55 min.

- Preparation of conidial suspension inoculum

- Harvest 2-3-week-old fungal conidia from fungal cultures of both M. pinghaense and M. robertsii by scraping, using a sterile surgical blade.

- Suspend the collected fungal conidia in 20 mL of sterile distilled water, supplemented with 0.05% Tween 20, and vortex-mix the conidial suspensions for 2 min.

- Prepare 20 mL of conidial suspensions, with a concentration of 1 × 107 conidia/mL, and inoculate the flaked oat and flaked barley solid substrates, respectively.

NOTE: Use a hemocytometer to determine conidial concentrations.

- Inoculation of the solid substrates

- Open each bag by removing the cotton wool neck plugs, and add the prepared 20 mL conidial suspension to the cooled autoclaved substrate.

- Close the bags again, using the neck plugs, and massage the contents of the bag to allow the fungal inoculum to become evenly mixed with the grain substrate.

- Incubate the fermentation bags at a controlled temperature of ± 25 °C, and ensure sufficient gaseous exchange between the culture and the environment.

NOTE: This procedure must be conducted under a laminar flow cabinet.

- Fermentation phase

- Manually massage the grain substrates in the fermentation bags 2 days after the inoculation and incubation, when visible mycelial growth occurs and the substrate has begun to be clumped by the growing fungus.

NOTE: This is done to mix the inoculated granules to allow for mycelial branching to take place during the first early stages of the vegetative growth of the fungi. - Use a kitchen rolling pin to manipulate the substrate bed to avoid the physical heterogeneity of the grain substrate beds and the bed thickness of the substrate mass.

NOTE: The process promotes fungal metabolism, which optimizes fungal spore production, and maximizes the surface area, promoting conidial yield18. - Leave the fermentation process to continue for up to 4-5 weeks, and check the fermentation bags every 2 days for the presence of any white vegetative overgrowth that can develop during the fermentation process, which can greatly affect the fungal conidia yield.

NOTE: Immediately terminate fermentation in the fermentation bags containing any white vegetative overgrowth, and dry the fungal cultures18.

- Manually massage the grain substrates in the fermentation bags 2 days after the inoculation and incubation, when visible mycelial growth occurs and the substrate has begun to be clumped by the growing fungus.

3. Blastospore inoculation

- Blastospore production and inoculation

- Prepare a liquid culture medium, containing 1 L of distilled water, 30 g of glucose, 20 g of yeast extract, 4 g of potassium phosphate diabasic (K2HPO4), 15 mL of corn steep liquor, and 10 µg/mL of the antibiotic Streptomycin, for both the M. pinghaense and the M. robertsii.

- First, heat the distilled water, switch off before reaching boiling point, and add each of the ingredients, except for Streptomycin, to the hot water in the pot. Bring the medium to a gentle boil for 3-4 min, and constantly stir the medium to allow for the proper mixing of the ingredients and prevent the settling of some of the ingredients at the bottom of the pot.

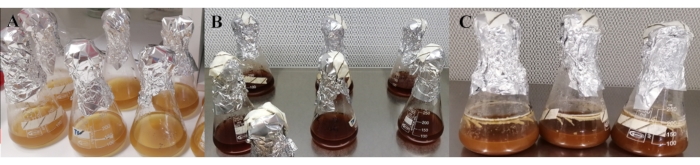

- Pour a total of 100 mL of the medium into nine different 250-mL flasks and place a cotton wool plug on each flask, and cover the cotton wool with aluminum foil as a stopper (Figure 1A).

- Autoclave the medium in the flasks for 55 min at 121 °C. Following the autoclaving, allow the medium in the flasks to cool and add 10 mg/mL of Streptomycin to the medium in each flask (Figure 1B).

- Collect two to three bacterial loops of fungal conidia from 2-3-week-old fungal culture plates for both the EPF isolates, M. pinghaense and M. robertsii, and transfer to each 100 mL liquid media in the 250-mL flasks, under sterile conditions, and seal the flasks.

- Incubate the liquid culture flasks at ± 25 °C, on an orbital shaker at 140 rpm for 3 days, and cease the incubation once the cultures show signs of high turbidity with fungal blastospore growth (Figure 1C).

- To detect any possible bacterial contamination from the cultures, draw a 100 µL sample from each liquid culture flask after 24 h during the incubation and plate on three SDA plates per isolate. Incubate the plates for 48 h, at a controlled temperature of ± 25 °C.

- Preparation of the solid substrate

- Use parboiled long-grain white rice as a solid substrate medium for the blastospores of both M. pinghaense and M. robertsii (adapted from Jaronski and Jackson18).

- Prepare the fermentation bags as detailed above, in steps 2.1.1-2.1.3, and for each bag, add 1 kg of rice and 300 mL of sterile distilled water.

- Gently mix the contents of the fermentation bags and place in outer autoclave bags in an upright position, and autoclave at 121 °C for 55 min. Following the autoclaving, allow the substrates to cool down for ± 45 min under sterile conditions.

- Inoculation and fermentation

- Remove the closure of each of the liquid culture flasks of both M. pinghaense and M. robertsii under a laminar flow and flame the rim of each flask for 10 s.

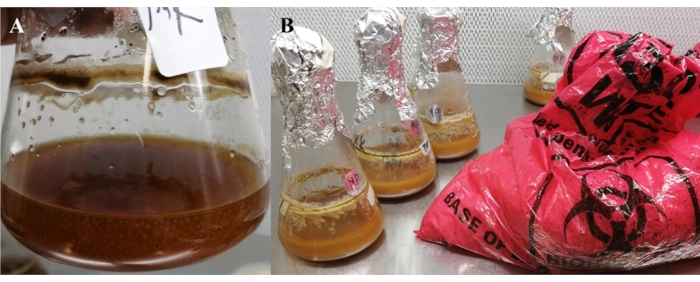

- Pour the 100-mL liquid cultures into the fermentation bags by removing the cotton wool plugs from their necks (Figure 2). Place the cotton plugs back on and cover the top of the bag's neck with surgical paper secured with a rubber band.

NOTE: Determine blastospore concentration for each flask using a hemocytometer, and use blastospore concentrations of 1 × 107 - 5 × 108 blastospores/mL to innoculate the substrates28. - Twist the top part of the bag and mix the contents of the bag by shaking and light manipulation of the substrate by massage, and incubate the bags at ± 25 °C, by flattening the substrate in the bags to prevent the formation of thick beds18.

- Break the substrate in the fermentation bags by massaging contents of the bags, 2-3 days following the inoculation and the incubation, when visible mycelial growth and the binding of the substrate by the fungus had occurred (adapted from the technique of Jaronski and Jackson18).

NOTE: Allow fermentation to continue for 4 weeks.

Figure 1: Liquid culture medium in 250-mL flasks. (A) Before autoclaving. (B) After autoclaving and inoculation with EPF spores. (C) Turbid medium with fungal blastospores. Please click here to view a larger version of this figure.

Figure 2: Prepared blastospore liquid culture medium. (A) Metarhizium robertsii and (B) Metarhizium pinghaense prior to the inoculation of rice as a solid substrate. Please click here to view a larger version of this figure.

4. Drying of fungal cultures

- Dry the fungal cultures for 10-12 days following fermentation, prior to their use in trials, by transferring the sporulated cultures into 26-30 kg (30 x 43 x 15250 cm3) brown paper bags.

- To improve the tensile strength of the paper bags, horizontally cut off one-third of the top part of each bag, and line the bottom of the bag (Figure 3A, B).

Figure 3: Preparation of paper bags, drying procedure of cultures, and packaging. (A,B) The preparation of brown paper bags. The drying procedure of Metarhizium species cultures grown on (C,E) parboiled rice and (D,F) flaked barley. (G) Paper bags closed with staples to create a triangular tent structure. Please click here to view a larger version of this figure.

- Gently crumble the substrate in each fermentation bag, cut off the corner of each bag and transfer the whole culture to the paper bags through the space left by the cut-off corner (Figure 3C-F). To avoid the excessive escaping of fungal spores into the air, perform this process slowly.

NOTE: Conduct this process under sterile conditions, using laminar flow, to avoid contamination. - Label each paper bag and fold over the top end of each bag twice and close with staples to create a triangular tent structure, and place the bags on wire drying racks to allow proper, even drying, at a controlled temperature of ± 25 °C and low humidity of 30-40%.

- Turn the bags daily to allow even drying of the cultures and to avoid any vegetative regrowth that might take place, which would lower the yield of harvestable fungal spores.

- Weigh each drying bag after every 2 days during the drying process, and continue the drying process for each bag until little to no change is observed in the mass of the bags between the successive days.

5. Harvest of fungal conidia

- Harvest fungal conidia mechanically from the cultures using three nested sieves, a test sieve (ETS) mesh no. 35 (with 500-µm aperture), nested on a test sieve (with 212-µm aperture), nested on ETS mesh no. 100 (with 150-µm aperture), mounted on a collection pan.

- Load the dry culture sample on the ETS mesh no. 35 sieve slowly and place a lid on the sieve to prevent the release of fungal conidia into the air.

- Add 10-12 glass marbles to the sieves to assist the passage of the fungal conidia through the mesh screens and avoid the retention of the conidia in the sieve, which can result in reduced spore recovery.

- Tape and seal the sieve joints using electrical tape to prevent the escape of conidial dust.

- Place the sieves on a vibratory shaker, fitted with a sticky pad, to secure the collection pan and sieves, for 20-25 min, at a motion of 560-640 vibrations per min (Figure 4).

NOTE: Technique adapted from Jaronski and Jackson18.

Figure 4: Harvesting of fungal spores from dried Metarhizium robertsii cultures on rice and flaked barley. (A) 10-12 glass marbles added to the sieves to assist the passage of the fungal conidia through the mesh screens. M. robertsii conidia harvested from cultures on (B) rice, and (C) flaked barely. (D) Sieves on a vibratory shaker. Please click here to view a larger version of this figure.

- Remove the test sieves from the collection pan, collect conidia and store the collected conidia in airtight and water-impermeable zipper-lock bags for long-term storage (3-6 months).

6. Quantification of fungal conidia produced

- Measure and record the mass of each grain substrate prior to the harvesting of the fungal conidia from each substrate.

- Measure the overall weight of the collected conidia by subtracting the mass of the collected spores from the mass of the solid substrate.

NOTE: The total conidia yield does involve not only the harvested conidia but also the fungal conidia left on the solid substrate. - Weigh the substrate and remove 10 g from the weighed substrate. Suspend the 10 g of the substrate in 0.05% Tween 20 and dilute in 10 mL of sterile distilled water.

- Vortex-mix the suspension for 2 min, and use a hemocytometer to do the spore count to determine the number of conidia washed from the substrate.

- Conduct further dilutions by transferring 1000 µL of the 10 mL washed conidial suspension to 9 mL of sterile distilled water to make up 10 mL of dilution suspensions.

- Vortex-mix the conidial suspensions for 2 min, and determine the conidial concentrations.

NOTE: Follow the procedure and formula described by Inglis, Enkerli, and Goettel30 to determine the conidial concentration of the suspensions. - Collect and suspend a total of 0.1 g of the collected conidial powder from each culture in 10 mL of sterile distilled water supplemented with 0.05% Tween 20, and vortex-mix the conidial suspension for 2 min, and determine the conidial concentration using a hemocytometer.

- Conduct further dilutions by transferring 1000 µL of the 10 mL conidial suspension to 9 mL of sterile distilled water to make up the 10 mL suspension dilutions.

- Vortex-mix the conidial suspensions for 2 min, calculate the conidial concentrations and determine the number of conidia per gram.

- Multiply the number of conidia per gram of harvested powder by the initial mass of the harvested conidial powder. Multiply the number of conidia washed from the substrate by the total weight of the spent substrate, being the substrate from which the conidia were harvested.

- Add the two given values together and divide by the initial dry weight of the substrate to calculate the number of conidia per kg or g of the substrate18.

NOTE: The calculations were done mainly for the rice substrate. The germination or conidial viability test was conducted for both the M. pinghaense and the M. robertsii isolates to determine the viability of the produced conidia.

7. Data analysis

- Use an appropriate computer software program to conduct the statistical analysis of the obtained results.

NOTE: Statistical analysis of the data was done using STATISTICA version 13.5.0.17.

Results

A decline in the content mass of the cultures on rice for both the M. pinghaense and the M. robertsii was observed over time during the drying stage of the fungal cultures, with no, or little, change being observed in the mass once the cultures were dry (Figure 5). The harvested dry fungal conidia powder of both the M. pinghaense and the M. robertsii is shown in Figure 6.

Discussion

The successful integration of microbial agents for the biological control of important agricultural insect pests in an agroecosystem depends on both success and ease of mass production of the entomopathogens as the first step under laboratory conditions. The mass production of EPF is important for the large-scale application and availability of EPF products for IPM programs using biological control9,10,11,

Disclosures

The authors have nothing to disclose.

Acknowledgements

The authors would like to thank Hort Pome, Hort Stone, and the Technology and Human Resources for Industry Programme (THRIP: TP14062571871) for funding the project.

ORCID:

Letodi L. Mathulwe http://orcid.org/0000-0002-5118-3578

Antoinette P. Malan http://orcid.org/0000-0002-9257-0312

Nomakholwa F. Stokwe http://orcid.org/0000-0003-2869-5652

Materials

| Name | Company | Catalog Number | Comments |

| 0.05% Tween 20 | Lasec | Added to conidial suspensions to allow fungal spores to mix with water | |

| 20 mL McCartney bottles | Lasec | Used to make conidial suspensions | |

| Aluminium foil | Used as a cover of the cotton wool plugs on 250-mL flask | ||

| Autoclave | Used to sterilize materials and ingredients used for the conidia production process | ||

| Autoclave bags | Lasec | Fermentation bags or solid substrate containers | |

| Autoclave tape | Lasec | To secure PVC pipes on the fermentation bags | |

| Brown Kraft paper bags | Used to dry conidia cultures on agricultural grains | ||

| Bunsen burnner | Labnet (Labnet International, Inc.) | Used to flame equipment (surgical blades,inoculating loops and rims of flasks) | |

| Clear edge test sieve | Used to separate fungal conidia from agricultural grain substrates | ||

| Corn steep liquor | SIGMA | 66071-94-1 | Ingredient of the blastospore liquid medium |

| Cotton Wool | Lasec | Used as plug of the neck for fermentation bags | |

| Duran laboratory bottles | Neolab | Used to autoclave SDA medium and distilled water | |

| Electrical tape | Used to tape and seal the sieve joints to prevent the escape of conidial dust | ||

| ENDECOTTS test sieve | Used to separate fungal conidia from agricultural grain substrates | ||

| Erlenmeyer Flasks, Narrow neck,250-mL flask | Lasec | Carrier of the blastospore liquid medium | |

| Ethanol (99%) | Lasec | Used to sterilize surgical blades and inoculating loops | |

| Flaked barley | Health Connection Wholefoods | Agricultural grain used as a solid substrate growth medium for conidia of both M. pinghaense and M. robertsii | |

| Flaked oats | Tiger brands | Agricultural grain used as a solid substrate growth medium for conidia of both M. pinghaense and M. robertsii | |

| Glucose | Merck | Ingredient of the blastospore liquid medium | |

| Growth Chamber/ incubators | For growing fungal conidia culture | ||

| Haemocytometer | Used to determine conidial concentrations | ||

| Inoculating loops | Lasec | For harvesting spores to innoculate liquid medium for blastospores growth | |

| Kitchen rolling pin | Used to manipulate the solid grain substrate bed | ||

| Laminar flow Cabinet | ESCO Laminar Flow Cabinet | Provide as sterile environment during substrate inoculation | |

| Metarhizium pinghaense conidia | Stellenbosch University | 5HEID | Cultures used to mass culture conidia of Metarhizium pinghaense |

| Metarhizium robertsii conidia | Stellenbosch University | 6EIKEN | Cultures used to mass culture conidia of Metarhizium robertsii |

| Microscope | ZEIZZ (Scope. A1) | Used to determine conidial concentrations and conidial viability | |

| Orbital shaker | IncoShake- LABOTEC | Used for the blastospore production process | |

| Parboiled rice | Spekko | Agricultural grain used as a solid substrate growth medium for conidia of both M. pinghaense and M. robertsii | |

| Penicillin-Streptomycin | SIGMA | Added to the SDA medium to prevent bacterial contamination | |

| Petri-dishes | Lasec | Containers for the SDA medium | |

| Pipettes and pipette tips | Labnet (BioPette PLUS) | Used to measure liquids ingredients | |

| Polyvinylchloride Marley waste pipe | Used to create a neck for the fermentation bag | ||

| Potassium phosphate dibasic (K2HPO4) | SIGMA-ALDRICH | Ingredient of the blastospore liquid medium | |

| Rubber band | Used to secure the secure the surgical paper over the fermentation bag PVC pipe necks | ||

| Sabaroud dextrose agar (SDA) | NEOGEN Culture Media | Medium used to culture spores of both Metarhizium pinghaense and Metarhizium robertsii | |

| Sterile distilled water | To hydrate agricultural grains, to make conidial suspensions | ||

| Sticky pad | Used to secure the seives on the vibratory shaker | ||

| Surgical blade | Lasec | Used to scrape off spores from fungal cultures | |

| Surgical paper | Lasec | Used to cover the PVC necks and cotton wool plugs of the fermentation bag | |

| Vibratory shaker | Used to shake conidia off the agricultural grain substrates | ||

| Vortex mixer | Labnet (Labnet International, Inc.) | Used to mix conidial suspensions in Mc Cartney bottles | |

| Yeast extract | Biolab | Added to the SDA medium to improve spore germination and growth | |

| Zipper-lock bags | GLAD | Used to to store harvested fungal conidia |

References

- Shah, P. A., Pell, J. K. Entomopathogenic fungi as biological control agents. Applied Microbiology and Biotechnology. 61 (5), 413-423 (2003).

- Mathulwe, L. L., Malan, A. P., Stokwe, N. F. A review of the biology and control of the obscure mealybug, Pseudococcus viburni (Hemiptera: Pseudococcidae), with special reference to biological control using entomopathogenic fungi and nematodes. African Entomology. 29 (1), 1-16 (2020).

- Ibrahim, L., Laham, L., Touma, A., Ibrahim, S. Mass production, yield, quality, formulation and efficacy of entomopathogenic Metarhizium anisopliae conidia. Current Journal of Applied Science and Technology. 9 (5), 427-440 (2015).

- Banu, J. G., Rajalakshmi, S. Standardisation of media for mass multiplication of entomopathogenic fungi. Indian Journal of Plant Protection. 42 (1), 91-93 (2014).

- Roberts, D. W., Humber, R. A., Cole, G. T., Kendrick, W. B. Entomogenous fungi. Biology of Conidial Fungi. , 201-236 (1981).

- Feng, M. G., Poprawski, T. J., Khachatourians, G. G. Production, formulation and application of the entomopathogenic fungus Beauveria bassiana for insect control. Current status. Biocontrol Science and Technology. 4 (1), 3-34 (1994).

- Karanja, L. W., Phiri, N. A., Oduor, G. I. Effect of different solid substrates on mass production of Beauveria bassiana and Metarhizium anisopliae entomopathogens. The Proceedings of the12th KARI Biennial Scientific Conference. , 8-12 (2010).

- Prasad, C. S., Pal, R. Mass production and economics of entomopathogenic fungus, Beauveria bassiana, Metarhizium anisopliae and Verticillium lecanii on agricultural and industrial waste. Scholars Journal of Agriculture and Veterinary Sciences. 1 (1), 28-32 (2014).

- Ehlers, R. U. Mass production of entomopathogenic nematodes for plant protection. Applied Microbiology and Biotechnology. 56 (5), 623-633 (2001).

- Pham, T. A., Kim, J. J., Kim, S. G., Kim, K. Production of blastospore of entomopathogenic Beauveria bassiana in a submerged batch culture. Mycobiology. 37 (3), 218-224 (2009).

- Bhadauria, B. P., Puri, S., Singh, P. K. Mass production of entomopathogenic fungi using agricultural products. The Bioscan. 7 (2), 229-232 (2012).

- Latifian, M., Rad, B., Amani, M. Mass production of entomopathogenic fungi Metarhizium anisopliae by using agricultural products based on liquid-solid diphasic method for date palm pest control. International Journal of Farming and Allied Sciences. 3 (4), 368-372 (2014).

- Agale, S. V., Gopalakrishnan, S., Ambhure, K. G., Chandravanshi, H., Gupta, R., Wani, S. P. Mass production of entomopathogenic fungi (Metarhizium anisopliae) using different grains as a substrate. International Journal of Current Microbiology and Applied Sciences. 7 (1), 2227-2232 (2018).

- Jackson, M. A. Optimizing nutritional conditions for the liquid culture production of effective fungal biological control agents. Journal of Industrial Microbiology and Biotechnology. 19 (3), 180-187 (1997).

- Deshpande, M. V. Mycopesticides production by fermentation. Potential and challenges. Critical Reviews in Microbiology. 25 (3), 229-243 (1999).

- Sahayaraj, K., Namasivayam, S. K. R. Mass production of entomopathogenic fungi using agricultural products and by products. African Journal of Biotechnology. 7 (12), 1907-1910 (2008).

- Feng, K. C., Liu, L. B., Tzeng, Y. M. Verticillium lecanii spore production in solid-state and liquid-state fermentations. Bioprocess Engineering. 23 (1), 25-29 (2000).

- Jaronski, S. T., Jackson, M. A., Lacey, L. A. Mass production of entomopathogenic Hypocreales. Manual of Techniques in Invertebrate Pathology 2nd edition. , 255-284 (2012).

- Vega, F. E., Jackson, M. A., Mercandier, G., Poprawski, T. J. The impact of nutrition on spore yields for various fungal entomopathogens in liquid culture. World Journal of Microbiology and Biotechnology. 19 (4), 363-368 (2003).

- El Damir, M. Effect of growing media and water volume on conidial production of Beauveria bassiana and Metarhizium anisopliae. Journal of Biological Sciences. 6 (2), 269-274 (2006).

- Pandey, A. K., Kanaujia, K. R. Effect of different grains as solid substrates on sporulation, viability and pathogenicity of Metarhizium anisopliae (Metschnikoff) Sorokin. Journal of Biological Control. 22 (2), 369-374 (2008).

- Kassa, A., et al. Whey for mass production of Beauveria bassiana and Metarhizium anisopliae. Mycological Research. 112 (5), 583-591 (2008).

- Sharma, S., Gupta, R. B. L., Yadavam, C. P. S. Selection of a suitable medium for mass multiplication of entomofungal pathogens. Indian Journal of Entomology. 64 (3), 254-261 (2002).

- Bich, G. A., Castrillo, M. L., Villalba, L. L., Zapata, P. D. Evaluation of rice by-products, incubation time, and photoperiod for solid state mass multiplication of the biocontrol agents Beauveria bassiana and Metarhizium anisopliae. Agronomy Research. 16 (5), 1921-1930 (2018).

- Price, R. E., Müller, E. J., Brown, H. D., D'Uamba, P., Jone, A. A. The first trial of a Metarhizium anisopliae var. acridum mycoinsecticide for the control of the red locust in a recognised outbreak area. International Journal of Tropical Insect Science. 19 (4), 323-331 (1999).

- Hatting, J. L., Moore, S. D., Malan, A. P. Microbial control of phytophagous invertebrate pests in South Africa. Current status and future prospects. Journal of Invertebrate Pathology. 165, 54-66 (2019).

- Mathulwe, L. L., Malan, A. P., Stokwe, N. F. Laboratory screening of entomopathogenic fungi and nematodes for pathogenicity against the obscure mealybug, Pseudococcus viburni (Hemiptera: Pseudococcidae). Biocontrol Science and Technology. , (2021).

- Inglis, G. D., Enkerli, J., Goettel, M. S. Laboratory techniques used for entomopathogenic fungi: Hypocreales. Manual of Techniques in Invertebrate Pathology. , 189-253 (2012).

- Mehta, J., et al. Impact of carbon & nitrogen sources on the Trichoderma viride (Biofungicide) and Beauveria bassiana (entomopathogenic fungi). European Journal of Experimental Biology. 2 (6), 2061-2067 (2012).

- Burges, H. D. Formulation of mycoinsecticides. Formulation of Microbial Biopesticides. , 131-185 (1998).

Reprints and Permissions

Request permission to reuse the text or figures of this JoVE article

Request PermissionThis article has been published

Video Coming Soon

Copyright © 2025 MyJoVE Corporation. All rights reserved