A subscription to JoVE is required to view this content. Sign in or start your free trial.

Method Article

Finite Element Modeling for the Simulation of the Quasi-Static Compression of Corrugated Tapered Tubes

In This Article

Summary

This protocol describes the study of the quasi-static compression performance of corrugated tapered tubes using finite element simulations. The influence of the thickness gradient on the compression performance was investigated. The results show that proper thickness gradient design can change the deformation mode and significantly improve the energy absorption performance of the tubes.

Abstract

In this study, the quasi-static compression performance of tapered tubes was investigated using finite element simulations. Previous studies have shown that a thickness gradient can reduce the initial peak force and that lateral corrugation can increase the energy absorption performance. Therefore, two kinds of lateral corrugated tapered tubes with variable thicknesses were designed, and their deformation patterns, load displacement curves, and energy absorption performance were analyzed. The results showed that when the thickness variation factor (k) was 0.9, 1.2, and 1.5, the deformation mode of the single corrugated tapered tube (ST) changed from transverse expansion and contraction to axial progressive folding. In addition, the thickness gradient design improved the energy absorption performance of the ST. The energy absorption (EA) and specific energy absorption (SEA) of the model with k = 1.5 increased by 53.6% and 52.4%, respectively, compared with the ST model with k = 0. The EA and SEA of the double corrugated tapered tube (DT) increased by 373% and 95.7%, respectively, compared with the conical tube. The increase in the k value resulted in a significant decrease in the peak crushing force of the tubes and an increase in the crushing force efficiency.

Introduction

Crashworthiness is an essential issue for lightweight automobiles, and thin-walled structures are widely used to improve crashworthiness. Typical thin-walled structures, such as round tubes, have good energy absorption capacity but usually have large peak forces and load fluctuations during the crushing process. This problem can be solved by introducing axial corrugations1,2,3. The presence of corrugations allows the tube to plastically deform and fold according to a predesigned corrugation pattern, which can reduce the peak force and load fluctuations4,5. However, this stable and controlled deformation pattern has a drawback: the energy absorption performance decreases. To improve the energy absorption of axial corrugated tubes, researchers have tried many methods, such as using a functional gradient design in the wavelength6,7 and amplitude8, using filling foam9,10, forming multichamber and multiwall structures11, and forming combined tubes12.

In addition, researchers have designed lateral corrugated tubes by introducing corrugations into the cross-section of circular tubes13,14,15,16. The existence of lateral corrugations greatly improves the energy absorption performance of the tube17,18,19. Eyvazian et al.20 compared the crashworthiness of lateral corrugated tubes and ordinary circular tubes and showed that lateral corrugated tubes had a better energy absorption capacity. One reason for this observation is that the lateral corrugation strengthens the tube wall, which makes it more resistant to plastic folding. In addition, the corrugated wall of the plastic folding part flattens, and this flattening also absorbs energy. However, the high initial peak force is a disadvantage of this type of tube, and this high initial force may seriously affect the safety of the passengers being transported.

Functionally graded structures have a natural advantage in reducing the peak force. Common functionally graded thin-walled tubes are usually formed by changing the geometric parameters (e.g., the diameter and wall thickness)21. The most prevalent structures for which the diameter is changed are tapered tubes, including circular tapered tubes22, square tapered tubes23,24,25, polygonal tapered tubes26,27, axial corrugated tapered tubes28,29,30, and tapered tubes with elliptical cross sections31. However, there are few studies on lateral corrugated tubes. Typical thickness gradient structures include square tubes32,33, circular tubes34,35, tapered tubes36, multicellular tubes37,38, and lattice structures39. Deng et al.40 reduced the initial peak force of lateral corrugated tubes with a thickness gradient design by 44.53%, but there have been no studies on lateral corrugated tapered tubes.

Although experiments are the most accurate and direct method to evaluate the crashworthiness of structures, they also require considerable money and resources. In addition, some important data, such as the stress-strain clouds of the structure and the energy values of different forms, are difficult to obtain in experiments18. Finite element analysis is a method to simulate the real load conditions by using mathematical approximation. This was first applied in the aerospace field, mainly for solving linear structural problems. Later, it was gradually applied to solve nonlinear problems in many fields, such as civil engineering, mechanical engineering, and material processing34. In addition, with finite element software development, simulation results have become increasingly close to those of the corresponding experiments. Therefore, simulation using finite element analysis is used to investigate the crashworthiness of the structures. In this study, finite element analysis of the quasi-static compression performance of corrugated tapered tubes was conducted. The energy absorption of two types of lateral corrugated tapered tubes (i.e., the single corrugated tapered tube [ST] and the double corrugated tapered tube [DT]) with variable thicknesses was studied numerically. The results were compared with those obtained for a conventional conical tube (CT). The dimensions of the three types of thin-walled tubes are shown in Figure 1A. The geometric parameters of the ST are shown in Figure 1B, and the DT is built by crossing two STs. The thickness gradient is designed as shown in Figure 1C, and the thickness variation is defined by introducing a variation: factor k. In Figure 1C, th/2 = 0.44 mm, and k is set to 0, 0.3, 0.6, 0.9, 1.2, and 1.5. The results show that the peak crushing force decreases and the crushing force efficiency increases with increases in k.

Protocol

1. Creating the surface in the CAD software

- Open the CAD software (see Table of Materials), left-click on File, left-click on New, and select Part.

- In Part1, right-click on Top, and select Show.

- Create a new plane: Press Ctrl, and left-click to select the Top plane and drag it up. Enter 30 mm as the Offset Distance, and rename the plane "Bottom".

- Create a sketch on the "Top" plane.

- Right-click on Top, and select Sketch to create Sketch 1. Select Equation Driven Curve in Spline of the Sketch.

- Select Parametric in Equation Type. Input the parameters according to Table 1.

NOTE: The sketch shape of the top plane is generated in this step. For example, if one desires to create a CT, enter 7.21 x sin(t), 7.21 x cos(t), 0 and 2 x pi in Table 1 in this step.

- Create a sketch on the "Bottom" plane.

- Right-click on Bottom, and select Sketch to create Sketch 2. Select Equation Driven Curve in Spline.

- Select Parametric in Equation Type. Input the parameters according to Table 1.

NOTE: The sketch shape of the bottom plane is generated in this step. For example, if you want to create a CT, enter 12.5 x sin(t), 12.5 x cos(t), 0, and 2 x pi in Table 1 in this step.

- Generate the surface.

- Left-click on Lofted surface. Select Sketch 1 and Sketch 2 in Profiles, and select OK (see Supplementary File 1).

- Repeat the above steps (steps 1.1-1.6) to generate three kinds of surfaces (Figure 1A), and name them CT, ST, and DT, as shown in Figure 1A.

NOTE: Step 1.4.4 and step 1.5.4 create the sketches of the top and bottom planes, respectively, and step 1.6 connects the sketches of the top and bottom planes together to form a surface. The difference between the three planes is in the sketch of step 1.4.4 and step 1.5.4.

2. Building the model in the finite element software

NOTE: The quasi-static compression model of ST with k = 0.9 is described here as an example. The finite element models of the three types of tubes are exactly the same. Therefore, the different types of tubes in step 2.1.1 are to be imported, and step 2 needs to be repeated to get all the results.

- Parts: Import and create the parts.

- Open the finite element software (see Table of Materials). Import the part "ST": left click File > Import > Part in order.Select the file ST, and name this part "ST" (see Supplementary File 2).

- Create the part "Bottom Plane": Left-click on Create Part. Under Shape, select Shell, name this part "Bottom Plane", and left-click on Continue. Select Create Circle: Center and Perimeter, and draw a circle with the origin as the center and a radius of 20 mm. Add the reference point set4 to the part "Bottom Plane".

- Create the part "Top Plane": Left-click on Create Part. Under Shape, select Shell, name this part "Top Plane", and left-click on Continue. Select Create Circle: Center and Perimeter, and draw a circle with the origin as the center and a radius of 20 mm.Add the reference point set5 to the part "Top Plane".

- Property: Define the materialproperties, and assign the material to the section.

- Create the material properties.

NOTE: The three types of tubes have the same material properties.- Left-click on Create Material > General > Density in order,and enter "7.85E-09 (7.85 x 10−9)" under "Mass Density".

NOTE: The material properties are obtained from previously published reports41 with the same materials, and an introduction to the materials is included in the discussion section. - Left-click on Mechanical > Elasticity > Elastic in order, and under Young's Modulus and Poisson's Ratio, input "185,000" and "0.3", respectively.

- Left-click on Mechanical > Plasticity > Plastic in order, and enter the data taken from Figure 2 in "Yield Stress" and "Plastic Strain".

- Left-click on Create Material > General > Density in order,and enter "7.85E-09 (7.85 x 10−9)" under "Mass Density".

- Assign the section.

- Left-click on Create Section, under "Category", select Shell, and left-click on Continue.

- Under "Shell Thickness" select Nodal Distribution, left-click on Create Analytical Field, select Expression field, and enter the formula "0.44 − 0.9/100 x (Y − 15)".

NOTE: The formula is used to change the thickness of the tube in the height direction and achieve the thickness gradient. The thickness variation factor k is defined as shown in Figure 1C, which indicates the thickness variation per unit height. In addition, the thickness of half of the height is set to a fixed value (i.e., th/2 = 0.44 mm) so that the thickness of the other heights can be derived from the middle height:

0.44 − k/100 × (Y − 15)

where Y is the height direction in the software. - Left-click on Assign Section, pick ST from the interface, left-click on Done, and left-click on OK.

- Create the material properties.

- Assembly: Assemble the parts into a whole.

- Left-click on Create Instance, and select ST, Bottom Plane, and Top Plane. Then, left-click on OK | Rotate Instance, and select Bottom Plane and Top Plane. Enter the start point (0, 0, 0) and end point (1, 0, 0) of the rotation axis in turn, and enter 90 under Angle of Rotation. Left-click on Translate Instance, select Top Plane, and enter the start point (0, 0, 0) and end point (0, 30, 0) of the translation vector in turn.

- Step: Create an analysis step, and set the history output items.

- Left-click on Create Step, select Dynamic, Explicit, and left-click on Continue. Under Time Period enter 0.05, and left-click on OK. Left-click on Create History Output, and select Energy.

- Left-click on Create History Output; under "Domain" select Set5, under "Output Variables" enter "RF2, U2", and left-click on OK.

- Interaction: Set the contact properties and type, and set the top plane and bottom plane as rigid bodies.

- Left-click on Create Interaction Property, and select Contact. Under "Mechanical" select Tangential Behavior, under "Friction formulation" select Penalty, and under "Friction Coeff" enter "0.2".

- Left-click on Create Interaction, select General Contact (Explicit), and under "Global property assignment" select intProp-1.

- Left-click on Create Constraint, under "Type" select Rigid body, and pick up Bottom Plane and Top Plane.

- Load: Fix the bottom plane, and set a downward loading speed of 500 mm/s on the top plane.

- Left-click on Create Boundary Condition, under "Types for Selected Step" select Displacement/Rotation, pick up set4, and enter 0 in all directions .

- Left-click on Create Boundary Condition, under "Types for Selected Step" select Velocity/Angular Velocity, pick up set5, enter −500 under "V2", and enter 0 in the other direction.

- Mesh: Meshing and determining the element types.

NOTE: Step 2.7 is important in the finite element analysis. The structure meshes into a finite number of elements, a suitable mathematical approximation solution is assumed for each element, and then the equilibrium conditions for the whole structure are derived and solved to obtain the solution to the problem.- Left-click on Seed Part, enter 0.8 under "Approximate Global Size", and enter 0.08 under "By Absolute Value". Left-click on Mesh Part, and select Yes.

- Left-click on Assign Element Type, pick up the part, and select Done. Under "Element Library" select Explicit, and left-click on OK.

- Repeat step 2.7 to mesh the three parts CT, ST, and DT.The finite element model of the ST is shown in Figure 3.

- Job: Submit the calculations, and export the results.

- Left-click on Create Job, select the model to calculate, and left-click on Continue. Left-click on Job Manager, select the model to calculate, and left-click on Submit.

- Select the completed model for calculation, and left-click on Results to enter the Visualization. The deformation mode of the ST (k = 0.9) is obtained from the Visualization. Left-click on Create XY Date. Select ODB history output, and click on Plot to plot the force-displacement curve of the ST (k = 0.9).

- In step 2, step 2.1.1 has three structural choices, and step 2.2.2.2 has six choices of thickness variation factor (k), while the other steps are the same. Therefore, repeat the above steps 18 times to obtain the deformation modes and force-displacement curves for 18 models, as shown in Figure 4, Figure 5, Figure 6, Figure 7, Figure 8. In addition, the crashworthiness evaluation indicators are obtained from the force-displacement curve through Equations 1-4, as shown in Figure 9, Figure 10, Figure 11 and Table 2.

NOTE: The introduction of the crashworthiness evaluation indicators and Equations 1-4 are in the representative results.

Results

Several commonly used indicators are used to determine the crashworthiness of structures, including the total energy absorption (EA), specific energy absorption (SEA), peak crushing force (PCF), mean crushing force (MCF), and crushing force efficiency (CFE)42.

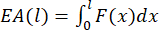

The total energy absorption (EA)43 can be expressed as follows:

...

...

Discussion

The quasi-static compression performance of tapered tubes was studied by finite element analysis. Two new types of corrugated tapered tubes with variable thicknesses were designed, and their quasi-static compression performance was investigated. In quasi-static compression simulations, some important steps and settings need to be verified.

The material parameters are the basic requirements for the finite element calculation (step 2.2.1 of the protocol). In this study, the material parameters w...

Disclosures

The authors have nothing to disclose.

Acknowledgements

The first author would like to acknowledge grants from the National Natural Science Foundation of China (No. 52078152 and No. 12002095), General Program of Guangzhou Science and Technology Plan (No. 202102021113), Guangzhou Government-University Union Fund (No. 202201020532), and Guangzhou Municipal Science and Technology Project (Grant No. 202102020606).

Materials

| Name | Company | Catalog Number | Comments |

| ABAQUS | Dassault SIMULIA | Finite element software | |

| CT | Botong 3D printing | Conical tube for experiment | |

| SOLIDWORKS | Dassault Systemes | CAD software | |

| Universal testing machine | SUNS | UTM5205, 200kN |

References

- Wu, S., Li, G., Sun, G., Wu, X., Li, Q. Crashworthiness analysis and optimization of sinusoidal corrugation tube. Thin-Walled Structures. 105, 121-134 (2016).

- Hao, W., Xie, J., Wang, F., Liu, Z., Wang, Z. Analytical model of thin-walled corrugated tubes with sinusoidal patterns under axial impacting. International Journal of Mechanical Sciences. 128-129, 1-16 (2017).

- Alkhatib, F., Mahdi, E., Dean, A. Crushing response of CFRP and KFRP composite corrugated tubes to quasi-static slipping axial loading: Experimental investigation and numerical simulation. Composite Structures. 246, 112370 (2020).

- Liu, Z., et al. Axial-impact buckling modes and energy absorption properties of thin-walled corrugated tubes with sinusoidal patterns. Thin-Walled Structures. 94, 410-423 (2015).

- Eyvazian, A., Tran, T. N., Hamouda, A. M. Experimental and theoretical studies on axially crushed corrugated metal tubes. International Journal of Non-Linear Mechanics. 101, 86-94 (2018).

- Rawat, S., Narayanan, A., Nagendiran, T., Upadhyay, A. K. Collapse behavior and energy absorption in elliptical tubes with functionally graded corrugations. Procedia Engineering. 173, 1374-1381 (2017).

- Rawat, S., Narayanan, A., Upadhyay, A. K., Shukla, K. K. Multiobjective optimization of functionally corrugated tubes for improved crashworthiness under axial impact. Procedia Engineering. 173, 1382-1389 (2017).

- Zhang, X., Zhang, H. Axial crushing of circular multi-cell columns. International Journal of Impact Engineering. 65, 110-125 (2014).

- Mahbod, M., Asgari, M. Energy absorption analysis of a novel foam-filled corrugated composite tube under axial and oblique loadings. Thin-Walled Structures. 129, 58-73 (2018).

- Niknejad, A., Abdolzadeh, Y., Rouzegar, J., Abbasi, M. Experimental study on the energy absorption capability of circular corrugated tubes under lateral loading and axial loading. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering. 229 (13), 1739-1761 (2015).

- Ma, W., Li, Z., Xie, S. Crashworthiness analysis of thin-walled bio-inspired multi-cell corrugated tubes under quasi-static axial loading. Engineering Structures. 204, 110069 (2020).

- Mozafari, H., Lin, S., Tsui, G. C. P., Gu, L. Controllable energy absorption of double sided corrugated tubes under axial crushing. Composites Part B: Engineering. 134, 9-17 (2018).

- Albak, E. &. #. 3. 0. 4. ;. Crashworthiness design for multi-cell circumferentially corrugated thin-walled tubes with sub-sections under multiple loading conditions. Thin-Walled Structures. 164, 107886 (2021).

- Deng, X., Liu, W., Jin, L. On the crashworthiness analysis and design of a lateral corrugated tube with a sinusoidal cross-section. International Journal of Mechanical Sciences. 141, 330-340 (2018).

- Li, Z., Ma, W., Xu, P., Yao, S. Crushing behavior of circumferentially corrugated square tube with different cross inner ribs. Thin-Walled Structures. 144, 106370 (2019).

- Li, Z., Ma, W., Xu, P., Yao, S. Crashworthiness of multi-cell circumferentially corrugated square tubes with cosine and triangular configurations. International Journal of Mechanical Sciences. 165, 105205 (2020).

- Sadighi, A., Eyvazian, A., Asgari, M., Hamouda, A. M. A novel axially half corrugated thin-walled tube for energy absorption under axial loading. Thin-Walled Structures. 145, 106418 (2019).

- Sadighi, A., Salaripoor, H., Asgari, M. Comprehensive study on the crashworthiness of a new developed axially-half corrugated aluminum tubes. International Journal of Crashworthiness. 27 (3), 633-650 (2022).

- Wu, S., Sun, G., Wu, X., Li, G., Li, Q. Crashworthiness analysis and optimization of fourier varying section tubes. International Journal of Non-Linear Mechanics. 92, 41-58 (2017).

- Eyvazian, A., Habibi, K., Hamouda, A. M., Hedayati, R. Axial crushing behavior and energy absorption efficiency of corrugated tubes. Materials & Design. 54, 1028-1038 (2014).

- Fang, J., Gao, Y., Sun, G., Zheng, G., Li, Q. Dynamic crashing behavior of new extrudable multi-cell tubes with a functionally graded thickness. International Journal of Mechanical Sciences. 103, 63-73 (2015).

- Pang, T., et al. On functionally-graded crashworthy shape of conical structures for multiple load cases. Journal of Mechanical Science and Technology. 31 (6), 2861-2873 (2017).

- Xu, F., Zhang, X., Zhang, H. A review on functionally graded structures and materials for energy absorption. Engineering Structures. 171, 309-325 (2018).

- Mahmoodi, A., Shojaeefard, M. H., Saeidi Googarchin, H. Theoretical development and numerical investigation on energy absorption behavior of tapered multi-cell tubes. Thin-Walled Structures. 102, 98-110 (2016).

- Asanjarani, A., Dibajian, S. H., Mahdian, A. Multi-objective crashworthiness optimization of tapered thin-walled square tubes with indentations. Thin-Walled Structures. 116, 26-36 (2017).

- Guler, M. A., Cerit, M. E., Bayram, B., Gerçeker, B., Karakaya, E. The effect of geometrical parameters on the energy absorption characteristics of thin-walled structures under axial impact loading. International Journal of Crashworthiness. 15 (4), 377-390 (2010).

- Zhao, X., Zhu, G., Zhou, C., Yu, Q. Crashworthiness analysis and design of composite tapered tubes under multiple load cases. Composite Structures. 222, 110920 (2019).

- Alkhatib, S. E., Tarlochan, F., Eyvazian, A. Collapse behavior of thin-walled corrugated tapered tubes. Engineering Structures. 150, 674-692 (2017).

- Alkhatib, S. E., Tarlochan, F., Hashem, A., Sassi, S. Collapse behavior of thin-walled corrugated tapered tubes under oblique impact. Thin-Walled Structures. 122, 510-528 (2018).

- Ahmadi, A., Asgari, M. Efficient crushable corrugated conical tubes for energy absorption considering axial and oblique loading. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science. 233 (11), 3917-3935 (2018).

- Gao, Q., Wang, L., Wang, Y., Wang, C. Multi-objective optimization of a tapered elliptical tube under oblique impact loading. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering. 231 (14), 1978-1988 (2017).

- Baykasoğlu, C., Baykasoğlu, A., Tunay Çetin, M. A comparative study on crashworthiness of thin-walled tubes with functionally graded thickness under oblique impact loadings. International Journal of Crashworthiness. 24 (4), 453-471 (2019).

- Li, G., Xu, F., Sun, G., Li, Q. Crashworthiness study on functionally graded thin-walled structures. International Journal of Crashworthiness. 20 (3), 280-300 (2015).

- Zhang, Y., Lu, M., Sun, G., Li, G., Li, Q. On functionally graded composite structures for crashworthiness. Composite Structures. 132, 393-405 (2015).

- Baroutaji, A., Arjunan, A., Stanford, M., Robinson, J., Olabi, A. G. Deformation and energy absorption of additively manufactured functionally graded thickness thin-walled circular tubes under lateral crushing. Engineering Structures. 226, 111324 (2021).

- Li, G., Xu, F., Sun, G., Li, Q. A comparative study on thin-walled structures with functionally graded thickness (FGT) and tapered tubes withstanding oblique impact loading. International Journal of Impact Engineering. 77, 68-83 (2015).

- Chen, Y., et al. Crashworthiness analysis of octagonal multi-cell tube with functionally graded thickness under multiple loading angles. Thin-Walled Structures. 110, 133-139 (2017).

- Pang, T., Zheng, G., Fang, J., Ruan, D., Sun, G. Energy absorption mechanism of axially-varying thickness (AVT) multicell thin-walled structures under out-of-plane loading. Engineering Structures. 196, 109130 (2019).

- Gautam, R., Idapalapati, S. Compressive properties of additively manufactured functionally graded Kagome lattice structure. Metals. 9 (5), 1-14 (2019).

- Deng, X., Qin, S., Huang, J. Energy absorption characteristics of axially varying thickness lateral corrugated tubes under axial impact loading. Thin-Walled Structures. 163, 107721 (2021).

- Xiang, X., et al. The mechanical characteristics of graded Miura-ori metamaterials. Materials & Design. 211, 110173 (2021).

- Sun, G., Pang, T., Fang, J., Li, G., Li, Q. Parameterization of criss-cross configurations for multiobjective crashworthiness optimization. International Journal of Mechanical Sciences. 124-125, 145-157 (2017).

- Xiang, X., et al. Energy absorption of multilayer aluminum foam-filled structures under lateral compression loading. Mechanics of Advanced Materials and Structures. , (2022).

- Hanssen, A. G., Langseth, M., Hopperstad, O. S. Static and dynamic crushing of circular aluminium extrusions with aluminium foam filler. International Journal of Impact Engineering. 24 (5), 475-507 (2000).

- Fang, Y., Wang, Y., Hou, C., Lu, B. CFDST stub columns with galvanized corrugated steel tubes: Concept and axial behaviour. Thin-Walled Structures. 157, 107116 (2020).

- Zhang, L., Hebert, R., Wright, J. T., Shukla, A., Kim, J. -. H. Dynamic response of corrugated sandwich steel plates with graded cores. International Journal of Impact Engineering. 65, 185-194 (2014).

Reprints and Permissions

Request permission to reuse the text or figures of this JoVE article

Request PermissionExplore More Articles

This article has been published

Video Coming Soon

Copyright © 2025 MyJoVE Corporation. All rights reserved

We use cookies to enhance your experience on our website.

By continuing to use our website or clicking “Continue”, you are agreeing to accept our cookies.