Mapeamento Quantitativo de Tensão de um Aneurisma da Aorta Abdominal

Visão Geral

Fonte: Hannah L. Cebull1, Arvin H. Soepriatna1, John J. Boyle2 e Craig J. Goergen1

1 Weldon School of Biomedical Engineering, Purdue University, West Lafayette, Indiana

2 Engenharia Mecânica & Ciência dos Materiais, Universidade de Washington em St. Louis, St Louis, Missouri

O comportamento mecânico dos tecidos moles, como vasos sanguíneos, pele, tendões e outros órgãos, são fortemente influenciados por sua composição de elastina e colágeno, que proporcionam elasticidade e força. A orientação de fibras dessas proteínas depende do tipo de tecido mole e pode variar de uma única direção preferencial a redes intrincadas de malha, que podem se tornar alteradas em tecido doente. Portanto, os tecidos moles muitas vezes se comportam anisotropicamente no nível celular e órgão, criando uma necessidade de caracterização tridimensional. Desenvolver um método para estimar de forma confiável os campos de cepas dentro de tecidos ou estruturas biológicas complexas é importante para caracterizar e entender a doença mecanicamente. A cepa representa como o tecido mole se deforma relativamente ao longo do tempo, e pode ser descrito matematicamente através de várias estimativas.

A aquisição de dados de imagem ao longo do tempo permite que a deformação e a tensão sejam estimadas. No entanto, todas as modalidades de imagem médica contêm alguma quantidade de ruído, o que aumenta a dificuldade de estimar com precisão a tensão in vivo. A técnica aqui descrita supera esses problemas com sucesso usando um método de estimativa de deformação direta (DDE) para calcular campos de cepa 3D espacialmente variados a partir de dados de imagem volumosas.

Os métodos atuais de estimativa de tensão incluem correlação de imagem digital (DIC) e correlação de volume digital. Infelizmente, o DIC só pode estimar com precisão a tensão de um plano 2D, limitando severamente a aplicação deste método. Embora úteis, métodos 2D como DIC têm dificuldade em quantificar a cepa em regiões que sofrem deformação 3D. Isso ocorre porque o movimento fora do avião cria erros de deformação. A correlação de volume digital é um método mais aplicável que divide os dados de volume inicial em regiões e encontra a região mais semelhante do volume deformado, reduzindo assim o erro fora do plano. No entanto, este método se mostra sensível ao ruído e requer suposições sobre as propriedades mecânicas do material.

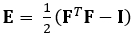

A técnica aqui demonstrada elimina essas questões utilizando um método DDE, tornando-o muito útil na análise de dados de imagem médica. Além disso, é robusto para tensão alta ou localizada. Aqui descrevemos a aquisição de dados de ultrassom 4D fechados, volumétricos, sua conversão em um formato analisável e o uso de um código Matlab personalizado para estimar a deformação 3D e as cepas verdes-lagrange correspondentes, um parâmetro que melhor descreve grandes deformações. O tensor de cepa Green-Lagrange é implementado em muitos métodos de estimativa de cepas 3D porque permite que f seja calculado a partir de um Ajuste De Menor Quadrado (LSF) dos deslocamentos. A equação abaixo representa o tensor de cepa Green-Lagrange, E, onde F e I representam o gradiente de deformação e tensor de identidade de segunda ordem, respectivamente.

(1)

(1)

Procedimento

1. Configuração de ultrassom 4D

- Ao usar o software de imagem, use um laptop capaz de executar software matemático de computação para automatizar o processo de aquisição 4D. Conecte o laptop com este código personalizado ao sistema de ultrassom através da porta USB. Observe que o software de imagem tem um recurso de ultrassom 4D integrado ao software.

- Depois de ligar o sistema de ultrassom, configure a unidade de monitoramento fisiológico e, ao mesmo tempo, garanta que os botões de frequência cardíaca

Resultados

Utilizando o procedimento descrito acima, foi adquirido ultrassom 4D de um angiotensin i-induzido por dissecação abdominal aorísmo abdominal (AAA) de um rato. Vários loops de vídeo EKV de curto eixo foram adquiridos ao longo da aorta e combinados para criar dados 4D, como mostrado na Figura 1. Esses dados foram então convertidos em um arquivo MAT usando um código personalizado, que foi então analisado em um código de cálculo de tensão 3D usando uma função de warping. Após a oti...

Aplicação e Resumo

A caracterização mecânica in vivo localizada é uma parte importante na compreensão do crescimento e remodelação dos tecidos biológicos. Em comparação com as abordagens existentes, o procedimento de quantificação da cepa descrito aqui utiliza um método aprimorado de calcular com precisão a cepa 3D através de distorcer a imagem não deformada antes da correlação cruzada. Este método não utiliza quaisquer suposições materiais na determinação de cepas dentro dos volumes teciduais. Infelizmente...

Pular para...

Vídeos desta coleção:

Now Playing

Mapeamento Quantitativo de Tensão de um Aneurisma da Aorta Abdominal

Biomedical Engineering

4.6K Visualizações

Imageamento de amostras biológicas com microscopia ótica e confocal

Biomedical Engineering

35.8K Visualizações

Imageamento por MEV de Amostras Biológicas

Biomedical Engineering

23.8K Visualizações

Biodistribuição de Nano-fármacos Transportadores: Aplicações de MEV

Biomedical Engineering

9.3K Visualizações

Ultrassonografia de alta frequência da aorta abdominal

Biomedical Engineering

14.5K Visualizações

Tomografia fotoacústica para imageamento de sangue e lipídios na aorta infrarrenal

Biomedical Engineering

5.7K Visualizações

Ressonância Magnética Cardíaca

Biomedical Engineering

14.8K Visualizações

Simulações computacionais de fluidodinâmica do fluxo sanguíneo em um aneurisma cerebral

Biomedical Engineering

11.8K Visualizações

Imageamento de fluorescência de infravermelho próximo de aneurismas da aorta abdominal

Biomedical Engineering

8.3K Visualizações

Técnicas não invasivas de medição da pressão arterial

Biomedical Engineering

11.9K Visualizações

Aquisição e análise de um sinal de ECG (eletrocardiografia)

Biomedical Engineering

106.0K Visualizações

Resistência à Tração de Biomateriais Reabsorvíveis

Biomedical Engineering

7.5K Visualizações

Imagem de micro-TC de uma medula espinal de camundongo

Biomedical Engineering

8.0K Visualizações

Visualização da degeneração da articulação do joelho após lesão não invasiva do LCA em ratos

Biomedical Engineering

8.2K Visualizações

Combinação de imagens de SPECT e TC para visualizar a funcionalidade cardíaca

Biomedical Engineering

11.0K Visualizações

Copyright © 2025 MyJoVE Corporation. Todos os direitos reservados