A subscription to JoVE is required to view this content. Sign in or start your free trial.

Method Article

Combining Microfluidics and Microrheology to Determine Rheological Properties of Soft Matter during Repeated Phase Transitions

In This Article

Summary

We demonstrate the fabrication and use of a microfluidic device that enables multiple particle tracking microrheology measurements to study the rheological effects of repeated phase transitions on soft matter.

Abstract

The microstructure of soft matter directly impacts macroscopic rheological properties and can be changed by factors including colloidal rearrangement during previous phase changes and applied shear. To determine the extent of these changes, we have developed a microfluidic device that enables repeated phase transitions induced by exchange of the surrounding fluid and microrheological characterization while limiting shear on the sample. This technique is µ2rheology, the combination of microfluidics and microrheology. The microfluidic device is a two-layer design with symmetric inlet streams entering a sample chamber that traps the gel sample in place during fluid exchange. Suction can be applied far away from the sample chamber to pull fluids into the sample chamber. Material rheological properties are characterized using multiple particle tracking microrheology (MPT). In MPT, fluorescent probe particles are embedded into the material and the Brownian motion of the probes is recorded using video microscopy. The movement of the particles is tracked and the mean-squared displacement (MSD) is calculated. The MSD is related to macroscopic rheological properties, using the Generalized Stokes-Einstein Relation. The phase of the material is identified by comparison to the critical relaxation exponent, determined using time-cure superposition. Measurements of a fibrous colloidal gel illustrate the utility of the technique. This gel has a delicate structure that can be irreversibly changed when shear is applied. µ2rheology data shows that the material repeatedly equilibrates to the same rheological properties after each phase transition, indicating that phase transitions do not play a role in microstructural changes. To determine the role of shear, samples can be sheared prior to injection into our microfluidic device. µ2rheology is a widely applicable technique for the characterization of soft matter enabling the determination of rheological properties of delicate microstructures in a single sample during phase transitions in response to repeated changes in the surrounding environmental conditions.

Introduction

Phase transitions in soft matter can change the scaffold structure, which has implications in the processing and final stability of the material1,2,3. The characterization of soft materials during dynamic phase transitions provides essential information about the relationship between structural evolution and equilibrium structure and rheological properties. For example, many home care products require a phase change during consumer use. Also, during manufacturing, processing steps, including dilution and mixing, can impart shear affecting the rheological properties and final microstructure of the product. Understanding the rheological properties throughout a phase change ensures that the product performs as designed. Additionally, if forces alter the starting rheology of the material during manufacturing, phase transitions can yield unexpected and undesired results, changing the intended function and effectiveness.At the critical gelation point, defined as the point where the material transitions from a solution of associated colloids or polymers to a sample-spanning gel network, material properties change drastically with slight changes to association. Any modification to the structure at the critical gel point can impact the end product4. During these dynamic transitions, soft materials have weak mechanical properties and measurements that use classical experimental techniques can be within the measurement noise limit5,6,7. To account for this, techniques such as microrheology, which is sensitive in the low moduli range (10-3 - 4 Pa), are used to characterize the weak incipient gel during dynamic evolution. Some materials are susceptible to changes in microstructure due to external forces, which presents a challenge during characterization, as any transfer of material or fluid can affect the structure and, ultimately, the final material properties. To avoid altering the material microstructure, we have developed a microfluidic device that can exchange the environmental fluid around a sample while minimizing shear. By exchanging the fluid environment, changes in rheological properties and microstructure are measured during phase transitions with minimal contributions from shear. The device is combined with multiple particle tracking microrheology (MPT) in a technique called µ2rheology. This technique is used to quantify material properties during consecutive phase changes of a gel in response to an external driving force. The technique will be illustrated using a fibrous colloidal gel, hydrogenated castor oil (HCO)9,10,11.

Gel scaffolds can undergo changes in association and dissociation due to their sample environment12,13,14,15. The driving force for gelation and degradation are material specific and must be tailored for each material of interest. µ2rheology can be used to characterize gel systems that respond to external stimuli, including colloidal and polymeric networks. Altering pH, osmotic pressure or salt concentration are examples of driving forces that can induce changes in the material microstructure. For example, HCO undergoes controlled phase transitions by creating an osmotic pressure gradient. When a concentrated HCO gel sample (4 wt% HCO) is submerged in water, the attractive forces between colloidal particles weaken, causing degradation. Alternatively, when a dilute solution of HCO (0.125 wt% HCO) is contacted with a hydrophilic material (referred to as the gelling agent and composed of mostly glycerin and surfactant), the attractive forces return, causing gelation. This gel system will be used to show the operation of the device as a tool for measuring consecutive phase transitions on a single sample9,10. To characterize these gel scaffolds during dynamic transitions and the delicate incipient gel structure at the critical phase transition, we use MPT to characterize these materials with high spatio-temporal resolution.

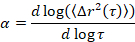

Microrheology is used to determine gel properties and structure, especially at the critical transition, of an array of soft materials, including colloidal and polymeric gels5,6,9,16. MPT is a passive microrheological technique that uses video microscopy to record the Brownian motion of fluorescent probe particles embedded within a sample. The particle positions throughout the videos are precisely determined to within 1/10th of a pixel using classical tracking algorithms17,18. The ensemble averaged mean-squared displacement (MSD, (Δr2(t))) is calculated from these particle trajectories. The MSD is related to material properties, such as the creep compliance, using the Generalized Stokes-Einstein Relation17,19,20,21,22,23. The state of the material is determined by calculating the logarithmic slope of the MSD curve as a function of lag time, α,

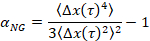

where t is the lag time, and comparing it to the critical relaxation exponent, n. n is determined using time-cure superposition, a well-documented technique that was modified to analyze MPT data by Larsen and Furst6. By comparison of n to α the state of the material is quantitatively determined. When α > n the material is a sol, and when α < n the material is a gel. Previous work has characterized the HCO system using microrheology to determine the critical relaxation exponent9. Using this information, we precisely determine when the material transitions from a gel to a sol during an experiment. Additionally, the non-Gaussian parameter, αNG, can be calculated to determine the extent of structural heterogeneity of a system,

where Δx(t) is the one-dimensional particle movement in the x direction. Using MPT, we can characterize a single phase transition, but by characterizing materials with MPT in a microfluidic device, we are able to manipulate the surrounding fluid environment and collect data of several phase transitions on a single gel sample.

This microfluidic device is designed to investigate the critical transitions of a single gel sample that undergoes phase changes in response to changes in the surrounding fluid environment. The device exchanges fluid surrounding the sample when it is either in the gel or sol state by locking the sample in place to induce a phase transition while minimizing shear. A solvent basin is located directly above the sample chamber, which are connected by six symmetrically spaced inlet channels. This symmetry allows for the exchange of fluid from the solvent basin to the sample chamber while creating equal pressure around the sample, locking it in place. There have been several studies that use this technique for single particle and DNA trapping, but this work scales up the volume from single molecules to samples that are approximately 10 µL24,25,26. This unique design also enables real-time microrheological characterization during phase transitions.

µ2rheology is a robust technique that is applicable to many soft matter systems. The technique described in this paper was designed for colloidal gels, but it can be easily adapted to other materials such as polymer or micellar solutions. With this technique, we determine not just how phase transitions affect the equilibrium material properties, but also how different processing steps can have lasting effects on the rheological evolution of the material and the final scaffold structure and properties.

Protocol

1. Fabrication of the Microfluidic Device

- Microfluidic stamp fabrication.

Note: This step requires the use of volatile materials and should be done in a chemical fume hood.- Use a negative printed design with the same dimensions as the glass slide (75×50 mm), the channels colored white, and the background colored black (See Figure 1). Print this design on a clear acetate sheet (transparency) with a resolution of 1200 dpi.

- If the dark section of the transparency still allows light through, layer several negatives and adhere using double sided tape.

- Turn on the high intensity ultraviolet (UV) light source and allow it to warm up to a constant output (approximately 30 min).

Note: UV protective eyewear should be worn when using the high intensity UV light source. - Fill three 150 mL Petri dishes with acetone, ethanol and distilled water.

- Place a blank transparency on a flat surface close to the high output UV source, but not directly under the UV light. This will provide a base to fabricate the microfluidic stamp.

- Outline the corners of a 75 × 50 mm glass slide in the center of the blank transparency using a permanent marker and place four glass spacers (approximately 30 × 30 × 1 mm) in the corners of the outlined rectangle.

- Pour approximately 5 mL of UV curable thiol:ene resin in the center of the spacers, then carefully place a 75 x 50 x 1 mm glass slide onto the glass spacers, so that the glue is completely covered by the glass slide with no air bubbles.

- Place the transparency with printed negative on top of the glass slide and move all the above components (from bottom to top: blank transparency, glass spacers and UV glue, glass slide, and negative printed transparency) by dragging the blank transparency carefully under the UV light source.

- Allow the UV light to shine through the negative onto the resin and cure. The cure time can be adjusted to change the height of the channel. A 45 s cure time results in a channel height of 1 mm, using our light source.

- Move the components away from the UV source and remove the negative printed transparency and glass slide. The glass slide with the channels fabricated in UV glue will now be referred to as the microfluidic stamp.

- Discard the transparency and glass spacers.

- Dip the microfluidic stamp in the acetone bath, followed by the ethanol bath. Repeat this step twice. Acetone will degrade the UV glue, so do not leave acetone on the stamp for greater than 10 s.

- While holding the stamp, submerge the stamp in the water and use a cotton swab to remove the rest of the unreacted resin. Do not directly wipe the cured portions, as it will make the channels rough.

- Place the stamp on a paper towel and return to the UV source for at least 30 minutes to ensure complete curing.

- Polydimethylsiloxane (PDMS) molding

- Pour 70 g of PDMS base into a clear cup and add the cross-linking agent to the base in a weight ratio of 1:10 crosslinker to base. These are the manufacturer recommended ratios. Do not use a glass container.

- Mix the cross-linker and base thoroughly with a metal stirrer; the mixture should be turbid due to entrapped air bubbles once properly mixed.

- Put the PDMS into a vacuum oven and pull vacuum on the mixed PDMS. Turn off vacuum if the solution begins to overflow from the cup, then resume vacuum after the overflow subsides. The total pressure in the vacuum oven does not matter, as the vacuum only speeds up the degassing process. Leave in the chamber until all bubbles have been evacuated from the mixture (approximately 60 min).

- Place the microfluidic stamp in an empty 150 mm diameter plastic Petri dish, then slowly pour the PDMS into the Petri dish, completely covering the microfluidic stamp. Pour close to the surface of the Petri dish to minimize bubbles reforming in the PDMS.

- Cover the Petri dish and place in a 55 °C oven overnight to cure. Once completely cured, cut the patterned PDMS using a knife and remove from the stamp. Retain excess PDMS for constructing the solvent basin (Protocol step 1.6.3) and PDMS stoppers (Protocol step 2.2.1.1).

- Using a 0.5 mm biopsy punch, cut holes into the following locations: one at each corner, one in the suction chamber near the edge of the channel, six in the sample chamber symmetrically placed 60° apart, and one in the center of the sample chamber. To ensure symmetrically placed holes print a pattern on a sheet of paper and place under the sample chamber. Since the PDMS is clear, you can easily see where the holes need to be placed.

- Preparation of sol-gel solution to create glass walls in microfluidic device

- In a 100 mL jar, add 25 mL of 90% ethanol, 25 mL of pH 4 (0.0001 M) hydrochloric acid solution, 25 mL of 98% tetraethoxysilane, and 25 mL of 98% methyltriethoxysilane. Place the 100 mL solution, now referred to as the preconverted fluid, in the microwave uncovered for 10 seconds, then place in an 80 °C overnight.

- Device assembly

- Place both the patterned PDMS and a 75 × 50 × 0.10 mm glass slide into the plasma cleaner and set the 3-way valve to the off position.

- Turn on the vacuum pump and allow one minute to evacuate the chamber.

- Put the 3-way valve to flow controller position and let the chamber equilibrate for 5 seconds. The flow controller position allows a small flow rate of air to enter the plasma cleaner, low enough to keep the chamber at low pressures. Turn on the radio frequency (RF) switch to medium for 40 seconds, then turn off the RF switch and vacuum pump.

- Place the 3-way valve to the open position to return the chamber to atmospheric conditions. Remove the patterned PDMS and glass slide.

- Carefully adhere the patterned PDMS to the glass slide by putting the two surfaces in contact with each other.

- Apply UV curable resin to the seams around the patterned PDMS and cure for 5 min under low intensity UV light.

- Fabrication of glass walls in the microfluidic channels.

Note: This step must be completed within 30 minutes of plasma treatment, as it relies on PDMS surface changes that occur during plasma treatment. The thickness of the layer will be approximately 5-10 µm. This step requires the use of volatile materials and should be done in a chemical fume hood.- Set a hotplate to 100 °C and prepare four syringes (three 30 mL and one 3 mL) with 18 gauge needles and approximately 30 cm length of clear thermoplastic tubing.

- Fill three 30 mL syringes with ethanol, chloroform and air, respectively. Fill one 3 mL syringe with preconverted fluid (from Protocol step 1.3.1.)

- Insert clear thermoplastic tubing using stainless steel connectors into each of the holes in the patterned PDMS, with the exception of one corner hole. This hole will be used as an inlet, while all others will be outlets.

- Fill the microfluidic device with preconverted fluid from the syringe, then place the microfluidic device on the 100 °C hot plate so the bottom glass is touching the surface of the hot plate.

- Flow 3 mL of preconverted fluid through the microfluidic device over 10 seconds. The thickness of the glass walls is adjusted by changing the flow rate of the preconverted fluid.

- Remove the microfluidic device from the hotplate. Replace the preconverted solution syringe with the air syringe and push out any excess preconverted fluid.

- Replace the air syringe with the chloroform syringe and slowly flow 15 mL of chloroform through the microfluidic device. Replace the chloroform syringe with the ethanol syringe and slowly flow 30 mL of ethanol through the microfluidic device. These steps should take approximately 1 min each.

- Replace the ethanol syringe with the air syringe and flow air through the microfluidic device until dry.

- Application of glass supports and solvent basin

- Cut 75 × 10 × 1 mm strips of glass from 75 × 25 × 1 mm glass slides.

- Apply UV curable resin to the glass strips. Place the microfluidic device onto the strips, with the PDMS side facing up. Move under low intensity UV light source for 5 minutes.

- Cut a 30 × 30 mm square of PDMS. Using a biopsy punch, cut a hole large enough to cover the 10 mm sample chamber.

- Place the PDMS square and microfluidic device into the plasma cleaner, then put the 3-way valve to the off position and turn on the vacuum pump.

- Allow one minute to evacuate chamber. Put the 3-way valve to the flow controller position and let the chamber equilibrate for 5 seconds.

- Turn on RF switch to medium for 40 seconds, then turn off RF switch and vacuum pump.

- Place the 3-way valve to the open position to return the chamber to atmospheric conditions.

- Remove the solvent basin and microfluidic device from the plasma chamber and adhere by contacting the surfaces. Be sure to place the solvent basin over the sample chamber.

2. µ2rheology Procedure

- Preparation of soft matter samples

- Washing probe particles

- Pipette water and 0.5 µm probes into a microcentrifuge tube at a ratio of water to probes of 10:1. Mix thoroughly using pipette mixing, then place the microcentrifuge tube into the microcentrifuge and spin at 4600 x g for 10 minutes.

NOTE: The probe solution used in this work is received suspended in water with an initial concentration of 2.6% solids/volume, and the final concentration of probes used in the sample is 0.1% solids/volume. - Remove the microcentrifuge tube and pipette out the supernatant. Replace the supernatant with DI water. Repeat centrifugation for a total of three times.

- Place microcentrifuge tube in the sonicator and sonicate on low for 15 minutes to remove any aggregates.

- Pipette water and 0.5 µm probes into a microcentrifuge tube at a ratio of water to probes of 10:1. Mix thoroughly using pipette mixing, then place the microcentrifuge tube into the microcentrifuge and spin at 4600 x g for 10 minutes.

- Combining probes and soft matter.

NOTE: For this procedure, a colloidal gel was used as the soft matter sample.- On a 75 × 50 mm glass slide, measure 1 mL of sample material. Pipette 40 µL of probe solution into the center of the sample.

- Gently fold the sample with a metal spatula until completely combined. Scoop the sample into a microcentrifuge tube and centrifuge at 2340 x g for 15 s to remove entrapped air.

- Fill a 1 mL syringe fitted with an 18 gauge needle and clear thermoplastic tubing with the probe/HCO mixture.

- Washing probe particles

- Consecutive phase transitions induced by fluid exchange

- Filling the microfluidic device

- To create PDMS stoppers, using excess PDMS from Protocol step 1.2.5, cut a 5 mm square section of PDMS. Using a 0.5 mm diameter biopsy punch, cut a hole halfway into the PDMS stopper. Insert a stainless steel connector into the 0.5 mm diameter hole.

- Connect thermoplastic tubing to three of the corner inlet channels and the suction chamber outlet channel. Completely fill the device with water using a syringe connected to the device. Ensure there are no bubbles in the sample chamber or in the microfluidic channels. Block the remaining corner hole with PDMS stoppers.

- The solvent basin should be partially filled from step 2.2.1.2; if it is not filled, fill the solvent basin with water.

- Using the syringe from Protocol step 2.1.2.3, inject 10 µL of sample/probe mixture through the center channel into the sample chamber at approximately 2 µL/s, then use a PDMS stopper to block the center channel in the sample chamber.

- Collecting microrheological data

- Turn the camera settings to those optimized to minimize static and dynamic particle tracking errors, then switch to the 63× water immersion objective and pipette a drop of water onto the lens.

- Place the microfluidic device on the microscope stage and raise the objective until it is focused on the sample.

- Take videos of the Brownian motion of the probes over time intervals appropriate for the total length of a phase change. For gelation, continue taking videos until probe movement has been completely stopped.

NOTE: We collect data every 10 min. If we start with a degradation experiment, data are collected until the probes are completely diffusing.

- Exchanging fluids in the sample chamber (gravity flow, exchange of lower density fluids with higher density fluids)

- Remove the microfluidic device from the microscope stage.

- Suction the water out of the solvent basin using a transfer pipette, then pipette 4 mL of higher density fluid into the solvent basin.

- Return the microfluidic device to the microscope stage and repeat to Step 2.2.2.3

- Exchanging fluids in the sample chamber (suction flow, exchange of higher density fluids with lower density fluids)

- Remove the microfluidic device from the microscope stage and remove the PDMS stopper from the suction chamber.

- Insert a syringe equipped with an 18 gauge needle and clear thermoplastic tubing to the suction chamber channel, and hook the syringe up to a syringe pump. Set the syringe pump to pull at 1 mL/min.

- Remove excess gelling agent in the solvent basin and rinse three times with water by filling the solvent basin and then suctioning out the rinse fluid.

- Begin suction with the syringe pump while adding water to the solvent basin for one minute. Do not let the solvent basin empty completely, as this will pull air into the sample chamber.

- Remove the syringe from the microfluidic device and replace the PDMS stopper on the suction chamber.

- Return the microfluidic device to the microscope stage and continue taking samples

- Filling the microfluidic device

- Continue taking samples at regular intervals during degradation/gelation cycles until the desired number of cycles is completed or there are insufficient probes for measurement.

Results

A two-layered microfluidic device is constructed with PDMS (Figure 1a,b), which is patterned on a microfluidic stamp. The design of the stamp is shown in Figure 1c. Improper experimental setup can result both in errors in passive microrheology and microfluidic flows during surrounding fluid exchange (Figure 2). Examples of improper experimental setup are detailed in ...

Discussion

The two-layer microfluidic device (Figure 1) can be easily made by following well-documented microfluidic fabrication techniques29. Glass supports are added to the bottom of the device to decrease vibrational effects on probe movement. The glass slide is very thin (0.10 mm) in order to accommodate the working distance of the microscope objective. This makes the device susceptible to small vibrations in the building and sample environment that are then measured with th...

Disclosures

There are no disclosures for this work.

Acknowledgements

Funding for this work was provided by the Procter & Gamble Co. and the American Chemical Society Petroleum Research Fund (54462-DNI7). Acknowledgment is made to the Donors of the American Chemical Society Petroleum Research Fund for partial support of this research. The authors would like to acknowledge Dr. Marco Caggioni for helpful discussions.

Materials

| Name | Company | Catalog Number | Comments |

| 150 x 15 mm Petri Dish | Corning, Inc. | 351058 | |

| 75 x 50 x 0.15 mm glass slide | Fisher Scientific | Custom | |

| 75 x 50 x 1.0 mm glass slide | Fisher Scientific | 12-550-C | |

| 75 x 25 x 1.0 mm glass Slide | Fisher Scientific | 12-550-A3 | |

| 22 x 22 Glass cover slips | Fisher Scientific | 12-542-B | |

| Acetone, 99.5% | VWR Analytical | 67-64-1 | |

| Low intensity UV source | UVP | UVL-56 | |

| Chloroform, 99.9% | Fisher Chemical | C298-500 | |

| Cotton Swabs | Q-tips | 83289205 | |

| Ethanol, 90% | Fisher Chemical | A962-4 | |

| Fluoresbrite® YG Carboxylate Microspheres 0.50µm | Polysciences, Inc. | 15700-10 | |

| High-Intensity UV Lamp | Spectroline Corp. | SB-100P | |

| Hot plate | Corning, Inc. | PC-420 | |

| Hydrochloric Acid, 6N | Ricca Chemical Company | 3750-32 | |

| Methyltriethyoxysilane, 98% | Acros Organics | 174622500 | |

| Microcentrifuge | Eppendorf | 5424 | |

| Plasma cleaner | Harrick Plasma, Inc. | PDC-32G | |

| Polydimethylsiloxane (PDMS) | Robert McKwown Company | 2065622 | |

| Sonicator | Branson, Emerson Electric | 1800 | |

| Steel connectors, ID 0.023 inch | New England Small Tube Corp. | Custom | |

| Tetraethoxysilane, 98% | Alfa Aesar | A14965 | |

| Thiol-ene Resin (UV curable) | Norland Products, Inc. | NOA81 | |

| Transparency | Staples Inc. | 21828 | |

| Tygon tubing, ID 1/32 inch | McMaster-Carr | E-3603 | |

| Vacuum oven | Fisher Scientific | 282A | |

| Biopsy punch 8 mm | World Precision Instruments | 504535 | |

| Bioposy punch 0.5 mm | World Precision Instruments | 504528 | |

| Syringe, 30 mL | BD | 309659 | |

| Syringe, 3 mL | BD | 309651 | |

| Needle, 18 gauge | BD | 305195 | |

| Microcentrifuge tube, 1.5 mL | Eppendorf | 22-36-320-4 | |

| High-speed Camera | Vision Research | Miro M120 | |

| Microscope | Carl Zeiss AG | Zeiss Observer, Z1 | |

| Syringe pump | New Era Pump Systems | NE-300 | |

| Hydrogenated castor oil | Procter & Gamble | N/A | |

| Afício MP 6002 Printer | Ricoh Company, Ltd. | 415877 |

References

- Mitchell, P. Microfluidics-downsizing large-scale biology. Nat. Biotech. 19, 717-721 (2001).

- Haber, C. Microfluidics in commercial applications; an industry perspective. Lab Chip. 6, 1118-1121 (2006).

- Whitesides, G. M. The origins and the future of microfluidics. Nature. 442, 368-373 (2006).

- Huang, X., Raghavan, S. R., Terech, P., Weiss, R. G. Distinct kinetic pathways generate organogel networks with contrasting fractality and thixotropic properties. J. Am. Chem. Soc. 128, 15341-15352 (2006).

- Larsen, T. H., Schultz, K. M., Furst, E. M. Hydrogel microrheology near the liquid-solid transition. Korea-Aust. Rheol. J. 20, 165-173 (2008).

- Larsen, T. H., Furst, E. M. Microrheology of the liquid-solid transition during gelation. Phys. Rev. Lett. 100, 146001 (2008).

- Schultz, K. M., Baldwin, A. D., Kiick, K. L., Furst, E. M. Rapid rheological screening to identify conditions of biomaterial hydrogelation. Soft Matter. 5, 740-742 (2009).

- Switzer, L. H., Klingenberg, D. J. Flocculation in simulations of sheared fiber suspensions. Int. J. Multiph. Flow. 30, 67-87 (2004).

- Wehrman, M. D., Lindberg, S., Schultz, K. M. Quantifying the dynamic transition of hydrogenated castor oil gels measured via multiple particle tracking microrheology. Soft Matter. 12, 6463-6472 (2016).

- Wehrman, M. D., Milstrey, M. J., Lindberg, S., Schultz, K. M. Using µ2rheology to quantify rheological properties during repeated reversible phase transitions of soft matter. Lab Chip. 17, 2085-2094 (2017).

- Wehrman, M. D., Lindberg, S. E., Schultz, K. M. Impact of shear on the structure and rheological properties of a hydrogenated castor oil colloidal gel during dynamic phase transitions. J. Rheol. , (2018).

- Loh, X. J. Dual-responsive "reversible micelles". J. Appl. Polym. Sci. 127, 992-1000 (2013).

- Kern, F., Zana, R., Candau, S. J. Rheological properties of semidilute and concentrated aqueous solutions of cetyltrimethylammonium chloride in the presence of sodium salicylate and sodium chloride. Langmuir. 7, 1344-1351 (1991).

- Trappe, V., Prasad, V., Cipelletti, L., Segre, P. N., Weitz, D. A. Jamming phase diagram for attractive particles. Nature. 411, 772-775 (2001).

- Philipse, A. P., Wierenga, A. M. On the density and structure formation in gels and clusters of colloidal rods and fibers. Langmuir. 14, 49-54 (1998).

- Schultz, K. M., Bayles, A. V., Baldwin, A. D., Kiick, K. L., Furst, E. M. Rapid, high resolution screening of biomaterial hydrogelators by mu2rheology. Biomacromolecules. 12, 4178-4182 (2011).

- Crocker, J. C., Grier, D. G. Methods of digital video microscopy for colloidal studies. J. Colloid Interface Sci. 179, 298-310 (1996).

- Mason, T. G. Estimating the viscoelastic moduli of complex fluids using the generalized Stokes--Einstein equation. Rheol. Actac. 39, 371-378 (2000).

- Mason, T. G., Ganesan, K., van Zanten, J. H., Wirtz, D., Kuo, S. C. Particle tracking microrheology of complex fluids. Phys. Rev. Lett. 79, 3282-3285 (1997).

- Mason, T. G., Weitz, D. A. Optical measurements of frequency-dependent linear viscoelastic moduli of complex fluids. Phys. Rev. Lett. 74, 1250-1253 (1995).

- Squires, T. M., Mason, T. G. Fluid mechanics of microrheology. Annu. Rev. Fluid Mech. 42, 413-438 (2010).

- Gittes, F., Schnurr, B., Olmsted, P. D., MacKintosh, F. C., Schmidt, C. F. Microscopic viscoelasticity: shear moduli of soft materials determined from thermal fluctuations. Phys. Rev. Lett. 79, 3286-3289 (1997).

- Mai, D. J., Brockman, C., Schroeder, C. M. Microfluidic systems for single DNA dynamics. Soft Matter. 8 (41), 10560-10572 (2012).

- Tanyeri, M., Ranka, M., Sittipolkul, N., Schroeder, C. M. A microfluidic-based hydrodynamic trap: design and implementation. Lab Chip. 11, 1786-1794 (2011).

- Lee, J. S., Dylla-Spears, R., Teclemariam, N. P., Muller, S. J. Microfluidic four-roll mill for all flow types. Appl. Phys. Lett. 90, 074103 (2007).

- Crocker, J. C., Grier, D. G. Methods of digital video microscopy for colloidal studies. J. Colloid Interface Sci. 179 (1), 298-310 (1996).

- Mason, T. G., Weitz, D. Optical measurements of frequency-dependent linear viscoelastic moduli of complex fluids. Phys. Rev. Lett. 74 (7), 1250 (1995).

- Schultz, K. M., Furst, E. M. High-throughput rheology in a microfluidic device. Lab on a chip. 11, 3802-3809 (2011).

- Abate, A. R., Lee, D., Do, T., Holtze, C., Weitz, D. A. Glass coating for PDMS microfluidic channels by sol-gel methods. Lab Chip. 8, 516-518 (2008).

- Happel, J., Brenner, H. . Low Reynolds Number Hydrodynamics: with special applications to particulate media. , (1965).

Reprints and Permissions

Request permission to reuse the text or figures of this JoVE article

Request PermissionThis article has been published

Video Coming Soon

Copyright © 2025 MyJoVE Corporation. All rights reserved