Method Article

Formation of Dispersible Taohong Siwu Tablets

In This Article

Summary

This article discusses the process used to formulate and prepare Taohong Siwu, a traditional Chinese medicine, as a dispersible tablet. We performed single-factor and orthogonal experiments to screen the prescription excipients, optimize the formulation process, and produce dispersible Taohong Siwu tablets.

Abstract

Here, we optimize the process used to formulate and prepare dispersible Taohong Siwu tablets and provide a foundation for expanding their clinical application. Taking dispersion uniformity and disintegration time as the indices for investigation, we used a single-factor test to match and filter the excipient categories for Taohong Siwu tablets. The formulation was optimized by an orthogonal test design. The content and dissolution rates of the effective substances in dispersible Taohong Siwu tablets when prepared with optimized prescriptions were determined by ultra-high performance liquid chromatography (UPLC), and the optimal preparation process was determined.

The optimal composition for dispersible Taohong Siwu tablets was 17% Taohong Siwu extract powder, 1% magnesium stearate, 49% microcrystalline cellulose, 20% cross-linked polyvinylpyrrolidone, and 13% sodium carboxymethyl starch. When dispersible Taohong Siwu tablets were prepared by direct compression and the optimized prescription powder was uniformly dispersed within 3 min, the dissolution rate reached more than 90% within 50 min.When prepared according to the optimized methods,dispersible Taohong Siwu tablets disintegrate rapidly in water with good dispersion uniformity and controllable quality.

Introduction

Taohong Siwu decoction is a prescription composed of peach kernel, safflower, angelica, white peony, ligusticum chuanxiong, and rehmannia1,2 that can be used to promote blood flow and reduce detumescence and pain3,4. Previous research has found that Taohong Siwu Tang is difficult to preserve and easily affected by mildew and other factors. Furthermore, the commonly used clinical decoction is inconvenient to transport, while the decoction procedure is laborious and subject to variations in quality. Therefore, there is an urgent need to develop a new formulation for Taohong Siwu tablets.

Dispersible tablets are those that can be rapidly disintegrated in water and distributed in uniform suspensions5. In traditional Chinese medicine (TCM), the main drug in dispersible tablets is normally prepared from the raw materials of the TCM powder, extracts, and other appropriate excipients6. Compared with conventional liquid preparations and ordinary tablets, dispersible tablets, as a new dosage form, are more rapidly absorbed in the human body, exhibit better stability, are easy to take and transport, and exhibit a series of beneficial characteristics, such as rapid disintegration, high bioavailability, and good dispersion uniformity7,8.

The orthogonal test design method utilizes an orthogonal table to scientifically select the test conditions, arrange a reasonable test plan, and then use the mathematical concepts of range and variance to analyze the test results and generate an optimal plan9,10. In this study, we are particularly interested in certain key characteristics: the uniformity of dispersion, neatness, and comparability. Orthogonal experimental designs can also be adapted to incorporate a fractional and factorial design. In the present study, we use an orthogonal experimental design to screen and optimize the excipient types, excipient ratios, and drug loading data for dispersible Taohong Siwu tablets. Compared with traditional decoctions of Chinese medicine, the dispersible Taohong Siwu tablets prepared by the methodology described herein are easy to take, easy to preserve, and highly resistant to mildew.

Protocol

1. Preparation of the Taohong extract

- Measure 39.6 g of prepared rehmannia root (Rehmannia glutinosa [Gaetn.] Libosch. ex Fisch. et Mey.), 29.7 g of peach kernel (Prunus persica [L.] Batsch), 19.8 g of safflower (Carthamus tinctorius L.), 29.7 g of angelica (Angelica sinensis [Oliv.] Diels), 29.7 g of white peony root (Cynanchum otophyllum Schneid), and 19.8 g of ligusticum chuanxiong (Ligusticum chuanxiong hort), totaling 168.3 g of medicinal materials11, and place these ingredients in a decoction casserole.

- Perform decoction three times.

- For each round, add 1,683 mL of water, and boil the ingredients for 1.5 h.

- Combine the filtrate, and filter the resultant liquid with gauze. Concentrate the liquid in a rotary evaporator to a final volume of 400 mL.

- Evenly pour the concentrate into an evaporation dish, and place in a water bath at 90 °C to dry the excess water.

- Place the thickened extract in a vacuum drying oven at 85 °C, and dry for 8 h to obtain a dry extract.

- Subsequently, grind the dried extract into powder in a mortar, and then sieve with an 80-mesh sieve.

NOTE: The resultant dry extract was in the form of a pink herbal powder containing the four medicinal ingredients.

2. Screening of the fillers

- Use lactose, pre-gelatinized starch, and microcrystalline cellulose as the fillers.

- Use cross-linked polyvinyl pyrrolidone (PVPP) as a disintegrant and magnesium stearate as a lubricant.

NOTE: Three formulas were used to generate prescriptions for testing. - Prepare Formula 1: 0.5 g of medicinal powder and 3.4 g of microcrystalline cellulose (MCC) to produce the filler and 1 g of PVPP and 0.1 g of magnesium stearate to produce the lubricant.

- Prepare Formula 2: 0.5 g of medicinal powder, 3.4 g of pre-gelatinized starch as the filler, 1 g of PVPP as the disintegrant, and 0.1 g of magnesium stearate as the lubricant.

- Prepare Formula 3: 0.5 g of medicinal powder, 3.4 g of lactose as the filler, 1 g of PVPP as the disintegrant, and 0.1 g of magnesium stearate as the lubricant.

- Mix each prescription thoroughly, and pass through an 80-mesh screen. Place the evenly mixed powder into a single punch tablet machine, and punch out a tablet.

- Test each tablet separately. Place the tablet into a beaker with 1 L of 37 °C distilled water.

- Place the beaker into a dissolution tester (Table of Materials).

- Start the dissolution tester, and time the reaction. When the tablets are completely disintegrated, stop the timer, and observe whether the tablets are evenly dispersed.

NOTE: We considered the disintegration time and dispersion uniformity as indicators in the subsequent experiments. The data arising from each prescription are given in Table 1.

3. Disintegrant selection

- Mix the three excipients in pairs to create three different prescriptions, and test the combinations.

- Prepare formulation 1 with PVPP and low-substituted hydroxypropyl cellulose (L-HPC) (1:1).

- Prepare formulation 2 with L-HPC and carboxymethyl starch sodium (CMS-NA) (1:1).

- Prepare formulation 3 with PVPP and CMS-Na (1:1).

- Mix each prescription thoroughly, and pass through an 80-mesh screen. Place the evenly mixed powder into a single punch tablet machine.

- Investigate the appearance and shape of the tablets. Place the tablets on a white background, and observe whether the appearance of the color is uniform. Measure the disintegration time as per steps 2.7-2.9.

NOTE: The results are shown in Table 2.

4. Optimization of the filler and disintegrant dosage

- Optimize the specific dosage of the fillers (step 2) and disintegrants (step 4) by performing an orthogonal experiment using the dosage of microcrystalline cellulose as factor A, the dosage of crosslinked polyvinylpyrrolidone as factor B, the dosage of sodium carboxymethyl cellulose as factor C, and the blank error as factor D.

- Prepare the excipients according to Table 3. Weigh the excipients separately, and mix the three formulations evenly.

- Pass the formulations through a sieve with a screen diameter of 0.18 mm.

- Press the formulations into tablets. Measure the disintegration time as per steps 2.7-2.9.

NOTE: Table 3 and Table 4 show the factor-level arrangement and orthogonal experiment arrangement. - Import the data obtained into spreadsheet software for data analysis.

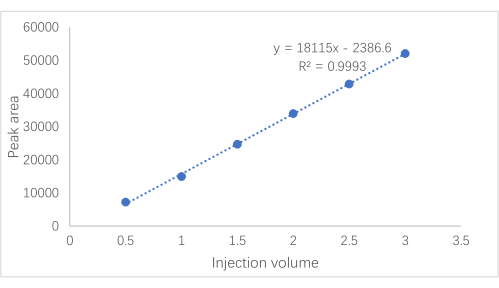

NOTE: Table 5 shows the results of the variance analysis, and Figure 1 shows the trends for each test index.

5. Screening of the drug loading

NOTE: Following the filler and disintegrant tests, the optimal contents of microcrystalline cellulose, cross-linked polyvinylpyrrolidone, sodium carboxymethyl starch, and magnesium stearate were determined to be 4.4 g, 1.8 g, 1.2 g, and 0.1 g, respectively.

- While keeping the relative content of the filler, disintegrant, and lubricant constant, prepare prescription 1 with 1 g of medicinal powder, prescription 2 with 1.5 g of medicinal powder, prescription 3 with 2 g of medicinal powder, and prescription 4 with 2.5 g of medicinal powder.

- Thoroughly mix the powder, filling agent, disintegrant, and lubricant used in each prescription, and pass through an 80-mesh sieve.

- Press the tablets, and place a tablet in the disintegration time tester.

- Start the instrument and time; stop the timer after the tablet has completely disintegrated.

NOTE: The prescription schedule is shown in Table 6.

6. Quality evaluation of the Taohong Siwu dispersible tablets

- Appearance evaluation

NOTE: According to the requirements of the 2020 edition of the Chinese Pharmacopoeia General Rule 010112, the appearance of the tablet should be complete and smooth, and the color should be uniform.- Randomly select six pieces from each of the three batches to observe whether the surface of the dispersible sheet is smooth and the color is uniform.

- Weight variation

- For the evaluation of the wet weight, take 20 tablets from each batch, and accurately determine the total weight. Determine the mean tablet weight.

- Weigh each tablet separately.

- Compare the weight of each tablet with the mean weight.

NOTE: The difference between the mean weight and the weight of an individual tablet should not exceed 0.30 g ± 7.5%. The difference in weight should not exceed that of two tablets, and the weight of no single tablet should exceed the limit by a factor of one.

- Disintegration and dispersion uniformity tests

NOTE: According to the provisions of General Rule 0921 of the Chinese Pharmacopoeia12, we determined the disintegration time for each batch of tablets.- Hang a gondola on a bracket with the stainless-steel shaft at the upper end. Immerse the apparatus in a 1 L beaker, and adjust the position of the gondola so that the screen is 25 mm from the bottom of the beaker when it drops to its lowest point.

- Fill the beaker with water at a temperature of 37 °C ± 1 °C, and adjust the height of the water level such that the sieve is 15 mm below the water surface when the gondola rises to its highest point. Ensure that the top of the gondola is not submerged in solution at any point.

- Take six tablets from each test batch, and place them in a glass tube in the gondola.

- Activate the dissolution tester.

NOTE: Each tablet needs to be completely disintegrated within 15 min. - If one tablet is not completely disintegrated, then take another six tablets for re-testing. All the tablets must meet the required regulations.

7. Characterization

- Chromatographic conditions

- Use a chromatographic column with a column of 2.1 mm x 100 mm (e.g., ACQUITY UPLC BEH C18 1.7 µm).

- Use a mobile phase of 100% acetonitrile (A) and 0.5% phosphoric acid aqueous solution (B).

- For gradient elution, use the following elution program: 0-4 min (10%-30%), 4-10 min (30%-60%), 10-15 min (60%-85%), 15-17 min (85%-50%) %), 17-20 min (50%-110%), 20-22 min (10%-10%).

- Use a flow rate of 0.2 mL/min, a detection wavelength of 260 nm, a column temperature of 30 °C, and an injection volume of 2 µL.

- Solution preparation

- Prepare an amygdalin reference solution. Dissolve the amygdalin in methanol at a concentration of 0.2 mg·mL−1.

- Prepare a test solution.

- For each sample, crush five tablets with a mortar, and place in a 25 mL volumetric flask with 25 mL of 80% methanol, volumetric to scale.

- Ultrasonicate each sample at 150 W and 40 kHz for 30 min to dissolve.

- Cool each sample to room temperature, and then add 80% methanol to a total volume of 25 mL.

- Finally, filter the sample with a microporous membrane (0.22 µm). Use the substrate as the product for testing.

- Linear relationship analysis

- Take 1 mL of the reference solution, and filter with a microporous filter membrane (0.22 µm).

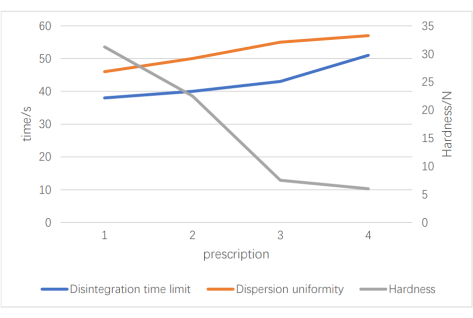

- Transfer 0.5 µL, 1 µL, 1.5 µL, 2 µL, 2.5 µL, and 3 µL of the reference solution into the chromatography column, and perform chromatography as described in section 7.1.

- Inject the sample, and record the peak area.

- Perform linear regression using the peak area (y) and injection volume (x) as the variables.

NOTE: The regression equation obtained was y = 18115x − 2386.6 (R² = 0.9993), thus indicating that amygdalin exhibits a good linear relationship in the range of 0.0492-0.3101 mg. Figure 2 shows the standard curve.

- Precision testing

- Inject 2 µL of the reference solution (prepared as described in section 5.2.1) into the chromatograph six times successively.

- Record the peak area, and calculate the relative standard deviation (RSD) value.

NOTE: The measured RSD value for the peak area of amygdalin was 2.7%, thus indicating that the instrument exhibited good precision.

- Repeatability experiments

- To evaluate the repeatability, grind 30 dispersible tablets into a fine powder, and mix the resultant powders together.

- Divide the pooled powder into six batches weighing approximately 1 g each.

- Prepare the test solution as described in section 7.2.2.

- Inject 2 µL of each sample, record the peak area, and calculate the RSD value.

NOTE: The measured peak area RSD value was 1.8%, thus indicating that the method exhibited good repeatability.

- Stability experiments

- Using the same test solution, inject 2 µL of solution at 0 h, 2 h, 4 h, 6 h, 8 h, 12 h, and 14 h.

- Record the peak area, and calculate the RSD value.

NOTE: The measured RSD value of the peak area of amygdalin was 2.8%, thus indicating that the test solution was stable for 24 h at room temperature.

- Sample recovery testing

- Take six samples of dispersible tablets, and prepare test solutions according to the method described in section 7.2.2.

- Add 1 mL of the control substance to the same injection bottle, measure the sample content according to the conditions described in section 7.1, and calculate the recovery rate.

NOTE: The analysis showed that the mean recovery rate of amygdalin (n = 6) was 101% and that the RSD value was 2.8%, thus indicating that the method exhibited good accuracy.

- Determination of the sample content

- Use three batches of dispersible tablets to prepare test solutions in accordance with the method given in section 7.2.2.

- Inject 2 µL of each sample under the chromatographic conditions described in section 7.1.

- Record the peak area, and measure the content.

NOTE: The mean content of amygdalin in the three batches of dispersible tablets was 0.257 mg/tablet.

- Dissolution determination

- Take six batches of dispersible tablets, and measure the dissolution rate according to the small cup method for dissolution determination described in the 2020 edition of Chinese Pharmacopoeia12.

- Use 0.1 M of hydrochloric acid (250 mL) as the dissolution medium, and perform the testing at 37 °C ± 0.5 °C and 100 rpm for 50 min.

- Immediately pass the samples through a microporous membrane (0.22 µm).

- Inject and test according to the chromatographic conditions described in section 7.1.

- Record the peak area and dissolution rate.

NOTE: The dissolution rates of the six batches of samples were 98%, 99%, 96%, 97%, 97%, and 98%, respectively.

Results

In this study, we used a traditional method to prepare liquid extracts of Taohong Siwu decoction and prepared an herbal powder by concentration and drying. By keeping the herbal powder, disintegrant, and lubricant unchanged, we screened r-lactose, pregelatinized starch, and microcrystalline cellulose as fillers to determine the disintegration time. Although the disintegration time with lactose as the disintegrant was better than that with pregelatinized starch and microcrystalline cellulose, the hardness and surface finish did not meet the required standards; thus, microcrystalline cellulose was selected as the filler.

To select an appropriate disintegrant, we established three prescriptions with the same herbal powder, filler, and lubricant: prescription 1 (cross-linked polyvinylpyrrolidone and low-substituted hydroxypropyl cellulose), prescription 2 (low-substituted hydroxypropyl cellulose and sodium carboxymethyl starch), and prescription 3 (crosslinked polyvinylpyrrolidone and sodium carboxymethyl starch); the ratio was 1:1 in each case. Taking appearance, disintegration time, and dispersion uniformity as the inspection indicators, we found the combined disintegration time and dispersion uniformity of crosslinked polyvinylpyrrolidone and sodium was optimal. Next, we performed orthogonal testing to identify the optimal filler and disintegrant content. The best results were obtained with 4.4 g of microcrystalline cellulose (MCC, Factor A), 1.8 g of crosslinked polyvinylpyrrolidone (PVPP, Factor B), and 1.2 g of sodium carboxymethyl starch (CMS-Na, Factor C). Once we had identified the optimal dosage and proportions of filler and disintegrant, we next identified the optimal amount of herbal powder by investigating the disintegration time, dispersion uniformity, and hardness of different proportions. Figure 3 shows that the four prescriptions passed the dispersion uniformity assessment. However, with a larger drug load, we observed a longer disintegration time and a reduction in harness. The final prescription was identified as 1.5 g of medicinal powder, 4.4 g of microcrystalline cellulose, 1.8 g of cross-linked polyvinylpyrrolidone, 1.2 g of sodium carboxymethyl starch, and 0.1 g of magnesium stearate. The final specification was 0.30 g per tablet and four tablets per administration (three times per day); this was equivalent to 1.068 g of the crude drug.

Content determination and dissolution testing showed that the content of amygdalin in each dispersible tablet was 0.257 mg. In the dissolution test, the dissolution rates of the six batches of dispersible tablets at 50 min were 98%, 99%, 96%, 97%, 97%, and 98%, respectively, thus indicating that the dissolution rate of dispersible Taohong Siwu tablets was good.

Figure 1: The mean trend for the test indices. The average trend chart for the test indicators. Factor A in the figure is the content of Taohong Siwu medicine powder, factor B is the content of PVPP, factor C is the content of CMS-Na, and factor D is the blank error group. The numbers in each factor represent different contents (see Table 3 for details). The value on the y-axis represents the K value, and lower K values indicate better results. Please click here to view a larger version of this figure.

Figure 2: Laetrile standard curve. The standard curve of amygdalin, with the x-axis representing the injection volume, and the y-axis representing the peak area. Please click here to view a larger version of this figure.

Figure 3: Drug load screening results. This figure shows the drug load results; the left y-axis is the time, the right y-axis is the hardness, and the four prescriptions on the x-axis represent different drug load volumes. Please click here to view a larger version of this figure.

| serial number | medicinal powder (g) | PVPP (g) | MCC (g) | pregelatinized starch (g) | lactose (g) | Disintegration time limit (s) | Exterior |

| 1 | 0.5 | 1 | 3.4 | 26 | clean | ||

| 2 | 0.5 | 1 | 3.4 | 54 | clean | ||

| 3 | 0.5 | 1 | 3.4 | 16 | common |

Table 1: Filler selection results. The main drug content and PVPP dosage in the three prescriptions remained unchanged; prescription 1 used MCC as the filler, prescription 2 used pregelatinized starch as the filler, and prescription 3 used lactose as the filler. From these, lactose as the filler had the shortest disintegration time, but the gloss was not up to standard.

| Disintegrant prescription | Exterior | Disintegration time limit (s) | Dispersion uniformity (s) |

| PVPP+L-HPC | clean | 39 | 39 |

| L-HPC+CMS-Na | clean | 40 | 52 |

| PVPP+CMS-Na | clean | 42 | 40 |

Table 2: Disintegrant combination screening. Under conditions with the main drug and filler remaining unchanged, different disintegrant combinations were tested in terms of their disintegration time limit and dispersion uniformity. Prescription 1 was PVPP + L-HPC, prescription 2 was L-HPC + CMS-Na, and prescription 3 was PVPP + CMS-Na, among which the combination of PVPP + CMS-Na had the shortest disintegration time limit.

| Level | A (g) | B (g) | C (g) | D (g) |

| 1 | 3.4 | 0.6 | 0.4 | blank |

| 2 | 4.4 | 1.2 | 0.8 | blank |

| 3 | 5.4 | 1.8 | 1.2 | blank |

Table 3: Factor levels for orthogonal designs. The dosage of the main drug of each prescription remained unchanged. Factor A is the dosage of filler MCC, factor B is the dosage of PVPP, factor C is the dosage of CMS-Na, and factor D is the blank error.

| Numbering | A (g) | B (g) | C (g) | D (blank) | Disintegration time limit (s) |

| 1 | 1 | 1 | 1 | 1 | 69 |

| 2 | 1 | 2 | 2 | 2 | 123 |

| 3 | 1 | 3 | 3 | 3 | 40 |

| 4 | 2 | 1 | 2 | 3 | 43 |

| 5 | 2 | 2 | 3 | 1 | 31 |

| 6 | 2 | 3 | 1 | 2 | 39 |

| 7 | 3 | 1 | 3 | 2 | 78 |

| 8 | 3 | 2 | 1 | 3 | 59 |

| 9 | 3 | 3 | 2 | 1 | 34 |

| K1 | 232 | 190 | 167 | 134 | |

| K2 | 113 | 213 | 200 | 240 | |

| K3 | 171 | 113 | 149 | 142 | |

| K1 | 77.333 | 66.333 | 55.667 | 44.667 | |

| K2 | 37.667 | 71 | 66.667 | 80 | |

| K3 | 57 | 37.667 | 49.667 | 47.333 | |

| R | 39.667 | 33.333 | 17 | 35.333 | |

| primary and secondary | RA>RD>RB>RC |

Table 4: Orthogonal experimental arrangement and experimental results.

| source of variance | sum of squared deviations | degrees of freedom | mean square | F value | salience |

| A | 236.667 | 2 | 1180.333 | 1.016 | >0.05 |

| B | 1828.667 | 2 | 914.333 | 0.787 | >0.05 |

| C | 446 | 2 | 223 | 0.192 | >0.05 |

| D (error) | 2322.667 | 2 | 1161.333 |

Table 5: Variance analysis results.

| Prescription | Medicinal powder (g) | MCC (g) | PVPP (g) | CMS-Na (g) | Magnesium stearate (g) |

| 1 | 1 | 4.4 | 1.8 | 1.2 | 0.1 |

| 2 | 1.5 | 4.4 | 1.8 | 1.2 | 0.1 |

| 3 | 2 | 4.4 | 1.8 | 1.2 | 0.1 |

| 4 | 2.5 | 4.4 | 1.8 | 1.2 | 0.1 |

Table 6: Drug load formulations. The dosage of MCC, PVPP, and CMS-Na for each prescription remained unchanged. The dosage of the main drug in prescription 1 was 1 g, in prescription 2 was 1.5 g, in prescription 3 was 2 g, and in prescription 4 was 2.5 g.

| Batch number | Exterior | Average sheet weight (g) | Weight difference (g) | Average hardness (N) | Disintegration time limit (s) | Dispersion uniformity (s) |

| 20220710 | clean | 0.1978 | qualified | 22 | 39 | 43 |

| 20220711 | clean | 0.186 | qualified | 21 | 35 | 41 |

| 20220712 | clean | 0.1948 | qualified | 18 | 29 | 32 |

Table 7: Quality evaluation for the dispersible Taohong Siwu tablets. An appearance analysis, average weight analysis, weight difference check, hardness check, disintegration time limit check, and dispersion uniformity check were performed for the three batches of samples.

Discussion

In this study, we tested the effect of filler, disintegrant, and medicinal powder dosage on the disintegration time and dispersion uniformity of dispersible tablets using an orthogonal design. We found that the preferred formulation disintegrated rapidly. When selecting the most appropriate filler, we found that although lactose exhibited the shortest disintegration time, the hardness of these tablets was not sufficient. Furthermore, the surface of the tablets was not smooth enough, and there was evidence of powder loss and loose tablets. As such, lactose did not meet the requirements of an appropriate filler; therefore, we selected microcrystalline cellulose as the optimal filler. Microcrystalline cellulose is a polymer in the form of powder or short rods with strong fluidity and without a fibrous structure13. Moreover, microcrystalline cellulose is odorless, non-toxic, easy to disintegrate, and non-reactive with drugs. This polymer is an important excipient in the pharmaceutical industry and can efficiently bond drug components to promote drug molding14. Furthermore, this polymer can facilitate the decomposition of drug components while enhancing drug strength and is used mainly as an excipient, filler, or drug release modifier for the preparation of drug tablets, drug granules, and drug capsules15,16.

Disintegrants have good water absorption and swelling properties and can promote the uniform dispersion of dispersible tablets in water. At present, the most commonly used disintegrants in dispersible tablets are L-HPC, cross-linked PVPP, and CMS-Na17. In this experiment, the combination of cross-linked PVPP and CMS-Na exhibited the shortest disintegration time. Most dispersible tablets use two or more disintegrants. Combinations of disintegrants can improve the disintegration effect and reduce costs18. When screening drug loading, we found that as the drug load increased, the hardness of the tablets decreased; this effect may be related to the nature of the medicinal material powder19. Finally, the process used to prepare the dispersible tablets (containing four ingredients) was optimized by formulation. This was followed by the indexing of the disintegration time and dispersion uniformity. The final ingredients were medicinal powder (17%), microcrystalline cellulose (49%), cross-linked polyvinylpyrrolidone (20%), sodium carboxymethyl starch (13%), and magnesium stearate accounting (1%).

Compared with traditional Chinese medicine decoctions, dispersible tablets can exert good therapeutic effects with high bioavailability, good stability, and easy portability, especially for patients who find it difficult to take decoctions and experience difficulties with swallowing20,21. In traditional Chinese medicine, the main drug in dispersible tablets is not usually a single compound; rather, the drug is composed of a complex mixture of ingredients. Furthermore, such powders have a relatively high viscosity and are usually able to absorb moisture. Ordinary tablets containing Chinese herbal medicine powder as the main drug are associated with a wide variety of problems, including a long disintegration time and poor dispersion uniformity, which influence the curative effect. Therefore, in the present research, we designed a new formulation, dispersible tablets, for the Taohong Siwu decoction to solve the problems associated with traditional decoctions, thus expanding the range of applications and promoting absorption in the body22. In this research, we extracted a dry powder from medicinal materials by applying the water extraction method. Traditional decoction methods involve complex ingredients that can be extracted according to the effective components and the characteristics of the active ingredients. Furthermore, the content of the active ingredients can be increased in dispersible tablets. The separation of impurities in medicinal materials and the preservation of their active ingredients is a problem that should be considered carefully during preparation. It is also important to provide favorable conditions for the preparation of subsequent dispersible tablets. Traditional decoctions such as the Taohong Siwu decoction generally have a high sugar content. Herbal powders can be readily prepared so that they absorb moisture. Therefore, it is important to take precautions when drying during the preparation. Furthermore, the finished tablets should be resistant to moisture.

It should be noted that this study only investigated one index component in the content determination experiments; this represents a notable limitation to this study, although our work provides a key foundation for subsequent in-depth research. Transforming a decoction of Taohong Siwuinto a dispersible tablet that is convenient for patients, more practical, and more feasible is also in line with the developing trends in traditional Chinese medicine preparations.

Disclosures

The authors declare no conflicts of interest.

Acknowledgements

This research was supported by the National Natural Science Foundation of China (Grant No. 82074059), the Open Fund for Key Laboratory of Xin'an Medical Ministry of Education, Anhui University of Traditional Chinese Medicine (No.2022XAYX07), the Anhui Provincial Key Laboratory of Traditional Chinese Medicine Compound Open Fund funded project (No.2019AKLCMF03), the Anhui Province Academic Leader Reserve Candidate Funding Project (No. 2022H287), and the Anhui Provincial Health Research Key Project (AHWJ2022a013)

Materials

| Name | Company | Catalog Number | Comments |

| Acetonitrile | OCEANPAK | A22T0218 | |

| Carboxymethyl starch sodium | Maclean | C12976293 | |

| Crosslinked Polyvinylpyrrolidone | Maclean | C12976293 | |

| Disintegration time limit tester | Tianjin Guoming Pharmaceutical Equipment Co., Ltd. | BJ-2 | |

| Electric heating constant temperature drying oven | Shanghai Sanfa Scientific Instrument Co., Ltd. | DHG-9202·2 | |

| Electric thermostatic water bath | Shanghai Sanfa Scientific Instrument Co., Ltd. | DK-S24 | |

| Electronic Balance | Sartorius Scientific Instruments (Beijing) Co., Ltd. | SQP | |

| Intelligent Dissolution Tester | Tianda Tianfa Technology Co., Ltd. | ZRS-8L | |

| Lactose | Maclean | C12942141 | |

| Low-Substituted Hydroxypropyl Cellulose | Anhui Shanhe Pharmaceutical Excipients Co., Ltd. | 190219 | |

| Magnesium stearate | Maclean | C12894996 | |

| Methyl Alcohol | TEDIA High Purity Solvents | 22075365 | |

| Microcrystalline cellulose | Maclean | 13028716 | |

| Single punch tablet machine | Nantong Shengkaia Machinery Co., Ltd. | TDP-2A | |

| Tablet hardness tester | Shanghai Huanghai Drug Testing Instrument Co., Ltd. | YPJ-200B | |

| Taohong Siwu Soup Extract | self made | ||

| Taoren, Honghua, etc. traditional Chinese medicine | The First Affiliated Hospital of Anhui University of Chinese Medicine | ||

| Waters Acquity H-Class Ultra High Liquid Chromatography |

References

- Wang, J. Y., et al. Effects of Erchen decoction and Taohong Siwu decoction on Nox4/NF-κB/HIF-1αsignaling pathway in aorta of ApoE~(-/-) atherosclerosis mice. China Journal of Traditional Chinese Medicine and Pharmacy. , (2019).

- Aslani, A., Ghasemi, A., Esfahani, S. K. Design, formulation and physicochemical evaluation of dimenhydrinate orally disintegrating tablets. Galen Medical Journal. 7, 936 (2018).

- Chen, K. X., Jiang, H. L., Luo, X. M., Shen, J. H. Drug discovery in post-genome era: Trend and practice. Chinese Journal of Natural Medicines. 2, 257-260 (2004).

- Wang, M., Liu, Z., Hu, S., Duan, X., Han, L. Taohong Siwu decoction ameliorates ischemic stroke injury via suppressing pyroptosis. Frontiers in Pharmacology. 11, 590453 (2020).

- Xin, R. H., Liang, G., Zheng, J. F. Design and content determination of Genhuang dispersible tablet herbal formulation. Pakistan Journal of Pharmaceutical Sciences. 30, 655-661 (2017).

- Yulin, D., Junxue, P., Rong, L., Jianlin, Y. Comparison of oral preparations of Chinese medicine dispersible tablets and traditional Chinese medicine. Chinese Journal of Ethnomedicine and Ethnopharmacy. 26 (8), 63-65 (2017).

- Yinghua, X., et al. Study on albendazole dispersible tablets based on solubilization effect. Journal of Hebei University of Science and Technology. 42 (6), 619-626 (2021).

- Mengzhu, Y., Kai, Y., Yi, H. Study on the prescription optimization and dissolution of Baicalin Dispersible Tablets. China Medical Herald. 10 (1), 122-123 (2013).

- Zhongan, X., et al. Introduction to the orthogonal experimental design method. Sci-Tech Information Development & Economy. (5), 1005 (2002).

- Liu Ruijiang, Z. Y., Chongwei, W., Jian, T. Study on the design and analysis methods of orthogonal experiment. Experimental Technology and Management. 27 (9), 4 (2010).

- Xianchun, D. Based on network pharmacology and transcriptomics to explore the main material basis and mechanism of ThaoHongSiWu Decoction in treating ischemic stroke. Anhui University of Chinese Medicine. , (2019).

- Pharmacopoeia Commission of the Ministry of Health of the People's Republic of China. . Pharmacopoeia of the People's Republic of China. , (2020).

- Jiaqiang, Y., et al. Research progress on preparation and application of microcrystalline cellulose. China Pulp & Paper Industry. 42 (10), 8-13 (2021).

- Nakamura, S., Tanaka, C., Yuasa, H., Sakamoto, T. Utility of microcrystalline cellulose for improving drug content uniformity in tablet manufacturing using direct powder compression. AAPS PharmSciTech. 20 (4), 151 (2019).

- Jinbao, L., et al. Effect of alkali pretreatment on preparation of microcrystalline cellulose. China Pulp & Paper. 39 (01), 26-32 (2020).

- Nsor-Atindana, J., et al. Functionality and nutritional aspects of microcrystalline cellulose in food. Carbohydrate Polymers. 172, 159-174 (2017).

- Wang, C., et al. Formulation and evaluation of nanocrystalline cellulose as a potential disintegrant. Carbohydrate Polymers. 130, 275-279 (2015).

- Huba, K., István, A. Drug excipients. Current Medicinal Chemistry. 13 (21), 2535-2563 (2006).

- Ping, Z., Jie, G. Talking about some problems of hardness and disintegration in traditional Chinese medicine tablets. Science and Wealth. 6 (181), 181 (2020).

- Pabari, R. M., McDermott, C., Barlow, J., Ramtoola, Z. Stability of an alternative extemporaneous captopril fast-dispersing tablet formulation versus an extemporaneous oral liquid formulation. Clinical Therapeutics. 34 (11), 2221-2229 (2012).

- Fini, A., Bergamante, V., Ceschel, G. C., Ronchi, C., de Moraes, C. A. F. Fast dispersible/slow releasing ibuprofen tablets. European Journal of Pharmaceutics and Biopharmaceutics. 69 (1), 335-341 (2008).

- Meidan, W. Study on compound Rhodiola relieving physical fatigue dispersible tablets. Jilin University. , (2009).

Reprints and Permissions

Request permission to reuse the text or figures of this JoVE article

Request PermissionThis article has been published

Video Coming Soon

Copyright © 2025 MyJoVE Corporation. All rights reserved