A subscription to JoVE is required to view this content. Sign in or start your free trial.

Method Article

Optimization of Processing of Tiebangchui with Highland Barley Wine Based on the Box-Behnken Design Combined with the Entropy Method

In This Article

Summary

The present protocol describes an efficient method for optimization of the processing technology of Tiebangchui processed with highland barley wine based on a Box-Behnken design response surface combined with the entropy method.

Abstract

The processing of toxic ethnomedicines is of great significance for their safe clinical application. Thus, the limitations of traditional processing should be addressed, and the processing method of ethnomedicines should be standardized using modern research methods. In this study, the processing technology of a commonly used Tibetan medicine Tiebangchui (TBC), the dried root of Aconitum pendulum Busch, processed with highland barley wine was optimized. Diester-diterpenoid alkaloid (DDA) (aconitine, 3-deoxyaconitine, 3-acetylaconitine) and monoester-diterpenoid alkaloid (MDA) (benzoylaconine) content were used as evaluation indicators, and the weight coefficient of each evaluation index was determined by the entropy method.

The single factor test and Box-Behnken design were used in investigating the influence of the ratio between highland barley wine and TBC, slice thickness of TBC, and processing time. Comprehensive scoring was performed according to the objective weight of each index determined by the entropy method. The optimal processing conditions of TBC with highland barley wine were as follows: the amount of highland barley wine is five times that of TBC, a soaking time of 24 h, and a TBC thickness of 1.5 cm. The results showed that the relative standard deviation between the verification test and predicted value was less than 2.55% and the optimized processing technology of TBC processed with highland barley wine is simple, feasible, and stable, and so can provide a reference for industrial production.

Introduction

Tiebangchui (TBC), the dried root of Aconitum pendulum Busch, is a well-known Tibetan medicine and was initially recorded in the classic Tibetan medical book "Four Medical Tantra"1,2. According to "Drug Standards of the Ministry of Health of the People's Republic of China (Tibetan Medicine)", TBC is effective in expelling cold, relieving pain, dispelling wind, and calming shock, and is commonly used to treat rheumatoid arthritis in clinics3,4,5.

TBC mainly contains alkaloids, including highly toxic diester-diterpenoid alkaloids (DDAs), and the moderately toxic monoester-diterpenoid alkaloids (MDAs)6,7,8. These chemical components are active ingredients with medicinal effects but are toxic. One of the most famous active and toxic ingredients, aconitine, causes poisoning when it exceeds 1 mg9. Therefore, improper or excessive use of TBC might result in poisoning and even death, and the toxicity attenuation and efficacy reservation of TBC is crucial for its safe clinical application10,11.

Processing is an effective method for detoxifying TBC. According to ancient Tibetan medicine books, processing with highland barley wine is an efficient way to attenuate toxicity and preserve the efficacy of TBC. TBC is soaked in highland barley wine, stored for one night, dried, and added to medicines12. However, the specific processing technology and potential influencing factors are rarely reported, and the traditional processing process often relies on experience and lacks standardized methods. Hence, modern scientific and technological methods for optimizing and standardizing the processing process are needed.

The Box-Behnken design method is used in investigating interactions among different factors and their influence on comprehensive scoring through quadratic polynomial fitting. This design allows the intuitive observation of optimal conditions and has been widely used in the field of pharmacy13. For example, the Box-Behnken design method, based on the entropy method, successfully optimized the processing technology of stir-frying with vinegar of Curcuma Longa Radix14. In this study, the Box-Behnken response surface experimental design combined with the entropy method was used in optimizing the processing technology of TBC processed with highland barley wine. The optimized processing technology is expected to ensure quality control and safe clinical use.

Protocol

In this study, the processing technology of TBC processed with highland barley wine was optimized with a Box-Behnken design combined with the entropy method. DDA and MDA content were used as evaluation indicators, and the weight coefficient of each evaluation index was determined by the entropy method.

1. Experimental preparation

- Prepare highland barley wine15.

- Take 500.00 g of black highland barley rice and add five times the amount of water. Cook the rice until the remaining water is absorbed (~2 h). Pour it out, wait until the temperature falls to 37 °C, add 4 g of Jiuqu (see Table of Materials), mix well, seal the can, wrap the container with cotton wool, and let it stew for 7 days.

- Add 300 mL of water on the 7th day and seal again. On the 8th day, begin removing the wine and replace with 300 mL of water afterward. Seal and ferment for 1 day, take the wine, and add 300 mL of water again. Repeat this procedure three times and combine the liquors.

- Bring to a boil, then reduce the heat to a simmer, and continue cooking until the remaining water is absorbed.

- To prepare processed products, accurately weigh the TBC in a container, add highland barley wine, and soak for 1 day. Then, dry in a constant temperature electric drying oven.

NOTE: The drying temperature should be less than 40 °C to avoid changes in the alkaloid composition. - Prepare test sample solution.

- Accurately weigh TBC processed product powder (2 g) in a conical flask, add 40% ammonia solution, and perform ultrasound-assisted extraction with isopropanol-ethyl acetate (1:1) mixed solvents (50 mL) (power: 200 W; frequency: 40 kHz; temperature: 40 °C) for 30 min.

NOTE: To prepare 40% ammonia solution, transfer 40 mL of ammonia to a 100 mL volumetric flask and then dilute with pure water. - Adjust the extracted solution to the original weight by adding an isopropanol-ethyl acetate mixture (1:1 v/v).

- Accurately transfer the extracted solution (25 mL) to a round-bottom flask for the recovery of the solvent under reduced pressure until dry.

- Finally, transfer 0.05% hydrochloric acid-methanol solution to dissolve the residue from step 1.3.3 in a 5 mL volumetric flask and dilute with 0.05% methanol hydrochloride solution. Filter the solution through a 0.22 µm microporous membrane filter prior to injection into the high-performance liquid chromatography (HPLC) systems.

NOTE: Prepare 0.05% methanol hydrochloride acid by adding 0.05 mL of hydrochloric acid to a 100 mL volumetric flask, then dilute with methanol.

- Accurately weigh TBC processed product powder (2 g) in a conical flask, add 40% ammonia solution, and perform ultrasound-assisted extraction with isopropanol-ethyl acetate (1:1) mixed solvents (50 mL) (power: 200 W; frequency: 40 kHz; temperature: 40 °C) for 30 min.

- Prepare a standard solution by weighing 5.18 mg of benzoylaconine, 13.13 mg of aconitine, 10.05 mg of 3-deoxyaconitine, and 10.09 mg of 3-acetylaconitine accurately, and then place the solids in a 5 mL volumetric flask individually. Dilute with 0.05% methanol hydrochloride solution.

2. Chromatographic condition

- Set up the chromatographic conditions as shown in Table 1 for HPLC. Details of the instruments used are provided in the Table of Materials.

3. System adaptability test

- Range of linearity

NOTE: First, we used HPLC to determine the peak areas of benzoylaconitine, aconitine, 3-deoxyaconitine, and 3-acetylaconitine in the sample, and then randomly determined the peak area of one known concentration of standard solution. Next, we compared the difference between two peak areas (sample solution and standard solution) to estimate the concentration of benzoylaconitine, aconitine, 3-deoxyaconitine, and 3-acetylaconitine in different samples, and then adjusted the standard solution into a linear range to include the concentration of the sample in the curve. The standard curve concentrations are shown in Table 2.- Prepare benzoylaconitine reference solutions containing 1.036 mg/mL, 0.518 mg/mL, 0.2072 mg/mL, 0.1036 mg/mL, and 0.0518 mg/mL.

- Prepare aconitine reference solutions containing 1.313 mg/mL, 0.5252 mg/mL, 0.2626 mg/mL, 0.1313 mg/mL, and 0.05252 mg/mL.

- Prepare 3-deoxyaconitine reference solutions containing 1.005 mg/mL, 0.5025 mg/mL, 0.201 mg/mL, 0.1005 mg/mL, and 0.402 mg/mL.

- Prepare 3-acetylaconitine reference solutions containing 0.2018 mg/mL, 0.1009 mg/mL, 0.04036 mg/mL, 0.02018 mg/mL, and 0.01009 mg/mL.

- Investigate the linearity of each compound by plotting the peak area versus injection concentration.

- To perform the precision test, inject 10 µL of each reference solution into the HPLC system six times daily and employ the same HPLC conditions described in step 2.1 to run the samples Record the peak area of each component.

- Perform intraday stability testing by injecting 10 µL of the prepared sample solution via step 1.3 and determine the peak areas after 0 h, 2 h, 4 h, 8 h, 14 h, 12 h, and 24 h16.

- Perform a reproducibility test by taking six samples of the same batch of TBC to prepare the test sample solution, according to step 1.3. Inject 10 µL of each sample into the HPLC system and run the samples as described in step 2.1.

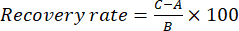

- Perform the recovery test to evaluate the accuracy of the method. Add 100% of the standard solution of each index component (benzoylaconitine, aconitine, 3-deoxyaconitine, and 3-acetylaconitine) in the test solution to calculate the recovery rate, respectively. For example, as the content of benzoylaconitine is 0.1524 mg/mL in the TBC sample, accurately weigh 0.1524 mg of benzoylaconitine standards and add to the TBC sample, then prepare the test sample solution according to step 1.3. Run these samples with the same HPLC conditions described in step 2.1. Calculate the recovery rate using Equation (1):

(1)

(1)

Here, A is the amount of component (benzoylaconitine, aconitine, 3-deoxyaconitine, or 3-acetylaconitine) to be measured in the sample solution, B is the amount of standard added (benzoylaconitine, aconitine, 3-deoxyaconitine, or 3-acetylaconitine), and C is the measured value of the solution containing the standard solution and the sample solution (see Table 3). Refer to step 2.1 for the chromatographic conditions to perform the above steps. The recovery rate reflects the degree of loss of the target component (benzoylaconitine, aconitine, 3-deoxyaconitine, or 3-acetylaconitine) during the sample analysis; the higher the recovery rate, the lower the loss of the target component.

4. Single factor test of TBC processed with highland barley wine

NOTE: The ratio between highland barley wine and TBC, slice thickness of TBC, and soaking time will affect the dissolution of more toxic components (aconitine, 3-deoxyaconitine, and 3-acetylaconitine) in TBC during the TBC processed with highland barley wine17. The single factor test and Box-Behnken design were used to investigate the influence of the ratio of highland barley wine to TBC, slice thickness of TBC, and soaking time.

- Perform the highland barley wine addition test (A) by setting up five groups of tests, each with 30 g of TBC, where the amount of highland barley wine is two, three, four, five, and six times the amount of TBC in the recipe. The soaking time is 12 h, and the slices are 1.0 cm thick18.

NOTE: Each group of the same condition test should be processed in three parallel groups. - Perform the soaking time test (B) by setting up five groups of tests, each with 30 g of TBC. The soaking times are 12 h, 24 h, 36 h, and 48 h. The amount of highland barley wine is five times that of TBC, and the slices are 1.0 cm thick19.

NOTE: Each group of the same condition experiment should be processed in three parallel groups. - Perform the slicing thickness test (C) by setting up five groups of tests, each with 30 g of TBC. The slices are 0.5, 1.0, 1.5, 2.0, and 2.5 cm thick, the soaking time is 24 h, and the amount of highland barley wine is five times that of TBC20.

NOTE: Each group of the same condition experiment should be processed in three parallel groups. - Accurately weigh processed products for each test group to prepare test sample solution according to step 1.3. Determine the peak area of each sample by HPLC and use the standard curve to estimate the amounts of MDAs and DDAs. In the standard curve, y is the peak area and x is the content. The content of MDAs is benzoyl aconitine, and the content of DDAs is the sum of aconitine, 3-deoxyaconitine, and 3-acetylaconitine.

- Use the total content of DDAs and the content of MDAs as evaluation indicators, and determine the weight coefficient of each evaluation index and the comprehensive scoring via the entropy method (section 5).

CAUTION: TBC is toxic, and thus protective measures should be taken during processing.

5. Entropy method to calculate the comprehensive scoring

NOTE: We use the experimental data of the slicing thickness test in the single factor test as an example to illustrate the calculation process in detail. We use the peak area of the components in each sample in Supplementary Table S1 and the standard curve in Table 2 to calculate the content of MDAs and DDAs (see Supplementary Table S2). In the linear equation, y is the peak area and x is the content. In this study, the moderately toxic MDA (benzoylaconitine) was used as the positive indicator, and the total content of DDAs (aconitine, 3-deoxyaconitine, and 3-acetylaconitine) with high toxicity was used as the negative indicator. The content of MDAs is benzoyl aconitine, and the content of DDAs is the sum of aconitine, 3-deoxyaconitine, and 3-acetylaconitine. Each sample has two evaluation indicators: i = 1,2,…,n, and j = 1,2,…m21.

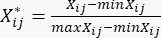

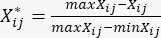

- Use Equation (2) to standardize the content of MDAs22.

(2)

(2)

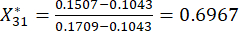

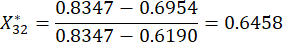

Thus,

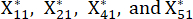

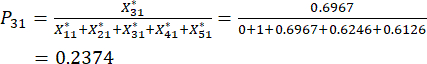

NOTE: Xij is the value of the j-th indicator of the i-th sample. Xij* is the standardized value of Xij. For example, i = 3 and j = 1, X31 represents the value of the first indicator of the third sample, and is the standardized value of the first indicator in the third sample.

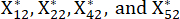

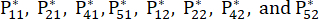

is the standardized value of the first indicator in the third sample.  are shown in Supplementary Table S3.

are shown in Supplementary Table S3. - Use Equation (3) to standardize the total content of the DDAs23.

(3)

(3)

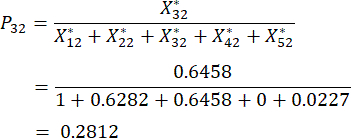

NOTE: Here, i = 3, j = 2, represents the second indicator of the third sample. is the standardized value of the second indicator in the third sample.

is the standardized value of the second indicator in the third sample.  are shown in Supplementary Table S3.

are shown in Supplementary Table S3. - Use Equations (4) and (5) to define the entropy value (Hj) of each indicator23.

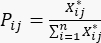

- Calculate the probability of the j-th trial under the i-th evaluation indicator Pij using equation (4).

(4)

(4)

For number 3,

NOTE: The probability values for the first indicator and second indicator of the third sample are 0.2374 and 0.2812, respectively. are shown in Supplementary Table S3.

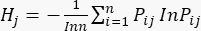

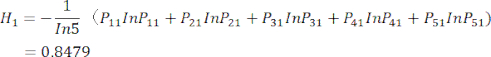

are shown in Supplementary Table S3. - Calculate the information entropy Hj.

(5)

(5)

NOTE: H1 is the entropy of the first indicator (MDAs) and H2 is the entropy of the second indicator (DDAs) in the slicing thickness test.

- Calculate the probability of the j-th trial under the i-th evaluation indicator Pij using equation (4).

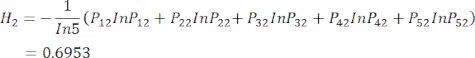

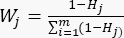

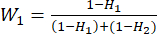

- Use Equation (6) to calculate the indicator weights (Wj)23.

(6)

(6)

= 33.3%

= 33.3%

= 66.7%

= 66.7%

NOTE: Wj is the weight coefficient of each indicator. In the slicing thickness test, the weight coefficient of the positive indicator (MDAs) and negative indicator (DDAs) are 33.3% and 66.7%, respectively. - Use Equation (7) to calculate the comprehensive scoring of the indicators23.

(7)

(7)

For number 3,

NOTE: Si is the comprehensive scoring of each sample. We need to obtain the highest score as the central point in the Box-Behnken design. S1, S2, S3, S4, and S5 are show in Supplementary Table S3.

6. Box-Behnken design

- Through the single factor test, use the condition with the highest comprehensive scoring (see Table 4, Table 5, Table 6, and Figure 2) as the center point of the response surface. Use the amount of highland barley wine (A), soaking time (B), and slice thickness of TBC (C) as the influencing factors and the comprehensive scoring as the response value24.

NOTE: Based on the single factor data in Table 4, Table 5, and Table 6, the highest comprehensive scoring is calculated by equations (2), (3), (4), (5), (6), and (7) in section 5, and the best point is obtained. The amount of highland barley wine was five times that of TBC, the soaking time was 36 h, and the slicing thickness was 1.0 cm.

7. Box-Behnken design software operation steps

- Open the software (see Table of Materials) and select New Design | Box-Behnken Design (see step 5.1; Supplementary File 1).

- Input the number of influencing factors and input the level information (three-level-three-factor; see Table 7). The Box-Behnken design is composed of 17 experiments in this study. Finally, click Continue (see step 5.2; Supplementary File 1).

- Set the comprehensive scoring (Y) by equations (2), (3), (4), (5), (6), and (7) in section 5 as the response. Input the number of response values (image shows only one response value) and click Finish (see step 5.3; Supplementary File 1).

- Process the TBC with highland barley wine according to the design results and complete the experiment based on the 17 scenarios designed for the response surface.

- Prepare the sample solutions by following step 1.3 and calculate the total content of the MDAs and DDAs by the HPLC system.

- Calculate the comprehensive scoring for each group by equations (2), (3), (4), (5), (6), and (7) in step 5, and input the score results (see step 5.4; Supplementary File 1).

- Click analyze to analyze the date and model information (see step 5.4.1; Supplementary File 1).

- Perform statistical validation of polynomial equations and response surface analysis plotted in 3D model plots obtained by the software.

- Click on ANOVA in the top menu and observe the results table.

- Click Optimization to view the predicted optimal process conditions (see step 5.4.2; Supplementary File 1).

8. Validation test

- According to the results predicted from the Box-Behnken response surface design, in step 7.3, identify the optimal processing condition of TBC. Here, it is as follows: TBC is soaked for 24 h in five times the amount of highland barley wine, and the thickness of the TBC is 1.5 cm. Take the optimal level of influencing factors as processing conditions and set up three parallel sets of experiments to verify the stability of the processing technology.

Results

In this study, the precision, stability, repeatability, and sample recovery of TBC indicated that the method is feasible. The four index components in TBC had a good linear relationship within a specific concentration range. Typical chromatograms are shown in Figure 1. The precision test results (Table 8) showed that the relative standard deviation (RSD) of the peak areas were 2.56%, 1.49%, and 2.03% for benzoylaconine, aconitine, and 3-deoxyaconitine, respectively, and 0.21...

Discussion

As a commonly used Tibetan medicine with toxic effects, the toxicity-attenuating effect of processing is extremely important for TBC's clinical application25. In this study, the processing technology of TBC processed with highland barley wine was optimized. By reviewing the main active ingredients and relating the pharmacological effects of TBC, we found that TBC alkaloids have anti-inflammatory and analgesic effects and can be used to treat rheumatoid arthritis. In this study, a moderate toxi...

Disclosures

The authors have no conflicts of interest to disclose.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 82130113), the China Postdoctoral Science Foundation (No. 2021MD703800), the Science Foundation for Youths of Science & Technology Department of Sichuan Province (No. 2022NSFSC1449), and the "Xinglin Scholars" Research Promotion Program of Chengdu University of Traditional Chinese Medicine (No. BSH2021009).

Materials

| Name | Company | Catalog Number | Comments |

| Aconitine | Chengdu Push Biotechnology Co.,Ltd | PS000905 | |

| 3-Acetylaconitine | Chengdu Push Biotechnology Co.,Ltd | PS010552 | |

| 3-Deoxyaconitine | Chengdu Push Biotechnology Co.,Ltd | PS011258 | |

| Benzoylaconine | Chengdu Push Biotechnology Co.,Ltd | PS010300 | |

| Circulating water vacuum pump | Gongyi City Yuhua Instrument Co., Ltd | SHZ-DIII | |

| Design-Expert | State-East Corporation | 8.0.6 | |

| Electric constant temperature drying oven | Shanghai Yuejin Medical Equipment Co., Ltd | 101-3-BS | |

| Electronic analytical balance | Shanghai Liangping Instruments Co., Ltd. | FA1004 | |

| High performance liquid chromatography | Shimadzu Enterprise Management (China) Co., Ltd | shimadzu 2030 | |

| Highland barley rice | Kangding City, Ganzi Tibetan Autonomous Prefecture, Sichuan Province | 20221015 | |

| Millipore filter | Tianjin Jinteng Experimental Equipment Co., Ltd | φ13 0.22 Nylon66 | |

| Rotary evaporator | Shanghai Yarong Biochemical Instrument Factory | RE-2000A | |

| Starter of liquor-making | Angel Yeast CO., Ltd | BJ22-104 | |

| Ultra pure water systemic | Merck Millipore Ltd. | Milli-Q | |

| Ultrasonic cleansing machine | Ningbo Xinyi Ultrasonic Equipment Co., Ltd | SB-8200 DTS |

References

- Zhang, J., et al. Study of quality standards for Aconitum pendulum Busch. Chinese Traditional Patent Medicine. 40 (9), 2100-2103 (2018).

- Liu, X. F., et al. Study on toxicity reduction and effect preservation of the compatibility of Tibetan medicine Aconitum pendulum Busch and Terminalia chebula Retz. Pharmacy and Clinics of Chinese Materia Medica. 13 (3), 69-72 (2022).

- Luo, D. S. . Chinese Tibetan herbs. 63, (2007).

- Li, C. Y., et al. Aconitum pendulum Busch and A. flavum Hand-Mazz: A narrative review on traditional uses, phytochemistry, bioactivities and processing methods. Journal of Ethnopharmacology. 292, 115216 (2022).

- Yu, L. Q., et al. Traditional Tibetan medicine: therapeutic potential in rheumatoid arthritis. Frontiers in Pharmacology. 13, 938915 (2022).

- Zhang, Y., Fu, X. Y. UPLC Simultaneous determination of six esteric alkaloids components in Aconitum pendulum Busch. Asia-pacific Traditional Medicine. 16 (5), 62-65 (2020).

- Wang, Y. J., et al. Determination of alkaloid content in different medicinal parts of the folk medicine. Aconitum pendulum Busch. Chinese Traditional Patent Medicine. 32 (8), 1390-1393 (2010).

- Shao, C. L., Fu, J. L., Fu, S. X., Ma, H. W., Sun, X. D. Toxicity research and processing methods of Aconitum pendulum Busch. Asia-pacific Traditional Medicine. 10 (2), 32-34 (2014).

- Chan, T. Y. K. Aconite poisoning. Clinical Toxicology. 47 (4), 279-285 (2009).

- Li, S. L., et al. An insight into current advances on pharmacology, pharmacokinetics, toxicity and detoxification of aconitine. Biomedicine & Pharmacotherapy. 151, 113115 (2022).

- Zhao, M. Y. Study on identification and processing attenuation of Tibetan drug Bangna. Southwest Jiaotong University. , (2018).

- Tibet Autonomous Region Food and Drug Administration. . Tibetan herbal medicine concoction specification. , 135 (2008).

- Abd-El-Aziz, N. M., Hifnawy, M. S., El-Ashmawy, A. A., Lotfy, R. A., Younis, I. Y. Application of Box-Behnken design for optimization of phenolics extraction from Leontodon hispidulus in relation to its antioxidant, anti-inflammatory and cytotoxic activities. Scientific Reports. 12 (1), 8829 (2022).

- Quan, L., et al. Optimization of processing technology of stir-frying with vinegar of Curcuma Longa Radix by orthogonal design and Box-Behnken design-response surface based on entropy method. Chinese Traditional and Herbal Drugs. 49 (8), 1823-1828 (2018).

- Jia, F. C., et al. Research on the brewing technology of Tibetan traditional barley liquor based on response surface method. Food and Fermentation Industries. 45 (22), 171-178 (2019).

- Zhao, X. H., et al. Determination of osthol in different traditional Chinese medicines by HPLC. Chinese Journal of Pharmaceutics. 19 (5), 154-158 (2021).

- Feng, Z. G., et al. Processing methods and the underlying detoxification mechanisms for toxic medicinal materials used by ethnic minorities in China: A review. Journal of Ethnopharmacology. 305, 116126 (2023).

- Wang, D. M., Lu, Z. J., Wang, Y. H., Zhang, C. S. Applying grading methods of synthesizing multiple guidelines to optimizing alcohol-steam processing technology from Ploygonatum odordatum. Journal of Zhejiang A & F University. 30 (1), 100-106 (2013).

- He, N. L., Bao, M. L., Ba, G. N. Study on the best processing technology of Terminalia Decoction soaking iron. Journal of Medicine & Pharmacy of Chinese Minorities. 20 (9), 36-38 (2014).

- Liu, C., et al. Optimization of processing technology for Saposhnikoviae Radix by Box-Behnken design-response surface methodology. Chinese Journal of Experimental Traditional Medical Formulae. 20 (5), 18-21 (2014).

- Ferreira, S. L. C., et al. Box-Behnken design: an alternative for the optimization of analytical methods. Analytica Chimica Acta. 597 (2), 179-186 (2007).

- Dong, R., Lu, Y., Wang, P. The process optimization of vinegar roasting of Bupleurum chinense by entropy weight method combined with Box-Behnken response surface method and its protective effect on mice liver injury. Science and Technology of Food Industry. 42 (23), 209-217 (2021).

- Li, W. J., et al. Analysis on the times of Polygonati Rhizoma steamed by multiple times based on entropy weight and gray relative analysis method. China Journal of Traditional Chinese Medicine and Pharmacy. 36 (11), 6764-6769 (2021).

- Huang, B. J., Liu, X. T., Mao, Y. M., Qi, B., Liu, L. Response surface methodology combined with analytic hierarchy process to optimize the processing technology of Custutae semen with wine. Lishizhen Medicine and Materia Medica Research. 33 (8), 1890-1894 (2022).

- Wang, J., Meng, X. H., Chai, T., Yang, J. L., Shi, Y. P. Diterpenoid alkaloids and one lignan from the roots of Aconitum pendulum Busch. Natural Products and Bioprospecting. 9 (6), 419-423 (2019).

- Xie, H. H., et al. Metabolomics study of aconitine and benzoylaconine induced reproductive toxicity in Be Wo cell. Chinese Journal of Analytical Chemistry. 43 (12), 1808-1813 (2015).

- Han, Y. F., et al. Optimization of extraction process for Yangyin Runmu granules by Box-Behnken design based on entropy weight method-analytic hierarchy process method. Chinese Journal of Modern Applied Pharmacy. 39 (7), 896-903 (2022).

- Chen, F. G., et al. Optimization of the baked drying technology of Clinamomi Ramulus based on CRITIC combined with Box-Behnken response surface method. Journal of Chinese Medicinal Materials. 2022 (8), 1838-1842 (2022).

- Pan, Y. L. Optimization of stir-baking process of Coix lacryma-Jobi Var.Mayuen Kernel by Box-Behnken response surface methodology. Shandong Chemical Industry. 51 (14), 73-75 (2022).

Reprints and Permissions

Request permission to reuse the text or figures of this JoVE article

Request PermissionThis article has been published

Video Coming Soon

Copyright © 2025 MyJoVE Corporation. All rights reserved