Se requiere una suscripción a JoVE para ver este contenido. Inicie sesión o comience su prueba gratuita.

Method Article

Una metodología sintética para la preparación de compuestos de sílice a base de aminas impregnados e injertados para la captura de carbono

En este artículo

Resumen

Este trabajo tiene como objetivo facilitar el desarrollo de técnicas estandarizadas para la impregnación o injerto de compuestos aminados sobre sustratos de sílice, que a menudo se describen ampliamente en la literatura. Se discutirán en detalle las cantidades específicas de disolvente, sustrato, aminas y los valores de otros parámetros experimentales importantes.

Resumen

Recientemente, se ha realizado un esfuerzo significativo para reducir o mitigar las emisiones deCO2 mediante el uso de materiales de captura de carbono para métodos de fuente puntual o captura directa de aire (DAC). Este trabajo se centra en los adsorbentes de CO2 funcionalizados con aminas para DAC. Estos materiales son prometedores para la eliminación deCO2 porque tienen un bajo consumo de energía de regeneración y una alta capacidad de adsorción. La incorporación de especies de aminas en un sustrato poroso combina las ventajas de la afinidad de las especies de aminas con elCO2 con los grandes volúmenes de poros y áreas superficiales del sustrato poroso. Hay tres métodos comúnmente utilizados para preparar sorbentes de CO2 a base de aminas, dependiendo de la selección de la especie de aminas, el soporte del material y el método de preparación. Estos métodos son la impregnación, el injerto o la síntesis química. La sílice es una opción frecuente de material de sustrato debido a su tamaño de poro ajustable, tolerancia a la humedad, estabilidad de temperatura y capacidad para adsorberCO2 en bajas concentraciones para aplicaciones DAC. En este documento se describen los procedimientos sintéticos típicos y los atributos primarios de los compuestos de amina y sílice impregnados e injertados.

Introducción

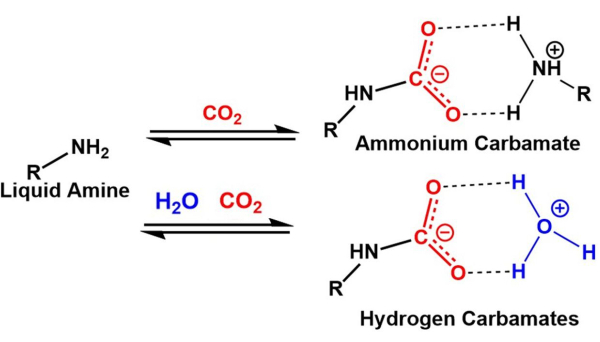

Las emisiones antropogénicas deCO2 en las últimas décadas han sido ampliamente implicadas como el principal factor que impulsa el efecto de los gases de efecto invernadero y, en consecuencia, el cambio climático relacionado 1,2,3,4. Existen dos métodos generales para la captura de CO2, la fuente puntual y la captura directa de aire. Durante más de 50 años, las tecnologías de captura de CO2 de lavado húmedo se han utilizado para la captura de fuentes puntuales dentro de la industria para mitigar las emisiones de CO2 5,6. Estas tecnologías se basan en aminas en fase líquida que reaccionan con el CO2 para formar carbamatos en condiciones secas y carbonatos de hidrógeno en presencia de agua7,8, ver Figura 1. La razón principal por la que la captura y el almacenamiento de carbono se utilizan en grandes fuentes puntuales (industriales) es para evitar la liberación de grandes cantidades de CO2, lo que tiene un efecto neutro en la concentración total deCO2 en la atmósfera. Sin embargo, los sistemas de captura de carbono de fuente puntual adolecen de varios inconvenientes, como la corrosión de los equipos, la degradación de los disolventes y los elevados requisitos energéticos para su regeneración9. La captura directa de aire (DAC) va más allá de la reducción de emisiones y puede facilitar la eliminación deCO2 de la atmósfera. La eliminación de esteCO2 existente es necesaria para limitar el cambio climático continuo. El DAC es una metodología emergente y debe abordar las dificultades de eliminar bajas concentraciones deCO2 en condiciones atmosféricas (400 a 420 ppm), operar en una variedad de condiciones ambientales diferentes y abordar la necesidad de materiales rentables que puedan reutilizarse muchas veces 1,2,3. Se necesita un trabajo significativo para identificar materiales que cumplan con estos requisitos, lo que acelerará la adopción de DAC y mejorará su viabilidad económica. Lo más importante es que se debe establecer un consenso comunitario sobre los parámetros críticos de medición, lo cual es esencial para que se desarrollen materiales de referencia.

Figura 1: Esquema del mecanismo de captura esperado de CO2 adsorbente de aminas líquidas. La reacción superior es en condiciones secas y la reacción inferior es en presencia de humedad. Haga clic aquí para ver una versión más grande de esta figura.

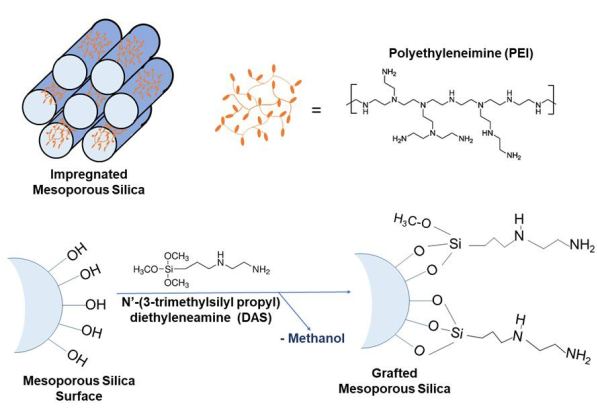

En un esfuerzo por remediar estos inconvenientes, la investigación y el desarrollo considerables de nuevas tecnologías de materiales porosos han dado como resultado una amplia gama de materiales prometedores que tienen el potencial de ser utilizados como materiales de captura o sustratos para DAC. Algunos ejemplos de estos materiales son las especies de sílice mesoporosa 10,11,12,13, las zeolitas14,15, el carbón activado 16,17 y las estructuras metal-orgánicas 18. Muchos adsorbentes de aminas con soporte sólido también muestran una mayor tolerancia al agua, lo cual es una consideración vital en la eliminación de CO2 a través de enfoques DAC. Para las aplicaciones DAC, los investigadores deben tener en cuenta las condiciones ambientales húmedas/secas, las temperaturas calientes/frías y una concentración general deCO2 atmosférico diluido. Entre los diversos materiales de sustrato, la sílice se usa comúnmente debido a sus tamaños de poro ajustables, su capacidad para funcionalizar la superficie y su gran área de superficie 1,2,3. En este trabajo se describen los procedimientos sintéticos típicos y las características principales de los compuestos de amina y sílice impregnados e injertados (Figura 2). La síntesis directa, en la que el material se realiza in situ con ambos componentes, sustrato y amina, es otra metodología comúnmente utilizada2.

Figura 2: Representaciones esquemáticas de la impregnación. Mezcla de PEI y sustrato de sílice en metanol por difusión (arriba) y compuestos injertados de amina-sílice por anclaje covalente (abajo). Haga clic aquí para ver una versión más grande de esta figura.

La impregnación es un método en el que una amina se adsorbe físicamente sobre una superficie, en este caso, un medio de sílice poroso, a través de las fuerzas de van der Waals y el enlace de hidrógeno entre la amina y la superficie de sílice19, ver Figura 2. Los solventes como el etanol y el metanol se usan comúnmente para promover la difusión de las moléculas en la estructura porosa del material del sustrato. La solución también se puede calentar para aumentar la solubilidad de las poliaminas de alta masa molar, aumentando así la homogeneidad de la penetración de las aminas dentro de los poros. En el caso de materiales impregnados, la cantidad de amina introducida en un sustrato de sílice está determinada por la cantidad inicial de amina y el área superficial del sustrato. Si la cantidad de amina introducida excede el área superficial disponible del sustrato de sílice, la especie de amina se aglomerará en su superficie. Esta aglomeración es fácilmente evidente, ya que el material impregnado parecerá tener una capa similar a un gel, a menudo amarilla, en lugar de la apariencia blanca y polvorienta esperada1. Entre los muchos tipos de adsorbentes sólidos a base de aminas, la polietileneimina (PEI) y la tetraetileno pentamina (TEPA) son los más utilizados debido a su alta estabilidad y alto contenido de nitrógeno20. Para los sistemas físicamente impregnados, la cantidad teórica de carga de amina se puede calcular a partir de las cantidades preponderadas del sustrato y la densidad de la amina. La ventaja obvia de la impregnación física radica en el sencillo procedimiento de síntesis para prepararla, así como en el potencial de un gran contenido de aminas debido a la alta porosidad del sustrato de sílice. Por el contrario, la estabilidad de la amina dentro de la sílice es limitada porque no hay enlace covalente entre la amina y el soporte de sílice. Por lo tanto, después de múltiples ciclos de absorción y regeneración deCO2 a través del calor o el vapor, la amina puede filtrarse por los poros. A pesar de estos inconvenientes, la implementación de estos materiales para DAC es muy prometedora para eliminar elCO2 de la atmósfera.

Otra opción para la preparación de materiales DAC es el injerto. El injerto es un método mediante el cual las aminas se inmovilizan sobre un sustrato de sílice poroso a través de una reacción química, como se muestra en la Figura 2. Esta reacción procede haciendo reaccionar un aminosilano con el grupo funcional silanol de la superficie, lo que da como resultado un enlace covalente. Por lo tanto, el número de grupos funcionales en la superficie del sustrato de sílice impacta en la densidad de aminas injertadas21,22. En comparación con los adsorbentes impregnados de aminas, los métodos de injerto químico han tenido una menor capacidad de adsorción deCO2 debido principalmente a la baja carga de aminas21. Por el contrario, las aminas injertadas químicamente tienen una mayor estabilidad térmica debido a su estructura unida covalentemente. Esta estabilidad puede ser útil en la regeneración del material, ya que los adsorbentes (como la sílice injertada) se calientan y presurizan para eliminar el CO2 capturado para su reutilización y ahorrar material y costos. En un procedimiento de síntesis típico, el sustrato de sílice mesoporosa se dispersa en un disolvente (por ejemplo, tolueno anhidro), que luego es seguido por la adición de aminosilanos. A continuación, la muestra resultante se lava para eliminar los aminosilanos que no han reaccionado. Se ha informado que se han logrado mejoras en la densidad de aminosilano mediante la adición de agua, específicamente con SBA-15, para expandir el tamaño de poro23. El procedimiento de injerto que se describirá en este documento utiliza técnicas sensibles a la humedad. Por lo tanto, no se utilizará agua adicional. La implementación de materiales injertados de aminosilano para DAC es prometedora debido a su estabilidad esperada durante los procesos de adsorción y desorción de CO2. Sin embargo, los principales inconvenientes de esta metodología incluyen las complejas reacciones/preparación de estos materiales, lo que lleva a un mayor costo, y su baja capacidad de adsorción deCO2 en general, lo que significa que se requieren mayores cantidades.

En general, los resultados de muchos estudios previos indican que la estructura del sustrato y la modificación relacionada con las aminas tienen un impacto significativo en el rendimiento de la adsorción, con estudios específicos que utilizan técnicas como la microscopía electrónica de transmisión (TEM) y la dispersión de neutrones cuasielástica (QENS) para caracterizar completamente estos materiales24,25. En otras palabras, las propiedades estructurales (por ejemplo, porosidad y área superficial) del material del sustrato determinan la carga de aminas, por lo que el aumento de estos parámetros puede mejorar la capacidad deCO2 24,25. La investigación continua en la optimización y el diseño de materiales de sustrato y procesos de preparación es fundamental para el desarrollo de adsorbentes de alto rendimiento para DAC. El objetivo de este trabajo es proporcionar orientación sobre la impregnación y la síntesis de aminas injertadas con la esperanza de facilitar una mejor transparencia de las técnicas sintéticas. Dentro de la literatura, no siempre se describen detalles específicos sobre las cantidades de solvente, sustrato y aminas, lo que dificulta la comprensión de la correlación entre las cantidades de carga experimental y las mediciones cuantitativas de compuestos de amina y sílice. Las cantidades exactas de carga y una descripción detallada de los procedimientos experimentales se proporcionarán aquí para facilitar mejor este tipo de comparaciones.

Access restricted. Please log in or start a trial to view this content.

Protocolo

NOTA: Los detalles relacionados con el equipo, la instrumentación y los productos químicos utilizados en esta sección se pueden encontrar en la Tabla de materiales.

1. Impregnación de sílice con polietileneimina de 800 g/mol de masa molar (PEI 800)

- Preparación de la reacción

- Utilice metanol anhidro como disolvente en esta reacción. Tiene un punto de ebullición bajo; Así, su volatilidad facilita su posterior eliminación a temperaturas más bajas.

NOTA: El solvente anhidro es importante porque el agua puede evitar que el PEI 800 ingrese a los poros del soporte de sílice. Otro solvente comúnmente utilizado es el etanol, que tiene un punto de ebullición más alto y requiere tiempos de secado más largos y temperaturas de secado más altas. - Calcule la fracción de masa (%) de amina utilizando la ecuación 1, donde m amina = masa deamina , m sílice = masa desílice utilizada.

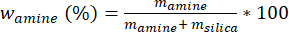

Ecuación 1:

- La fracción de masa de amina (w amina) en la sílice MCM-41 será del 59,9 % (750 mg de amina y 500 mg de sílice). Por cada 1 g de amina, use 10 ml de metanol anhidro. Esto se hace para que la mezcla general sea una suspensión diluida. Estas cantidades calculadas se clasificarán como experimentales (pamine_exp) y se clasificarán a su vez para cada metodología sintética (por ejemplo, w amine_exp_imp (impregnado) y wamine_exp_graft (injertado)).

- Para asegurarse de que toda la cristalería esté desprovista de humedad, colóquela en un horno a 140 °C durante al menos 1 h antes de su uso.

- Utilice metanol anhidro como disolvente en esta reacción. Tiene un punto de ebullición bajo; Así, su volatilidad facilita su posterior eliminación a temperaturas más bajas.

- Preparación del soporte de sílice

NOTA: La sílice MCM-41 es el sustrato sólido utilizado en este proceso. Dado que MCM-41 es sílice adsorbente, se espera que adsorba agua de la atmósfera o durante la fabricación.- Seque la sílice MCM-41 para asegurarse de que no se haya adsorbido agua en sus poros. Coloque la cantidad deseada de sílice en una placa de Petri de vidrio, cúbrala con papel de aluminio perforado y luego colóquela en un horno al vacío.

- En primer lugar, aplique el vacío (normalmente inferior a 3 kPa, que cambia en función de cada sistema de aspiración individual) y, a continuación, ajuste el horno a una temperatura de unos 110 °C para garantizar la eliminación del agua. Realice este paso durante un mínimo de 2 h antes de continuar con la síntesis.

- Metodología de impregnación

- Utilice una espátula de laboratorio limpia y seca y transfiera la cantidad deseada (750 mg) de polietileneimina (PEI) al recipiente de reacción (en este caso, un vial seco de 35 ml). Tape el recipiente de reacción cuando esté en transporte.

- Transfiera el recipiente de reacción a una campana de extracción de gases químicos, sujételo o asegúrelo dentro de la campana y colóquelo sobre una placa de agitación. Retire la tapa del recipiente de reacción.

- Coloque una barra agitadora limpia y seca en el recipiente de reacción.

NOTA: El uso de una barra agitadora asegurará una mezcla uniforme, puede permitir que la solución se agite durante períodos más largos, facilitará una mejor dispersión y puede permitir un calentamiento seguro de la reacción sin la necesidad de mezclar manualmente. - Con una pipeta, agregue 7,5 ml de metanol anhidro (por cada 1 g de amina, use 10 ml de metanol) de un cilindro graduado. Encienda la placa para revolver. Deje que la solución se mezcle durante 15 minutos para asegurarse de que el PEI se disuelva completamente y se disperse homogéneamente dentro del disolvente.

NOTA: Después de mezclar, la solución aparecerá clara/transparente, lo que denota una disolución completa del polímero. - Utilice una espátula de laboratorio limpia y seca para transferir la cantidad deseada (500 mg) de sílice preseca (en este caso, MCM-41) al papel de pesaje. Transfiera la sílice al recipiente de reacción dentro de la campana extractora.

NOTA: Esta cantidad de carga experimental de amina coincidirá con la cantidad real medida por análisis termogravimétrico (TGA).

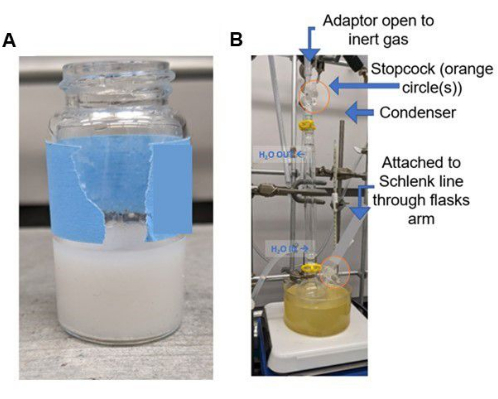

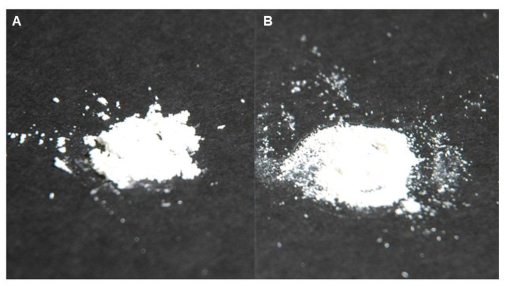

PRECAUCIÓN: Respirar polvo de sílice puede dañar el tejido pulmonar. Se recomienda usar un respirador N95 cuando se trabaja con sustratos de sílice (consulte las pautas de seguridad locales para conocer las opciones adecuadas para un laboratorio individual) y trabajar en una campana extractora de productos químicos. Estos materiales de sílice a menudo exhiben propiedades de "adherencia estática" y se dispersan fácilmente dentro de la campana extractora. Realice este paso rápidamente para evitar la adsorción de humedad en la sílice del aire. - Agregue metanol adicional para enjuagar la sílice en el recipiente para garantizar una exposición completa a PEI dentro de la solución si es necesario. La mezcla aparecerá como una suspensión; véase la figura 3.

- Coloque el recipiente en un baño de aceite de silicona, un bloque calefactor o una manta calefactora a 40 °C a 50 °C para garantizar la solubilidad total del PEI, la mezcla homogénea y para estimular la carga de aminas en la sílice porosa.

NOTA: Las temperaturas elevadas no siempre se utilizan durante los procedimientos de impregnación, y la literatura ha demostrado que otras se han mezclado a temperatura ambiente (RT)1,2,3. En este protocolo, se utiliza el calentamiento para facilitar una mezcla homogénea. - Asegúrese de que la barra agitadora mezcle uniformemente la solución. Deje que la solución se revuelva a fuego durante aproximadamente 1 hora.

NOTA: Dependiendo del tamaño de la reacción y de las preferencias individuales, la selección del recipiente de reacción puede variar. Por lo tanto, la forma en que se calienta la reacción (baño de aceite, bloque calefactor o manto calefactor) puede variar para adaptarse mejor a la elección del recipiente de reacción. - Retire el recipiente de reacción de la fuente de calor y deje que se enfríe a RT sin dejar de remover. Cuando esté completamente frío, deje de revolver y retire la barra de agitación.

- Coloque el recipiente que contiene la muestra al vacío en una línea Schlenk (normalmente <3 kPa, reduzca la presión lentamente para evitar golpes).

- Deje que el recipiente de reacción permanezca en la línea Schlenk hasta que se elimine visiblemente todo el disolvente. Luego, transfiera la muestra a un recipiente de almacenamiento diferente de su elección, como una placa de Petri de vidrio.

- A continuación, coloque la muestra en un horno de vacío, encienda el vacío (normalmente <1,3 kPa) y, a continuación, ajuste el horno a aproximadamente 70 °C. Deje que la muestra se seque al vacío durante al menos 18 h para asegurarse de que se ha eliminado una cantidad suficiente de metanol.

NOTA: Considere el nivel de solvente antes de colocar el recipiente de su elección en un horno de vacío debido al riesgo de que la muestra y la solución salgan erráticamente del recipiente debido al vacío. Por lo general, no queda más de 1 ml de solvente dentro de la muestra/recipiente antes de colocarla en el horno de vacío. - Después del secado, los materiales aparecen blancos y polvorientos. Guárdelo en un ambiente libre de humedad y aire hasta que lo necesite para su uso posterior.

NOTA: Este paso puede ser en un desecador al vacío o en una guantera que esté preparada con un ambiente libre de aire y humedad. Consulte la Figura 4 para ver la apariencia esperada del producto final.

Figura 3: Imágenes representativas de las reacciones. (A) Fotografía de la suspensión de sílice PEI (en metanol) durante la impregnación de PEI antes de la transferencia a un bloque calefactor y (B) aparato para injertar DAS después de que se complete el calentamiento durante 6 horas. Haga clic aquí para ver una versión más grande de esta figura.

Figura 4: Aspecto representativo de los productos finales después del secado. (A) Impregnación de PEI a amine_exp_imp W = 59,9 %. (B) DAS injertado a wamine_exp_das = 90,0 %. Haga clic aquí para ver una versión más grande de esta figura.

2. Preparación de sílice injertada húmeda con N'-(3-trimetilsilil propilo) dietileneamina (DAS)

- Preparación de la solución

- Utilice tolueno anhidro en esta reacción. Tiene un alto punto de ebullición (110 °C), lo que permite mezclar a alta temperatura. El aminosilano (N'-(3-trimetilsilil propil) dietileneamina (DAS) es altamente soluble en este medio.

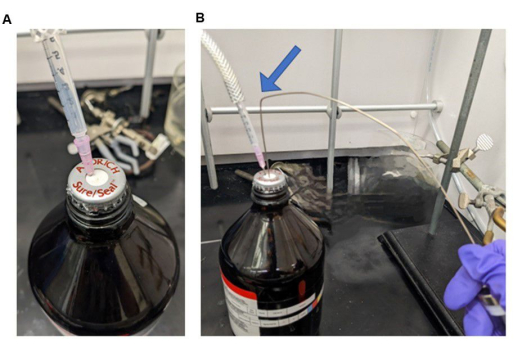

NOTA: Realizar esta reacción en condiciones anhidras es importante porque el agua puede interactuar con los aminosilanos para cambiar la naturaleza de su unión a la superficie de sílice. El tolueno anhidro utilizado viene con una tapa con tapón de tabique. Por lo tanto, se utilizará una jeringa hermética al gas para transferir el disolvente al recipiente de reacción. Por cada 1 g de DAS, se utilizan 5 mL de tolueno. Por lo tanto, para 5 mL de DAS (1.028 g/mL), se utilizan 25 mL de solvente.

- Utilice tolueno anhidro en esta reacción. Tiene un alto punto de ebullición (110 °C), lo que permite mezclar a alta temperatura. El aminosilano (N'-(3-trimetilsilil propil) dietileneamina (DAS) es altamente soluble en este medio.

- Preparación del soporte de sílice

- Seque la sílice siguiendo el procedimiento descrito anteriormente en el paso 1.2.

- Preparación de siloxano

- El aminosilano es sensible a la humedad, ya que la presencia de agua puede provocar la polimerización. Por lo tanto, maneje la reacción como una reacción libre de humedad. Guarde el DAS dentro de un frasco con tapa de tabique y use una jeringa hermética para la transferencia.

PRECAUCIÓN: Hay muchos riesgos para la salud y peligros asociados con los aminosilanos. Revise la hoja de datos de seguridad antes de comenzar el experimento y observe todas las precauciones de seguridad recomendadas.

- El aminosilano es sensible a la humedad, ya que la presencia de agua puede provocar la polimerización. Por lo tanto, maneje la reacción como una reacción libre de humedad. Guarde el DAS dentro de un frasco con tapa de tabique y use una jeringa hermética para la transferencia.

- Metodología de sílice injertada

- Es importante tener en cuenta que, a diferencia de la metodología de impregnación, se espera que los aminosilanos tengan un bajo contenido de nitrógeno de injerto en el sustrato de sílice. Por lo tanto, en esta reacción, cargue w amine_exp_graft = 90.0 % de DAS experimentalmente para aumentar la probabilidad de que el aminosilano localice grupos silanol en el soporte de sílice y se adhiera covalentemente con éxito.

- Seque toda la cristalería en el horno durante al menos 2 h antes de usarla para garantizar una superficie libre de humedad.

- Llene un matraz Schlenk de fondo redondo equipado con una barra de agitación magnética con la cantidad deseada (500 mg) de soporte de sílice (MCM-41).

- Inserte un tabique de goma en el recipiente de reacción y ciña el recipiente de reacción en una línea Schlenk tres veces para eliminar el aire y la humedad. Para ello, abra la llave de paso del recipiente de reacción al vacío durante unos 30 s, cierre la llave de paso, cambie a un gas inerte (N 2 o Ar2) durante unos 30 s y, a continuación, vuelva a abrir la llave de paso. Después de que se haya ciclado el recipiente de reacción, mantenga un entorno de gas inerte para los siguientes pasos del procedimiento.

- Inserte una línea de gas inerte en la botella con tapa de tabique (sellado seguro), luego use la jeringa hermética al gas y purgue la jeringa con gas inerte antes de extraer la cantidad deseada de tolueno anhidro (en este caso, 25 ml).

NOTA: Consulte la Figura 5 para obtener una imagen del recipiente de sellado seguro con una entrada de gas inerte y una jeringa hermética al gas. La curva (flecha azul) se coloca en el tubo antes de la transferencia para evitar cualquier goteo. Esta técnica se utiliza cada vez que se necesita una jeringa hermética al gas de un líquido. La cantidad de disolvente está dictada por la cantidad de aminosilano añadido. Por cada 1 ml de aminosilano, utilice 5 ml de tolueno anhidro para garantizar la solubilidad. Es importante llenar la jeringa con 25 ml de tolueno y luego elevar la aguja por encima del nivel de la solución dentro del frasco. A continuación, extraiga un poco de gas inerte del espacio de cabeza por encima del tolueno antes de retirar la jeringa del recipiente de tolueno. - Asegúrese de que la barra de agitación magnética dentro del recipiente de reacción se agite suavemente antes de comenzar este paso. Transfiera el tolueno anhidro contenido en la jeringa hermética al gas perforando el tabique en el recipiente de reacción y liberando el tolueno en el recipiente.

- Retire la aguja con gas inerte.

- Repetir los mismos pasos (2.4.6 a 2.4.8) con el aminosilano (4,8 ml de DAS).

- Utilice un adaptador para conectar una línea de la línea Schlenk a un condensador de agua con grasa de vacío. Envuelva la parte inferior del aparato del condensador con cinta de politetrafluoroetileno (PTFE) (este paso garantiza que no se contamine con grasa). A continuación, conecte el aparato condensador al matraz Schlenk de fondo redondo para preparar la configuración de la cristalería; véase la figura 3.

- Conecte las líneas de agua "fría" al condensador de agua y enciéndalo.

NOTA: El agua "fría" (por debajo de 23 °C) viajará hacia el fondo del condensador y saldrá por la parte superior hacia un fregadero. Los tubos estarán asegurados (con cables, bridas o abrazaderas de manguera de acero) para evitar fugas de agua en los sitios de conexión. - Baje el recipiente de reacción en un baño de aceite de silicona o en un bloque calefactor, o colóquelo en una manta calefactora entre 80 °C y 100 °C. Esta temperatura se selecciona para ayudar a facilitar el injerto de aminosilano (DAS), la mezcla homogénea y fomentar la carga de aminas.

- Cierre la llave de paso al gas inerte en el matraz Schlenk de fondo redondo y deje abierta la llave de paso en el condensador; véase la figura 3B.

NOTA: Este paso se realiza para evitar que el tolueno suba al tubo ubicado cerca del aparato (brazo lateral del matraz Schlenk) mientras se mantiene la reacción bajo una atmósfera inerte debido a la entrada en la parte superior del condensador; consulte la Figura 3 para esta configuración. - Asegúrese de que la barra agitadora mezcle uniformemente la solución. Removemos mientras calentamos durante 6 h.

- Deje que el recipiente de reacción se enfríe a RT. Use filtración al vacío para capturar la sílice sólida injertada en el papel de filtro y enjuague con grandes cantidades de tolueno anhidro (3 veces con 10 ml).

- Para aspirar el filtro, equipe un matraz de filtro Erlenmeyer con brazo para aspirar a través de una manguera. Coloque un tapón de goma en la abertura, coloque el embudo Buchner encima del tapón de goma y, por último, coloque un papel de filtro dentro del embudo Buchner. Humedece el papel de filtro con tolueno anhidro.

- Encienda la aspiradora y dispense rápidamente la solución sobre el papel de filtro. Es útil enjuagar el recipiente de reacción con el tolueno anhidro antes de verterlo sobre el papel de filtro durante los lavados.

- El material final aparece blanco en el papel de filtro. Retire el material de silano injertado del papel de filtro con una espátula de laboratorio limpia y seca y colóquelo en un vial.

- Cubra el vial con papel de aluminio perforado y colóquelo en un horno al vacío. Enciende la aspiradora. Pon el horno a unos 100 °C y déjalo secar durante aproximadamente 18 h para eliminar el exceso de tolueno.

NOTA: Los materiales aparecen blancos y polvorientos después del secado y se almacenan en un ambiente libre de humedad y aire. Esto puede ser en un desecador al vacío o en una guantera que esté preparada con un ambiente libre de aire y humedad. Consulte la Figura 4 para ver la apariencia del producto final. - Este procedimiento se repite dos veces más (3 veces en total, pasos 2.4.1 - 2.4.16).

Figura 5: Fotografías de un recipiente con cierre seguro. (A) Recipiente con una aguja conectada a un gas inerte (N 2 o Ar2) y (B) con gas inerte conectado y jeringa hermética al gas adherida, con aguja "doblada" (flecha azul), que se utilizará para transferir sin fugas. Haga clic aquí para ver una versión más grande de esta figura.

3. Análisis de materiales compuestos de sílice por TGA

NOTA: La incertidumbre estándar asociada a esta medición es de aproximadamente ± 0,01 % en masa y ± 1 °C en temperatura.

- Utilizando el software de aplicación del instrumento para el TGA, tara una bandeja vacía.

- Retire la bandeja tarada del área de carga de la muestra y agregue la muestra a la bandeja. Coloque la muestra en el centro de la sartén y use al menos 2 mg para asegurar una resolución adecuada de la pérdida de masa. Vuelva a colocar la bandeja con la muestra en el área de carga.

- Utilizando el software del instrumento, personalice un procedimiento que primero se equilibre a aproximadamente 50 °C durante 5 min en un entorno de 100 % N2 con un caudal de gas de 60 mL/min. A continuación, ajuste una rampa de 2 °C/min a 5 °C/min a 1000 °C. Marca el final del ciclo. Estas mediciones se denotan como wamine_TGA ya que evalúan el contenido real de aminas dentro del material utilizando TGA. Esto se clasifica a su vez para cada metodología sintética (por ejemplo, w amine_TGA_imp (método impregnado) y wamine_TGA_graft (método injertado)).

NOTA: Las recomendaciones específicas para los caudales pueden diferir para los TGA individuales. Consulte las especificaciones del fabricante antes de seleccionar el caudal adecuado para un experimento individual. - Repita los pasos 3.1 a 3.3 para cualquier ejecución experimental adicional.

- Aplique el paso 3.1 para la configuración del experimento de adsorción de CO2 .

- Con el software del instrumento, personalice una ejecución de procedimiento que primero se equilibre a 100 °C durante 5 min, luego aumente a 20 °C/min a 40 °C. A continuación, aplicar una retención isotérmica a 40 °C durante 10 min antes de introducir un gas mezclado de 5 % deCO2 en N2, con un caudal de 60 mL/min.

- Mantener la muestra a 40 °C en esta condición de mezcla de gases durante 100 min. Este procedimiento se realiza para medir la adsorción de CO2 por ganancia de peso. Estas mediciones se denotan como w CO2, ya que evalúan la adsorción de CO2 dentro del material. Esto se clasifica a su vez para cada metodología sintética (por ejemplo, w CO2_imp (método impregnado) y wCO2_graft (método injertado)).

- Para los estudios de ciclos, utilizando el software del instrumento, personalice una corrida de procedimiento que primero se abra al 100 % de gas N2 , retención isotérmica durante 5 minutos, antes de aumentar a 20 °C/min a 105 °C, y retención isotérmica durante 5 minutos.

- A continuación, se debe reducir a 10 °C/min hasta 40 °C, y mantener la isoterma durante 1 min antes de que se libere una mezcla de 5 % de CO 2 en N2, y mantener la isoterma durante 35 min. Repita los pasos del procedimiento 10 veces.

- Dentro del software, agregue esta ejecución tantas veces como desee para agregar pasos de ciclo adicionales. Asegúrese de no cambiar el número de bandeja y de eliminar el paso de estabilización de peso para las carreras anexadas después de la primera ejecución. Esto permite al usuario colocar varias ejecuciones de 10 ciclos juntas en un método.

4. Análisis de materiales compuestos de sílice mediante espectroscopia infrarroja por transformada de Fourier (FTIR) utilizando un accesorio de reflectancia total atenuada (ATR)

NOTA: Las incertidumbres estándar asociadas con este instrumento son ± 1 % en intensidad de pico y ± 4 cm−1 en número de onda, por lo tanto, la incertidumbre en intensidad en la curva informada es ± 1,4 % utilizando una propagación lineal de incertidumbres.

- Limpie la ventana (diamante) del accesorio FTIR-ATR con una toallita baja en pelusa y metanol.

- Recopile un espectro de fondo utilizando la ventana de medición básica del software.

- Con una espátula limpia y seca, coloque la muestra sobre la ventana FTIR-ATR. Utilice la sonda de compresión ATR para empujar la muestra en contacto con la ventana.

- Recopile un espectro de muestra presionando el botón Recopilar muestra en la ventana de medición básica y cargue el fondo asociado desde el archivo obtenido en el paso 4.2.

- Repita los pasos 4.1 a 4.4 para todas las muestras.

5. Análisis de materiales compuestos de sílice antes y después de la impregnación e injerto de aminas mediante microscopía electrónica de barrido (SEM)

- Monte las muestras en forma de polvo en trozos de aluminio extendiéndolas con cuidado sobre cinta conductora de carbono de doble cara. Un microscopio estereoscópico ayuda en este procedimiento al aumentar la visibilidad de la extensión de la muestra.

- Recubrimiento catódico de cada muestra con un recubrimiento conductor de oro-paladio (Au-Pd) de 5 nm para obtener unas condiciones óptimas de obtención de imágenes.

- Obtener imágenes de la morfología de la superficie del material de sílice del sustrato antes y después de la impregnación o el injerto en un SEM de emisión de campo de doble haz bajo alto vacío (es decir, menos de 0,4 mPa, 3 x 10−6 torr).

NOTA: Los parámetros de energía del haz (1 keV) y corriente de la sonda (6,3 pA y 25 pA) elegidos se optimizaron para obtener imágenes nítidas con una carga, artefactos y deriva mínimos.

Access restricted. Please log in or start a trial to view this content.

Resultados

El TGA se usa comúnmente para cuantificar la cantidad de amina cargada o injertada en la superficie de sílice para estos materiales. Las curvas de TGA obtenidas muestran una pérdida de disolvente residual y agua entre 60 °C y 100 °C, que se muestra en la curva de peso derivado (% en peso/°C) como el primer pico, y una pérdida de amina, que se muestra en la curva de peso derivado (% en peso/°C) como el segundo pico. En el caso de la sílice impregnada con PEI, se espera que esta pérdida de amina aparezca entre lo...

Access restricted. Please log in or start a trial to view this content.

Discusión

Los métodos descritos en este documento están destinados a proporcionar un protocolo para la preparación de adsorbentes compuestos de sílice de amina impregnados e injertados. Los procedimientos que hemos documentado se basan en la revisión de las técnicas reportadas en la literatura y las refinadas en nuestro laboratorio. 1,2,3. La preparación de estos materiales es útil en el campo de la investigación sobre la elimina...

Access restricted. Please log in or start a trial to view this content.

Divulgaciones

Todos los autores no revelan conflictos de intereses contrapuestos. La descripción completa de los procedimientos utilizados en este documento requiere la identificación de ciertos productos comerciales y sus proveedores. La inclusión de dicha información no debe interpretarse de ninguna manera como una indicación de que dichos productos o proveedores están respaldados por el NIST, o son recomendados por el NIST, o que son necesariamente los mejores materiales, instrumentos, software o proveedores para los fines descritos.

Agradecimientos

Charlotte M. Wentz desea agradecer la financiación a través del Premio NIST # 70NANB8H165. Zois Tsinas desea agradecer la financiación a través del Premio NIST # 70NANB22H140.

Access restricted. Please log in or start a trial to view this content.

Materiales

| Name | Company | Catalog Number | Comments |

| Anhydrous methanol | Sigma-Aldrich | 322415 | Does not come with sure-seal |

| Anhydrous toluene | Sigma-Aldrich | 244511 | Comes with sure-seal |

| Ceramic Stirring Hot Plate | NA | NA | The size, watage, and thermal capabilities of the stirr plate will differ depending on individual lab facilities. |

| Fourier Transform Infrared Spectroscopy (FTIR) | Nicolet i550 series spectrometer | NA | Run on OMNIC standard software |

| Gastight syringe | NA | NA | As long as the gas tight syringe has a PTFE plunger and luer tip, is suited for air sensitive technique and can be used in this protocol. |

| Glass vial | NA | NA | As long as the vial is made if borosilicate glass and has a screw based cap the brand name, size, or general shape does not matter for the protocol. |

| MCM-41 silica | ACS Material | MSM41A01 | Cas no. 7631-86-9 |

| Metal needle | NA | NA | Syringe needles need to be stainless steel. It is recommended to determine length and outerdiameter of needle by what will be transferred using the gas tight syringe. For large quantities of liquid a larger outer diameter will improve transfer rates. |

| N’-(3-trimethylsilyl propyl) diethyleneamine (DAS) | Sigma-Aldrich | 104884 | Comes with sure-seal |

| Polyethyleneimine (PEI) | Sigma-Aldrich | 408719 | Does not come with sure-seal |

| Schlenk round bottom flask | ChemGlass AirFree | NA | As long as the flask is suited for high pressure and temperture but the brand name, size, or general shape does not matter for the protocol |

| Thermogravemetric Anlysis (TGA) | TA Advantage | NA | 550 series from Waters and TA Instruments |

Referencias

- Zhu, X., et al. Recent advances in direct air capture by adsorption. Chemical Society Reviews. 51 (15), 6574-6651 (2022).

- Zhao, P., Zhang, G., Yan, H., Zhao, Y. The latest development on amine functionalized solid adsorbents for post-combustion CO2 Capture: Analysis review. Chinese Journal of Chemical Engineering. 35 (8), 17-43 (2021).

- Chen, D., Zhang, S., Row, K. H., Ahn, W. -S. Amine-silica composites for CO2 capture: A short review. Journal of Energy Chemistry. 26 (5), 868-880 (2017).

- Nie, L., Mu, Y., Jin, J., Chen, J., Mi, J. Recent developments and considerations issues in solid adsorbents for CO2 capture from flue gas. Chinese Journal of Chemical Engineering. 26 (11), 2303-2317 (2018).

- Nithyashree, N., Manohara, G. V., Maroto-Valer, M. M., Garcia, S. Advanced high-temperature CO2 sorbents with improved long-term cycling stability. American Chemical Society Applied Material Interfaces. 12 (30), 33765-33774 (2020).

- Song, C., et al. Alternative pathways for efficient CO2 capture by hybrid processes-A review. Renewable and Sustainable Energy Review. 82, 215-231 (2018).

- Rochelle, G. T. Amine scrubbing for CO2 capture. Science. 325 (5948), 1625-1654 (2009).

- Vaidye, P. D., Kenig, E. Y. CO2-alkanolamine reaction kinetics: A review of recent studies. Chemical Engineering & Technology. 30 (11), 1467-1474 (2007).

- Veawab, A., Tontiwachwuthikul, P., Chakma, A. Corrosion behavior of carbon steel in the CO2 adsorption process using aqueous amine solutions. Industrial & Engineering Chemical Research. 38 (10), 3917-3924 (1999).

- Chen, S., Bhattacharjee, S. Trimodal nanoporous silica as a support for amine-based CO2 adsorbents: Improvement in adsorption capacity and kinetics. Applied Surface Science. 396, 1515-1519 (2017).

- Jiao, J., Cao, J., Xia, Y., Zhao, L. Improvement of adsorbent materials for CO2 capture by amine functionalized mesoporous silica with worm-hole framework structure. Chemical Engineering Journal. 306, 9-16 (2016).

- Guo, X., Ding, L., Kanamori, K., Nakanishi, K., Yang, H. Functionalization of hierarchically porous silica monoliths with polyethyleneimine (PEI) for CO2 adsorption. Microporous and Mesoporous Materials. 245, 51-57 (2017).

- Fatima, S. S., Borhan, A., Ayoub, M., Ghani, N. A. Development and progress of functionalized silica-based adsorbents for CO2 capture. Journal of Molecular Liquids. 338, 116913(2021).

- Cheng, J., Liu, M., Hu, L., Li, Y., Wang, Y., Zhou, J. Polyethyleneimine entwine thermally-treated Zn/Co zeolitic imidazolate frameworks to enhance CO2 adsorption. Chemical Engineering Journal. 364, 530-540 (2019).

- Zagho, M. M., Hassan, M. K., Khraisheh, M., Al-Maadeed, M. A. A., Nazarenko, S. A review on recent advances in CO2 separation using zeolite and zeolite-like materials as adsorbents and fillers in mixed matrix membranes (MMMs). Chemical Engineering Journal Advances. 6, 100091(2021).

- Wang, J., Wang, M., Zhao, B., Qiao, W., Long, D., Ling, L. Mesoporous carbon-supported solid amine sorbents for low-temperature carbon dioxide capture. Industrial & Engineering Chemistry Research. 52 (15), 5437-5444 (2013).

- Ünveren, E. E., Monkul, B. O., Sarioğlan, S., Karademir, N., Alper, E. Solid amine sorbents for CO2 capture by chemical adsorption: A review. Petroleum. 3 (1), 37-50 (2017).

- Demir, H., Aksu, G. O., Gulbalkan, H. C., Keskin, S. MOF membranes for CO2 capture: Past, present and future. Carbon Capture Science & Technology. 2, 100026(2022).

- Xu, X., Song, C., Andresen, J. M., Miller, B. G., Scaroni, A. W. Novel polyethylenimine-modified mesoporous molecular sieve of MCM-41 type as high-capacity adsorbent for CO2 capture. Energy & Fuels. 16 (6), 1463-1469 (2002).

- Gelles, T., Lawson, S., Rownaghi, A., Rezaei, F. Recent advances in development of amine functionalized adsorbents for CO2 capture. Adsorption. 26 (94), 5-50 (2020).

- Rao, N., Wang, M., Shang, Z., Hou, Y., Fan, G., Li, J. CO2 adsorption by amine-functionalized MCM-41: A comparison between impregnation and grafting modification methods. Energy Fuels. 32 (1), 670-677 (2018).

- Anyanwu, J. T., Wang, Y., Yang, R. T. Amine-grafted silica gels for CO2 capture including direct air capture. Industrial & Engineering Chemistry Research. 59 (15), 7072-7079 (2020).

- Anyanwu, J. -T., Wang, Y., Yang, R. T. CO2 capture (including direct air capture) and natural gas desulfurization of amine-grafted hierarchical bimodal silica. Chemical Engineering Journal. 427 (14), 131561(2022).

- Sanz, R., Calleja, G., Arencibia, A., Sanz-Pérez, E. S. Amino functionalized mesostructured SBA-15 silica for CO2 capture: Exploring the relation between the adsorption capacity and the distribution of amino groups by TEM. Microporous and Mesoporous Materials. 158, 309-317 (2012).

- Moon, H. J., et al. Understanding the impacts of support-polymer interactions on the dynamics of poly(ethyleneimine) confined in mesoporous SBA-15. Journal of the American Chemical Society. 144 (26), 11664-11675 (2022).

- Xu, X., Song, C., Andresen, J. M., Miller, B. G., Scaroni, A. W. Preparation and characterization of novel CO2 "molecular basket" absorbents based on polymer-modified mesoporous molecular sieve MCM-41. Microporous and Mesoporous Materials. 62 (1-2), 29-45 (2003).

- Sousa, J. A. R., et al. H2S and H2O combined effect on CO2 capture by amino functionalized hollow microsphere silicas. Industrial & Engineering Chemistry Research. 60 (28), 10139-10154 (2021).

- Rim, G., et al. Sub-ambient temperature direct air capture CO2 using amine-impregnated MIL-101(Cr) enables ambient temperature CO2. JACS Au. 2 (2), 380-393 (2022).

Access restricted. Please log in or start a trial to view this content.

Reimpresiones y Permisos

Solicitar permiso para reutilizar el texto o las figuras de este JoVE artículos

Solicitar permisoExplorar más artículos

This article has been published

Video Coming Soon

ACERCA DE JoVE

Copyright © 2025 MyJoVE Corporation. Todos los derechos reservados