Reactor de fase líquida: Inversión de sacarosa

Visión general

Fuente: Kerry M. Dooley y Michael g. Benton, Departamento de ingeniería química, Universidad Estatal de Louisiana, Baton Rouge, LA

Reactores de flujo continuo y por lotes son utilizados en reacciones catalíticas. Camas embaladas, que utilizan catalizadores sólidos y un flujo continuo, son la configuración más común. En la ausencia de una corriente de reciclaje extenso, tales reactores de lecho empacado se modelan generalmente como "plug flow". El otro reactor continuo más común es un tanque agitado, que se supone que se mezcla perfectamente. 1 una de las razones para la prevalencia de reactores de lecho empacado es que, a diferencia de la mayoría de los diseños de tanque agitado, un área de pared grande al cociente del volumen del reactor promueve la transferencia de calor más rápida. Para casi todos los reactores, calor debe añadido o retirado para controlar la temperatura para la reacción deseada.

La cinética de reacciones catalíticas son a menudo más complejos que la simple orden de 1st , 2nd orden, cinética etc. encontrado en los libros de texto. Las tarifas de la reacción también pueden verse afectadas por tarifas de transferencia de masa - reacción no puede ocurrir más rápidamente que la tasa en que reactivos se suministran a la superficie o la tasa a la que se eliminan los productos - y la transferencia de calor. Por estas razones, la experimentación es casi siempre necesaria para determinar la cinética de reacción antes de diseño de equipos a gran escala. En este experimento, exploramos cómo llevar a cabo tales experimentos y cómo interpretar mediante la búsqueda de una expresión de la velocidad de reacción y una constante de velocidad aparente.

Este experimento explora el uso de un reactor de lecho empacado para determinar la cinética de la inversión de la sacarosa. Esta reacción es típica de aquellos caracterizados por un catalizador sólido con productos y reactantes de la fase líquida.

sacarosa → glucosa (dextrosa) + fructose(1)

Un reactor de lecho empacado será operado en diferentes caudales para controlar el espacio tiempo, que se relaciona con tiempo de residencia y es análogo al tiempo transcurrido en un reactor discontinuo. El catalizador, un ácido sólido, primero va ser preparado mediante el intercambio de protones para otros cationes presentes. Entonces, el reactor se calentará a la temperatura deseada (operación isotérmica) con el flujo de reactivos. Cuando se ha equilibrado la temperatura, muestreo de producto comenzará. Las muestras se analizarán por un polarímetro, que mide la rotación óptica. Rotación óptica de la mezcla puede estar relacionada con la conversión de sacarosa, que se puede utilizar entonces en el análisis de la cinética de la estándar para determinar el orden de la reacción, con respecto a la sacarosa reactivo y la constante de velocidad aparente. También analizarán los efectos de la mecánica de fluidos - no axial mezcla (flujo tapón) vs algunos mezcla axial (tanques agitados en serie) - en la cinética.

Procedimiento

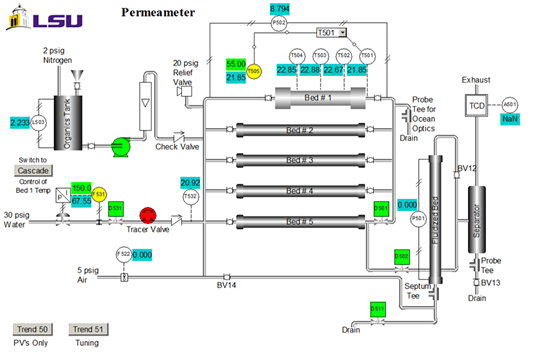

Propiedades del catalizador son: tamaño = 20-40 malla; peso = 223 g; contenido de agua = 30 wt. %; densidad aparente (aparente) = 1,01 g/mL; concentración de ácido sitio = 4,6 mmol sitios de ácido/g peso seco; área de superficie = 50 m2/g; macroporosidad (macropore volumen total volumen cat.) = 0,34; macropore tamaño promedio = 80 nm. En la figura 2muestra un diagrama P & ID de la unidad. Para este experimento, se utilizan sólo cama #1, el depósito de materia orgánica

Resultados

El polarímetro determina las conversiones fraccionarias de sacarosa después de la reacción en un reactor de lecho empacado. Una previa calibración del polarímetro para un tres fuentes diferentes de la sacarosa se muestra en la figura 3.

Figura 3 . Relación entre el grado de...

Aplicación y resumen

La reacción no se comportan exactamente como se esperaba porque el aparente orden n es > 1. De todos los fenómenos que pueden causar tales desviaciones en los reactores reales, desviaciones del comportamiento ideal de PFR por mezcla axial son sugeridas por el hecho de que ajuste para el modelo de tanques en serie da sólo un pequeño número de tanques - para un perfecto PFR, N debe ser al menos 6 . Tales desviaciones se encuentran en las camas relativamente corto, especialmente si el flujo es multifase (el agua se vap...

Tags

Saltar a...

Vídeos de esta colección:

Now Playing

Reactor de fase líquida: Inversión de sacarosa

Chemical Engineering

9.7K Vistas

Prueba de la eficiencia de transferencia de calor de un intercambiador de calor de tubos con aletas

Chemical Engineering

18.0K Vistas

Uso de una bandeja de secado para investigar la transferencia de calor convectiva y conductiva

Chemical Engineering

44.0K Vistas

Viscosidad de las soluciones de propilenglicol

Chemical Engineering

33.2K Vistas

Porosimetría de un polvo de alúmina de sílice

Chemical Engineering

9.7K Vistas

Demostración del modelo de ley de energía a través de extrusión

Chemical Engineering

10.3K Vistas

Amortiguador de gas

Chemical Engineering

36.9K Vistas

Equilibrio vapor-líquido

Chemical Engineering

89.7K Vistas

El efecto de la relación de reflujo en la eficiencia de destilación de bandeja

Chemical Engineering

77.9K Vistas

Eficiencia de la extracción líquido-líquido

Chemical Engineering

48.6K Vistas

Cristalización del ácido salicílico mediante modificación química

Chemical Engineering

24.3K Vistas

Flujo monofásico y bifásico en un reactor de lecho compacto

Chemical Engineering

19.0K Vistas

Cinética de la polimerización por adición de polidimetilsiloxano

Chemical Engineering

16.4K Vistas

Reactor catalítico: Hidrogenación de etileno

Chemical Engineering

30.5K Vistas

Spin y Chill

Chemical Engineering

7.4K Vistas

ACERCA DE JoVE

Copyright © 2025 MyJoVE Corporation. Todos los derechos reservados