Aby wyświetlić tę treść, wymagana jest subskrypcja JoVE. Zaloguj się lub rozpocznij bezpłatny okres próbny.

Method Article

Capillary Electrophoresis Separation of Monoclonal Antibody Isoforms Using a Neutral Capillary

* Wspomniani autorzy wnieśli do projektu równy wkład.

W tym Artykule

Podsumowanie

Here, we present a comprehensive capillary zone electrophoresis protocol for the assessment of intrinsic physicochemical heterogeneity of monoclonal antibodies as a quality attribute.

Streszczenie

Biotherapeutic proteins, such as monoclonal antibodies (mAbs), are feasible alternatives for the treatment of chronic-degenerative diseases. The biological activity of these proteins depends on their physicochemical properties. The use of high-performance techniques like chromatography and capillary electrophoresis has been described for the analysis of physicochemical heterogeneity of mAbs. Nowadays, capillary zone electrophoresis (CZE) technique constitutes one of the most resolutive and sensitive assays for the analysis of biomolecules. Besides, the electro-driven separation in CZE is governed by extensive properties of matter and offers the advantage of analyzing proteins close to their native state. However, the successful implementation of this technique for routine analysis depends on the skills of the analyst at the critical steps during sample and system preparation. The purpose of this tutorial is to detail the steps to succeed in the CZE analysis of mAbs. Further, this protocol can be used for the development and improvement of skills of the personnel involved in protein analytical chemistry laboratories.

Wprowadzenie

Monoclonal antibodies (mAbs) are biotherapeutic proteins with increasing interest due to their capacity to act against several chronic and degenerative diseases1. Like other biomolecules, mAbs are prone to undergo several physicochemical modifications at all stages of their life cycle (i.e., from biosynthesis to the final product). Such modifications include, but are not limited to: deamidation, glycosylation, oxidation, cyclization, isomerization, aggregation and proteolytic cleavage2. Hence, analytical techniques capable to resolve intrinsic isoforms are needed to monitor mAbs heterogeneity and stability in order to establish quality specifications.

Capillary electrophoresis (CE) is a high-performance separation technology carried outinside of a narrow fused-silica tube (µm range) filled with a background electrolyte (BGE). Upon application of an electrical field (up to 30,000 V), charged molecules migrate towards the electrode with opposite charge (i.e., electro-driven separation). The use of high voltages in CE permits fast analyses and increased efficiency, which are superior to classical gel electrophoresis. Capillary zone electrophoresis (CZE) is a CE-based technique routinely used in the biopharmaceutical industry for product quality assessment3-9. Unlike other modes of CE (e.g., capillary gel electrophoresis, capillary isoelectric focusing) or chromatography-based methods, CZE can be conducted without using denaturants or solid-phase interfaces, allowing the analysis of the inherent heterogeneity of mAbs close to their native state10. CZE separation of mAb isoforms occurs inside of a fused-silica capillary covered with a hydrophilic polymer (neutral capillary) and is based on their different electrophoretic mobility, which is ruled by charge, mass, size and shape (or hydrodynamic volume)11. mAb moieties are detected when they are mobilized and pass through the detection window, which is sensed by an ultraviolet (UV) absorbance detector at 214 nm4.

The successful implementation of this analytical technique will depend on proper attention to details before and during the experiment. Acting otherwise will increase the cost and time to conduct the analysis, ultimately leading to constant failure and frustration.

Here, we present a step-by-step guide to conduct a successful analysis of mAb heterogeneity by CZE through the detailed explanation of the preparation of solutions and samples, the preparation of CE system, the instrument methods set up, the data acquisition, and the processing. For the purpose of this tutorial, a recombinant fully human anti-tumor necrosis factor alpha (anti-TNFα) mAb is used as protein model; however, this protocol can be easily customized for the analysis of other proteins considering brief modifications. Additionally, several recommendations to mitigate potential issues are proposed. The reader is encouraged to strictly follow the proposed protocol, as the probability to succeed will increase.

Protokół

1. Preparation of Solutions

- Prepare the BGE solution.

- Prepare 100 ml of a solution composed of 0.05% (m/v) hydroxy propyl methyl cellulose (HPMC), 200 mM ε-amino n-caproic acid (EACA) and 30 mM lithium acetate.

NOTE: As HPMC is a viscoelastic polymer, pour the powder into a glass beaker, add 80 mL of water and finally add the stirring bar. Continue adding the remaining reagents as normally. Wear safety glasses when handling lithium acetate as it can cause eye irritation. - Adjust to pH value 4.8 ± 0.1 with 50% (v/v) acetic acid. Allow the solution to stabilize for 5 min and adjust as necessary.

- Add water to make up to a final volume of 100 ml in volumetric flask.

- Filter through a hydrophilic membrane with a 0.2 µm pore size.

- Store at 2-8 °C for up to 7 days.

- Prepare 100 ml of a solution composed of 0.05% (m/v) hydroxy propyl methyl cellulose (HPMC), 200 mM ε-amino n-caproic acid (EACA) and 30 mM lithium acetate.

- Prepare the internal standard.

- Prepare 1 mL of a solution composed of 1% (m/v) histamine.

- Filter through a hydrophilic membrane with a 0.2 µm pore size.

- Store at 2-8 °C for up to 1 day.

2. Sample Preparation

- Prepare 180 µl of mAb sample diluted with Tris buffer (50 mM tris(hydroxymethyl)aminomethane, pH 8.0) to a final concentration of 1 mg/ml.

- Add 20 µl of 1% (m/v) histamine.

- Mix and centrifuge at 1,000 x g for 5 sec.

- Place a micro vial inside a universal vial.

- Transfer the sample into the micro vial and cap the universal vial. Dispense the sample upwards in order to avoid introducing any bubbles.

- Store at 2-8 °C for up to 1 day.

- Place the universal vial (with micro vial containing the sample solution) in the sample inlet tray.

3. Preparation of CE System.

- CE system cleaning.

NOTE: Conduct this procedure at least once a week in order to avoid electric current leakage derived from accumulation of dust and debris. However, depending on the application (e.g., use of a BGE with increased viscosity or with high salt concentration, samples with increased viscosity) electrodes and opening levers may require to be cleaned more frequently to prevent cross contamination and sample carryover.- Turn off the power switch of the CE instrument and open the front door.

- Clean the surface of the sample cover, sample holding system (sample and buffer trays), cartridge cover, clamp bar, interface block and electrodes with a water-dampened nonwoven wipe. Repeat the procedure with an ethanol-dampened wipe and dry before use.

- Rinse the opening levers thoroughly with water. Clean their surface with a nonwoven wipe. Repeat the procedure with an ethanol-dampened wipe and dry before installation.

- Clean the two ends of the fiber optic cable carefully with a water-dampened microfiber cloth. Repeat the procedure with an ethanol-dampened cloth.

- Cartridge assembly.

- Remove a new neutral capillary (50 µm internal diameter) from its package.

- Tape down one end of the capillary protective tubing to the workbench. Uncoil, straighten and pull the capillary out the tubing.

- Stick a piece of tape or paper to the workbench and add measurement marks as follows: length to the detector (30 cm), capillary window (0.2 cm) and length to the outlet end (10 cm) (i.e., 40.2 cm total length, 30.0 cm effective length).

- Align the capillary window to the 0.2 cm measurement mark in the reference paper. Fix the capillary with tape and mark the capillary ends 2 mm outside the measurement marks.

- Cut the protective cap at the capillary inlet end (the end farthest from the window) in a single straight movement using the flush edge of the cleaving stone.

- Immerse the capillary end into a capped universal vial filled with water in order to avoid permanent damage to the capillary inner coating. Repeat this procedure each time the capillary end is exposed to the ambient for more than 1 min.

- Insert the capillary inlet end into the outlet side of the cartridge.

- Push and pull the capillary through the cartridge as necessary until the capillary window is centered to the cartridge window.

- Insert the aperture plug (100 µm x 200 µm) into the cartridge window.

NOTE: Confirm that white light passes through the window when exposed to a white source of light. If the light that passes through has a brownish appearance, adjust as necessary. - Insert the capillary into the pre-formed coolant tubing for a total capillary length of 40.2 cm (with pre-installed tubing nut, ferrule and O-ring at both ends in that order).

- Push the capillary through the coolant tubing as necessary until the capillary appears at the other side of the tubing.

- Insert the end of the coolant tubing into the outlet side of the cartridge and tighten the tubing nut.

- Insert the capillary inlet end into the inlet side of the cartridge.

- Push and pull the capillary through the cartridge as necessary until the capillary appears at the inlet side of the cartridge.

- Insert the end of the coolant tubing into the inlet side of the cartridge and tighten the tubing nut.

- Cut the protective cap at the capillary outlet end (the end nearest from the window) in a single straight movement using the flush edge of the cleaving stone.

- Insert the seal-retainer clips over the capillary ends and press to snap into position. Visually inspect the capillary ends. If they are not even, repeat the procedure.

- Place the capillary-length template on the edge of the workbench.

- Place the cartridge facing down against the capillary-length template and align the capillary ends with the reference lines on the template. If the capillary measurement marks (see 3.2.4) do not align with the reference lines, adjust as necessary.

- Hold the capillary against the capillary-length template and cut both ends of the capillary using the flush edge of the cleaving stone 2 mm below the reference lines on the template.

- Visually inspect the capillary ends with a magnifying glass. If capillary ends are not smooth, burnish them using the soft face of the cleaving stone.

- Insert the aperture O-ring into the aperture plug hole using the O-ring insertion tool.

- Install capped universal vials filled with water into the cartridge case and place cartridge into case immediately with capillary ends inserted into vials. For short and long term storage keep at 2-8 °C.

- Preparation of buffer trays.

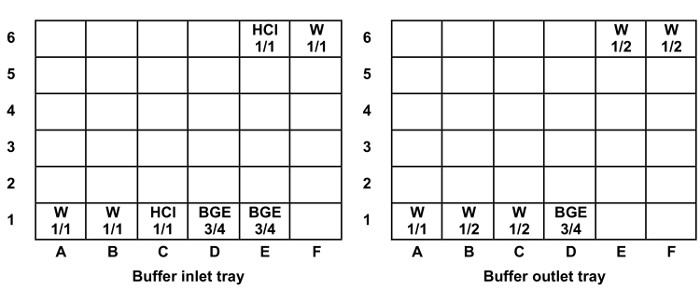

- Fill and place capped universal vials in the buffer inlet and outlet trays (Figure 1). Repeat vial positions in lanes 2, 3, 4 and 5 according with the number of samples to be analyzed, placing one lane for every six sample injections.

NOTE: Avoid wetting the vial caps in order to prevent current leakage.

- Fill and place capped universal vials in the buffer inlet and outlet trays (Figure 1). Repeat vial positions in lanes 2, 3, 4 and 5 according with the number of samples to be analyzed, placing one lane for every six sample injections.

Figure 1: Position and fill level of universal vials in the buffer inlet and outlet trays. Fill levels: 1/1 = 1400 µL, 3/4 = 1300 µL and 1/2 = 1000 µL. Abbreviations: W = water, HCl = 0.1 M hydrochloric acid. Please click here to view a larger version of this figure.

- CE system components assembly.

- Install the UV detector.

- Install the opening levers by pressing up into the interface block.

- Install the fiber optic cable. Insert the corresponding end to the clamp bar and, while holding both ends, rotate clockwise. Connect the other end to the UV detector.

NOTE: Handle the fiber optic cable with care during this procedure since bending could cause its fracture. - Place sample and buffer trays into the sample holding system and snap into position.

- Place the capillary cartridge into the interface block and, while pressing the clamp bar at both ends, tighten the knobs.

4. Instrument Methods Set-up

- Create the conditioning, running and shutdown instrument methods according with the following parameters and Table 1: Voltage, max: 30.0 kV; Current, max: 300.0 µA; Cartridge temperature: 20.0 °C; Sample storage temperature: 10.0 °C; UV detector initial conditions: Wavelength: 214 nm; Data rate: 4 Hz; Filter: Normal; Peak width (points): 16-25; Absorbance signal: Direct.

NOTE: Data acquisition rate can be increased up to 25 Hz in order to improve the coverage of narrow separation zones.

| Conditioning method time program | |||||||

| Time (min) | Event | Value | Duration | Inlet vial | Outlet vial | Summary | Comments |

| - | Rinse - Pressure | 2068 mbar | 1.0 min | BI:C1 | BO:C1 | Forward | HCl 0.1 M |

| - | Rinse - Pressure | 2068 mbar | 2.0 min | BI:B1 | BO:C1 | Forward | Water |

| - | Rinse - Pressure | 2068 mbar | 10.0 min | BI:E1 | BO:C1 | Forward | BGE |

| 0.00 | Separate - Voltage | 15.0 KV | 10.0 min | BI:D1 | BO:D1 | 0.17 Min ramp, normal polarity | Separate |

| 10.00 | Rinse - Pressure | 2758 mbar | 10.0 min | BI:E1 | BO:C1 | Forward | BGE |

| 20.01 | Wait | - | 0.0 min | BI:A1 | BO:A1 | - | Rinse tips |

| Running method time program | |||||||

| Time (min) | Event | Value | Duration | Inlet vial | Outlet vial | Summary | Comments |

| - | Rinse - Pressure | 2068 mbar | 1.0 min | BI:C1 | BO:C1 | Forward, In / Out vial inc 6 | HCl 0.1 M |

| - | Rinse - Pressure | 2068 mbar | 2.0 min | BI:B1 | BO:C1 | Forward, In / Out vial inc 6 | Water |

| - | Rinse - Pressure | 2068 mbar | 4.0 min | BI:E1 | BO:C1 | Forward, In / Out vial inc 6 | BGE |

| - | Inject - Pressure | 34 mbar | 20.0 sec | SI:A1 | BO:B1 | Override, Forward | Sample Injection |

| - | Wait | - | 0.4 min | BI:A1 | BO:A1 | In / Out vial inc 6 | Wash tips |

| 0 | Separate - Voltage | 15.0 KV | 30.0 min | BI:D1 | BO:D1 | 0.17 Min ramp, normal polarity, In / Out vial inc 6 | Sample Separation |

| 0.5 | Autozero | - | - | - | - | - | - |

| 30.01 | Stop data | - | - | - | - | - | - |

| 30.02 | Rinse - Pressure | 2068 mbar | 2.0 min | BI:B1 | BO:C1 | Forward, In / Out vial inc 6 | Water |

| 32.03 | Wait | - | 0.0 min | BI:A1 | BO:A1 | In / Out vial inc 6 | Rinse tips |

| 32.04 | End | - | - | - | - | - | End |

| Shutdown method time program | |||||||

| Time (min) | Event | Value | Duration | Inlet vial | Outlet vial | Summary | Comments |

| - | Rinse - Pressure | 2068 mbar | 1.0 min | BI:E6 | BO:E6 | Forward | HCl 0.1 M |

| - | Rinse - Pressure | 2068 mbar | 6.0 min | BI:F6 | BO:F6 | Forward | Water |

| - | Lamp - Off | - | - | - | - | - | - |

| - | Wait | - | 0.0 min | BI:A1 | BO:A1 | - | Rinse tips |

Table 1: Conditioning, running and shutdown time programs.

5. Data Acquisition and Processing

- Program the sample set.

- Program the capillary for conditioning using the conditioning instrument method. When the capillary is used for the first time, program four repetitions; otherwise program only two repetitions of the conditioning method.

- Program the samples to be analyzed using the running instrument method.

- Program the capillary for storage using the shutdown instrument method and repeat the procedure indicated in section 3.2.22.

- Run the experiment.

- Export the electropherograms.

- Calculate the migration time and the percentage content of basic, main and acidic isoforms using vertical drop line integration of the electropherogram profile.

Wyniki

Figure 2 shows the typical electrical current profile of a 200 mM EACA, 30 mM lithium acetate, pH 4.8 BGE with anti-TNFα mAb sample diluted with Tris buffer (50 mM, pH 8.0). As can be observed, the current is stable throughout the analysis and can oscillate between values of 30 to 35 µA. Figure 3 shows the CZE electropherogram of a blank sample where the detected peak corresponds to the histamine internal standard. It is expected for histamine t...

Dyskusje

In this tutorial, we highlight the importance of proper practices when conducting CZE analyses of mAbs in order to increase the probability to succeed. However, when CZE is used on a routine basis, issues arise inevitably12.

For best results, it is important to follow the notes that were included throughout the protocol, as they will help the analyst to overcome and troubleshoot difficult steps. A major consideration to obtain optimum resolution at a given set of conditions is the c...

Ujawnienia

The authors Carlos E. Espinosa-de la Garza, Rodolfo D. Salazar-Flores, Néstor O. Pérez, Luis F. Flores-Ortiz and Emilio Medina-Rivero are employees of Probiomed S.A. de C.V., which is developing, manufacturing and marketing biosimilar products. All authors are involved in the development of biosimilar products for Probiomed.

Podziękowania

The authors thank Wiley for the granted permission to use the concepts of the following publication for this tutorial. Carlos E. Espinosa-de la Garza, Francisco C. Perdomo-Abúndez, Jesús Padilla-Calderón, Jaime M. Uribe-Wiechers, Néstor O. Pérez, Luis F. Flores-Ortiz, Emilio Medina-Rivero: Analysis of recombinant monoclonal antibodies by capillary zone electrophoresis. Electrophoresis. 2013. 34. 1133-1140. Copyright Wiley-VCH Verlag GmbH & Co. KGaA. This work was supported by CONACyT, Mexico, grant 230551.

Materiały

| Name | Company | Catalog Number | Comments |

| Glacial acetic acid | Tecsiquim | AT0035-7 | |

| ACS grade hydrochloric acid | J.T. Baker | 9535-05 | |

| Histamine dihydrochloride | Fluka | 53300 | |

| (Hydroxypropyl) methyl cellulose | Fluka | 09963 | |

| Lithium acetate | Sigma-Aldrich | 517992 | |

| 6-Aminocaproic acid | Sigma-Aldrich | A2504 | |

| eCAP Tris Buffer, 50.0 mM, pH 8 | Beckman Coulter | 477427 | |

| PA 800 Plus Pharmaceutical Analysis System | Beckman Coulter | A66528 | |

| eCAP Neutral capillary | Beckman Coulter | 477441 | |

| Vial, Micro, 200 µl | Beckman Coulter | 144709 | |

| Universal Vial Caps | Beckman Coulter | A62250 | |

| Universal Vials | Beckman Coulter | A62251 | |

| Cable, Optics, UV/Vis | Beckman Coulter | 144093 | |

| UV/Vis Detector Module | Beckman Coulter | 144733 | |

| Cartridge Assembly Kit, Blank | Beckman Coulter | 144738 |

Odniesienia

- Bruno, V., Battaglia, G., Nicoletti, F. The advent of monoclonal antibodies in the treatment of chronic autoimmune diseases. Neurol. Sci. 31, 283-288 (2011).

- Liu, H., Gaza-Bulseco, G., Faldu, D., Chumsae, C., Sun, J. Heterogeneity of monoclonal antibodies. J. Pharm. Sci. 97 (7), 2426-2447 (2008).

- Creamer, J. S., Oborny, N. J., Lunte, S. M. Recent advances in the analysis of therapeutic proteins by capillary and microchip electrophoresis. Anal. Methods. 6 (15), 5427-5449 (2014).

- Fekete, S., Guillarme, D., Sandra, P., Sandra, K. Chromatographic, Electrophoretic, and Mass Spectrometric Methods for the Analytical Characterization of Protein Biopharmaceuticals. Anal. Chem. 88 (1), 480-507 (2016).

- He, Y., et al. Analysis of identity, charge variants, and disulfide isomers of monoclonal antibodies with capillary zone electrophoresis in an uncoated capillary column. Anal. Chem. 82 (8), 3222-3230 (2010).

- He, Y., Isele, C., Hu, W., Ruesch, M. Rapid analysis of charge variants of monoclonal antibodies with capillary zone electrophoresis in dynamically coated fused-silica capillary. J. Sep. Sci. 34 (5), 548-555 (2011).

- Zhao, S. S., Chen, D. D. Y. Applications of capillary electrophoresis in characterizing recombinant protein therapeutics. Electrophoresis. 35 (1), 96-108 (2014).

- Štěpánová, S., Kašička, V. Determination of impurities and counterions of pharmaceuticals by capillary electromigration methods. J. Sep. Sci. 37 (15), 2039-2055 (2014).

- Štěpánová, S., Kašička, V. Recent applications of capillary electromigration methods to separation and analysis of proteins. Anal. Chim. Acta. 933, 23-42 (2016).

- Espinosa-de la Garza, C. E., et al. Analysis of recombinant monoclonal antibodies by capillary zone electrophoresis. Electrophoresis. 34 (8), 1133-1140 (2013).

- Staub, A., Guillarme, D., Schappler, J., Veuthey, J. L., Rudaz, S. Intact protein analysis in the biopharmaceutical field. J. Pharm. Biomed. Anal. 55 (4), 810-822 (2011).

- Altria, K. D., Altria, K. D. Troubleshooting. Methods in Molecular Biology, Vol 52. Capillary Electrophoresis Guidebook: Principles, Operation and Applications. , (1996).

- Ma, S., Nashabeh, W. Analysis of protein therapeutics by capillary electrophoresis. Chromatographia. 53 (5), 75-89 (2001).

- Jaccoulet, E., Smadja, C., Prognon, P., Taverna, M. Capillary electrophoresis for rapid identification of monoclonal antibodies for routine application in hospital. Electrophoresis. 36 (17), 2050-2056 (2015).

Przedruki i uprawnienia

Zapytaj o uprawnienia na użycie tekstu lub obrazów z tego artykułu JoVE

Zapytaj o uprawnieniaThis article has been published

Video Coming Soon

Copyright © 2025 MyJoVE Corporation. Wszelkie prawa zastrzeżone