A subscription to JoVE is required to view this content. Sign in or start your free trial.

Method Article

Green Synthesis, Characterization, Encapsulation, and Measurement of the Release Potential of Novel Alkali Lignin Micro-/Submicron Particles

In This Article

Summary

We describe novel, simple methodologies of synthesis and characterization of biocompatible lignin micro- and submicron particles. These formulations provide a facile approach for the utilization of the heteropolymer, as well as an alternative for the rational design of multifunctional carrier matrices with potential applicability in biomedicine, pharmaceutical technology, and the food industry.

Abstract

The applicability of biopolymer micro-/nano- technology in human, veterinary medicine, pharmaceutical, and food technology is rapidly growing due to the great potential of biopolymer-based particles as effective carrier systems. The use of lignin as a basic heteropolymer biomatrix for the design of innovative micro-/submicron formulations allows the achievement of increased biocompatibility and offers various active functional groups presenting opportunities for customization of the physicochemical properties and bioactivities of the formulations for diverse applications. The aim of the present study was to develop a simple and ecofriendly methodology for the synthesis of lignin particles with micro- and submicron size; to evaluate their physicochemical, spectral, and structural characteristics; and to examine their capacity for encapsulation of biologically active molecules and potential for in vitro release of bioflavonoids in simulated gastrointestinal media. The presented methodologies apply cheap and green solvents; easy, straightforward, quick, and sensitive processes requiring little equipment, non-toxic substances, and simple methods for their characterization, the determination of encapsulation capacity towards the poorly water-soluble bioactive compounds morin and quercetin, and the in vitro release potential of the lignin matrices.

Introduction

Nowadays inclination towards biopolymers such as cellulose, chitosan, collagen, dextran, gelatin, and lignin as precursors for the design of micro-/submicron carriers with customizable size, physicochemical properties, and biofunctionalities has increased in the biomedical, pharmaceutical, and food technology industries due to their applicability in tissue engineering, 3D bioprinting, in vitro disease modeling platforms, packaging industry, emulsion preparation, and nutrient delivery among others1,2,3.

Novel studies highlight the aspects of lignin-based hydrogels as well as micro- and nano- formulations4 as advantageous vehicles used for food packaging materials5, energy storage6, cosmetics7, thermal/light stabilizers, reinforced materials, and drug-carrier matrices8 for the delivery of hydrophobic molecules, improvement of UV barriers9, as reinforcing agents in nanocomposites, and as an alternative to inorganic nanoparticles due to some recent safety issues10,11,12. The reason behind this tendency is the biocompatibility, biodegradability, and non-toxicity of the natural hetero biopolymer, as well as its proven bioactivities of lignin-antioxidant potential and radical scavenging, anti-proliferative, and antimicrobial activities13,14,15,16,17.

Scientific literature reports various methods for synthesis (self-assembly, anti-solvent precipitation, acid precipitation, and solvent shifting)18 and characterization of lignin-based micro-/nano- scaled formulations, including the application of expensive or harmful solvents such as tetrahydrofuran (THF), dimethyl sulfoxide (DMSO), N,N-dimethylformamide (DMF), and acetone, and complicated, indirect, and tedious processes that use a lot of equipment and toxic substances12,19,20.

To overcome the latter disadvantages, the following protocols present novel methodologies for the synthesis of lignin-based micro-/submicron particles using cheap and green solvents; easy, straightforward, quick, and sensitive processes requiring little equipment, non-toxic substances, and simple methods for their characterization and the determination of encapsulation capacity towards poorly water-soluble bioactive compounds and in vitro release potential of the lignin matrices. The presented lab-scale production methods are advantageous for the manufacture of functional lignin carriers with tunable sizes, high encapsulation capacity, and sustainable in vitro release behavior utilizing simple characterization procedures and eco-friendly chemicals that can find application in various areas of biomedical sciences and food technology. Two flavonoids were applied as target molecules encapsulated into the lignin particles: morin-into the microparticles, and quercetin-into the submicron particles. The difference in the structures of both flavonoids Is only the position of the second -OH group in the B-aromatic ring: the -OH group is on the 2' position in morin and on the 3' position in quercetin, thus both organic compounds are positional isomers. The latter fact presumes similar behavior of both bioactive natural compounds in the processes of encapsulation and/or release.

Access restricted. Please log in or start a trial to view this content.

Protocol

1. Synthesis of lignin microparticles

- Prepare a 50 mg/mL alkali lignin aqueous solution by dissolving 2.5 g of alkali lignin in 50 mL of ultrapure water on a magnetic stirrer.

- Prepare 1% Tween 80 solution by dissolving 1 mL of Tween 80 in 100 mL of ultrapure water.

- Prepare a 2 M solution of HNO3 by diluting 6.65 mL of 67% HNO3 (density = 1.413 g/mL) with ultrapure water to a final volume of 50 mL.

- Slowly add 15 mL of the 1% Tween 80 solution to 50 mL of the 50 mg/mL alkali lignin solution.

- Agitate the mixture on a magnetic stirrer at 500 rpm for 10 min so that the surfactant becomes well dispersed.

- Add 20 mL of 2 M HNO3 dropwise with a syringe at a flow rate of approximately 150 µL/s to the mixture.

- Continue stirring the mixture for 30 min when the dark brown solution is transformed into a light brown suspension of microparticles.

- Transfer the suspension into 1.5-2 mL test tubes and centrifuge for 30 min at 15,000 × g in an ultracentrifuge at 10 °C.

- Collect the supernatant for further analyses and rinse the microparticles with ultrapure water.

- Repeat the rinsing/ultracentrifugation procedures 3x.

- Dip the container with the microparticles in an ice bath before the ultrasonic homogenization.

- Homogenize the microparticles for 4 min at an intensity of 93% on an ultrasound homogenizer.

- Lyophilize the microparticles at a temperature of -64 °C in a freeze dryer and store them in an exicator for further use.

2. Synthesis of lignin submicron particles

- Prepare a 5 mg/mL alkali lignin aqueous solution by dissolving 125 mg of alkali lignin in 25 mL of ultrapure water on a magnetic stirrer.

- Slowly add 1 mL of 96% EtOH to the alkali lignin solution.

- Agitate the mixture on a magnetic stirrer at 500 rpm for 3 min.

- Prepare 50 mL of a 1% solution of citric acid by dissolving 0.5 g of citric acid in ultrapure water to a final volume of 50 mL.

- Add 7 mL of 1% citric acid dropwise with a syringe at a flow rate of approximately 4 mL/min to the mixture.

- Continue stirring the mixture for 10 min when the brown clear solution will transform into a cloudy light brown suspension of submicron particles.

- Transfer the suspension into test tubes and centrifuge for 30 min at 15,000 × g in an ultracentrifuge at 10 °C.

- Collect the supernatant for further analyses and rinse the microparticles with ultrapure water.

- Repeat the rinsing/ultracentrifugation procedures 3x.

- Dip the container with the microparticles in an ice bath before the ultrasonic homogenization.

- Homogenize the microparticles ultrasonically for two cycles of 4 min each at an intensity of 96% in an ultrasound homogenizer.

- Cool the containers for 1 min after the first cycle.

- Lyophilize the microparticles at a temperature of -64 °C in a freeze dryer and store them in an exicator for further use.

3. Synthesis of natural flavonoid-encapsulated lignin micro-/submicron particles

- Repeat steps 1.1-1.5 for the microparticles.

- Weigh 0.08 g of morin, dissolve it in 1 mL of EtOH, and add this ethanolic solution to the mixture.

- Agitate the mixture on a magnetic stirrer at 500 rpm for 20 min.

- Add 20 mL of 2 N HNO3 dropwise with a syringe at a flow rate of approximately 150 µL/s to the mixture.

- Continue stirring the mixture for 60 min.

- Repeat steps 1.8-1.13.

- Repeat step 2.1 for the submicron particles.

- Weight 0.04 g of quercetin, dissolve it in 1 mL EtOH and add this ethanolic solution to the alkali lignin aqueous solution.

- Agitate the mixture on a magnetic stirrer at 500 rpm for 10 min.

- Repeat steps 2.4-2.13.

4. Determination of the encapsulation efficiency of lignin micro-/sumicro- particles

- Calculate the content of the added bioactive substance during the procedure for the synthesis of both types of flavonoid-encapsulated lignin particles.

- Determine spectrophotometrically the absorption of the flavonoid in the supernatant obtained during steps 1.9 and 2.8 after diluting it with 96% EtOH.

- Calculate the concentration of the non-entrapped morin/quercetin using the calibration curves of the flavonoids.

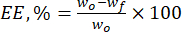

- Calculate the encapsulation efficiency (EE, %) of the lignin microparticles towards the natural flavonoids by using equation (1):

(1)

(1)

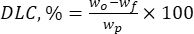

Where wo is the total quantity of the bioactive substance added (mg) and wf is the quantity of the free non-entrapped flavonoid (mg). - Calculate the drug loading capacity (DLC, %)-an important parameter representing the amount of drug in the particles per unit weight of the carrier system-by using eq. (2):

(2)

(2)

Where wp is the total quantity (yield) of lignin micro-/submicron particles obtained after lyophilization (mg).

5. Characterization of lignin micro- and submicron particles

- Determination of particle number, size, and size distribution

- Assess the particle size and particle size distribution of the samples using an automatic-cell counter with the option for bead count. Add with a micropipette 1 µL of the lignin/flavonoid micro-/submicron particles suspension in ultrapure water in the well of the counting slide required for the operation.

- Wait for the number of particles in 1 mL of the suspension, as well as their number and distribution by size to be shown in the display of the automatic cell counter.

NOTE: The apparatus allows the storage of the data on a USB flash. The automatic cell counter special software allows further processing of the saved digital and photo files.

- Determination of the content of surface acidic/basic groups of lignin particles by potentiometric titration

- Weight 0.04 g of unloaded/flavonoid-encapsulated lignin particles.

- Transfer them to an Erlenmeyer flask, add 10 mL of 0.1 M HCl, and place the flask on a magnetic stirrer at 250 rpm.

- Fill a 50 mL burette with a 0.1 M standard solution of the titrant NaOH.

- Measure the initial pH of the solution in the Erlenmeyer flask with a bench pH meter before starting the titration.

- Start the titration and measure the pH of the analyzed solution after each 0.5 mL added portion of the titrant.

- Store the experimental data in a table containing the volume of the titrant applied and the corresponding value of pH.

- Stop the titration when an approximately constant value of the pH is reached by increasing the volume of the titrant solution.

- Plot the experimental data in the form of zero-, first- and second-derivative differential titration curves.

- Determine the equivalent points and the corresponding equivalent volumes of the titrants used.

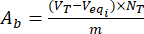

- Calculate the contents of the acidic Aa and Ab basic groups on the surface of unloaded and flavonoid-loaded lignin particles by using equations (3) and (4):

, mgeq/g (3)

, mgeq/g (3)

mgeq/g (4)

mgeq/g (4)

Where Veqi is the equivalent volume (mL); NT the normality of the titrant (mgeqv/mL); VT the volume of the titrant used for the determination procedure (mL); m the weight of the analyzed sample (g).

- Determination of the pH point of zero charge (pHPZC) of lignin-based particles by the solid addition method.

- Prepare 60 mL of 0.1 M aqueous solution of NaCl.

- Add 9 mL of the 0.1 M NaCl solution in each of five stoppered conical flasks and adjust the pH to pHi = 2, 4, 7, 10, and 12 (where i = 1-5 denote the number of the corresponding solution), respectively by the addition of either 0.1 M HCl or 0.1 M NaOH. Adjust the total volume of the solution in each flask to 10 mL exactly by adding NaCl solution of the same strength.

- Add 40 mg of dry lignin particles (unloaded, flavonoid-loaded micro-/submicron) to each flask and cap the flasks securely.

- Secure the flasks upright on an orbital shaker and keep them shaking for 24 h.

- Allow equilibration for 30 min and subsequently measure the final pH (pHf) of the supernatants in each flask.

- Plot pHf values against the corresponding initial pH values (pHi).

- The point of zero charge (pHPZC) is defined as the pH value at which the curve ΔpH versus pHi intersects the straight line with coordinates (pHi; pHi).

- Determination of total phenolic content (TPC) of lignin particles

NOTE: The total phenolic content (TPC) of the micro-/submicron lignin particles is determined via a modified Folin-Ciocalteu colorimetric method.- Mix 200 µL of an aqueous suspension of particles with a concentration of 500 µg/mL with 600 µL of ultrapure water and 200 µL of Folin-Ciocalteu reagent (1:1, v/v).

- After 5 min, add 1.0 mL of 8% Na2CO3 and 1.0 mL of Milli-Q water to the mixture and incubate it in the dark at 40 °C for 30 min in a water bath with intermittent agitation.

- Centrifuge the suspension at 5,300 × g for 2 min.

- Prepare a blank containing no particles.

- Transfer 3.5 mL of the supernatant in a 10 mm quartz cuvette and measure the absorbance on a UV/Vis spectrophotometer in the visible region at 760 nm against the blank.

- Prepare a calibration curve of the standard gallic acid following steps 5.3.1-5.3.5; only instead of 200 µL of the lignin particle suspension, use the ethanolic solution of gallic acid with initial concentrations of 10, 20, 30, 40, 50, 60, 70, 80, 90, 100, 150, and 200 µg/mL.

- Express the experimental data of the microparticles as mg of gallic acid equivalents in milligrams per gram of dry sample (mg GAE/g).

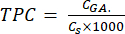

- Calculate TPC using equation (5):

mg GAE/g (5)

mg GAE/g (5)

Where CGA is the concentration of the sample equivalent to the concentration of the standard gallic acid obtained from the calibration plot of the acid (µg GA/mL); Cs is the concentration of the sample, which is equal to the dry sample mass divided by the volume of the solvent (µg/mL).

6. Determination of the in vitro release capacity of lignin particles

- Prepare 250 mL of simulated enzyme-free gastric medium by adjusting the pH of standard PBS solution with 0.1 M HCl to pH = 1.2.

- Prepare 250 mL of each of the two simulated intestinal fluid solutions by adjusting the pH of the standard PBS solution with 0.1 M NaOH/0.1 M HCl to pH = 6.8 and 7.4, respectively.

- Add 25 mg of flavonoid-encapsulated micro-/submicron particles to 50 mL of the simulated enzyme-free gastric medium in a glass batch reactor supplied with a mechanical stirrer and place it in a thermal water bath at a constant temperature of T = 37 ± 0.2 oC.

- Dip the stirrer to a depth of 2/3 of the liquid volume to ensure full mixing of the solid and liquid phases and ensure maximal mass transfer without stagnant zones.

- Take out 1 mL of sample from the reactor every 10 min up to the 90th min and immediately pipette 1 mL of fresh simulated fluid solution into the reactor to prevent change of the total volume and to ensure sink conditions.

- Repeat the same procedure including steps 6.3-6.6 with both simulated intestinal fluid solutions with pH = 6.8 and 7.4, respectively, for 200 min.

- Perform analogous experiments with unloaded lignin particles in the three simulated media and use the samples as blanks for zeroing the spectrophotometer.

- Determine the absorption of the samples spectrophotometrically after filtering the samples and diluting them with 96% EtOH against the blank samples from step 6.7 and calculate the corresponding flavonoid concentration using the corresponding calibration curves of morin obtained at pH = 1.2, 6.8, and 7.4, respectively.

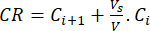

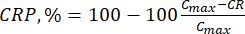

- Calculate the cumulative release (CR) of the bioflavonoids by using equation (6) in µg/mL and the cumulative release percentage (CRP) by equation (7):

(6)

(6)

Where Ci and Ci+1 are the concentrations of morin/quercetin in the ith and (i+1)th samples (µg/mL); Vs the sample volume taken from the batch reactor (mL); V the total volume of the simulated media (mL).

(7)

(7)

Where Cmax is the maximum concentration of the biologically active compound in the carrier (µg/mL).

7. Statistical analyses

- Express the experimental data as means ± standard deviations (SD) of three independent measurements.

- Determine the statistical significance of the experimental results by performing the ANOVA test as the post hoc test. Consider a value of p < 0.05 statistically significant.

Access restricted. Please log in or start a trial to view this content.

Results

An anti-solvent precipitation technique was executed to produce alkali lignin micro-/submicron particles. An aqueous solution of diluted inorganic acid-nitric acid/organic acid-citric acid was dispersed into an alkali lignin aqueous solution, enriched with an eco-friendly surfactant/ethanol, which resulted in the gradual precipitation of the biopolymer solute and, after sonication, a suspension of compact micro-/submicron particles was finally produced (Figure 1).

Access restricted. Please log in or start a trial to view this content.

Discussion

Among the main critical issues of modern synthesis methodologies for the design of drug-carrier formulations based on biopolymers is the application of hazardous organic reagents - volatile and flammable solvents, such as tetrahydrofuran, acetone, methanol, and even DMSO in high concentrations - which limits their applicability in biomedicine, pharmaceutical industry, and food technology due to the manifestation of possible toxic effects20,21,

Access restricted. Please log in or start a trial to view this content.

Disclosures

The authors have no conflicts of interest to disclose.

Acknowledgements

This study was supported by the Bulgarian Scientific Fund under Contract № KΠ-06 H59/3 and by Scientific Project No. 07/2023 FVM, Trakia University.

Access restricted. Please log in or start a trial to view this content.

Materials

| Name | Company | Catalog Number | Comments |

| automatic-cell counter | EVE, NanoEnTek | ||

| Citric acid | Sigma | 251275 | ACS reagent, ≥99.5% |

| digital water bath | Memmert | ||

| Eppendorf tubes, 1.5-2 mL | |||

| Ethanol | Sigma | 34852-M | absolute, suitable for HPLC, ≥99.8% |

| Folin–Ciocalteu’s phenol reagent | Sigma | F9252 | |

| freeze dryer | Biobase | ||

| gallic acid | Sigma- | BCBW7577 | monohydrate |

| HCl | Sigma | 258148 | ACS reagent, 37% |

| HNO3 | Sigma | 438073 | ACS reagent, 70% |

| lignin, alkali | Sigma | 370959 | |

| morin | Sigma | PHL82601 | |

| NaCl | Sigma | S9888 | ACS reagent, ≥99.0% |

| Na2CO3 | Sigma | 223530 | powder, ≥99.5%, ACS reagent |

| NaOH | Sigma | 655104 | reagent grade, 97%, powder |

| orbital shaker | IKA | KS 130 basic | |

| pH-meter | Consort | ||

| phosphate-buffered saline (PBS) | Sigma | RNBH7571 | |

| Quercetin hydrate | Sigma | STBG3815V | |

| statistical software for Excel | Microsoft Corporation | XLSTAT Version 2022.4.5. | |

| Tween 80 | Sigma | P8074 | BioXtra, viscous liquid |

| ultracentrifuge | Hermle | Z 326 K | |

| Ultrapure water system | Adrona | INTEGRITY+ | |

| ultrasound homogenizer | Bandelin Sonopuls | HD 2070 | |

| UV/Vis spectrophotometer | Hach-Lange | DR 5000 |

References

- Yu, X., et al. Lignin nanoparticles with high phenolic content as efficient antioxidant and sun-blocker for food and cosmetics. ACS Sustainable Chem. Eng. 11 (10), 4082-4092 (2023).

- Boarino, A., Klok, H. -A. Opportunities and challenges for lignin valorization in food packaging, antimicrobial, and agricultural applications. Biomacromolecules. 24 (3), 1065-1077 (2023).

- Aadil, K., Barapatre, A., Jha, H. Synthesis and characterization of Acacia lignin-gelatin film for its possible application in food packaging. Bioresour. Bioprocess. 3 (27), 1-11 (2016).

- Sharma, S., et al. Valorization of lignin into nanoparticles and nanogel: characterization and application. Bioresour. Technol. Reports. 18, 101041(2022).

- Zadeh, E. M., O'Keefe, S. F., Kim, Y. -T. Utilization of lignin in biopolymeric packaging films. ACS Omega. 3 (7), 7388-7398 (2018).

- Beaucamp, A., et al. Lignin for energy applications - state of the art, life cycle, technoeconomic analysis and future trends (Critical Review). Green Chem. 24, 8193-8226 (2022).

- Antunes, F., et al. From sugarcane to skin: Lignin as a multifunctional ingredient for cosmetic application. Int J Biol Macromol. 234, 123592(2023).

- Garg, J., et al. Applications of lignin nanoparticles for cancer drug delivery: An update. Materials Letters. 311, 131573(2022).

- Anushikha, K. K. Lignin as a UV blocking, antioxidant, and antimicrobial agent for food packaging applications. Biomass Conv. Bioref. , 1-14 (2023).

- Freitas, F. M. C., et al. synthesis of lignin nano- and micro-particles: Physicochemical characterization, bioactive properties and cytotoxicity assessment. Int J Biol Macromol. 163, 1798-1809 (2020).

- Rismawati, R., Nurdin, I. A., Pradiptha, M. N., Maulidiyah, A., Mubarakati, N. J. Preparation and characterization of lignin nanoparticles from rice straw after biosynthesis using Lactobacillus bulgaricus. Journal of Physics: Conference Series. 9th International Seminar on New Paradigm and Innovation of Natural Sciences and its Application. 1524, 012070(2020).

- Worku, L. A., et al. Synthesis of lignin nanoparticles from Oxytenanthera abyssinica by nanoprecipitation method followed by ultrasonication for the nanocomposite application. Journal of King Saud University - Science. 35 (7), 102793(2023).

- Gala Morena, A., Tzanov, T. z Antibacterial lignin-based nanoparticles and their use in composite materials. Nanoscale Adv. 4, 4447-4469 (2022).

- Ivanova, D., Nikolova, G., Karamalakova, Y., Marutsova, V., Yaneva, Z. Water-soluble alkali lignin as a natural radical scavenger and anticancer alternative. Int J Mol Sci. 24 (16), 12705(2023).

- Ivanova, D., Toneva, M., Simeonov, E., Antov, G., Yaneva, Z. Newly synthesized lignin microparticles as bioinspired oral drug-delivery vehicles: Flavonoid-carrier potential and in vitro radical-scavenging activity. Pharmaceutics. 15 (4), 1067(2023).

- Yaneva, Z., et al. Antimicrobial potential of conjugated lignin/morin/chitosan combinations as a function of system complexity. Antibiotics. 11, 650(2022).

- Handral, H. K., Wyrobnik, T. A., Lam, A. T. -L. Emerging trends in biodegradable microcarriers for therapeutic applications. Polymers. 15 (6), 1487(2023).

- Figueiredo, P., Lintinen, K., Hirvonen, J. T., Kostiainen, M. A., Santos, H. A. Properties and chemical modifications of lignin: Towards lignin-based nanomaterials for biomedical applications. Prog. Mater. Sci. 93, 233-269 (2018).

- Tang, Q., et al. Lignin-based nanoparticles: a review on their preparations and applications. Polymers. 12 (11), Basel. 2471(2020).

- Zhao, W., Simmons, B., Singh, S., Ragauskas, A., Cheng, G. From lignin association to nano-/micro-particle preparation: extracting higher value of lignin. Green Chemistry. 18 (21), 5693-5700 (2016).

- Stewart, H., Golding, M., Matia-Merino, L., Archer, R., Davies, C. Manufacture of lignin microparticles by anti-solvent precipitation: Effect of preparation temperature and presence of sodium dodecyl sulfate. Food Res Int. 66, 93-99 (2014).

- Beisl, S., Friedl, A., Miltner, A. Lignin from micro- to nanosize: Applications. Int. J. Mol. Sci. 18, 2367(2017).

- Mishra, P. K., Ekielski, A. A simple method to synthesize lignin nanoparticles. Colloids Interfaces. 3, 52(2019).

- Qian, Y., Deng, Y., Qiu, X., Li, H., Yang, D. Formation of uniform colloidal spheres from lignin, a renewable resource recovered from pulping spent liquor. Green Chem. 16, 2156-2163 (2014).

- Tardy, B. L., et al. Lignin nano- and microparticles as template for nanostructured materials: formation of hollow metal-phenolic capsules. Green Chem. 20, 1335-1344 (2018).

- Silva, M., et al. Paraquat-loaded alginate/chitosan nanoparticles: preparation, characterization and soil sorption studies. J Haz Mat. 190 (1-3), 366-374 (2011).

- Georgieva, N., Yaneva, Z. Comparative evaluation of natural and acid-modified layered mineral materials as rimifon-carriers using UV/VIS, FTIR, and equilibrium sorption study. Cogent Chem. 1 (1), 1-16 (2015).

- Zhang, P., Chen, D., Li, L., Sun, K. Charge reversal nano-systems for tumor therapy. J Nanobiotechnol. 20, 31(2022).

- Yaneva, Z. L., Georgieva, N. V. Removal of diazo dye from the aqueous phase by biosorption onto ball-milled maize cob (BMMC) biomass of Zea mays. Maced. J. Chem. Chem. Eng. 32 (1), 133-149 (2013).

- Zatorska, M., et al. Drug-loading capacity of polylactide-based micro- and nanoparticles - Experimental and molecular modeling study. Int J Pharmaceutics. 591, 120031(2020).

- Yaneva, Z., Georgieva, N. Chapter 5 - Physicochemical and morphological characterization of pharmaceutical nanocarriers and mathematical modeling of drug encapsulation/release mass transfer processes. Nanoscale Fabrication, Optimization, Scale-Up and Biological Aspects of Pharmaceutical Nanotechnology. Grumezescu, A. M. , William Andrew Publishing. 173-218 (2018).

- Yaneva, Z., Georgieva, N., Staleva, M. Development of d,l-α-tocopherol acetate/zeolite carrier system: equilibrium study. Monatshefte fur Chemie Chemical Monthly. 147 (7), 1167-1175 (2016).

- Yaneva, Z., Georgieva, N. Study on the physical chemistry, equilibrium, and kinetic mechanism of Azure A biosorption by Zea mays biomass. Journal of Dispersion Science and Technology. 35 (2), 193-204 (2014).

Access restricted. Please log in or start a trial to view this content.

Reprints and Permissions

Request permission to reuse the text or figures of this JoVE article

Request PermissionThis article has been published

Video Coming Soon

Copyright © 2025 MyJoVE Corporation. All rights reserved